Showing 1977 items matching " industrial"

-

Melbourne Tram Museum

Melbourne Tram MuseumNewsletter, Tramways rank and file group, "Trammie Link", 1978 - 1982 and 1991 and 1992

Set of 14 duplicated newsletters printed on coloured quarto or foolscap duplicated paper, "Trammie Link" .1 - November 1978 - 1 quarto sheet - complaining about the lack of union leadership - published by a "tramways rank and file group" .2 - March 1979 - 4 sheets - training, shift work, Burke Road tram, route 72 tram, Gardiner, lifeguards, uniforms. .3 - April 1979 - 4 sheets - disciplinary panel, rosters, Camberwell depot, route 72, buses, North Fitzroy, Doncaster, Clifton Hill, Z class cars. .4 - May 1979 - 4 sheets - discipline, lifeguards, bus safety, union issues. .5 - June 1979 - 3 sheets - politics and unions, Preston depot, Camberwell depot, wage indexation, union matters, finance for public transport, Tramway Record. .6 - August 1979 - 10 pages- Preston Depot, item written by Jim Harper, public transport and government, hook turns, union meetings, women, ACTU, wages, shift work, rosters, depots, wage indexation, shift lengths. .7 - June 1980? - two pages - undated - Service cuts at North Fitzroy, depot committees, news from depots, and note re a meeting on Monday 7 July. .8 - July 1979? - 4 pages - strikes, union campaigns, depot management, industrial issues, discipline, depot facilities. .9 - Sep. 1980 - 3 pages - Lonie report, buses, closure, public transport, union, 35 hour week, unions. .10 - Oct. 1980 - 4 pages - union elections, industrial campaigns, 35 hour week, Lonie repot, public transport. .11 - Oct. 1982 - 3 pages - Preston workshops and new trams, new trams, W class trams, accidents. .12 - Undated - 2 pages about Paul Krutulis - a scab or an Agent Provocateur - see https://www.anu.edu.au/polsci/marx/interventions/years/11revival.htm - accessed 30-8-2016. - Extracted are the 4th and 5th paragraph below which give a bit of a background. .13 - July 1991 - 4 pages - open letter to Jim Harper re union Amalgamation, rank file view, what it would mean to workers - a negative view. Amalgamation was a major push of the Hawke - Keating Government. .14 - March 1992 - supportive of Jim Harper, dismissive of Lou DiGregorio, Union executive, union amalgamation, cross linking of tram routes, racial discrimination within the PTC, Kew Depot, ACTU. Lists the rank and file committee - see key associations. Latham’s frustrations were shared by several would-be heroes in Victoria. In 1977 Paul Krutulis gained an exemption from union membership from the Arbitration Commission as a conscientious objector, only to find that tramway workers at Kew planned to stop work as soon as he appeared. Commissioner Cohen then recommended his dismissal, saying she “had to deal with the reality of the situation.” Krutulis later became president of a group called People Against Communism, before being murdered in September. Thus Krutulis departed the scene to be followed in early 1978 by motor mechanic Jack Kane, who had crossed a picket line at a Melbourne City Council depot. The AMWU forced the Council to sack him before it would end the strike. In September of the same year, Barbara Biggs succeeded in provoking a confrontation in the tramways where Krutulis had failed, by refusing to join the union and prompting 100 unionists at Brunswick depot to go on strike. The union executive had arranged token action confined to this depot, but the members wanted more. The strike spread to Preston, then 2,000 trammies at a mass meeting voted for an indefinite strike amidst “rowdy outbursts”. When Biggs complained at being excluded from the meeting a conductress told her, “We should have let you in, love. You would have been torn to pieces.” Paul was murdered by his brother George in Sydney - see the Age 29/11/1977, but there seems to be some conspiracy theories abounding as well.Handwritten note / letter from Chris Jacobson.trams, tramways, unions, training, shifts, uniforms, route 75, gardiner, light rail, camberwell, z class, buses, discipline, tramway record, preston, north fitzroy, services, strike, depots, discipline, lonie report, public transport, preston workshops, rtbu, actu, ptc -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

This rectangle black and white photograph shows a bush scene with part of a suspension rope and wooden plank bridge visible in the middle of the image. It is likely this suspension bridge was used by the Tannery workers to move between the town and the Ovens Tannery located South-West of Beechworth due to its secluded bush location, the bridge likely spanned the gorge across Spring creek. The tannery itself was located alongside Gimlet Creek, about three kilometres from town, down what is now known as Malakoff and Old Tannery Road but which at the time was remote and accessed through bushland. The Ovens tannery was stablished in 1858 by Matthew Dodd and Hallahan and later Matthew and his brother Thomas Dodd in 1866 who developed it over the years. According to Doyle, 'we have little information about its early operations except the tannery itself comprised four small buildings' by 1870 ‘a small village with gardens of vines and fruit trees surrounded the tannery’ (Woods, 121), and by 1887 the Tannery employed fifteen men. The Ovens tannery was among several new businesses establishing themselves such as a foundry that brought industrial manufacturing alongside the developing township and which strengthened the economic stability of Beechworth after the receding mining surge. According to Woods (p. 121) in the 1860’s the government spent considerable sums to establish several public buildings such as the Benevolent Asylum, the Hospital and Insane Asylum to support those in need of care in the area directly after the Indigo gold rush which had left Beechworth, a fairly remote regional and newly formed township (Gold was first discovered in Beechworth in 1852) with a number of infirm and destitute people in its wake and which due to the support and establishment of these facilities ‘made Beechworth a significant social welfare centre in Victoria’ (Woods, p. 121). The tannery provided employment and connected the regional centre with other parts of Victoria and the wider colonial outposts and would have been a welcome opportunity for those seeking work after gold was no longer a source of income.A good example of the ingenuity of regional settlers to achieve what would have been a difficult and remote construction of a bridge as a means of access. This bridge is evidence of planning and forethought and shows dedication to establishing a life in a remote landscape.Black and white rectangular photograph printed on paperreverse: / 2983 / / BMM2983 /black and white photograph, bush, suspension bridge, rope bridge, tannery, spring creek, ovens tannery, bushland, gimlet creek, matthew dodd, beechworth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Teapot, Josiah Wedgwood & Sons Ltd, 1890

