Showing 171 items matching "acid"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

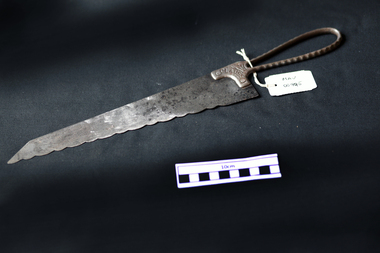

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham, -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg carving, pulpit of St Stephen's Presbyterian Church, Surrey Hills

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Colour photo of the central panel of the pulpit at St Stephen's Presbyterian Church in Canterbury Road, Surrey Hills. It depicts the burning bush.hogg memorial pulpit, st stephens presbyterian church, churches, woodcarving, church furniture, john kendrick blogg, john blogg -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg carving, pulpit of St Stephen's Presbyterian Church, Surrey Hills

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Colour photo of the some of the 13 panels forming the pulpit at St Stephen's Presbyterian Church in Canterbury Road, Surrey Hills.st stephens presbyterian church, churches, hogg memorial pulpit, woodcarving, church furniture, john kendrick blogg, john blogg -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Golden Wattle: Flower arrangement used for J K Blogg carving

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Black and white photo of an urn on a pedestal contianing stems of wattle with leaves and blooms.woodcarving, surrey hills shrine, monuments and memorials, john blogg, john kendrick blogg, r falconer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Dundas Pottery, 1856-1910

This bottle is part of the John Chance Collection of shipwreck artefacts. The Dundas Pottery works were established in 1828 by William Johnstone in partnership with John Forsyth and John Mc Coll. Located where the Forth and Clyde Canal joined the Monkland Canal, North of Glasgow. Johnstone sold the pottery in 1835 to Robert Cochran and James Couper. Mc Coll was retained as manager until 1837when in 1839 Cochran & Couper sold the pottery and purchased the St Rollex Glass Works. George Duncan took over briefly but died in 1841, with the pottery possibly being run by his widow Helen and a potter named Alexander Paul. James Miller was the manager at the time and he bought the pottery in 1856, in partnership with John Moody. Miller's long and careful stewardship of the pottery saw success from the export market which allowed him to purchase the North British pottery in 1867 until 1874 when it was sold. In 1875, Miller, in partnership with John Young, leased part of Caledonian Pottery, naming it Crown Pottery, however, it burned down in 1879. In the early 1880s, Young extended the pottery and named it Milton Pottery. Miller’s son, James W., became a partner in Milton pottery in 1905. James Miller Snr died in 1905 and the company continued as a limited liability company, being sold to the Borax Consolidation Ltd in 1929, but it was unsuccessful and Possil pottery purchased some of the company's equipment before it finally closed in 1932. From 1828 until the James Miller period of circa 1856, the pottery produced salt-glazed stoneware for the local industrial trade; mainly bottles and drain pipes. James Miller produced various bottles, whisky and acid jars, casks, butter crocks, jam jars and domestic wares in Bristol glaze. He streamlined the water filter manufacturing, which had become a speciality of the pottery, and a dedicated section of the pottery was created solely for their production, which was exported worldwide. A significant item of salt-glazed ceramic stoneware made by the Dundas potteries in Scotland who were renowned for making quality ironstone pottery. The bottle that was in common use throughout the British colonies and America for the containment of ale The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime museum collection by his family Illustrating the level of historical value the subject item has.Beige salt glazed stoneware, bottle with discolorations above base. Manufacturer's oval Inscription lozenge stamped near base. Stamp: [symbol of concentric ovals], text within the symbol "PORT DUNDAS POTTERY COY." and "GLASGOW". Stamp:[Symbol - square with short vertical line in centre of base line]flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, stoneware bottle, pottery, port dundas pottery, william johnstone, bottles, shipwreck artefact, stoneware, ironstone, bottle, glasgow, antique bottle -

Surrey Hills Historical Society Collection

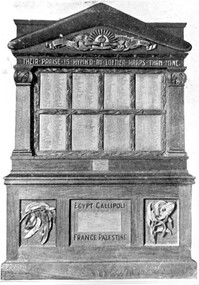

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg, John Kendrick Blogg carving, Soldiers' Honour Board, Shrine in the Surrey Gardens

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993. The images derives from an early brochure. The number of panels has been increased having been updated on at least 2 occasions. Whereas the date 1914 is at one end of the boomerang, the other end is not dated reflecting that the dedication of The Shrine before the war ended.Black and white photo of the Soldiers' Memorial Honour Board housed in The Shrine in the Surrey Gardens. The wooden part of the board was carved by John Kendrick Blogg. A large boomerang forms part of the apex underneath which is an emblem with the rising sun. Under this are 8 panels on which are the names of service personnel. The supporting timber is carved with designs including varied flora. At the base are 2 larger carved panels; on the LHS a sprig of eucalyptus leaves and on the RHS a sprig of wattle. surrey gardens, world war, 1914-1918, woodcarving, monuments and memorials, surrey shrine, john blogg, john kendrick blogg -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Boiler, Jackson Boilers Ltd, 1920s

