Showing 1587 items matching "blade"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSaw

John Heath tool boxHandsaw wooden handle with 3 rivets with one missing. Red paint on handle. Handle also has a carved leaf motif. blade 560mmL. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Doyen's mouth gag used by Dr Mitchell Henry O'Sullivan

A mouth gag was used when required to assist in the administration of anaesthesia to a patient. It is used to keep the patient's mouth open, and could also be used for oral surgery or airway management. This particular mouth gag is known as a Doyen's type.Dr Mitchell Henry O'Sullivan worked in the Victorian country town of Casterton as a general practitioner from 1919 until his death in 1977. He also practiced obstetrics. His son, Dr David More O'Sullivan donated the obstetric bag and its contents to the College in 1999. The gladstone bag and contents are a unique time capsule of the type of instruments and pharmaceuticals used in the inter-war period.Stainless steel mouth gag. Design of item resembles a pair of scissors, but with a foot at the end of each blade and a ratchet attached to keep the device open.anaesthesia -

Anglesea and District Historical Society

Anglesea and District Historical SocietyGillette Blue Blades, Gillette (Australia) Pty. Ltd, Estimated date: 20th Century?

Package containing 5 Gillette Blue Blades. Partially opened. Package has blue and white background with text in reverse colour. Graphic in black.[See packaging]shaving, gillette, king gillette -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Memorabilia - Paper knife, 1944

Brass paper knife made in scimitar shape with handle formed from bullet; blade inscribed with palm trees (4) & 'New Guinea 1944'.New Guinea 1944metalcraft, brassware, recreations, souvenirs -

Mont De Lancey

Mont De LanceyDomestic object - Fruit Pitter, D CARMICHAEL, c1920's

Used by Dianne McIntyre's grandmother c 1910 and possibly by an earlier generation too.Antique wooden handled metal fruit pitter with bevilled edges on both sides of the wedge shaped blade. Usually used for pitting peaches or apricots.D CARMICHAEL is stamped on the scoop.kitchen equipment, domestic equipment -

Mont De Lancey

Mont De LanceyTool - Cooper's Shave, Unknown

Used in the late 19th century.A steel curved bladed woodworking tool with two wooden handles used to scrape logs or circular pieces of of wood. It was used in the late 19th Century.woodcarving tools, shaves, handtools, steel, wood, woodworking tools -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Fishing Knife, n.d

Fishing knife, wooden, floating shaped like a fish, top end of fish removable, to expose metal blade inserted in bottom half of fish.fishing, recreation, sport, knife -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Equipment - Tissue forceps associated with Dr Felix Meyer

This is one of a collection of items associated with Dr Felix Henry Meyer (1858-1937). Meyer was a very prominent early obstetrician and doctor, playing a part in the establishment of the role of the chair of obstetrics at the University of Melbourne in 1929. He was also a foundation member of the Royal Australian College of Surgeons.Set of tissue forceps. Forceps resemble a thin, elongated pair of scissors with a locking latch below the handle and a round loop at the end of each blade.surgery -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeDispenser, wrapping paper, Unknown

Used in shops for holding brown paper roll to wrap parcels. Paper was torn off against the metal ;blade on the swing bar.Wooden horizontal beam and vertical cross metal bar holding rod and metal swing bar with wooden top bar. Base is badly scratched and worn paint. Nonbrown paper, parcels, shop keeper, wrapping, shops, shopping -

Frankston RSL Sub Branch

Frankston RSL Sub BranchKnife, Pocket

Standard Australian Army servicemans metal pocket knife with three folding implements. It has a single edge knife blade, a can and bottle opener and a marlin spike all hinged to fold away into the knife body. One end of the knife is equipped with a screwdriver blade stub. The other end is equipped with a pivoting copper suspension loop. The body of the knife is stamped with the manufacturer's details, which includes a description of the style of knife as an 'opener', patent number '15737' and a 'D^D' stamp. This knife is wrapped in a waxed piece of paper printed with the instructions for using the can opener blade.The body of the knife is stamped with the following inscription "WITTINGSLOWE, OPENER, ADELAIDE, PAT.APPLN 15737" and a 'D^D' stamp.vietnam, australian, army, pocket knife, opener -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Laryngoscope, Lynah, Circa 1915

Lynah's Ovoid Laryngeal Speculum with the light bulb and part of the connection wires still attached. Its semi square shape is characteristic of this kind of instrument, also has an screwable pointed end attachment. It has dusty and grey spots inside the canal of the blade near the light bulb canal. Solder spots are visible at the top of the blade as attachment of the laryngeal speculum blade base. General discolouration over the surface of this piece and hit marks present at the base of the handle. It was roughly engraved over the handle the owner’s details and year. Stamped at the base of the handle are the manufacturer’s details partially visible. Engraved at the handle, U N N A M E T . A D E L A I D E . c. 194[6] . Stamped at the base of the handle, [first line worn away might be MADE BY] / E / A D / [might be an S] YDN [might be an EY] / CHROME PLAT [incomplete word due stamp near the edge]laryngeal speculum, laryngeal instruments, unnamet, adelaide, lynah, henry lowndes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Wood Planes (9), Late 19th century

