Showing 8130 items

matching water

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDomestic object - Plastic Drink Bottle - Portland Coast Water, n.d

Portland Coast Water plastic drink bottle, opaque, blue lid, Portland Coast Water logo back and front.Front: Side: metric scale from 100-400mls - embossed Back: Base: Bottles of Australia - Logo) Made in Australia ) embossedportland coast water -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - DAVID MCDONALD COLLECTION: EPPALOCK. CONSTRUCTION, c1963

Eppalock. Construction. Picture of the blue water in Lake Eppalock, the road going over the spillway and the water going over the spillway.Agfacolorcivil engineering, water supply, eppalock -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Laundry Eqipment , 'ACME' clothes wringer, mid 20thC

This ACME portable clothes wringer could be attached to a wash trough or hand washing machine to remove excess water from the washing. It was much less cumbersome that the earlier Mangles used for this purposeMost homes of 20th C in City of Moorabbin would have had one of these ACME wringers . It greatly eased the washday burden of the women. The Exchange Hotel Nepean Highway Cheltenham was a well established meeting place for Moorabbin Shire settlers by 1915A metal clothes wringer with side hand crank and 2 rollers that could be attached by screw clamps to a wash trough or washing machine for removing excess water from washing. The pressure of 2 rollers was controlled by a screw on the top of machine that could be loosened or tightened according to the material being passed through.ACME 14 INCH / on hand crank is list of patents for Great Britain, USA, Aust. NZ, Germany, Belgium, Sweden moorabbin, bentleigh, cheltenham, laundry equipment, washing, washing mangles, washing machines -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncHorizontal Oil Engine, Early 20th century

Horizontal cylinder oil engine in working order. Mounted on a steel chassis with 4 cast iron wheels. Two flywheels and one flat belt pulley. Cylindrical cooling water tank and exhaust vertical exhaust pipe mounted at crankshaft end. Engine painted green with red wheels and red crankshaft balance weights. Oval brass plate on cylinder - "The Austral Oil Engine / Ronaldson Bros. / Makers / No. 1113 ? & Tippett / Ballarat Victoria" Thin oval metal transfer on cooling water tank with makers name and place of manufacture around Australian coat of arms.machinery; oil engine; metalwork -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - DAVID MCDONALD COLLECTION: EPPALOCK. CONSTRUCTION, c1963

Eppalock. Construction. Lake appears to be full or close to it with beautiful blue water. The bank to the left is the bank which the road goes across, the walkway out to the water tower and the water tower. Markings: Eppalock Dam March 1963.Kodakcivil engineering, water supply, eppalock -

Bendigo Military Museum

Bendigo Military MuseumEquipment - WEBBING KIT, 1911; Post 1911

The 1908 pattern was used during WWI, made from woven cotton & water proofed. The kit is used for school groups.Webbing kit complete including 1908 pattern webbing, gas mask haversack, personnel items, rations. Refer attached sheet. .1) Waist belt with brass buckles & keepers. .2) Braces x 2, connects to waist belt & large pack. .3) Bayonet. .4) Bayonet carrier. .5) Bayonet scabbard. .6) Entrenching tool carrier [fits to .5)]. .7) Entrenching tool handle, wood & metal [fits to .6)]. .8) Entrenching tool, metal, combination shovel & pick. .9) Entrenching tool carrier [fits inside .8)]. .10) Cartridge carriers x 2, 1 left hand, 1 right hand. .11) Water bottle, metal, blue colour. .12) Water bottle cover, khaki wool. .13) Water bottle carrier. .14) Pack, large. .15) Great coat, wool, [inside .14)]. .16) Helmet, steel with inside liner & chin strap. .17) Mess tin carrier, replica. .18) Haversack, side pack. .19) Carry all, white cotton, for personnel hygiene items [inside .18)]. .20) Razor, cut throat [inside .19)]. .21) Comb [inside .19)]. .22) Toothbrush [inside .19)]. .23) Shaving brush [inside .19)]. .24) Laces, leather, not original, [inside .19)]. .25) Soap [inside .19)]. .26) Tin bully beef x 2, replicas, [inside .18)]. .27) Tin stew, replica, [inside .18)]. .28) Pair socks, khaki wool, not original, [inside .18)]. .29) Field dressing, WWII issue, [inside .18)]. .30) Towel, brown colour, not original, [inside .18)]. .31) Gas mask carrier bag & straps. (Cowley) .32) Water bottle, metal, blue colour, [inside .31)].Items 1 - 13, there are numerous markings all stamped on from, “A.A.O.D”, “L”, “R”, “S”, “M.E.C.O”, “49th INF”, Years examples, “8.12”, “1.13”, “1911”military history - equipment / army, medicine-first aid, personal effects - containers, toilet requisites - shaving -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSlide - Slide - Cashmore Airport, Portland, 1980s

