Showing 1315 items

matching hand operated

-

National Wool Museum

National Wool MuseumTextile - Beanie, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Teal knitted ribbed beanie with gathered crown.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green skirt shaped with darts and has an elastic waistband. Has a brown silky lining. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Jumper, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green long sleeved crew neck jumper with black horizontal stripes on lower half. Button at the back of neck. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Cardigan, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green cardigan with black edged scallop detailing on collar, button band and faux pockets.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

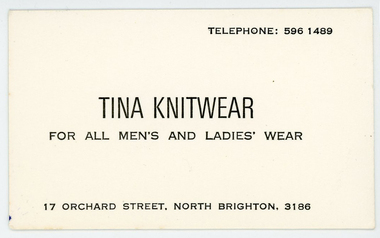

National Wool MuseumDocument - Business Card, Tina Knitwear, 1980-2000

Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Standard size cream business card with black embossed lettering.front: TELEPHONE: 596 1489 / TINA KNITWEAR / FOR ALL MEN'S AND LADIES' WEAR / 17 ORCHARD STREET, NORTH BRIGHTON, 3186knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

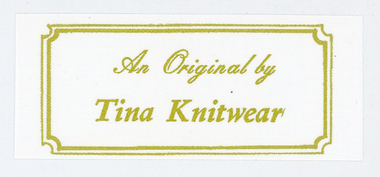

National Wool MuseumDocument - Label, Tina Knitwear, 1980-2000

Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Thin paper white label with gold printed text.front: An Original by / Tina Knitwearknitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumFunctional object - Magnifying Lens, c.1930s

This item was inherited from the donor's father, René Dupuche. John Dupuche, writes: This magnifying glass was used to remove the burrs and thorns that wool-buyers tended to get in their fingers when examining bales of wool. The open end was placed on the finger since the thorn was sometimes buried under the skin. The buyer looked through the magnifying glass and with tweezers or a pin removed the thorn which had rendered the finger inoperative. The wool-buyers needed the sensitivity of their fingers to appraise the suitability of the wool, as buyers had for centuries past, measuring the length of the staple, feeling and counting the crimps in the fibre, its finesse, softness, elasticity and strength, assessing the colour, watching for extraneous matter such as dust or seeds which would not be welcome by manufacturers half-way across the world. Their skills took years to acquire. Knowledgeable buyers were invaluable to their employers, since they were able to evaluate to the last percentage the yield of a bale. My father, René Dupuche, was the ‘principal buyer’ from 1927-1966 in Victoria, South Australia and Tasmania for the international wool company ‘Masurel Fils’ which was one of the largest wool businesses in Europe. It was based in the north of France, in Tourcoing, one of the major wool centres of the world. He was sent to Australia as a young man at the age of 23 and took part in the ‘golden era’ of wool in Australia, and the eventual replacement of hands-on appraisal by ‘core-testing’. Masurel Fils was one of the dozens of French and Belgian firms operating in Australia. These men from Flanders enjoyed a cosmopolitan society augmented by diplomats, European bankers and shipping-line executives for various countries and a handful of scientists and academics.Small black metal magnifying lens with three fold design and two hinges. One panel contains a circular glass lens, the centre panel has a circular hole, and the third panel has a square hole with three lines on each side.wool buyer, magnifying glass, magnifying lens, burrs, rené dupuche, john dupuche, migrants, masurel fils, french, belgian, flanders, working life, sheep industry, wool industry, agriculture -

![Ceramic, Malcolm Boyd, Untitled [Male Form] by Malcolm Boyd, 1977](/media/collectors/530576742162ef0fa09a2288/items/556e8b9f2162f1015460fbfb/item-media/62a9b7295a061b9db7f1e053/item-fit-380x285.jpg) Federation University Art Collection

Federation University Art CollectionCeramic, Malcolm Boyd, Untitled [Male Form] by Malcolm Boyd, 1977