Josiah Wedgwood (1730–95), came from an established family of potters and trained with his elder brother. He was in partnership with the leading potter Thomas Whieldon from 1754 until 1759 when a new green ceramic glaze he had developed encouraged him to start a new business on his own. Relatives leased him the Ivy House in Burslem, Stoke-on-Trent, and his marriage to Sarah Wedgwood, a distant cousin with a sizeable dowry, helped him launch his new venture. After an extensive and systematic program of experiment Wedgwood in 1765 created a new variety of creamware, a fine glazed earthenware, which was the main body used for his table wares thereafter. After he supplied Queen Charlotte with a tea set for twelve the same year, she gave official permission to call it "Queen's Ware" (from 1767). This new form, perfected as white pearlware (from 1780), sold extremely well across Europe, and to America. It had the additional advantage of being relatively light, saving on transport costs and import tariffs in foreign markets. Wedgwood developed several further industrial innovations for his company, notably a way of measuring kiln temperatures accurately, and several new ceramic bodies including the "dry-body" Stoneware, "black basalt" (by 1769), cane ware, and jasperware (the 1770s), all designed to be sold unglazed, like "biscuit porcelain". In the later 19th century the company returned to being a leader in the design and technical innovation, as well as continuing to make many of the older styles. Despite increasing local competition in its export markets, the business continued to flourish in the 19th and early 20th centuries, remaining in the hands of the Wedgwood family, but after World War II it began to contract, along with the rest of the English pottery industry. After buying several other Staffordshire ceramics companies, in 1987 Wedgwood merged with Waterford Crystal to create Waterford Wedgwood plc, an Ireland-based luxury brands group. After a 2009 purchase by KPS Capital Partners, a New York-based private equity firm. Wedgwood has always been associated with fine china, porcelain, and luxury accessories, the entrepreneur Josiah Wedgwood rapidly became successful and was soon one of the largest manufacturers of Staffordshire pottery. Wedgwood is a significant pottery manufacturer as the company is especially associated with the "dry-bodied" (unglazed) stoneware Jasperware in contrasting colours, and in particular that in "Wedgwood blue" and white that has become a trademark. Teapot and lid, Wedgwood blue Jasperware with white patternImpressed name Wedgewood and date letter "S" = 1890flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, teapot, wedgewood blue, wedgewood teapot, tea pot, kitchen ware, josiah wedgwood, staffordshire potteries -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Submission for Approval, VIOSH: Ballarat College of Advanced Education; Submission to the Victorian Institute of Colleges, 1978

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Ballarat College of Advanced Education had been trying for approval of a PG1 Graduate Diploma in Occupational Hazard Management during 1976 and 1977. This last application was 1978. They were hoping to introduce it in 1979. Present at this meeting held on Tuesday 8th August 1978 were representatives from: EAC Subcommittee; W J Robertson (Convenor), Dr K B Brown (Medical Officer}, Dr A J Christophers (Chief Industrial Hygiene Officer, Dept of Health, E O'Keefe (Secretary to the Committee) Ballarat CAE Course Advisory Committee; W Jinkins (Safety Engineer, Gas & Fuel), E Wigglesworth (Injury Research Unit, Royal College of Surgeons) Ballarat College of Advanced Education; D J Woolley (Head of School of Engineering), T D Norwood (Head of Dept Mechanical Engineering), D Viner (Course Co-ordinator}, G Fernandez (School of Business} Recommendation that the proposed course for the award of PG1 Graduate Diploma in Occupational Hazard Management at Ballarat College of Advanced Education be approved for introduction in 1979 at first year level. This still needs approval from the Tertiary Education Commission for the purposes of the expenditure of funds under the provision of the State Government.Ten A4 pages - typed. Four correspondence and six the Draft of course for the applicationLetterhead of Victoria Institute of Colleges and the Prime Minister, Canberra Signature: R I Viner - Minister assisting the Prime MInister in Public Service Matters Elizabeth O'Keefe - Secretary to the Academic Committee in Engineering, V.I.C.viosh, victorian institute of occupational safety and health, ballarat college of advanced education, pg1, graduate diploma in occupational hazard management, minister assisting prime minister, r i viner, elizabeth o'keefe, victoria institute of colleges, vic academic committee, w j robertson, k b brown, a j christophers, bcae advisory committee, w jinkins, e wigglesworth, bcad staff, d j woolley, t d norwood, d b viner, g fernandez, royal australian college of surgeons, department of health, gas and fuel corporation, medical officer olympic tyres, school of engineering, mechanical engineering, school of business, tertiary education committee, state government, state grants -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoon, Henry Barnascone & Sons, 1860s-early1930s