Coloured slide. Excavation site. Body of water on left. A retaining wall, formwork for concrete pour, right hand end of water.portland airport, cashmore airport, construction site, engineering -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Receipt, Melbourne Water Supply, 1880s

Receipt from Melbourne Water Supply for supply of 47,000 gallons of water to ornamental reserve, Nott Street, Port Melbourne 1880ssport - lawn bowls, parks and gardens, port melbourne bowling club, henry norval edwards, michael tarver quinn, local government - borough of sandridge -

Seaworks Maritime Museum

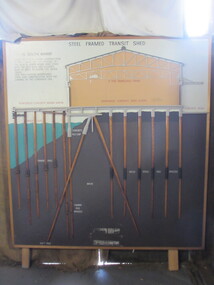

Seaworks Maritime MuseumDiagram

Cross section of wharves and steel framed sheds built along the Yarra river between the 1920s and 1960s. The South Melbourne side of the Yarra River is reclaimed swamp land. Without a solid foundation for the construction of the wharves and transit sheds, extended piles were sunk into the mud to support the wharf and shed structures. An example of this design may be found at 5 South Wharf which was built in the 1930s. The transit sheds gave shelter for cargo while waiting to be loaded onto a ship or to be collected by truck after being unloaded from a ship. The transit shed became surplus to requirements with the introduction of containers.Wooden diagram of a transit shed featuring a shed sitting atop mud with some water. It shows the splices sitting in the mud to support the shed. "Steel Frames Transit Shed/ 15 South Wharf/ Model of Typical wharf construction/ of 1940- made for the opening of/ the "new" 15 South wharf shed (1944),/ Note the deep piles and elevated/ rear of the shed to allow for the truck/ trays./ This shed feature disappeared/ from port construction with the/ coming of the container era/ reinforced wharf apron/ 3 ton travelling crane/ reinforced concrete shed floor/ concrete road/ water level/ concrete pile cap/ cradled piles/ timber pile splices/ mud/ mild steel pile splices/ 110 ft pile" "On loan from Port of Melbourne Authority" -

City of Ballarat

City of BallaratArtwork, other - Public Artwork, Petersen Fountain, 1922

This fountain was created as the result of a bequest from Ballarat businessman Carsten Heinrich Petersen who was killed at the age of eighty-five years when crossing Sturt Street opposite the Base Hospital. On the other side of the street were three brick shops which he owned. The fountain has four bronze frog water spouts beneath four marble stork spouts. Above the top bowl is another stork in bronze with its wings spread and water issues from its outstretched beak. The Petersen Fountain has been restored many times, first in 1977 with funds provided by the Rotary Club of Ballarat South. In 1989 further restoration works were completed to replace bronze frogs and a brass and copper stork made by Ballarat craftsman Lloyd Lusk to replace the original bird which was stolen and never recovered. The second stork was also stolen on the 3rd of August 1983 and further repairs of the fountain were carried out in 1993. The artwork is of historical and aesthetic significance to the people of Ballarat. The Petersen Fountain is carved marble, features storks carved into its base and the faces of cherubs in the bowl. It has a copper crane perched at the top and bronze frogs surrounding that spray water. The fountain stands on a granite base. PRESENTED/ BY/ C.H. PETERSEN/ BORN IN DENMARK 2nd MARCH 1836/ DIED BALLAARAT 9 FEBRUARY 1922petersen fountain -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPot Large with Tap, Circa 1950

