Showing 256 items matching "fire iron"

-

Federation University Historical Collection

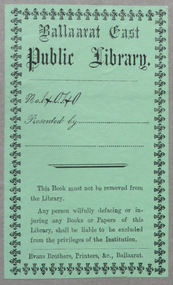

Federation University Historical CollectionBook, Mechanics' Magazine vol. 3, 1825 (exact)

Hardcovered book, half leather bound with marbled paper. Formerly book number 4040 from the Ballaarat East Public Library. Contents include: new pit-saw, self-moving carriage (car), Lord Worcestor's steam engine, extinction of fires, Cameron's Soda Water Apparatus, Newton's Lectures on Astronomy, coining at the Royal Mint, mechanical geometry, lifting ships by steam, voltaic-mechanic agent, steam navigation, portable hand-mill, Brown's pneumatic engine, Bell's invention for saving lives from shipwreck, triple pump, cycloidal chuck, potato-washer, sand clock, Galvanic electricity, perpetual motion, Hadley's Quadrent, Wollaston's Night-Bolt, rope bridges, boring machinery, locomotive steam-engines, new London Bridge, naval architecture, steam and water wheel, Spencer's Patent Forge, boat with wings, ivory profile portraits, Jenning's Gas burner, Ramage's Telescope, washing machine, tallow lamp, iron masts, self regulating pendulum, prismatic compass, simple blowpipe. Includes image of Henry Brougham, and many drawings of inventions.non-fictioncar, newton, fire, shipwreck, bell, naval architecture, locomotive, ballaarat east public library, ballarat east public library, ballarat east library, henry brougham, potassium, meridian lines, pit saw, self moving carriage, lord worcestor, steam engine, cameron s, soda water, astronomy, royal mint, mechanical geometry, lifting ships by steam, voltaic mechanic agent, steam navigation, hand mill, brown s pneumatic engine, triple pump, cycloidal chuck, potato washer, sand clock, galvanic electricity, perpetual motion, hadley s quadrent, wollaston s night bolt, rope bridges, boring machinery, steam engines, new london bridge, steam and water wheel, spencer s patent forge, boat with wings, ivory profile portraits, jenning s gas burner, ramage s telescope, washing machine, tallow lamp, iron masts, self regulating pendulum, prismatic compass, simple blowpipe, bookplate -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and White, Geoff Biddington, Views of Ballarat, 1967

These images were taken by Geoff Biddington who was highly active in the Ballarat Branch of the National Trust. Twenty two black and white photographic views of Ballarat by Geoff Biddington. 1. Ballarat Mechanics' Institute 2. 18-20 Lyons Street south, Ballarat 3. Licensed grocer (Corner Eyre and Lyons Street South) featuring Ballarat Bertie Sign 4. Cast Iron Gasometer Frames 5. Former Ballarat Supreme Court (Ballarat School of Mines Electrical Engineering 6. Telegraph Station (Castlemaine?) 7. Ballarat Fine Art Gallery (later Art Gallery of Ballarat) 8. Former Ballarat Police Station, Camp Street 9. Former Baptist Church, Dawson Street 10. Craig's Hotel Lamp 11-13. Goller's, Camp Street 14. Old Post Box- Crown on Top 15. Former Ballarat Gaol Gates 16. Golden Point Football Club Rooms, Main Road 17. Ballarat Fire Station, Ballarat East 18. Ballarat Town Hall Tower 19. Ballan Hotel 20. Building on Inglis street, Ballan 21. Ballan News Building (Est 1872) 22. Adam Lindsay Gordon Cottagebiddington, ballarat mechanics' institute, ballaarat mechanics' institute, mechanics institute, gasometer, ballarat police station, police, baptist church, craig's hotel, goller, post box, crown, golden point, ballarat town hall, ballan hotel, adam lindsay gordon cottage, ballarat gaol gates, wrought iron, bluestone, ballarat bertie, orlando, penfolds, signwriting, licensed grover, ballarat bitter, craig's royal hotel lamp, craig's hotel -

Federation University Historical Collection

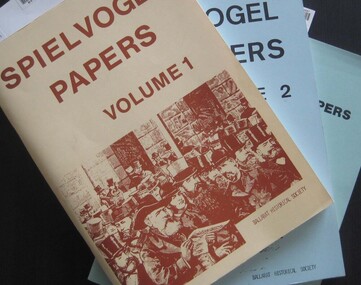

Federation University Historical CollectionBooklets, Ballarat Historical Society, Spievogel Papers, volumes 1,2, & 3