This spoon, made by Henry Barnascone of Sheffield, was recovered from an unknown shipwreck in the coastal waters of Victoria in the late 1960s to early 1970s. The spoon is one-o-a-kind in our Flagstaff Hill Maritime Village Collection of shipwreck artefacts. It is possibly from a passenger’s luggage on one of the shipwrecks. The shipwrecks in the area range from around the 1840s to the early 1930s. It is part of the John Chance Collection. HENRY BARNASCONE & SONS, Sheffield, UK- Henry Barnascone (1827-1894) was born in Switzerland. He and his brother Lewis settled in Sheffield in 1851. Henry operated as Henry Barnascone from 1868 to 1883, trading in Angel Street as a cutler, manufacturer and general merchant, moving to York Street in 1874. His work included electroplating metalware. Products ranged from cutlery and serving trays to straight razors, measuring tapes and pocket knives. In 1884 his firm became H. Barnascone & Son and from 1901 to 1934 be firm was renamed H. Barnascone & Sons, with his son (or nephew) Charles Henry ‘Harry’ Barnascone brought in to join the business. The firm employed eight men and four women in 1881. Around 1892 the firm moved to Empire Works in Eyre Street. Charles (Harry) inherited the business when Henry died in 1894. In 1909 the company became ‘Ltd.’, with Charles continuing until his death in 1917. The firms trademarks were EMPIRE (with ‘trefoil’ or ‘clover’ symbol), THE HUNGRY WOLF BRAND and PROLIFIC. The firm was liquidated in 1934 and acquired by Harrison Fisher & Co. Ltd., which specialised in plated goods and silverware, and retained Barnascone’s trademarks. In the early 1990s Harrison Fisher, which employed about 200, was arguably the only surviving example of the type of firm that had flourished in nineteenth century Sheffield – one which marketed a full range of cutlery. It remained family-owned. In 2007 Harrison Fisher & Co. Ltd. was renamed Taylor’s Eye Witness Ltd, which, in 2016, ‘swapped’ the nineteenth century historic factory for a new industrial unit in Sheffield. Although the spoon is not linked to a particular shipwreck, it is recognised as being historically significant as an example of hardware either as part of the ship’s flatware service or imported for use in Colonial Victoria in the 19th to early 20th century. The spoon is significant for being Flagstaff Hill’s only shipwreck artefact amongst many hundreds of objects, including cutlery, to be branded with ‘Empire Silver’ and the only piece in our collection by Sheffield manufacturer Henry Barnascone. The spoon is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Spoon; teaspoon, electroplate nickel-silver, silver discoloured to brown. Fiddle design. Five embossed Hallmarks. Five embossed Maker’s Marks on back of handle, arranged in a column from tip towards bowl. Made by William Page and Co., Birmingham. The spoon no longer has its silver plating. Bowl has a cut in the side, and is nicked and dented. Embossed “EMPIRE“ (trefoil or clover logo) “SILVER” flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, henry barnascone, sheffield, cutlery, eating utensils, electroplate, silver plate, silverware, flatware, empire works, prolific, hungry wolf brand, antique flatware, old english flatware pattern, spoon, teaspoon -

National Wool Museum

National Wool MuseumMedallion, CENTENAIRE DU DELAINAGE MAZAMET, 1951

This medallion was struck to celebrate the 100th anniversary of fellmongering in Mazamet in 1951. Fellmongering - In French, ‘delainage” means, literally, ‘de-wooling'. It is the industrial process of separating wool from sheepskins. In the 19th century, the southern French town of Mazamet became the world centre of délainage and played an important part in the Australian wool industry. At one time Mazamet was reputed to be the 15th richest town in Europe, and it was said that the town’s branch of the Banque Nationale de Paris (French banking firm) was the second largest in France. At its height, Mazamet had 48 fellmongeries and imported more than 100,000 tonnes of sheepskins a year from the southern hemisphere, mostly from Australia and Argentina. It also supported numerous associated industries such as tanneries, spinning mills and clothing manufacturers. In the 1980s Mazamet’s fellmongering industry fell into decline under pressure from environmental concerns and cheap imports. The town’s last two fellmongeries closed in 2004. The town continues to have a strong relation to Australia, with street names such as, Rue de Australie, Adelaide, Brisbane, Melbourne and Sydney in recognition of a connection to the two distant lands. Today, half a century since wool importation largely ended, there remains a link to the past. Elite quality leather and woollen clothing companies such as Hermes and Chanel still source much of their stock in Mazamet. This medallion was presented to William Haughton and Co. who were one of Australia’s largest wool-buying companies of the first half of the 20th century. Wm Haughton had a major presence in Geelong and its “SKINS WOOL HIDES TALLOW etc.” signs were prominent on railways stations throughout the Western District and beyond. Haughtons had branches in all Australian capital cities, New Zealand, London and Bradford. Its agents in Mazamet were Maison Louis Maffre, an enterprise founded by M. Louis Maffre, mayor of Mazamet from 1912 to 1919. This medallion was donated to the National Wool Museum by the family of Sir Robert Southey AO CMG, former managing director of Wm Haughton & Co.Bronze medallion contained within purple case. On one side of the medallion, a mill worker is seen scraping the wool off the treated sheepskin. On the reverse the inception can be read.Wording: CRESCAM ET LUCEBO // CENTENAIRE / DU DELAINAGE / MAZAMET // 1851-1951. Smooth edge stamped with a cornucopia and the inscription BRONZEmazamet, fellmongering, délainage -

Surrey Hills Historical Society Collection

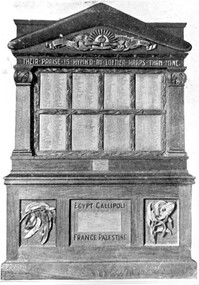

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg, John Kendrick Blogg carving, Soldiers' Honour Board, Shrine in the Surrey Gardens