MALCOLM BOYD Born Gippsland, Victoria In 1977 Malcolm Boyd graduated with a Diploma of Visual Arts from the Gippsland Institute of Advanced Education. It was at this time that he presented this work to the Jan Feder Memorial Ceramics Collection. Over thirty years later he still has a passion for ceramic history and design. Boyd operated the Black Cockatoo Pottery from around 1980-1995, starting in Essendon, then moving to Ascot Vale, Stratford, Bairnsdale and finally Fernbank in Gippsland. His handbuilt stoneware pots and clay sculptures are wood fired at his East Gippsland studio. He often uses ochre coloured dam banks on his property at Fernbank. The local clays are crushed, screened and blended with a white stoneware body to produce a number of shades and textures. All Malcolm Boyd's pot's are hand built using moulding, coiling, slabbing, and modelling techniques, and are high temperature fired (1300C) to allow some of the very ancient oriental glazes to mature. All works spend at least 20 hours in the wood fired kilns. This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.malcolm boyd, ceramics, artist, artwork, jan feder memorial ceramics collection, gippsland campus, alumni -

Federation University Art Collection

Federation University Art CollectionCeramic, Malcolm Boyd, Stoneware sculptured sphere, 1977

MALCOLM BOYD Born Gippsland, Victoria In 1977 Malcolm Boyd graduated with a Diploma of Visual Arts from the Gippsland Institute of Advanced Education. It was at this time that he presented this work to the Jan Feder Memorial Ceramics Collection. Over thirty years later he still has a passion for ceramic history and design. Boyd operated the Black Cockatoo Pottery from around 1980-1995, starting in Essendon, then moving to Ascot Vale, Stratford, Bairnsdale and finally Fernbank in Gippsland. His handbuilt stoneware pots and clay sculptures are wood fired at his East Gippsland studio. He often uses ochre coloured dam banks on his property at Fernbank. The local clays are crushed, screened and blended with a white stoneware body to produce a number of shades and textures. All Malcolm Boyd's pot's are hand built using moulding, coiling, slabbing, and modelling techniques, and are high temperature fired (1300C) to allow some of the very ancient oriental glazes to mature. All works spend at least 20 hours in the wood fired kilns. This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. Jan Feder Memorial Collection Presented by the artist in 1977. malcolm boyd, ceramics, stoneware, artists, artwork, jan feder memorial ceramics collection, alumni, woodfire -

Vision Australia

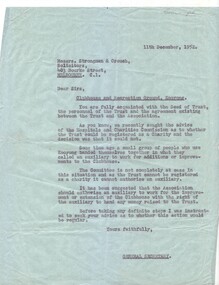

Vision AustraliaLetter - Text, Letter to Strongman & Crouch regarding auxiliary formation, December 1952

Letter to Strongman & Crouch Solicitors regarding the formation of an auxiliary to work for additions or improvements to the clubhouse, despite the inability to register the clubhouse and recreation ground as a charity. The Association had been advised it could authorise such an auxiliary, but as the clubhouse operates under a Deed of Trust, was unsure if this was possible. In reply, the advice was to register the auxiliary as one of the Association, thereby all monies paid direct to the Association which could then ear-mark some for expenditure on the club house and recreation ground, or hand to the Trust to do so.2 typed letters on blue and white paperassociation for the advancement of the blind, auxiliaries, kooyong club house -

Vision Australia

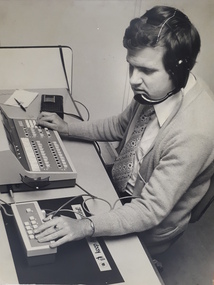

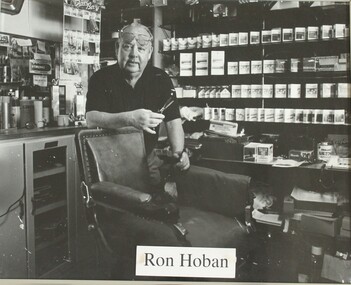

Vision AustraliaPhotograph - Image, Man using telephone exchange

Male sits at a desk, wearing a headset, with his hands on a telephone switchboard and another device to his right. A small black radio sits to his right, as does a pen attached to the desk itself and a piece of paper. Switchboard training was provided to many blind and vision impaired people, who could adeptly operate the switch to connect callers through to employees.Digital image of man operating a telephone exchangeemployment, royal blind society of new south wales -