Jackson Boilers Ltd., brass founders, electro platers and sheet metal works made this tube water boiler. It was a fitting in the vessel Reginald M, a small cargo ship built at Port Adelaide in 1922 and named after her builder and first owner, John Murch. The Reginald M was launched at Largs Bay, South Australia, in 1922 to carry cargo around South Australia that included guano, barley, wool, horses, cattle, timber, explosives, potatoes, shell grit, and gypsum. It passed through numerous owners over the years and primarily maintained its purpose as a cargo vessel. In 1975, the decommissioned Reginald M was purchased by Flagstaff Hill Maritime Museum as an attraction. Although restoration efforts were undertaken and maintained for the craft above the water line, deterioration occurred below the surface and resulted in the ship being unsafe for visitors to board. It was broken up and removed from Flagstaff Hill in 2018, but items such as the historical boiler remain in Flagstaff Hill’s Collection. JACKSON BOILERS LTD.: - In 1911, Henry Jackson was the Managing Director at Jackson Boilers Ltd. He had gained around 30 years’ experience as a tin plate worker, plumber and gas fitter at Ilkey in 1881, then at Leeds by 1901. By 1921, he had changed employment from Jackson Boilers to Managing Director of Patent Water Boilers. During World War I, Jackson Boilers Ltd of Leeds performed war work like many other manufacturers at that time. The firm made cases for the explosive picric acid and electroplated fuse hole plugs. In 1918, the firm employed 15 males and 19 females. Jacksons Boilers became very successful throughout the first half of the twentieth century with showrooms and sales offices in Scotland, the Midlands and Southern England. It also had an office in Dublin, Ireland. In the post-war 1920s, the firm’s production included instantaneous water boilers and coffee machines for cafes, restaurants and canteens. Jackson Boilers also began to supply shipping lines with catering water boilers for their ships. The firm applied for a USA patent for the tube boiler in 1930, for the design which appears to have been invented in 1926. A 1971 advertisement adds the credentials, Members of the Catering Equipment Manufacturers’ Association. The tube water boiler was designed specifically for use in a ship's restaurant or dining area and patented by Jackson Boilers Ltd. of Leeds. The boiler is significant as a patented design, illustrating the evolution of maritime, commercial and domestic water boilers that have led to many innervations and improvements in today's boilers that are used in heating and in producing hot water for domestic and catering use. It is also significant as it is one of the earlier boilers the Jackson company made in the early 1920s before they applied for a US patent on their revised design in 1926.Water boiler, free standing Jackson's Tube boiler. A tall metal cylindrical stand with a metal sphere on top and several pipe fittings on the sides. A brass tap with a lever handle is connected to the front. A plaque with maker's details is attached under the tap. Details are also impressed into the cylinder above the tap.Jackson Boilers Leeds Ltd. "JACKSON'S PATENT" . Other details indecipherable. flagstaff hill maritime museum and village, flagstaff hill maritime museum, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, leeds, jackson boilers ltd, jackson boilers, henry jackson, brass founders, electro platers, sheet metal works, patent water boilers, leeds manufacturer, tube water boiler, domestic boiler, tube domestic boiler, tube boiler, water heaters, water boilers, self-feeding water boilers, sheet metal work instantaneous water heaters, engineering, allied trades, metal workers, metal trade, food machinery, hospitality equipment, ship equipment, ship water boiler, ship heater, catering boilers, café boiler, restaurant boiler, canteen boiler, catering equipment manufacturers’ association, cema, kitchen equipment, kitchen appliance, war work, world war i, wwi, picric acid, picric acid cases, fuse hole plugs, electro plated fuse hole plugs, reginald m, cargo ship, port adelaide, 1922, john murch -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

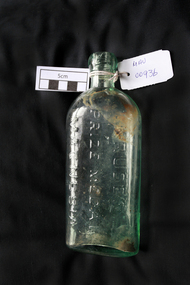

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, bottle 'Kruse's Magnesia', 20thC