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993. The images derives from an early brochure. The number of panels has been increased having been updated on at least 2 occasions. Whereas the date 1914 is at one end of the boomerang, the other end is not dated reflecting that the dedication of The Shrine before the war ended.Black and white photo of the Soldiers' Memorial Honour Board housed in The Shrine in the Surrey Gardens. The wooden part of the board was carved by John Kendrick Blogg. A large boomerang forms part of the apex underneath which is an emblem with the rising sun. Under this are 8 panels on which are the names of service personnel. The supporting timber is carved with designs including varied flora. At the base are 2 larger carved panels; on the LHS a sprig of eucalyptus leaves and on the RHS a sprig of wattle. surrey gardens, world war, 1914-1918, woodcarving, monuments and memorials, surrey shrine, john blogg, john kendrick blogg -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Brewery Building, Ballarat School of Mines Brewery Building, 06/10/2011

In 1872 William Tulloch and Alexander McLaren constructed a new brick 'Royal Standard Brewery' to the design of architect Henry R. Caselli. They had been operating a much smaller 'Royal Standard' Brewery, possibly since 1859. The Ballarat Brewing Company was established in 1895 and took over operations of the 'Royal Standard'. This new company resulted in the merger of the 'Royal Standard Brewery', James Coglans 'Phoenix Brewery' (Warrenheip) and Henry Leggo's 'Barley Sheaf Brewery' (Creswick Rd). J. Coglan and W. Tulloch were principals of the new company. By 1912 the Ballarat Brewery buildings fronting Armstrong Street were upgraded and new plant installed. Ballarat Brewing Company was well established as a thriving business. In 1926 'Ballarat Bertie' (the cellar-man) advertising image was introduced. It was used successfully until 1994 on 'Ballarat Bitter' labels. During the1940s and 50s the Ballarat Brewing Company was significantly upgraded and extended equipment and buildings. In 1959 Carlton and United Breweries purchased the Ballarat Brewery, its brewing rights and the land (but not the 114 BBC hotels or the Dana Street offices). The Lydiard Street frontage become the 'front' of the CUB Brewery. CUB ceased brewing at the Ballarat Brewery site in 1989 and closed the plant. Four years later the 'brewery site' was purchased by the Ballarat School of Mines to enlarge its campus area as TAFE was a rapidly expanding areas of education. In 1994 plans were developed for the 'Brewery Complex' with careful regard for needed educational facilities and due concern regarding historical aspects of the site and its buildings. There was close consultation and cooperation with the Ballarat City Council during the planning process. In 1995 most of the Brewery buildings were demolished by some special structures and features are preserved. The old brewery chimney was retained as a permanent reminder of the original industrial site, as were two boilers. The SMB Brewery Complex was completed in 1996 and reflects aspects of the former brewery's appearance. It was opened by Prime Minister John Howard on 28 February 1997. Further details at http://guerin.ballarat.edu.au/curator/buildings/site_listing_brewery-complex.shtml Twenty five colour photographs of the Brewery Building at the University of Ballarat SMB (Ballarat School of Mines) campus. The Brewery Building is built on the site of the former Ballarat Brewery and incorporates the chimney and 'Cowley' boilers from that site. ballarat school of mines, henry richards caselli, henry caselli, ballarat brewing, brewery, beer, cowleys foundry, carlton and united breweries, ballarat brewery site -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Tap, mid-late 19th century

This type of large, brass tap is typical of the plumbing fittings manufactured in the late 19th and early 20th centuries. The tap has encrustations and concretion inside, showing that it had been in the sea for quite some time. The pipe leading to the spout is squashed, nicked and appears to have been sawn or broken off. It could have once been part of the plumbing from a ship, perhaps from one of the boilers used in the kitchen, for bathing or for laundry or cleaning. The name “BEST” on the tap signifies that it could have been made by Robert Best who began his Birmingham brass foundry c. 1840, and even though The information from the donor is that tap was given to her father (1906-1982) who lived in the Warrnambool district. It was likely given by a cray fisherman or diver, who said that the tap came from the Loch Ard shipwreck, wrecked on Mutton Bird Island, east of Port Campbell, Victoria, on 1st June 1878. This could easily be the case but there is no provenance for it. ROBERT BEST, BRASS FOUNDRY Circa 1840 Robert Best founded his brass foundry business and was referred to as a Brass Chandelier of Birmingham”. In 1864 an advertisement in the Journal of Gas Lighting, Water Supply, & Sanitary Improvement announces Best and Hobson, late Robert Best, 100 Charlotte Street Birmingham, manufacturers of Chandeliers, Brass and iron fittings, Steam and Water-cocks etc. gas apparatus of every description, Plumber's brass foundry, with works at Birmingham and Great Bridge, Staffordshire. In 1867 Best & Lloyd was formed, after Best and Hobson went into liquidation, manufacturing at the Cambray Works of Wattville Road, Handsworth. It was a light industrial engineering works and one of the owners was Robert Dudley Best’s father. Robert Dudley Best (1892-1984) later took over the business of Best & Lloyd. The company is still in business at Downing Street, Smethwick, Birmingham. In 1878, brass ship furniture and bell fittings stamped “BEST” was made by William Udal & Co., who advertised as manufacturers of BEST cast and stamped brass foundry goods. This large brass tap is typical of industrial tapware of the mid-late 19th and 20th centuries. The location of the tap, when found, is associated with the Warrnambool district and could have easily been from a shipwreck due to the encrustation found inside the tap. Due to its design and manufacturer, the tap is associated with the mid-late 19th and early 20th-century manufacture of plumbing fittings. Tap, brass, heavy-duty, with butterfly handle. The design and style are typical of the plumbing of the late 1800s. Inscription pressed into the handle, within rectangular border "BEST". Encrustation and concretion are inside the tap spout. “BEST” on one side of the tap handle (Also, a label from the donor attached to the tap “from the wreckage of the LOCH ARD")flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, robert best brass foundry, best and hobson, best & llyod, birmingham brass foundry, brass tap, best brand tap, heavy duty brass tap, industrial brass tap, boiler tap, 19th century plumbing, 19th century tapware, 19th century plumbing fitting, tap with butterfly handle, tap salvaged from shipwreck, brass fittings, steam engine fittings, water-cock fitting -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Magazine - HANRO COLLECTION: JOHN BROWN FASHION NEWS LETTER VOL 1NO. 2, April 1968

BHS CollectionJohn Brown Fashion News Letter Vol 1, No 2.: A paper newsletter on a white back ground printed in black and tan colour box at the top, 20 x 5.2cm with fashion repeated three times filling the area on the right side. A stylized figure appears on the left hand side with its left leg pointed upwards. Underneath is Vol 1, No.2, Published by John Brown Industries Ltd. 110 Trennery Crescent Abbotsford, Vic. 3067. April 1968, (underlined). Page 1. The article is headed *Admiral Club Afloat* which is a new trade name for knit shirts, that has 300 colours and style combinations. Tricel is a new fibre introduced for the first time in Australia. On the right hand side is a black and white photo of two men wearing Tetoron and Polycott in a contemporary design wearing Bermuda shorts standing on a boat. On the left of the photo is a girl in a bikini top. On page 2 is a report on the increase on imports of knitted garments against local production. Also an article on quality control in Bendigo and a photo showing Mr Frank Harris viewing a fabric through an industrial magnifying glass. Page 3 shows knitwear from *The Admiral Club Range* Second item on page 2 is of The successful Kyneton Mill being established in 1921 bringing employment from the extended district. A photo of an original employee Mr Jim Roberts is at the bottom. Last page is an article top left side is The Welmar Men's Dress Shirt proved very popular and sold out before Christmas. Under that is a photo of the busy pressing room in Bendigo. Bottom left : *Sales Network Expanded* an article on sales covering Brisbane and a new office in Townsville. Top right is an article about Anne Hine an employee of John Brown, runner up of the Miss Victoria Quest enjoying herself in Queensland on the Gold Coast which was part of her prize. A photo of Anne with a dolphin is included. Other topics include *Ten pin Bowling trophy to Victoria* and New President announced*, Mrs Molly Lapsley Retires. Box 116AAssociated World Public Relations Pty Ltd. Printed by Aldine Press.bendigo, industry, john brown knitting mills, john brown industries. mr frank harris. mr jim roberts. michael robinson. welmar plant bendigo. norma gardner. mrs molly lapsley -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

Taken some time between 1914-18, the photograph depicts an aerial view of Villers-Bretonneux in France, a region which was part of the Western Front during World War I. The image mostly shows rural landscape. The Western Front was the main theatre of war during World War I. Following the outbreak of war in August 1914, the German Army opened the Western Front by invading Luxembourg and Belgium, then gaining military control of important industrial regions in France. The German advance was halted with the Battle of the Marne. Following the Race to the Sea, both the French-British and German armies dug in along a meandering line of fortified trenches, stretching from the North Sea to the Swiss frontier with France. The First Battle of Villers-Bretonneux occurred between 30 March - 5 April 1918. It took place during Operation Michael, part of the German Spring Offensive on the Western Front. The offensive began against the British Fifth Army and the Third Army on the Somme, and pushed back the British and French reinforcements on the north side of the Somme. The capture of Villers-Bretonneux, close to Amiens, a strategically important road and rail-junction, would have brought the Germans within artillery-range. In late March, troops from the Australian Imperial Force were brought south from Belgium as reinforcements to help shore up the line. In early April, the Germans launched an attack to capture Villers-Bretonneux. After a determined defence by British and Australian troops, the attackers were close to success until a counter-attack by the 9th Australian Infantry Brigade and British troops late in the afternoon of 4 April restored the situation and halted the German advance on Amiens. The Second Battle of Villers-Bretonneux occurred between 24 - 27 April 1918, during the German Spring Offensive to the east of Amiens. It is notable for being the first occasion on which tanks fought against each other. A counter-attack by two Australian brigades and a British brigade during the night of 24 April partly surrounded Villers-Bretonneux, and on 25 April, the town was recaptured. On 26 April, the role of the Moroccan division of the French army was crucial in pushing back German units. Australian, British and French troops nearly restored the original front line by 27 April.The record is historically significant due to its connection to World War I. This conflict is integral to Australian culture as it was the single greatest loss of life and the greatest repatriation of casualties in the country's history. Australia’s involvement in the First World War began when the Australian government established the Australian Imperial Force (AIF) in August 1914. Immediately, men were recruited to serve the British Empire in the Middle East and on the Western Front. Additionally, the record's significance is enhanced by its depiction of Villers-Bretonneux. The battles that occurred in this town during World War I are especially historically significant to Australia as this is where the Australian Imperial Force had one their greatest World War I victories. An Australian flag still flies over Villers-Bretonneux in the present. Furthermore, a plaque outside the Villers-Bretonneux Town Hall recounts the battles fought to save the town in 1918. Kangaroos feature over the entrance to the Town Hall, and the main street is named Rue de Melbourne. More officially, recognition of the significance of the battle in Villers-Bretonneux is found at the Australian National Memorial, which was built just outside the town. It commemorates all Australians who fought in France and Belgium and includes the names of 10,772 who died in France and have no known grave. Each year, a small ceremony is held at the memorial to mark the sacrifice made by the soldiers. Lastly, the record has strong research potential. This is due to the ongoing public and scholarly interest in war, history, and especially the ANZAC legend, which is commemorated annually on 25 April, known as ANZAC Day.Sepia rectangular photograph printed on matte photographic paper.Obverse: yAE.2.35. / 125 / 62d.2834.35.36.VA.5. / 12.G.18-11 / F.-(?)" /military album, wwi, world war i, villers-bretonneux, australian imperial force, aif, france, war, army, conflict, germany, 1918, battle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1873