Falls Creek Historical Society

Falls Creek Historical SocietyJournal - Schuss Vol. 19. No. 2 March - April 1953

Schuss was advertised as Victoria’s Official Ski Journal It was issued monthly from 1935 to 1961 except during the war when summer issues covered two months. This continued after the war, but it averaged 10 issues annually over its 25 year life. Schuss was published by the Ski Club of Victoria which had a membership of 38 Ski Clubs and demanded to be recognised as the prime authority on skiing in the state. The other 30 ski clubs with 85% of the members disagreed and the politics of skiing became heated. These clubs formed the Federation of Victorian Ski Clubs with their own journal, Ski Horizon. With the establishment of the Victorian Ski Association, Ski-Horizon published its last issue in Nov - Dec. 1955 and the role of the official journal was fully taken over by “Schuss”. This item is significant because it contains stories, images and information documenting the development of the ski industry in Victoria.The journal features stories and events chronicling developments in Victoria and internationally. Items related to the Falls Creek Area in this issue include:- Cover - Features a photo by H.Gibbs titled "Western Cliffs of Mt. Bogong" Page 65 - BOB HYMANS reported news of Falls Creek. At his own Ski School, notable improvements to accommodation have been made and additions to the building itself, which will make it very much more comfortable and serviceable to visitors. Water supply and heating are amongst the items in hand. Bob has acquired a Land Rover which will be a power of assistance to him in maintaining fresh supplies and in servicing his project generally. Kiewa Valley Ski Club members are making splendid progress with the erection of their Lodge. This is the latest building addition in that area and raises the number of clubs resident there to nine. Nissen Ski Tow members intend to operate their tow on the upper slopes of Falls Creek every day during the coming season that conditions permit. They are to be warmly commended on their enterprise. Page 65 - Advertisement for Bob Hymans' Ski School and Lodgeschuss journal, bob hymans, kiewa valley ski club, nissen tow -

Falls Creek Historical Society

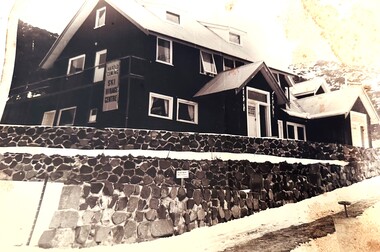

Falls Creek Historical SocietyPhotograph - Harold Cuming Ski Hirage Centre

Cuming's Ski Hire was an early establishment in Falls Creek, owned and operated by Harold and Jean Cuming. Located in Main Falls Creek Road only 70 yards from the top station of the chairlift, it had a wide range of skis for hire and many other accessories for sale. It also operated simple accommodation, a cafe and apres ski shop. The business changed hands and the cafe had many names throughout its history. It was the centre of many activities - including skiers using the roof as a ski jump!This image is significant because it depicts the original Cumings Ski Hire building at Falls Creek, Victoria.A black and white photo of the Harold Cuming Ski Hirage Centre at Falls Creek.On sign on wall: Harold Cuming Ski Hirage Centrecuming's ski hire, harold cuming, jean cuming, ski hire falls creek -

Falls Creek Historical Society

Falls Creek Historical SocietyPhotograph - Harold and Jean Cuming with staff

Cuming's Ski Hire was an early establishment in Falls Creek, owned and operated by Harold and Jean Cuming. Located in Main Falls Creek Road only 70 yards from the top station of the chairlift, it had a wide range of skis for hire and many other accessories for sale. It also operated simple accommodation, a cafe and apres ski shop. The business changed hands and the cafe had many names throughout its history. It was the centre of many activities - including skiers using the roof as a ski jump!This image is significant because it depicts Harold and Jean Cuming and staff from the Cuming's Ski Hirage Centre at Falls Creek, Victoria.A black and white photo of the Harold and Jean Cuming with staff and a large snowmancuming's ski hire, harold cuming, jean cuming, ski hire falls creek -

Melton City Libraries

Melton City LibrariesDocument, Service of Celebration and Thanksgiving for the life of Ernest Wesley Barrie (Bon) 1909-1985, 1985

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Service held at Melton Uniting Church local identities -

Falls Creek Historical Society

Falls Creek Historical SocietyBooklet - Harold Cumimg Ski Hire

Cuming's Ski Hire was an early establishment in Falls Creek, owned and operated by Harold and Jean Cuming. Located in Main Falls Creek Road only 70 yards from the top station of the chairlift, it had a wide range of skis for hire and many other accessories for sale. It also operated simple accommodation, a cafe and apres ski shop. The business changed hands and the cafe had many names throughout its history. It was the centre of many activities - including skiers using the roof as a ski jump!This brochure is significant because it represents a long established and popular business in Falls Creek. A foldout brochure printed in black ink on red paper. A symbol of a pair of skis and poles is on the front.On Cover: HAROLD CUMING / SKI HIRE & FALLS CTEEK THE COMPATIBLE PAIRcuming's ski hire, cuming inn falls creek, harold cuming -