Johann August (John) Kruse was instrumental in the development of the pharmaceutical industry and pharmacy training in Victoria. He was a driving force behind the creation of the Pharmaceutical Society of Victoria and was appointed a founding member of the Society's inaugural council in 1857. He manufactured many pharmaceuticals and health products such as mineral waters and 'Kruse's Fluid Magnesia' (1863) which is still in use today. He later went on to produce insecticides and dynamite, then established his own analytical chemistry service. In 1878 Kruse established Victoria's first pharmacy training facility - the Melbourne School of Pharmacy. There pharmacy apprentices were taught chemistry, botany, materia medica and Latin, while country students could study by correspondence. The School was endorsed and monitored by the Pharmacy Board of Victoria to which Kruse was appointed in 1880. Kruse's pharmacy school was the forerunner of the Victorian College of Pharmacy, Monash University, which remains Victoria's only pharmacy training institute. In 1853, shortly after qualifying as pharmacist at the University of Göttingen, Johann August (John) Kruse, moved to London. The medical practitioner Dr S. Weil sent Kruse to Victoria, Australia to manage a new pharmacy and tobacconist's shop which he was having built at 136 Bridge Rd in Richmond. In 1856 Kruse opened a second pharmacy 'John Kruse and Company Chemists and Druggists' at 207 Bourke Street. 1857 the Richmond shop was destroyed by fire, so all pharmaceutical production was moved to the Bourke St premises and later to his new location at 184 Bourke St.. Kruse was forced to sell his business in 1868 to Felton Grimwade and Company and work for them as manager of their chemical works. By the early 1870s he had regained financial independence so left the company to establish his own businesses again. He opened up a pharmacy at 31 Swanston St and in c1874 leased Victoria's premier natural springs, Clifton Springs, on the northern side of the Bellarine Peninsula, where he established a bottling plant. Suspensions of magnesium hydroxide in water, often called Milk of Magnesia, are used as an antacid to neutralize stomach acid, and as a laxative. Milk of magnesia is sold for medical use as chewable tablets, capsules, and as liquids having various added flavours Kruses Fluid Magnesia 300ml Extralife Kruse’s Fluid Magnesia, Magnesium supplement. Rapidly absorbed, easily digested. Improves general well being, corrects magnesium deficiency. Helps relieve indigestion, when due to acidity. In 1878 Kruse established Victoria's first pharmacy training facility - the Melbourne School of Pharmacy, the forerunner of the Victorian College of Pharmacy, Monash University, which remains Victoria's only pharmacy training institute. A glass bottle containing ‘Kruse’s’ Magnesia’ medicineKRUSE’S / PRIZE MEDAL / MAGNESIA/ K / FELTON-GRIMWADE & CO. MELBOURNE Directions for use ......glass works, pharmaceutical glass, pharmacy, kruse johann august (john), dr weil s, ., victorian college of pharmacy, monash university, university of göttingen, felton grimwade and company, magnesium bicarbonate, magnesium oxide -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c.1934 - c.1975

TROVE : The Australian Women's Weekly (1933-1982), Wednesday 22 January, 1964, p.32, Advertising. Dexsal, containing 34% pure medicinal glucose for nausea . sick headache . mild indigestion . over indulgence . in food or drink . biliousness . acidity . heartburn . periodic upsets. Directions one or two teaspoons in a tumbler of cold water and drink during effervescence. May be taken as often as desired. Keep tightly capped. Net contents 4 ozs. Reg. VIC 2102, 758. Manufactured by Drug Houses of Australia. For your family - pick the simplest way to settle 'upset tummy' - double-acting DEXSAL The simplest - and safest - because it's formulated wholly and solely to settle upset tummy, nothing else. It contains no pain killer, which can so often set up an excess-acid reaction in the stomach. The lively, sparkling drink of Dexsal dissolved in water is safe. Simply-formulated Dexsal acts in two ways: brings quick, direct relief to upset tummy discomforts or sick feelings and, simultaneously, restores your lost energy. That's because Dexsal contains 34 % medicinal glucose - the energy-builder that quickly restores your natural vitality. Take care of your family, when upset-tummy strikes, with the lively Dexsal drink - the simplest way to settle tummy upsets. (N.B. Children love the fresh tingly-taste of Dexsal) Double-acting Dexsal quickly relieves: . Ordinary indigestion . Sick headache . Heartburn . Nausea . Acidity . Periodic upsets . Biliousness . Over-eating or . Car and travel sickness drinking Safe for alt the family. And especially recommended for expectant mothers. DEXSAL A product of Drug Houses of Australia. Drug Houses of Australia Ltd. (DHA) was established in 1930 after the amalgamation of several proprietary medicine companies, including Felton Grimwade & Co. and Duerdin & Sainsbury Ltd. In 1974 the decision was made, after suffering from enormous financial losses, to break up the company and sell it. Several sections of the company became Felton Grimwade & Bickford Pty Ltd. Timeline of amalgamations 1855 - 1867 Youngman McCann & Co, 1863 - 1930 A. M. Bickford & Sons, 1867 - 1930 Felton Grimwade & Co, - 1930 Taylor-Elliotts Ltd, ? - 1930 Duerdin and Sainsbury Ltd, ? - 1930 Elliott Brothers Limited, - 1930 Rocke Thompsitt, 1863 - 1930 A. M. Bickford & Sons, 1867 - 1930 Felton Grimwade & Co.' 1902 - 1930 Felton Grimwade & Bickford Ltd, 1930 - 1974 Drug Houses of Australia Ltd (DHA), c. 1974 - Felton Grimwade & Bickfords Pty Ltd. Large clear amber glass bottle, rectangular in section with angled corners, wide neck. Embossed text on large side panel, numeral on corner panel near base, monogram, letters and numerals on base.On side panel 'DEXSAL REG. TRADE MARK'. On corner panel near base '4'. On base the letter 'g' or numeral '9' on its side, AGM monogram, 'F397' over '4' , A space then the letter 'M'.dexsal, medicine, drug houses of australia -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined