Showing 167 items

matching block equipment

-

Mont De Lancey

Mont De LanceyTool - Hay Knife, James Griffin & Sons, Unknown

A large steel curved bladed silage or hay knife with a tapered handle and a bent pointed sharp end. It was used to cut hay when it is dry. Blocks were cut for the ? or stack as needed for stock feed. Silage is an animal feed cut and stored while still green.agricultutal tools, hay knife, agricultural equipment -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationMegaphone

... . Manufacturers. 139 Border St. East Boston, Mass. Their equipment.... Manufacturers. 139 Border St. East Boston, Mass. Their equipment, which ...Used to communicate with ships from Point Hicks Lightstation. In Greek mythology, "Stentor" was a herald on the Greek side during the Trojan War. His name has given rise to the adjective "stentorian", meaning loud-voiced, for which he was famous. Homer said his "voice was as powerful as fifty voices of other men." He died after his defeat by Hermes in a shouting contest. See the Iliad, V. The large funnel-shaped device is nearly 750mm (30 inches) in length and is made of re coated cardboard that is riveted together. It has a metal mouth-piece at the narrow end and a metal edge at the wide end, and a metal handle. The maker’s information inside indicates that it is a ‘Stentor Megaphone’ patented on 4 April 1899 by a company in Boston. Stentor brand megaphones were manufactured by Merriman Brothers, a firm established in Boston in 1898 specializing in hardware for yachts. Merriman Bros. Manufacturers. 139 Border St. East Boston, Mass. Their equipment, which included pulley blocks, winches and fittings, was well-known worldwide before the company closed in about 1995. However, their ‘main business was not blocks and winches’…‘it was Merriman megaphones, including the familiar cheerleader megaphones’. They came in different sizes, one of which was employed by the United States Navy because of its scientifically proven horn angle of 22 degrees’. Their patent for the device, dated April 4, 1899, specified details such as the ‘rivets, metal mouthpiece, and adjacent parts’,and an undated pamphlet promoting the Stentor Megaphone emphasizes its ‘highly finished’ appearance ‘with nickel mouthpiece, rim and other fittings’. It also pronounces ‘the carrying power of a Megaphone is astonishing. Even under adverse conditions, it magnifies the power of the voice many times. For listening to distant sounds, it is also of great assistance’. Various sizes were designed for particular uses, and the pamphlet advises that the 30 inch no.2 model, which cost US $2.50, ‘makes it easy to talk half-a-mile and shout a mile’. An advertisement also stresses that it has ‘no iron parts’, making it ideal for marine situations.The Penobscot Marine Museum, Searsport, Maine, United States, has the same or similar model of megaphone in its collection, and the Flagstaff Hill Maritime Village Museum, Warrnambool, Victoria, has a galvanised metal ‘Acme Stentor’ megaphone. The Point Hicks Stentor Megaphone has first level contributory significance for its provenance and historic value, and also as a relatively rare item of equipment once used worldwide in marine situations, such as lightstations, as demonstrated by this example in a Victorian lightstation.One large funnel shaped megaphone made of coated cardboard riveted together. Has a metal handle and metal rims at each end. Dark reddish brown colour."No 2 / THE / STENTOR MEGAPHONE / PATENTED APRIL 4TH 1899 / .../ MAKERS / .OSTON. MASS" -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryEngine, gas

This engine turned belts to power battery operation. Used from C 1910-1920, some are parts missing. 'Tangye' had offices in Sydney.The first gas engine, a 1 nominal horsepower two-cycle type, was sold in 1881, and in 1890 the firm commenced manufacture of the four-cycle gas engine. Incorporated as a limited company from 1881, in 1894 they produced their first hot bulb engine.[2] Richard Tangye was knighted in 1894. After the deaths of Richard (1906) and George (1920), with the family owning the majority of shares, their sons entered the business.[2] In 1919, the company started production of large-scale industrial diesel engines, pumps and hydraulic equipment. Engine production was stopped after World War Two. A Tangye 35HP suction gas engine. (incomplete). Large green cast iron engine sitting on large white concrete block, with inscriptions on both sides. The green engine has 3 outlet/inlet pipes and joins onto one belt wheel; belt wheel joins onto another belt wheel which is sitting on another white concrete block."Tangye/patents/birmingham" -

Mont De Lancey

Mont De LanceyPrinting set, c1900

... . printing blocks printing equipment Wooden child's printing set ...Medal was awarded in Paris Exposition in 1900.Wooden child's printing set in box, with letters of the alphabet and numbers. Has metal hinges. Patented 5/2/1901printing blocks, printing equipment -

Woodend RSL

Woodend RSLEquipment - Lighthorse Rifle Holder, Lighthorse Rifle Holder

Standard issue blocked brown leather rifle bucket for attachment to the Pattern 1912 UP saddle. Rifle buckets were used by British and Commonwealth mounted troops from the First World War to around 1941. In the Australian Light Horse units their use did not become common until the end of the First World War. Prior to this rifles were carried slung across the rider's back.light horse, 1941, rifle bucket, pattern 1912 up saddle -

Ringwood and District Historical Society

Ringwood and District Historical SocietyEquipment - Rubber Stamp, Ringwood Technical School Rubber Stamp on wooden block (pre 1990)

... Rubber Stamp on wooden block (pre 1990) Equipment Rubber Stamp ...Ringwood Technical School Rubber Stamp of school crest on wooden block; Also a blue ink impression of the stamp. "Ringwood Technical School" around tree image, with "Growth Through Knoweldge" at top. rts, ringwood tech -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Sharpening Stone, 1950+

Honing stones or sharpening stones are often included in a carpenter's and woodworkers tool kits to keep tool blades sharp.The sharpening stone is an example of carpentry equipment used to sharpen tools and blades in the 19th and 20th centuries.Sharpening stone, also called an oil stone, whetstone, or honing stone. Rectangular stone is semi-recessed in a wooden block with another block on top that forms a lid. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening stone, oil stone, blade sharpeing, tool, whet stone, whetstone, honing stone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Sharpening Stone, 1950+

Sharpening stones are part of a carpenter or woodworker's took kit so that blades of tools can be kept sharp.The sharpening stone is an example of equipment used in the 19th and 20th centuries by woodworking tradesmen.Sharpening stone, sometimes called oil stone, whetstone or honing stone. Rectangular block of stone within a recessed wooden block, with a matching wooden lid.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening stone, whet stone, honing stone, oil stone, carpenters tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Education kit - Cuisenaire Blocks, c1960s

Used in schools to teach maths during 1960-70s. Used by Julie Jones at 10 Francis Street, Blackburn.Set of Cuisenaire Rods, multicoloured. Used as an educational tool to teach children maths. Wood was stained in different colours to donate a numeric value.school, equipment -

Ballarat Tramway Museum

Ballarat Tramway MuseumEquipment - Motor lead terminal block, c1915

... steel engine bolts. Equipment Motor lead terminal block ...Item used to terminate motor leads on a tram. The wood block is used as insulation and is located on the wooden body of tram on one side of the motor access hatch to allow a worker to easily disconnect the leads.Demonstrates an item fitted to a tramcar to terminate motor leads.Softwood wood block fitted 8 brass bolts and two steel engine bolts.tram 14, tramcars, tramcar maintenance, motors -

Falls Creek Historical Society

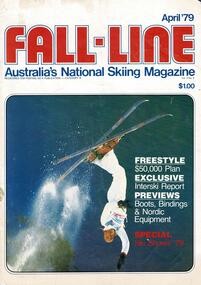

Falls Creek Historical SocietyMagazine - Fall-Line - Australia's National Skiing Magazine April '79