This crucible was raised from the wreck of the Loch Ard. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All were manufactured by the Morgan brothers who founded the Patent Plumbago Crucible Company in 1856, making crucibles in a small factory in Battersea London. A crucible is a container used for purifying and melting metals so that they can be cast in a mold to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles this technique was pioneered by the Morgan Bros thereby making a significant technological advance in foundry technology and metallurgy. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially, they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm's manufacturing rights and began producing their graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the Loch Ard suggests they may have been part of a sample shipment intended for similar promotion in the Australian colonies or at Melbourne's International Exhibition to be held in 1880. A newspaper account of an 1864 tour of the Morgan brothers' 'Black Potteries' at Battersea indicates: "All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilograms; a No. 3, three kilograms, and so on." These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six is of the same size. (For more information on the Loch Ard wreck see note sec this document) The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck of which the crucible is a small part. The collections objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history.A medium size crucible, or fluxing pot, for heating and pouring molten metal. The container rises in a slight curve from a smaller flat base to a wider open top with a lip for pouring. It was recovered from the wreck of the LOCH ARD. The crucible has a coating of sediment that obscures its numerical specifications of size and capacity. The markings that remain visible indicate it is a Morgan’s crucible, made with graphite to prevent cracking and provide a smooth non-adhesive inner surface. .On base: “…ORGAN’S …ENT”flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgan's crucible company, loch ard, morgan potteries, crucible, fluxing pot -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, William Marple & Sons, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. William Marples junior joined his father's joinery making business in 1821. In 1860 William's sons joined him and the firm became William Marples and sons. Over the years they acquired John Moseley & Sons a London plane maker and Thomas Ibbotson & Co a Sheffield edge tool maker. Growing to become the most prolific and best known Sheffield tool maker. Their large factory was known as the Hibernia Works. Their trademark was a shamrock that appeared on some of their tools, in 1961 they had about 400 employees. In 1962 the record Tool Company and William Ridgway acquired a fifty percent interest in the company and in 1972 the companies merged with several others to form Ridgway Tools Ltd. After 116 years at its Hibernia Works, the company was moved to Dronfield. A 1982 takeover by A G Bahco of Sweden was short-lived and in 1985 Record Ridgway returned to British ownership first as Record Marples Woodworking Tools Ltd. In 1988 then as Record Holdings PLC in 1993. In 1998 the company accepted a bid from American Tool Corporation, subsequently trading as Record Irwin. The Irwin company itself was acquired by Newell Rubbermaid in 2002 and renamed Irwin Industrial Tool Co. Both the Marples and Record names were re-branded "Irwin" However the name has since been resurrected as Irwin/Marples and applied to wood chisels and table saw blades now made at their new facility in Udine, Italy. As a footnote, William Marples was the uncle of Robert Marples and Joseph Marples, both of whom established competing tool making businesses in Sheffield. The Robert Marples firm disappeared early in the 20th century. After several changes in the company's ownership tools are now made under the Ridgway name but in China. A tool made by a company with a long family history of tool making in Sheffield England, with a member of the Marples family, Joseph Marples establishing a competing tool company which continues today to manufacture quality products for the joinery and shipwrights trades.Caulking tool straight wide blade, Stamped "W Marples & Sons" & James S Steele tool box.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking tool, caulking iron, james s steele -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Sunshine and District Historical Society Incorporated

Sunshine and District Historical Society IncorporatedAir Raid Precautions (ARP) badges, Circa early 1940's

Mr Webb King was an Air Raid Warden during World War 2. These badges were found when his workshop was being cleared out, and so were donated to our society. The badges in our possession do not have the word WARDEN printed on them, like the image of the badge shown on the Darebin Heritage 'Air Raid Protection Services (ARP)' publication, or the image of a badge offered for sale on ebay. At this stage we are uncertain of why this is so. If anybody knows the answer then please leave a message on this site. During World War 2 Australian municipalities were expected to take precautions against air raids, with the Government campaigning to recruit men over 45 to be volunteer Air Raid Wardens. It was also common for women to become wardens. Wardens carried gas masks, helmets, and rattles or whistles. The wardens received 7 to 8 one hour sessions of training, and their chief duty was to advise people of precautions to take, and to ensure those precautions were taken. Air Raid Precautions included air raid drills, shelters (usually trenches), first aid, fire fighting, rescue of 'gassed' persons, evacuation drills, demolition and repair squads, monitoring of blackouts. Melbourne was deemed vulnerable to aerial attack because of its centralised port and industrial facilities and so Anti-aircraft guns were installed in Maribyrnong. By early 1942 more than 60,000 people voluntarily carried out Air Raid Precautions duties according to the Autobiography of Robert V. J. Padula OAM. As the threat diminished during 1943 and 1944 the need for air raid precautions was slowly reduced, and some shelters (trenches) were filled. The two photos showing Air Raid Wardens are out of copyright and have been sourced from the 'Argus Newspaper Collection of Photographs, State Library of Victoria.' The image showing one warden on Swanston Street Melbourne has been cropped to remove extras not connected with the photo. Other sources of information for this report are: (1) http://bpadula.tripod.com/autobiography/id100.html, (2) https://www.awm.gov.au/exhibitions/underattack/mobilise/precautions.asp, (3) http://heritage.darebinlibraries.vic.gov.au/article/57. The ARP badges are a historic reminder of the precautions that were taken in Victoria during the early years of World War 2. The precautions were an effort to minimise the harmful effects of a theoretical air raid. The war started to turn and so an air raid never came, however many people received valuable training in what precautions needed to be taken.Pressed metal round badges with pins. Main feature of badges is the large whitish lettering ARP on a red background. A black outlined crown and the word VICTORIA in red on whitish background is also on the badges. At the bottom of the badges in black are the letters DC plus the numbers of the badges.Serial Numbers of the badges are: DC 361, DC 362, DC 364, DC 368, DC 370, DC 374, DC 375, DC 376, DC 377, DC 379, DC 388, DC 389.arp. arp badge, air raid precautions, air raid precautions warden, warden, badges -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncCostume - Wedding dress- Elaine Mann nee Milnes 1957

Elaine Margaret Milnes of Tallangatta married David Ernest Mann of Wodonga on 30 March 1957. At the time of their first meeting, Elaine was living in Tallangatta where her father had moved as a bank manager. She was a member of the Drama Club. She and David met at the Rutherglen Town Hall whilst attending an Arts Festival. David was attending as a member of the Wodonga Music Club. David Mann was the son of Ernest and Evelyn Mann of Wodonga who had operated the family business since 1921. David joined the business in 1945 and became the managing director of Mann Wodonga from 1965. Under his management and leadership, it expanded to become one of Australia’s largest regional shopping centres, with a Supermarket, Hardware Store, Steel Store, Plumbing and Industrial supplies store, at one stage employing over 100 people. He continued to head the business until it was sold in 2006. He was a leader in many other fields in the Wodonga community, from leading the Wodonga Chamber of Commerce to scouting, Apex and Rotary and was a prime mover in establishing Aware Industries for people with disabilities. He chaired the Wodonga Chamber of Commerce on several occasions. David was a man of vision who was involved in many charitable and community organisations. These included membership of the hospital board and President of the Wodonga High School Council. was a prime mover in establishing Aware Industries for people with disabilities. Elaine also played an active role in the business. She developed and managed a quality giftware department from 1969 to 1987. Some of her local involvements included the School Mothers’ Club and Kindergarten, Girl Guides, the Quota and Penguin Clubs and Meals on Wheels. David also advocated passionately for the development of a university and TAFE to be established in Wodonga. In 1993 he inaugurated the Jonathan Mann lectures series at La Trobe University in honour of his grandfather. The university honoured Mr Mann in two significant ways, giving him an honorary degree of Doctorate of Law in 1998 and in 2002 named its new library the David Mann Library. David Mann died in Albury in June 2012. Elaine now (2024) lives in Melbourne. “The little I have done for Wodonga and district is only in return for what Wodonga and district has done for me.” David MannThis dress was worn by Elaine Milnes at her marriage to David Mann who became a prominent businessman and contributor to many aspects of the Wodonga community.A wedding dress dating from 30 March 1957. The dress consists of a fitted bodice with tulle frills around the body. The bodice has a square neckline decorated with tiny seeded pearls and blue stones. The long sleeves are made of sheer tulle with lace and a frill at the wrist. The skirt is made of two layers of white tulle with five lace and tulle frills around the body. Under the tulle is a pale blue satin slip with two more layers of white tulle underneath it. It was worn with a fingertip length veil held in place by a lace coronet. The bridal bouquet consisted of red and white roses. The bride also wore a single string of pearls. The dress was made by Olive Ferris Wedding Dresses of Sydney.mann wodonga, david mann, elaine mann, wodonga businesses -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheet, circa 1878

In 1984 the Commonwealth Government made available to Flagstaff Hill a collection of lead ingots and copper sheets recovered from the wreck-site of the LOCH ARD. They were presented to the Warrnambool City Council by the Hon. Tom Uren MHR, Minister for Territories and Local Government: “The Commonwealth recognises that shipwrecks like the LOCH ARD are our national heritage with important educational, recreational and tourist applications” (The Standard, Tuesday 8 May 1984). The LOCH ARD was wrecked in 1878. Unsuccessful salvage operations were then undertaken with the 90 ton paddle steamer NAPIER. In sudden bad weather this vessel too was sunk. The precise position of the LOCH ARD in the exposed and dangerous waters off Mutton Bird Island became lost to memory. The underwater location of the LOCH ARD was rediscovered in 1967 by a Warrnambool skindiver, Stan McPhee. In the two years following his find, the vessel was systematically pillaged by unauthorised salvagers. This led to the State and Federal Governments’ intervention in 1969. A roundup and seizure of recovered lead ingots and copper sheets was conducted by Commonwealth and Victorian Police. Offenders were charged and convicted. The “repossessed loot of the Tassie Boys” was placed into secure storage (Jack Loney, 1978, Wrecks & Reputations). The LOCH ARD manifest of cargo lists “Pig lead 50 tons, 994 pig & 37 rolls” and “Copper 33 plates, 53 bolts”. While the lead ingots have been subsequently described as “ballast”, the copper sheets are unlikely to have been associated with the ship’s normal complement in that way. Similar product lines in the cargo manifest are “Bar and rod iron 102 tons”, “Plate iron 3 tons” and “Zinc 12 tons”. These raw materials were used by colonial artisans such as blacksmiths and metal smelters to fashion, and repair, agricultural implements and industrial machinery. Copper was valued for its non-corrosive properties and its malleability, or ease of working. Both these qualities were useful, for example, in laying underground gas pipes that supplied lighting to residences, businesses and streetscapes in the mid-nineteenth century. As the nineteenth century progressed, the metal was also increasingly valued for its conductivity, with copper wiring linking colonial communities to each other, and the wider world, via the Telegraph system. The average weight of the copper sheets is 216 kilograms, calculated by "volume 0.1936m³ X Cu density 8930kgs/m³".The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collections historically significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Large heavy sheets or panels of copper metal raised from the wreck of the LOCH ARD. The 10 sheets are of roughly similar dimensions and rectangular shape. They bear signs of prolonged submersion in seawater, with various degrees of limestone accretion, adhered marine growth, and green oxidisation. Three of the sheets are severely buckled, demonstrating the force of underwater explosives used in their salvage. One sheet appears cut or severed in a diagonal line downwards from its top left hand corner. One sheet has a 10cm X 10cm square cut out of its top right hand corner. All sheets are in sturdy, stable condition. No maker’s marks are visible.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, sailing ship, copper sheet, manutacturing materials, metal imports, muntz -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity in foundries and expansion of demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggest they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. The summary of cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’ does not mention any crucibles, implying that they were not a large consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six are of the same size from a visual appraisal.The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417A large crucible, or fluxing pot, for heating and pouring molten metal. It was recovered from the wreck of the LOCH ARD. The clay fired vessel rises from circular flat base to a larger rim with pouring lip. It is stained a rust colour and bears some sedimentary accretion. Half of its loose fitting lid with central knob has also survived. Markings on the artefact indicate it is a Morgan’s crucible, made with graphite to prevent cracking in the furnace and provide a smooth (non-adhesive) inner surface. On base: “…RGAN’S PATENT CRUCIBLE”. On rim: “MORGAN’S PATENT P…” Below top edge "BAK"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgans crucible company, loch ard, fluxing pot, crucible -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity and expansion in foundries and demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggest they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. A summary of the LOCH ARD cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’ does not mention any crucibles, implying that they were not part of a larger consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six are of the same size from a visual appraisal. The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417A No. 6 size Morgan’s graphite crucible (i.e. 6kgs capacity). The crucible rises in a slight curve from a smaller flat base up to a wider top with a (chipped) pouring lip. It was recovered from the wreck of the LOCH ARD. The artefact is largely accretion free despite its long period of submersion at the wreck site. It has a number of visible maker’s markings which identify the manufacturer and the smelting capacity of the pot. The graphite crucible is in fair and stable condition. The number “6” which is framed in a square. The letters “THE PATENT PLUMBAGO CRUCIBLE COMPANY” and “BATTERSEA WORKS COMPANY”. Below rim "... GNS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgan's crucible company, loch ard, crucible, fluxing pot -

Federation University Historical Collection

Federation University Historical CollectionWork on paper - Cartoons, Edwin Cannon, World War One Cartoons by Edwin Cannon, 1916, 1916

Edwin (Ted) Cannon was born at Ballarat on 30 July 1895, the only son of Edwin and Florence Cannon. He studied art at the Ballarat School of Mines Technical Art School. Ted displayed a talent for industrial design but it was his black and white work that 'drew' most attention. His cartoons and caricatures, heavily influenced by Phil May, were of a particularly high standard. During the Ballarat Exhibition of 1913 Ted's work was singled out for notice and he was awarded First Prize. After completing his art course Ted was employed as an assistant teacher at the Ballarat Technical Art School, before taking a position as cartoonist with the Ballarat Star newspaper at the end of 1914. With the war raging in Europe Ted discovered a darker aspect for his artwork, but, still, he could not resist depicting Turkey as a full-feathered, fez-wearing bird. In 1915 Ted was awarded the prestigious Victorian Education Department Senior Technical School Scholarship. Only months into his scholarship, Ted volunteered for the AIF. A keen member of the local 71st "City of Ballarat" Regiment Ted was already primed for a life in the army. He embarked from Port Melbourne on 23 November 1915 with reinforcements to the 6th Infantry Battalion bound for Egypt. It was during the Battle of Pozieres on the Western Front that Ted Cannon came into his own. His work with the Scout Platoon (under the command of Lieutenant Jack Rogers) sketching the enemy's gun emplacements proved invaluable to the Brigade and brought Ted to the attention of the Australian High Command. On 13 September 1916 Ted was given a special assignment for General C.B.B. White. Ted was sent out forward of the Old Mill at Verbrandenmolen (in the Ypres Salient) to draw a panorama of the German lines in the area from Hill 60 to The Bluff. It was a hazardous task and Ted was warned to be careful. Tragically he was sniped by an enemy machine-gunner and sustained severe abdominal wounds. Stretcher-bearers rushed him to the 17th Casualty Clearing Station where he was operated on by the doctors at 8.30 that night. With little chance of success, but ever resilient, Ted remained conscious almost to the end. He died early in the morning of the 14 September 1916. His body was buried in the large Military Cemetery at Lijssenthoek. See http://www.ballarat.edu.au/about-ub/history/art-and-historical-collection/ub-honour-roll/c/edwin-joseph-ted-cannon-1895-1916Digital images of a number of cartoons published in the Ballarat School of Mines Students' Magazine, 1916. Ted Cannon sent cartoons home to Ballarat from the World War One front.edwin cannon, ted cannon, cartoons, world war, world war 1 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers' Equipment, hair clippers 'BURMAN", c1950