Falls Creek Historical Society

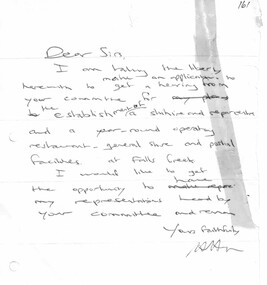

Falls Creek Historical SocietyDocument - Hand-Written Note - Application For Hearing With Committee

Bob (Herman) Hymans (a former member of the Royal Netherlands Navy) was born in Bloemendaal, Holland on 30th September 1922. During World War II he fought against the Japanese in the Dutch East Indies (now Indonesia) and was imprisoned in Changi and on the Burma Railway. After gaining qualifications as a Ski Instructor, Bob arrived in Falls Creek in July 1950. Working as an Instructor and Supervisor at Bogong Lodge, Bob decided his future was in accommodation. He was successful in negotiating an indenture for land from the State Electricity Commission (SEC). It took Bob two years to build his Grand Coeur Chalet but, tragically, it was burned down in August 1961. Bob also built the first Chairlift in Australia. This was a single chairlift and the structure was built from wooden electricity poles. He was constantly full of new ideas and proposals for the village. Bob Hymans die on 7th July 2007. This Collection of documents and letters tells the story of Bob's endeavours to develop Falls Creek into the ski village it is today.This item is significant because it documents proposals put forward by Bob Hymans to develop facilities in the Falls Creek Tourist Area.A handwritten letter from Bob Hymans to the Management Committee requesting a hearing to discuss his future plans.TRANSCRIPT Dear Sirs, I am taking the liberty herewith to make an application to get a hearing from your committee for the establishment of a ski hire and repair centre and a year-round operating restaurant-general store and postal facilities at Falls Creek. I would like to get the opportunity to have my representations heard by your Committee and remain Yours faithfullyfalls creek tourist area management committee, falls creek administration, bob hymans -

Box Hill RSL Inc.

Box Hill RSL Inc.Memorabilia - Walkie Talkie- USA, Galvin Manufacturing Co, c. 1942

From the Imperial War Museums website (IWM UK): Second World War period transceiver set widely used by US, and Allied, Armed Forces in Italy, N W Europe, and the Pacific. The US Signal Corps developed the SCR-536 early in the Second World War, It was produced from 1942 onwards by the Galvin Manufacturing Co. By 1945 130,000 had been produced. The SCR-536 was an extremely popular set and was colloquially known as a "Handie-Talkie". It consisted of a five-valve, low-power, battery operated, AM (HF) transceiver that was designed for portability and ease of operation. It featured a single channel crystal control between 3.5 and 6Mc/s, and it had an R/T communication range of 1 mile over land and 3 miles over salt water. The set was switched into a receiving mode by extending the telescopic aerial, and to transmit the press-to-talk switch was depressed. The aerial was protected by a connected cover. The set was well-engineered and designed and could be held in one hand, hence "Handie-Talkie" . It was used virtually everywhere in the world, weighed only 2kg, and was proofed against fungi and moisture.The SCR-536 was also modified for use in military gliders under the designation SCR-585.Short range portable transceiver. A large green-painted metal box with perforated small round holes in the shape of hexagons (original perforated round black earpiece and mouthpiece missing). On the back is a long green webbing carrying strap. (not original)Between the earpiece and mouthpiece is a plaque that reads "SIGNAL CORPS US ARMY RADIO RECEIVER AND TRANSMITTER BC-611-C. SERIAL NUMBER: 3017. ORDER NUMBER: 1345-WF-43. MADE BY GALVIN MFG CORPORATION CHICAGO ILLINOIS. On label : FREQUENCY 3996 Kev/ CHANNEL/ BAT. DATE Red square stamp walkie talkie, handie talkie, telecommunication, ww2, world war 2, american, wireless equipment, signal corps, us army, transceiver, bc 611 c -

Melton City Libraries

Melton City LibrariesPhotograph, Bon Barrie, c.1940, Unknown

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Photographs of Bon Barrielocal identities, pioneer families -

Melton City Libraries

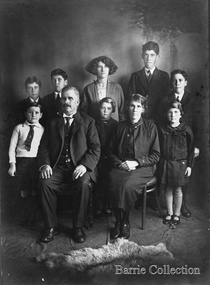

Melton City LibrariesPhotograph, Charles Ernest and Jessie Barrie with family, Unknown