“Fall-Line” was one of a series of magazines published by the Victorian Ski Association. It was produced from 1979 until 1985. It superseded their previous publication, “Ski” magazine and was followed by the “Australian Skiing” magazine. The Victorian Ski Association was formed in 1955.This magazine is significant because it documents developments in the ski industry in Australia.A magazine featuring a coloured image on the cover and containing articles and advertising related to developments in skiing in Australia. This issue included an update on improvements being made at Falls Creek. FALLS CREEK The chairlift access area near the medical centre, long famous as the Mudpie Parlour of Falls Creek, has been sealed and Falls Creek itself, the waters of which have filled many an unsuspecting gum- boot, has been bridged, also near the medical centre. A lock-up storage shed will be built along Bogong High Plains Road, just below the oversnow terminal, for the use and convenience of all village commercial operators and site holders. Direct access will be possible by snowmobile. Falls Creek rates have risen to $82.50 per bed (less 10% discount if paid on time). The rise is the first in two years, and is less than the corresponding rise in the C.P.I. over that period. The access trail from the water tanks at the base of the Home Trail to the nursery slope has been smoothed and widened to 12 metres, and a new six metre wide access trail has been cut from Falls Creek Road, just behind Diana lodge to the chairlift bottom station. The Village Bowl comfort station is being extended and renovated, and the finishing touches are being put on the comfort station in the upper car park. Construction of an akja station/toilet block in Sun Valley will commence in 1980. The Management Committee is investigating the purchase of a Mercedes 800 series snow-clearing machine to supplement the CRB equipment in use in village parking areas The village water supply has been re- designed to ensure adequate supply at all times.australian ski magazines, skiing australia, victorian ski association -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart home, 93 Arthur Street, Eltham, 11 November 2006

Situated at the top of the hill in Arthur Street, the former Jelbart residence and barn were part of a major change that transformed Eltham's character in the late 1960s. Built from the mid 1940s through mid 1950s when Eltham was a rural community, the Jelbrat residence and barn are all that remain of a family property of some 250 acres (100 ha). With growing population pressures, in the late 1960s, owners Ron and Yvonne Jelbart decided to subdivide their property creating the Woodridge Estate in the early 1970s, a major factor towards the transformation of Eltham to the suburb it is today. The Jelbarts had moved to Eltham in the early 1940s when they purchased a poultry farm in New Street, now Lavendar Park Road. (The local Black Friday bushire of January 13, 1939 had started at C.A. (Clarrie) Hurst’s Eltham Poultry Farm and Hatchery in New Street.) Jelbart was primarily a businessman importing office machinery but desired farm beef and dairy cattle so the couple purchased the virgin bushland at what was then at the end of a dirt road, Arthur Street. With post war shortages of most building materials, they followed the example of the Eltham Artists' Colony (later called Montsalvat) and built thier home from mud-bricks and recyclked materials. The barn was first to be completed in 1945 which they made their home whilst building the main residence. It took eight years to complete the two buildings. Both the main residence and the barn are now separate homes, and along with the remaining property being sub-divided further in 1998 are now part of the Kinloch Gardens Estate at 93 Arthur Street. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p139 Standing on a hilltop at Arthur Street, Eltham, the Jelbart residence and former barn were part of a major change that transformed Eltham’s character in the late 1960s. Built from the late 1940s to the mid 1950s when Eltham was a rural community, they are all that remain of what was once a family property of around 250 acres (100 ha). As population pressure increased in the late 1960s, owners Ron and Yvonne Jelbart, decided to subdivide their property. The break-up of this property into the Woodridge Estate in the early 1970s, was a major factor towards transforming Eltham into the suburb it is today.1 Although standing only a few minutes from Eltham’s busy hub and hundreds of houses in Woodridge, scarcely any urban sound disturbs the peace. Views from the two buildings are almost exclusively of trees and extend to Mt. Dandenong to the south-east, the Great Divide to the north, and Melbourne city to the south-west. The Jelbarts had lived in Eltham since the early 1940s when they bought a poultry farm in New Street, now Lavender Park Road. Although Jelbart was primarily a businessman importing office machinery, he was keen to farm dairy and beef cattle, so the couple bought rough bushland at what was then the end of Arthur Street. But a shortage of building materials following World War Two hampered their plans to build their new home, so they followed the example of the Eltham Artists’ Colony (later called Montsalvat) and used mud-bricks and recycled materials.2 With great determination the family and friends constructed their house. Massive timber frames and huge quantities of mud-bricks were made on site. The barn was built first in 1945, and two years later, while camping inside, the Jelbarts started building their house. It took eight years to construct the two buildings, even with the help of professional tradesmen. The buildings, with timber frames infilled with mud-brick and plastered, are reminiscent of the English Tudor style. The Jelbarts are of Cornish stock. Much of the timber framework came from demolished bridges or warehouses, and recycled slate was used for roofs and floors. Quality second-hand materials were readily available in the late 1940s and 1950s when there was much demolition in Melbourne and little respect for heritage. A former 19th century Toorak mansion Woorigoleen provided the magnificent stone fireplace, the timber panelling and the parquetry floor in the living room. The large stone gateposts at the entry of the property came from Melbourne University. Almost no mechanical equipment was used to build the 55 square house and the 25 square barn. Massive timber frames were erected using block and tackle pulleys and timbers were shaped, sawn and drilled by hand. Son and architect Ian, with his family, have lived in and extensively renovated both buildings since the early 1970s. Ian transformed the steep ridge of the property into a plateau, where the main house Kinloch stands, surrounded by terraces and lawns. The grounds retain many native plants, including massive yellow boxes – some nudging 80 years. Ian attached 70 metres of pergolas draped with wisteria, roses and grape vines, to three sides of the house. The beautiful garden is featured in the book Through the Rose Arbour by Rosemary Houseman. The two-storey barn – now a house – retains traces of its original use. The cow-shed with milking and feed-rooms, and the machinery-shed remain. The house, separated on the ground floor by a breeze-way, soars two storeys and includes a mezzanine. These are connected by spiral staircases, to timber-beamed and plaster-lined high-pitched ceilings. The house also descends to a wine cellar. Curiously the roof is of corrugated iron on the south and slate on the north, to save costs. Small-paned windows and three French doors open onto the front lawn, which extends to Jelbart Court.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, arthur street, jelbart barn, jelbart home, kinloch gardens -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumElectro Magnet, between 1881 and 1968

Horace Darwin, youngest surviving son of Charles Darwin, was a founding partner of the Cambridge Scientific Instrument Company in 1881 (http://www.museumoftechnology.com/cic.html).Composite object with three feet supporting two squared cylinders attached to a clamping device and metal block with four current terminals. Cylinders are covered with red leather. Metal block and clamp base appear painted.Engraved on terminal block: 'No 15548 / THE CAMBRIDGE SCIENTIFIC INSTRUMENT CO LTD. CAMBRIDGE. ENGLAND' Engraved on side of terminal block: 'To be excited from 200 volts circuit / with coils in series. Connect terminals 2 & 3.'cambridge scientific instrument company, electro magnet, electrical equipment, electrical instrumentation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesAlbum - Colour 35mm slides, James (Jim) Pleasance, Miscellaneous Burnley Views, 1975-1988

Box of coloured slides, all from different collections. (1) "Students Margaret Oliver," on reverse,"Equipment 2190 Cultivator" (2) "Green manure crops. Field peas lupins." 1975 (3) "B.H.C." on reverse, "Seed beds." (4) "29/4/64 Crops Section." (5) "Seed Testing Lab (1966)." (6) "Julie Provan Peach stock Block." Sep (7) View of back of lawn." Aug 1980 (8) View of Ponds." ((0 Constructing Native Garden. (10) Crack Willow in winter. Jul 1978 (11) Crack Willow in summer. Jul 1988 (12) Administration Building. 1985 (13) Blossom. (14) Blossom on fruit trees. Sep (15) Children Planting. Aug 1985. Also others.students, margaret oliver, cultivator, lupins, crops section, seed testing lab, julie provan, lawn, ponds, native garden, blossom, fruit trees, children, planting, green manure, garden views, administration building, crack willow, peach blossom, orchard, sunken garden, rose garden, flowers, acacia maidenii, vegetables -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Ballarat Tramway Museum

Ballarat Tramway MuseumManual, Warren Doubleday, "Scrubber No. 8 Training Manual", Jun. 2006

Ten page plus cover sheet document titled "Scrubber No. 8 Training Manual", detailing Controls, Auxiliary equipment of ex MMTB Scrubber No. 8 ( 8W), with photographs of the controls, scrubbing blocks, pipework, preparation, operation, stabling, appendix showing cut out switches and tool box and Scrubber car operator competency sheet. Version 1, dated 8/6/1001. (has been replaced since). Prepared by Warren Doubleday 6/2001.trams, tramways, scrubber tram, btm, manual, instructions -

Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveEquipment - Wooden leg rest, (c. 1960s)

Often used to support a leg when sitting out of bed. Also used when plastering a leg. Elevation of the limb to prevent swelling. Likely made on site by engineering team as there are no manufacturers markings.Stained timber, mid brown, 4 piece pyramidal shape, scoop for leg rest out of block at top. Horizontal stability panel. Assembled with nails, v shape cut out at base of side panels176.054 [black marker on side panel] / 176-/054 [blue ink on discoloured white sticker]orthopaedic, nursing history, alfred hospital nurses league, orthopaedic equipment -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Report, Conference committee, "Australian and New Zealand Tramways / Fourth Conference Sydney March 1934", 1934

Report - approximately 350 pages, with heavy card covers, leather corners and centre and spine titled with letters in gold block "Australian and New Zealand Tramways / Fourth Conference Sydney March 1934" and name "H. Stephenson" on front bottom edge. Perfect bound with glued end covers. Details the proceedings of the conference held from 19th to 23rd March 1934, attendees, papers, appendices. Covers all engineering, operations and technical aspects of Australian and NZ tramways. Attending were representatives from Adelaide, Auckland, Brisbane, Dunedin, Hobart, Melbourne and Sydney. Detailed table of contents, program and attendees.trams, tramways, conferences, sydney, tramways, equipment, rails, mmtb -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 12 Black & White Photograph/s, Melbourne & Metropolitan Tramways Board (MMTB), 1966

Series of 12 black and white photographs of the construction of a new substation, during 1966 at the corner of Greville St and Punt Road, South Yarra. Shows the vacant block, construction of the foundations, walls and a part of the roof. In the box was a slip of paper marked - "To Architect 6.6.66" See item 7269 for three colour photographs of the completed building.On the rear of some of the photos are dates eg 30/5 on .1 trams, tramways, substation, electrical equipment, electrical switching, buildings -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 6 Black & White Photograph/s, Sutcliffe Pty Ltd, c1940

Series of 6 black and white photographs of work in the Nicholson St bus workshops of staff at work. Possibly c1940. .1 - three workers, possibly apprentices working on engine blocks with a supervisor/manager in a suit looking on. .2 - with a crank shaft and other equipment. .3 - motor on a stand with piston rods in the background. .4 - possibly the or "testing" room with a fluid being tested? .5 - An engine part (end block) on a "Central Garage" trolley. .6 - Battery room. All stamped "Sutcliffe Pty Ltd of 94 Elizabeth St Melbourne" with a sequence number on rear.trams, tramways, buses, nicholson st, workshops -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 12 Black & White Photograph/s, Melbourne & Metropolitan Tramways Board (MMTB), 1966

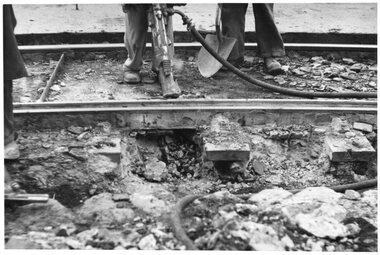

Series of 8 black and white photographs of the trackwork equipment and tools on the MMTB system. .1 - Hydraulic drain cover lifting device. .2 - rack of jack hammers being lifted - St Kilda Road? .3 - length of rail being lifted by 12 men with MMTB equipment in the background. .4 - Pack of sleepers being lifted with many wood blocks in the background. .5 - pack of 12 jack hammers in their lifting rack. .6 - light weight tool being used to lift a track pit cover by two men. .7 - One man demonstrating the lifting of a 44 gallon drum. .8 - two men rolling a 44 gallon drum off a truck.trams, tramways, trackwork, rails, track materials, track repairs, sleepers, equipment -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 15 Black & White Photograph/s, Melbourne & Metropolitan Tramways Board (MMTB), 1950's

Series of 15 black and white photographs of the track works to reconstruct tram lines showing various methods and works during the 1960's. .1 - Jackhammers concrete out around wooden sleepers - the rails have been bolted to them. .2 - Excavated track or temporary track next to newly relaid track - Hawthorn Road by Caulfield Park? .3 - Partly completed work - nearest track relaid, second track still has wood blocks? and then a temporary track. .4 - Excavated previously concreted and bolted track. Appears to be new rail. .5 - Compacting a new track bed with work laying track in the background. .6 - Rail being craned into position onto small concrete blocks - Nicholson St North Fitzroy at Church St - the church is now Melbourne City Mission Palliative care centre. 1955/56 - construction of the replacement track. Note the Hail bus stop sign on the corner. .7 - Thermite welding being set up. .8 - after a Thermite welding joint completed. .9 - track reading for pouting concrete, with a rebuilt track alongside and temporary track on the other side. .10 - ditto .11 - Concrete being poured .12 - ditto - could be Maribyrnong Road bridge replacement. .13 - Screeding off the concrete - possibly Nicholson St North Fitzroy .14 - completed surface - location as above .15 - completed surface with cloth covers to assist the concrete being cured. Has a MMTB hut and two worker amenity buses alongside. - location as above.Some photos have pencil marks on rear.trams, tramways, trackwork, rails, track materials, track repairs, sleepers, equipment, concrete, welding, nicholson st, new tramway, buses -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black & White Photograph/s, Melbourne & Metropolitan Tramways Board (MMTB), early 1955

Black and white photographs of the construction of the junction at Gertrude and Nicholson St c1955. On the right hand side of the photograph are two buses showing the Destination of Northcote. The former cable tram track in Nicholson St is yet to be removed - shows the offset between the tracks and the wood blocks. Possibly only the junction tracks have been completed at this time as there appears to be an excavation and a hut in the distance. There is a detour sign indicating that possibly vehicles used the completed section and that trackwork was underway for Gertrude St. The overhead has been erected. In the background is Osborne House. signs for The Age, The Sun and Peters Ice Cream. Early 1955?trams, tramways, trackwork, rails, track materials, track repairs, sleepers, equipment, cable trams, gertrude st, nicholson st, overhead -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Tender Document, Tramway Board, Misc. Tramway Board contracts, 1916 - 1919

Set of 23 tender documents, typed or duplicated, for the Tramway Board, typed or printed onto Foolscap sheets. Each give some detail of the contract, quantities, delivery and quality. Short titles are: .1 - Contract No. 4 - supply and delivery of wood paving blocks. .2 - No. 5 - steel castings .3 - No. 7 - rolled steel bars for grip dies .4 - No. 9 - rolled mild steel plates .5 - No. 10 - Kerosene oil .6 - No. 12 - Tar paving .7 - No. 13 - steel files .8 - No. 15 - iron castings .9 - No. 16 - cotton waste .10 - No. 18 - hemp rope .11 - No. 19 - tar oils .12 - No. 23 - steel wire rope (for cables) .13 - No. 24 - cotton waste .14 - No. 26 - iron castings .15 - No. 27 - purchase and removal of cottage at 87 Acland St St Kilda .16 - No. 28 - radial drilling machine .17 - No. 29 - steel castings .18 - No. 31 - paving blocks .19 - No. 33 - cotton waste .20 - No. 40 - substation building at Rathdown Street .21 - No. 47 - iron castings .22 - No. 54 - steel castings .23 - No. 72 - tar oils - from the Board's distilling works in Flinders St extension. Documents note scanned, just two samples.trams, tramways, tramway board, tenders, cable trams, grip tram, equipment, substation, cable grip, cables, demolition -

Melbourne Tram Museum

Melbourne Tram MuseumPostcard, Kew Depot Committee - AETA, "Seattle", 1991

Postcard - full colour, Divided back type of SW5 840 inbound in Victoria Parade May 1973 with the destination of City, Route 42. Note the hedges on either side of the tram reservation. Tram has front advertisements for TEAC sound equipment and Courage Draught. On the rear has a photo of a destination blind - showing Kew Depot with the words "75 years of Service" underneath, address and stamp blocks, PMTT logo with an A class tram in the centre. In the bottom left hand corner are the details of the photo, printer - Biscay Greetings and photographer - Ray Marsh and the number T102. 2nd copy added 15/9/2020.trams, tramways, postcards, kew depot, victoria parade, celebrations, pmtt, tram 840, sw5 class, mmtb