These items are among several tools that are believed to have belonged to the Warrnambool carpenter and businessman, Henry Phillips. English-born Henry Phillips (1821-1896) came to Australia with his wife Elizabeth in 1849. They lived for some time in Port Fairy. In 1865 Henry formed a partnership with Christopher Beattie and established the Warrnambool undertaking business of Beattie and Phillips. This business continued on after the deaths of the founders and lasted until the year 2000. In Warrnambool Henry Phillips was involved in the management of the Mechanics Institute. These tools are retained as examples of vintage tools and as mementoes of the Warrnambool carpenter and businessman, Henry Phillips.These are nine brown wooden tools, rectangular in shape and similar in size and design. An extra piece of wood adjoins one side of each tool. A thin metal blade has been inserted at an angle in each tool in a slot at the top of the wooden blocks and these have small wooden pieces resting on them. The blades protrude at the base of the wooden blocks to form planing mechanisms. vintage tools, henry phillips, warrnambool, history of warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, 1930-1955's

This wooden spokeshave was used in the making of ship model Sovereign of the Seas. It would have been used to shave and shape wood in a similar way that a plane would be used. Its name comes from its use for shaping curved objects such as wheel spokes, oars, paddles, chair legs and bows. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker.This spokeshave is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This spokeshave was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Spokeshave; two-handled, medium coloured wood tool, slightly curved centre. The front has two blade screws protruding from it, the back has a flat ‘sole’ with removable brass blade attached by screws. This spokeshave is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. (Illegible text is pressed into the top side of the spoke shave.)flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, spokeshave, spoke shave, sovereign of the sea, ship model, hobby, ship model tool, english war ship -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrawing Knife

Very old. A drawknife is used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded edges. Can be used to shape the curve of a cricket bat. Used by woodworkers in the Kiewa Valley.Steel frame with wooden handles at each end and a sharp steel blade attached in the middle.Ref. Page 83 Tools for all Trades Catalogue.The drawknife / drawing knife,/ draw shave, / shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. The blade is much longer (along the cutting edge) than it is deep. It is pulled towards the user. woodworking tool, drawing knife, hand tool -

Orbost & District Historical Society

Orbost & District Historical Societymincer, 1890's

This item was used by Helena Warren (nee McKeown), a well known photographer and local press correspondent. She lived at Newmerella. The meat mincer was a particularly popular kitchen gadget. By means of the mincer left overs and off cuts could be transformed into shepherd's pie or mince steak. Gadgets like this Universal food chopper are typical of domestic inventions designed to reinforce the principles of thrift and labour-saving. Many of these gadgets were imported from the United States. A cast iron metal hand mincer with a long metal body with an opening at one end, inside which is a circular spiral blade and a screw clamp attachment at the other end. On one side of the mincer is a curved metal handle held in place by a metal nut and a wooden bulb shaped knob at the end. There is a metal circular webbed blade held in place by a metal nut and bolt."Universal No. 2 brand; L.F. & C., New Britain, Conn., U.S.A."mincer chopper food-preparation -

Federation University Historical Collection

Federation University Historical CollectionModel, Model of the Munro Reaper, 1887

An example of good invention in an era of innovation in Australian manufacture and production. Levers raise the height of the cutter, disengaging the drive from the blades. The moveable blades under the fixed ‘fingers’. An eccentric rod changes circular motion to linear back and forth of the blades. Such a machine is now known as a mower for cutting grass for hay, and other grasses for storing as sheaves. 'Gift for Museum - The School of Mnes committee has accepted the offer from mr H.B. Munro, of Elsternwick, of a model reaping machine made in 1887 when the Munro machinery business was in operation in Alfredton. The model, which has won gold medals at various exhibitions, is to be placed in thr school museum. (Ballarat Courier 22 April 1932) Metal model with red paint detail in sectionsM263ballarat school of mines, ballarat school of mines museum, munro machinery, model, munro reaper -

Tatura Irrigation & Wartime Camps Museum

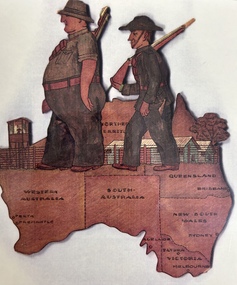

Tatura Irrigation & Wartime Camps Museumcut out plywood figures, Guarding Australia