Nathan Spielvogel was a local historian. The Spielvogel Papers consist of the articles he prepared for a series of weekly talks on Radio 3BA in 1936 and 1937. According to Alex Barnett there is a reference in the Spielvogel Papers to the moving of the bodies of diggers killed at the Eureka Stockade to the old cemetery on 26 November 1857.3 soft covered books with text relating to the history of Ballarat. .1) yellow cover .2) blue cover .3) green cover .1) includes topics such as Gold discovery, Eureka, Main Road, Ballarat Fire Brigade, Ballarat Benevolent Home, Buninyong, Burke and Wills Monument, Chinese in Ballarat, Dana Street School, Ballarat Hospital, Lost Trades of Ballarat, Ballarat Military, Mount Pleasant, Old Colonists' Club, Phoenix Foundry, Ballarat Post Office, Railways, Ballarat School of Mines, South Street Society, Martin Hosking, Charles Curnow Phillips, James Sainsbury, and William Cross Yuille. .2) includes topics such as Ballarat streets, bowls, cricket, football, hotels, Little Bendigo, Lake Wendouree, Ballarat Quartz Mines, Sebastopol, Ballarat Turf Club, Ballarat Zoo, water supply. .3) includes topics such as the Kohinoor Nugget, Eureka, Black Hill, Sebastopol, oddietown, Joe the bellman, Trades Hall, Lal Lal Iron, Ballarat Library, Yuille Creek, Martin Hosking, Stonewall Jackson, steeplechase, Lemonade Paddock, Ivey's Flour Mill, Salvation Army, Stick Jaw Davey, Unicorn Hotel, doctors, Alfred Bells, Ballarat School of Mines Museum (War Museum), Joseph Orange, Ballarat East Post Office.ballarat, speilvogel, nathan spielvogel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Porthole, c 1888

This porthole was part of the ship's fittings when the Antares was constructed. THE ANTARES In mid-November 1914, after the beginning of the First World War, a young local man went one evening to fish near the Bay of Islands, west of Peterborough. He later arrived home hurriedly and in an agitated state declaring: "The Germans are coming!" His family laughed and disbelieved him, as this young fellow was prone to telling fictional tales. About a month later, on December 13th 1914, local farmers Phillip Le Couteur and Peter Mathieson were riding in the vicinity, checking on cattle. Phillip Le Couteur saw what he “thought was the hull of a ship below the cliffs.” He rode to Allansford and contacted police. The next day, two Constables and Phillip Le Couteur returned to the site, where they dug a trench near the top of the cliff and sank a log in it. To this they attached a rope, which they threw down the cliff face. Constable Stainsbury and Phillip Le Couteur then made the dangerous descent down the rope on the sheer cliff face. They found wreckage strewn around a small cove and a portion of a man's body under the cliffs. The hull of the ship could be seen about 300 metres out to sea. Some of the wreckage revealed the name Antares and the remains of the ship's dinghy bore the name Sutlej. During the next two weeks and with the help of the Warrnambool lifeboat and crew, two more bodies were found. Later investigations proved that the tragic wreck was indeed that of the Antares, reported overdue on the 207th day of her voyage from Marseilles, France, to Melbourne. She was a three masted, 1749 ton iron clipper, built in Glasgow in 1888 and originally named and launched as the Sutlej. Bought in 1907 by Semider Bros. from Genoa, Italy, she was refitted and renamed Antares. It was later realised that the local lad who a month earlier had declared he had seen German guns being fired, had probably seen distress flares fired from the deck of the Antares the night she was wrecked. She was last sailed under Captain Gazedo and wrecked at what is now known as Antares Rock, near the Bay of Islands. She had been carrying a large cargo of roofing tiles from France to Melbourne, consigned to Mullaly & Byrne. Many of them are now to be seen amongst the battered and scattered remains of the wreck. Some of the timbers were found to be blackened by fire. An Information Board has been erected on the cliff top near to the site of the Antares wreck, at the end of Radfords Rd, west of Peterborough. (Ref: Flagstaff Hill Maritime Village’s “Antares” fact sheet, Victorian Heritage Database, Information Board at Peterborough, Flagstaff Hill Significance Assessment 2010)The Antares was one of the last of the 'tall ships' to be lost along the south west coast of Victoria, and is the only wreck that took the lives of all people on board. She is listed on the Victorian Heritage Register VHS S34. The Antares is significant as a sail trader carrying an international inbound cargo. It is part of the Great Ocean Road Historic Shipwreck Trail. Porthole with glass, brass, screw dog broken off, glass has cracks through it, some encrustation. Artefact Reg No A/5, recovered from the wreck of the Antares.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, porthole, antares., tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, antares rock., bay of islands, ship's fitting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The brass letter “A” is from the starboard bow of the FALLS OF HALLADALE, a 2085-ton iron-hulled and four-masted sailing ship that was wrecked near Peterborough on 14 November 1908. Two companion pieces, the letters “S” and “D”, are also in the Flagstaff Hill Maritime Village collection of shipwreck artefacts (as registered numbers 748 and 6596). The ship’s name originally appeared in these impressively large brass letters across the stern and both port and starboard bows of the vessel. The FALLS OF HALLADALE was built in 1886 by Russell & Co at their Greenock shipyards on the River Clyde. She was the seventh of nine similar cargo carriers produced for the owners of the Falls Line, Wright, Breakenridge & Co of Glasgow. All nine ships were named after waterfalls in Scotland. First was the FALLS OF CLYDE in 1878, then the FALLS OF BRUAR in 1879 (lost in 1887), the FALLS OF DEE in 1882 (sunk in 1917), the FALLS OF AFTON in 1882, the FALLS OF FOYERS in 1883 (disappeared in 1898), the FALLS OF EARN in 1884 (wrecked in 1892), the FALLS OF HALLADALE in 1886 (wrecked in 1908), the FALLS OF GARRY in 1886 (wrecked in 1911), and the last of the fleet, the FALLS OF ETTRICK (lost in 1906). The FALLS OF CLYDE is still afloat as an exhibit at the Hawaii Maritime Center in Honolulu. Russell & Co delivered the owners full-bottomed, economical ships of 1800 to 2000 tons, practically designed to minimise loss of speed while increasing seaworthiness and carrying capacity. The sturdily constructed FALLS OF HALLADALE had iron masts and wire rigging, allowing her to maintain full sail even in gale conditions, and square “warehouse-type” bilges to accommodate maximum bulk cargo on her long-haul voyages. This class of ship remained commercially competitive into the twentieth century despite the advantages of coal-fired steamships. When the 22 years old FALLS OF HALLADALE finally foundered on Victoria’s Shipwreck Coast in 1908, the Melbourne Court of Marine Inquiry held it was entirely due to Captain D.W. Thomson’s navigational error, rather than any technical failure of the Clyde-built ship. The shipwreck of the FALLS OF HALLADALE is of state significance — Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).A brass letter “A”, from the shipwreck FALLS OF HALLADALE, raised along the central axis to form three dimensional effect, in unrestored and fair condition. Of dull grey-green metal, bent and with irregularly worn edges, it has been subjected to amateur cleaning on the front face, with some remaining greenish copper oxidation and surface pitting. The rear face is uncleaned with a layer of sedimentary concretion, orange-red staining from the iron hull, and green copper oxidisation. Three sediment-filled bolt collars on the rear face are part of the original casting.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, russell & co., ship's nameplate, letter, letter a -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The brass letter “D” is from the starboard bow of the FALLS OF HALLADALE, a 2085 ton iron-hulled and four-masted sailing ship that was wrecked near Peterborough on 14 November 1908. Two companion pieces, the letters “S” and “A”, are also in the Flagstaff Hill Maritime Village collection of shipwreck artefacts (as registered numbers 748 and 6595). The ship’s name originally appeared in these impressively large brass letters across the stern and both port and starboard bows of the vessel. The FALLS OF HALLADALE was built in 1886 by Russell & Co at their Greenock shipyards on the River Clyde. She was the seventh of nine similar cargo carriers produced for the owners of the Falls Line, Wright, Breakenridge & Co of Glasgow. All nine ships were named after waterfalls in Scotland. First was the FALLS OF CLYDE in 1878, then the FALLS OF BRUAR in 1879 (lost in 1887), the FALLS OF DEE in 1882 (sunk in 1917), the FALLS OF AFTON in 1882, the FALLS OF FOYERS in 1883 (disappeared in 1898), the FALLS OF EARN in 1884 (wrecked in 1892), the FALLS OF HALLADALE in 1886 (wrecked in 1908), the FALLS OF GARRY in 1886 (wrecked in 1911), and the last of the fleet, the FALLS OF ETTRICK (lost in 1906). The FALLS OF CLYDE is still afloat as an exhibit at the Hawaii Maritime Center in Honolulu. Russell & Co delivered the owners full-bottomed, economical ships of 1800 to 2000 tons, practically designed to minimise loss of speed while increasing seaworthiness and carrying capacity. The sturdily constructed FALLS OF HALLADALE had iron masts and wire rigging, allowing her to maintain full sail even in gale conditions, and square “warehouse-type” bilges to accommodate maximum bulk cargo on her long-haul voyages. This class of ship remained commercially competitive into the twentieth century despite the advantages of coal-fired steamships. When the 22 years old FALLS OF HALLADALE finally foundered on Victoria’s Shipwreck Coast in 1908, the Melbourne Court of Marine Inquiry found it was entirely due to Captain D.W. Thomson’s navigational error, rather than any technical failure of the Clyde-built ship. The shipwreck of the FALLS OF HALLADALE is of state significance — Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Large brass letter “D”, from the shipwreck FALLS OF HALLADALE, dented but in generally good unrestored condition. Front face of dull grey-green metal showing reddish oxide stain and some cream-coloured concretisation. Rear face has not been brushed clean and displays more encrustation.The four bolt collars for fixing letter to ship are filled with sediment.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, russell & co., ship nameplate, nameplate, letter, letter d -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Hearth Brush, ca 1878

This hearth brush section would have had a handle at the top and bristles protruding from the base. It has been hand-crafted, likely by a blacksmith. A hearth brush is used to clean away fine ash from brick, iron and stone fireplaces and stoves after the fire has died. The hearth brush section was recovered from the wreck of the sailing ship Loch Ard, which was wrecked on June 1st 1878 at Mutton Bird Island near Port Campbell, Victoria. There were 54 people on board and only two survived. The cargo included items for Melbourne's International Exhibition.The hearth brush is an example of domestic cleaning equipment from the late 19th century. The brush is significant for its connection to the Loch Ard sailing ship, which is listed on the Victorian Heritage database. Hearth brush section, copper alloy, bullet-head shaped; bristles and handle are missing. It is covered in verdigris. The metal is hand-beaten. Recovered from the wreck of the Loch Ard. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hearth brush, loch ard, cleaning, fireplace, domestic fireplace, domestic oven, ash, brush, 19th century, victorian era, 1878 -

Federation University Historical Collection

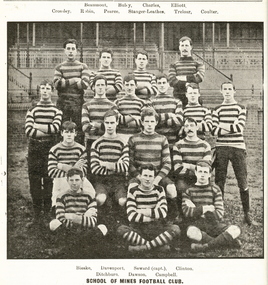

Federation University Historical CollectionBook, Ballarat School of Mines Students' Magazine, 1907-1909, 1907-9