This document is has been compiled by Wendy Barrie daughter of Ernest (Bon) and Edna Barrie and granddaughter of Charles E and Jessie M Barrie. I was born in during WW 11 and the first child of my generation to live on the ‘ Darlingsford’ property at Melton. My grandfather was well known in the district and was mostly referred to as Ernie. He shared the same initials as his second son Edgar. His three eldest sons lived and farmed in Melton for their entire lives. His descendants are still associated with farming, engineering and earthmoving in Melton. Ernie Barrie operated a travelling Chaff Cutter in the St Arnaud area where his parents William and Mary Ann had taken up land at Coonooer West in 1873. Ernie commenced his working life with a team of bullocks and a chaff cutter. The earliest connection he had with Melton was in 1887. By the beginning of the 20th century Ernie and his father William and brothers, William, Samuel, James Edwin,[Ted] Robert, Arthur and Albert have been associated with farming and milling in the Melton district. In the early 1900’s Ernie and his brother Ted were in partnership in a Chaff cutting and Hay processing Mill on the corner of Station and Brooklyn road Melton South. The mill was managed by William for a time. By 1906 Charles Ernest and James Edwin were in partnership in the Station Road mill when a connecting rail line across Brooklyn Road for a siding was constructed to the Melton Railway Station. In 1911 the Mill’s letterhead shows C.E. BARRIE Hay Pressing and Chaff Cutting Mills. Melton Railway Station. Telephone No 1 Melton. This Mill as sold to H S K Ward in 1916 and stood until 1977 when it burnt down in a spectacular fire. Ernie built a house at Melton South beside the Chaff Mill at Station Road in 1906 and married Jessie May Lang in August at the Methodist Church. Jessie’s father was Thomas Lang. He came to Melton in 1896 and was the Head Teacher at Melton State School No 430 until he retired in 1917. They had 9 children with 8 surviving to adulthood. Jessie and Ernie had 6 sons and 3 daughters. All the children lived at Darlingsford. In April 1910 the family left Melton for a brief period and moved to a farm in Trundle in NSW. They returned to Melton and purchased Darlingsford in May 1911. For a time during WW1 they lived at Moonee Ponds near the Lang grandparents at Ascot Vale. Mary and Bon attended Bank St State School. The children developed diphtheria in 1916 and their youngest boy, Cecil died of complications. Mary and Bon were taken to Fairfield Hospital and both recovered. At the end of the war influenza broke out the family returned to Darlingsford and shared the home for a short while with the Pearcey family who had been working the farm. By 1922 the family had and grown and Edgar, Tom, Horace, Jessie, Joyce and Jim were living a Darlingsford. Ernie continued during the 1920’s working the farm and attend his many civic and community commitments. Two 8 clydesdale horse teams were used to work the land which meant early rising for the horses to be fed and harnessed to commence the days work. In 1916 Ernie also became involved in a Chaff Mill on the corner of Sunshine and Geelong Road West Footscray, which at the time was being run by John Ralph Schutt. It was known an Schutt Barrie. A flour mill was added at a later stage. Other Schutt and Barrie mills were situated at Parwan and Diggers Rest. Another mill was situated beside the railway line at Rockbank. The Footscray mill ceased operation in 1968 Ernie spent a lot of time and energy at the Parwan Mill and travelling around Parwan and Balliang farms, where he came to know many of the families in the district. Ernies commitment to the civic development to the Melton and district was extensive, he was involved with a number of large events during the 1920’s such as the Melton Exhibitions and the 1929 Back to Melton Celebrations. He was a member of the Australian Natives Association at the turn of the century. He was Chairman of the School Committee at Melton State School 430 and the Melton South State School in thw1920s. He donated the land for a Hall for Melton South in 1909, known as Exford Hall and later in 1919 renamed Victoria Hall. The Hall was demolished in 1992. He was a Councillor, JP, and Vice President and President of the Melton Mechanics Institute Hall Committee in 1915- 1916. He was a member of the Methodist Church and later the Scots Presbyterian Church. He was Superintendent of the Sunday School of the Methodist Church to 1910 and later Scots Presbyterian Church until 1931. This is reflected in the theme of children in the stained glass window which was dedicated in his memory by his wife Jessie as a gift to the Scots Church. Charles Ernest Barrie made many generous donations to many charities who