This type of cast iron kettle was used by pioneer families, mainly rural in the early 1900's upon open fires (log). It covered rural activities that needed a constant readily available source of boiling water, in or mainly outside the kitchen of homesteads. This kettle was used in the early to late 1900's for the refreshment of stock men and farmers that had irregular "tea" breaks under sometimes hard and gruelling conditions.This kettle belonged to and was used by a Kiewa Valley, pioneer family, the Roper Family. This kettle was moved from their Kiewa Valley property to their hut built on the Bogong High Plains. The Bogong High Plains area provided Kiewa Valley cattlemen a good supply of fodder to supplement their Kiewa Valley grazing areas. This "camp draft" activity , in the high plains, could take up to six weeks.This large cast iron modified camp pot (cauldron) has a long tap connection located at the bottom end. The "tap" is made from brass and has a simple elongated "bar" control swivel at the end to control the water flow. The tap suggests that only water was heated (to a constant boil) for the replenishment of cattlemen's, or other horse rider's, tea or coffee mugs. Refreshments at a "temporary" location on the Bogong High Plains. There was a "log" hut built by the Roper family as temporary accommodation for cattlemen and other family members.Ot the flat bottom "FIRST QUALITY 2 GALLONS"camp fire cooking utensils, hot plate, cast iron cooking appliance, drovers kitchen -

Lara RSL Sub Branch

Lara RSL Sub BranchPainting Lara RSL, March 2018

Painting of Lara RSL in 2018. Building erected in June 1864. Used by the Shire of Corio from 1874 to 1937. The Lara RSL sub branch had their first official meeting in the building on 11/4/1949.Water Coloured Painting in Wooden FrameRear of Painting - Donated by Karen and Rob Dick. Painted by Karen Dick March 2018lara rsl buiding watercolour karen dick 2018 -

Federation University Historical Collection

Federation University Historical CollectionGeological specimen - Rocks, Petrified Wood

From the Ballarat School of Mines.Petrified wood with some water polish.rocks, geology, petrified wood -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, small brass water tap, c1900

This Water tap is typical of those used by early settlers in Moorabbin Shire c1900 Water tap, small brassearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, metal workers, plumbers -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Bottle

Water bottle, no webbing, Aluminium. Chineseequipment, vietnam, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Bottle

Australian water bottle attached to EQ146equipment, ww2, army -

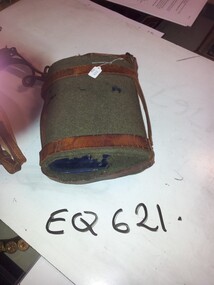

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Bottle

Water Bottle comprising pannikin and holderequipment, 1st gulf war, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Sterilization Kit

Sterilizling outfit for use with Water Bottlesequipment -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Bottle Webbing

Water bottle webbing pattern 37equipment, ww2+, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchWater Bottle

Water bottle blue enamel and strappingequipment, ww1, army -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - BENDIGO VIEWS, Apr 1960

Slide. Bendigo Views. Water and trees.slide, bendigo, bendigo views, bendigo views -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph - copy

Borrowed for copying.Rushworth's first water pumping station. -

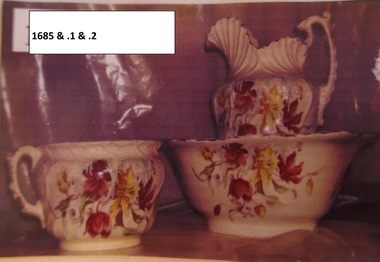

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1910-1930

Bedroom Water Jug . Leyshon Familystawell -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, c1940's

I. Richards – Aerated Water Stawellstawell -

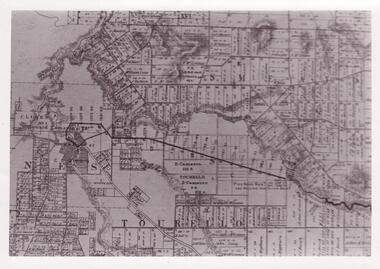

Clunes Museum

Clunes MuseumPhotograph

PHOTOCOPY OF CLUNES TOURELLO WATER SHED.local history, photography, photographs, water supply -

Clunes Museum

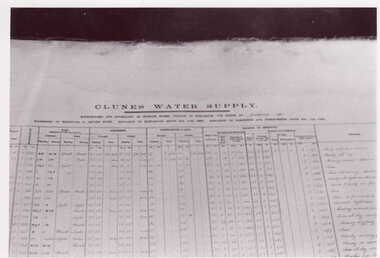

Clunes MuseumPhotograph

PHOTOGRAPH - CHART - CLUNES WATER SUPPLYlocal history, photography, photograph, water supply -

Stawell Historical Society Inc

Stawell Historical Society IncSlide, Ian McCann, Lake Bellfield

Lake Bellfield With Water after completionlake bellfield -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Bottle

Hemley & Sons Aerated Water Bottlestawell -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Gold Mine

Mine at Dusk or Dawn across watergold mining