Karl Streker cut out the map of Australia using a razor blade with Private Tony Connor and Private Alf Gillespie on garrison duty.Cut out plywood subjects - two of our Garrison guards with guns, standing on cut out map of Australia. Borders and capital cities are marked. Guard tower and barracks are in the background. State borders and capital cities are marked on map.internee hand craft, karl streker, private tony connor, private alf gillespie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers’ Equipment, hair clippers steel, c1950

Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. A set of hand held barbers’ hair clippers with an adjustable screw. Chrome plated, in good condition, c1950 barbers, hairdressing, hair clippers, grooming, horse clippers, steel manufacture, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreMemorabilia - Emergency survival kit

This emergency kit was carried by Merv Schneider when flying missions out of Northern Australia.Red colour case with transparent lid packed tightly with various medical supplies, powders, ointments, drugs, dressings, razor blades and small signaling mirror. Emergency Sustenance Type E-3 Specifications Number 94-40441 Air Forces, U.S. Army.emergency kit, survival kit, merv schneider, medical -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph, 1983

Photograph taken by Herald & Weekly Times, showing Malcolm McFee, Robert Bruce, Robert Eddy at work. Chicory was first grown on Phillip island in 1870. It was used in coffee essence and for medicinal purposes.Chicory being picked by hand after the chicory had been loosened in the ground by Tractor and rip blade through a row of the crop. this was on Audrey McFee's farm.local history, photography, photographs, slides, film, chicory industry, black & white photograph, audrey mcfee, chicory, phillip island -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionWeapon - Grain Spear, n.d

Part of collection purchased by the City of Portland in 1990s from Brendon Kurtze (Kurtze's Museum Portland). “Grains with Five Prongs. GRAIN. An iron instrument with four or more barbed points, and a line attached to it, used at sea for striking and taking fish.” -Whitney, 1911Grain spear used to harpoon dolphins. Iron, painted black gloss, no handle. 3 flat blades on one end of shaft and handle sleeve on the other.fishing -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomWeapon - Bayonet, Wilkinson, Bayonet, Lee-Metford MK I Type 2, October 1897

Issued to 2nd Battallion Scottish Rifles "Cameronians" for Rifle no 823Steel bayonet, 28 cm blade, 11 cm handle, wood hand grips secured by brass fasteners, fitted for fixing to Lee-Metford rifle 10-97, Wilkinson London, Govt broad arrows, inspectors' stamps, bayonet, edged weapons, lee-metford rifle, wilkinson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAxe

Axe, ships carpenters broard axe. two rivet on side of blade, cross mark on heel. Straight wooden handle cracked with hole in the bottom and rivet. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane

Toothing plane, blade is missing, J. Heath stamped on the end, adjustable depth gauge on one end, 165mm long, 65mm high, 70mm wideflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGouge

Gouge tanged paring gouge, metal blade, wooden handle with brass ferrule. Part of handle missing. Gouge is a regular sweep. 186mmL x 24mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, gouge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePeeler

Peeler with turned wooden handle with metal blade and serrated edge. Metal section tapers to a sharp point. Wooden handle has been painted blue.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, peeler -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

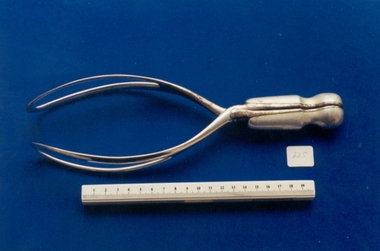

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Denman-type short handled obstetric forceps used by Dr Ronald Rome and Dr Kelvin Churches, Lindsay

These forceps were owned and used by Dr Ronald Rome and Dr Kelvin Churches. Notes suggest that these may be a modified set of Denman-type forceps, as appearance of the outer part of the handles indicate they are an 'adaption' for independent use. (Note from Helen Johnson, 2000).Set of short handled forceps. Both blades of forceps are stamped "Lindsay of London" (for manufacturer) and "R & C" (for Dr Ronald Rome and Dr Kelvin Churches). "R & C" "Lindsay of London"obstetric delivery -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBow Saw, 1940s

Made and used by internees at Camp 3Handmade wooden frame, wooden centre strut across frame. Metal serrated edged blade. Later addition of twisted baling twine at top of saw.camp 3, tatura, saw -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBow Saw, 1940's

Made by internees at Camp 3, Tatura and used there as carpentry toolLarge handmade bow-saw with turned wooden handles either end of wooden frame next to metal toothed blade. Metal rod at top of framebow saw, hoefer family, camp 3, tatura, ww2 camp 3, trades, carpentry -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumHair Clippers

Small metal hair clippers with two handles to be held in one hand and operated by opening and closing hand. Has blade concealed underneath metal teeth