supported young people and children. In 1918 Jessie and Ernie made the first donation to a very prominent Victorian charity whose work still continues. Yooralla. In July 1931 Ernie’s untimely death was a major blow to the family and the Melton community. To this day people still vividly recall the day they lined the streets for his funeral. The day of the funeral is recalled as the day Melton stood as two of their prominent citizens who tragically died on the same day. Their eldest daughter Mary had married Keith Robinson in 1930 and had just moved to Heatherdale Toolern Vale with their year old baby son. Bon the eldest son was 22, Edgar 18, Tom 16, Horace 15, Jessie and Joyce 10 and Jim 8 years old. A heavy burden of responsibility fell on the shoulders of the two eldest children, Mary particularly for her mother and Bon stepped in assuming head of the family for his mother, brothers and sisters living at the Darlingsford homestead. In the early 1930’s the three eldest sons took on many of the Civic and Church commitments which their father had held. This community involvement extended well into the 1980s. In 1941 Bon married Edna Myers and they moved into a house shifted from Harkness Lane to Harkness Lane on the eastern section of the Darlingford property. Edgar married Margaret Hodgkinson a Primary school teacher at Melton in 1949 and they lived in the Darlingsford house. Earlier Tom married May Ferris and lived on the eastern side of Ferris Lane in the Ferris home. Bon , Edgar and Tom often operated as a team effort, in particular at harvest time when a larger team of workers was needed. The three farms cultivated wheat, barley and oats and supplied the Mill with sheafed hay. They continued using horse teams until mechanisation in the 1940’s made the horses redundant. By the 1960s their five sons continued with farming. Many loads of hay were transported to the Mill in Footscray. Well into the 1960s hired harvest hands along with agricultural university students were involved in bringing in he harvest. Stacking was an art form in itself and Tom held the expertise for building and shaping the sides and roof. The stacks built in the district each had their own unique shape and could be recognized by their builders. The Barrie brothers developed a mechanical fork lift for picking up complete stooks and moving them to be loaded to the elevator to build the haystack. The prototype built by Bill Gillespie was attached to a Bedford truck. Later refinements in a collaborative effort with the Gillespie brothers a multi pronged fork was attached to the front of tractor which was hydraulically operated to raise each stook onto trucks to be transported to the site of the haystacks. This method of handling sheaves significantly reduced laborious pitchforking individual sheaves. This invention was soon taken up by farmers far and wide and was a common sight in the district at harvest time in the stacking season. I recall visiting farmers calling in at the house at Ferris Road farm to inspect this break through invention. The Clydesdale horse teams were used into the 1940s but by the 1950s the Barries’ farms were fully mechanised. When the demand for sheafed hay declined other crops were introduced these included barley, lucerne, wheat and peas. Sheep were added to the mix in the 1950s in an attempt to keep the farms more viable. In the 1970s part of the Barrie’s farms were facing a major disruption with the impending compulsorily acquisition of a strip of land for the construction the freeway bypass, which divided access between the Darlingsford homestead with those on Ferris Lane. Charles Ernest Barrie and Jessie May Lang's children: 1. Mary Ena BARRIE was born on 07 October 1907. She died on 29 April 1999. 2. Ernest Wesley BARRIE was born on 29 April 1909 in Ascot Vale, Victoria, Australia.He died on 25 December 1985 in Melton, Victoria, Australia. 3. Cecil William BARRIE was born on 23 February 1911.He died on 25 May 1916. 4. Charles Edgar BARRIE was born on 01 June 1913.He died on 06 October 1975. 5. Thomas Lindsay BARRIE was born on 25 November 1914.He died on 14 September 1990 in Melton, Victoria, Australia. 6. William Horace BARRIE was born on 11 October 1915.He died on 19 December 1950. 7. Jessie Maud BARRIE was born on 06 November 1920 in Bacchus Marsh, Victoria, Australia.She died on 26 February 1994. 8. Dorothy Joyce BARRIE was born on 06 November 1920 in Bacchus Marsh, Victoria, Australia.She died on 18 March 2003.. 9. James Edward BARRIE was born on 17 January 1922 in Bacchus Marsh, Victoria, Australia.He died on 23 August 2004Family Photo with Edgar, Tom, Mary, Ernest (Bon), Horace, Jim, Charles Ernest, Jessie and Joycelocal identities -

Melton City Libraries

Melton City LibrariesPhotograph, Harvesting, 1950