Bound volume of the Ballarat School of Mines Students' Magazine for 1907-1909. Articles include the location and pegging of a tramway Route, the transmission of Power by Rope Driving by A.E.C. Kerr, A visit to the Briseis Mine, and New Brothers' Home, Mining Engineers in Tasmania, Obituaries for David Ham and Matthew Lyndsay, Pioneer Mining at Leichhardt, Automatic Ore Feeders and Chacedony Park by J.H. Adams. Images include the Ballarat School of Mines Football Team and the Ballarat School of Mines Sports Committee. 1907 * Hubert Krause 1908 * The location and Pegging of a Tramway Route by Yamba * The Unity of things by John Brittain * The transmission of power by Rope Driving, by A.E.C. Kerr * A visit to the Briseis Mine, and New Brothers' Home (includes photographs) * Mining Engineers in Tasmania * Limericks Sluiced at Snake Valley * David Ham Obituary * Matthew Lyndsay Obituary * Some Bunsen Memories by Professor Alfred Mica Smith * Geological Camp to Daylesford * Practical Mathematics by Hubert F. Hall * Pioneer Mining - Leickhardt * Automatic Ore Feeders * A Unique Ore Deposit (Lucknow Goldfield, NSW) * A country Ramble * The Alkaline Titration for Zinc * Chalcedony Park, Arizona, United States of America by J.H. Adams * Notetaking at Lectures * Smelter Cost-Keeping by Oliver E. Jaeger * Benefits of Physical Culture * Mineral Tasmania and its Wonderful Resources by F.F. Bradford * A holiday Trip to Queensland * The Compression of Air as Applied to Mining * Machine V Hand Drilling * The mining in the Malay States * William Thomas Grownow Obituary (includes image) * Timbering Stopes (Includes images) * Trip to Melbourne * Two Problems of Alluvial Mining by Richard Hain * The Berry Leads (includes plan of mines) * Black Pudding Supper * Observations for Meridian * NOtes on Coking Plants (includes plan) * How Old is the Earth * Conglomerations * A Pat Formula * The making of a Suitable Muffle for General Assay Work * Reduction of Gold Chloride by Charcoal * Chemical Definitions * Old Boys (R.J. Allen, W.B. Blyth, F. Brinsden, Lindsay D. Cameron, George W. Cornwell, John M. Currie, C.M. Harris, T. Wighton-Hood, W. Lakeland, W.S. Macartney, Fred A. Marriott, Karl B. Moore, G.E. Sander, Sherb. H. Sheppard, Norman S. Stuckby, John Sutherland, Lewis A. Westcott, Walter White, O.C. Witherden, Gerald Young) 1909 * The Graduates Problem * An Interesting Nevada Cyanide Plant (Bamberger De Lamar Gold Mines) * Easter Geological Camp to Ingliston * New Methods for the Volumetric Estimation of Lead * William Charles Kernott Obituary * Mount Morgan Mine by G.W. Williams * Tin Dredging at Tingha, New South Wales * Notes on the Iodide estimation of Copper * Photograph of the Ballarat School of Mines Students' Association Committee * The Importance of Mine Ventilation to the Students by F. Howells * Life in Mining Camp * Wise Words to Mining School Students * Military Search Lights * Gleaning s on resistance * Ministerial Visit to the Ballarat School of Mines by the Hon. A.A. Billson, Minister of Education , accompanied by Frank Tate, Director of Education. * Picture Making in Photography Composition * Mountains of Fire * A Walking Engine - New Military Machine - Guns into Action - Caterpillar No. 1. (Tank) * Fireless Locomotives * Elmore Concentrating Process (includes plan of Elmore Concentrator) * Mount Pani Limited * Surveying for Irrigation * Weights and Measures * Carbon Monoxide * Joseph Francis Usher obituary * The Problem of the Metalliferous Veins * Ballarat School of Mines Ambulance Class * Treatment of Gold in a battery Without the Use of Copper Plates by E.C. Hurdsfield * Meteorites * Werribee Gorge * Dredging in the Ovens Valley * Electrical Chatter - Electrocution by an Imaginary Eye-Witness * The Electric Furnace in Iron Metallurgy ballarat school of mines, ballarat school of mines football team, football, sports, tramway, mining engineers, david ham, matthew lyndsay, jack adams, berry lead, hepburn consuls, madame berry, west ristori, ristori no 1, allendale, dyke's co, charleson's mill, australian extended, mining, r.j. allen,, w.b. blyth, f. brinsden, lindsay d. cameron, george w. cornwell, john m. currie, c.m. harris, t. wighton-hood, w. lakeland, w.s. macartney, fred a. marriott, karl b. moore, g.e. sander, sherb. h. sheppard, norman s. stuckby, john sutherland, lewis a. westcott, walter white, o.c. witherden, gerald young, ballarat school of mines students' association, hubert krause, krause, vfl, afl -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph Album, Photographs of Ballarat Buildings by Geoff Biddington, 1967, 1967

At one time Her Majesty's Theatre was known as the Memorial Theatre. When these photos were taken Geoffrey Biddington was highly involved with the Ballarat Branch of the National Trust. Lenaghan of Tourello "Master Dan Lenaghan, eldest son of Mr. and Mrs. R. Lenaghan, of Tourello, has been successful in obtaining a Government scholarship, tenable for four years at St. Patrick's College, Ballarat.(Melbourne Advocate, 02 March 1939) Black folders of Ballarat photographs as follows: .1) Ballarat City Council Logo on Ballarat Botanical Garden Gates .2) Ballarat Railway Station .3) Ballarat Town Hall .4) Ballarat Fire Station, Ballarat East .5) Interior of Ballarat Railway Stations .6) Ballaarat Municipal Libraries Barkly Street Branch, formerly Ballarat East Library .7) Entrance to Ballarat Presbyterian Church? .8) Former Ballarat Baptist Church, Dawson Street .9) Church with small steeple, erected AD 1860 .10) Brick Church with steeple .12) Gates of the former Ballarat Gaol .13) Gates of the former Ballarat Gaol .15) Craig's Hotel, Nominee Brian D. Foley .16) ? .17) Interior of Her Majesty's Theatre, Ballarat .18) Bailey's Mansion, later used as the St John of God Convent .19) Lal Lal Blast Furnace .20) Gates of St Patricks Cathedral Ballarat, looking towards the Cathedral Hall .21) .20) Gates of St Patricks Cathedra, Sturt Street, Ballarat .22) ? .23) Lenaghan's Tourello .24) Ballarat Terrace, c1967 .25) Entrance to Ballarat Terrace, c1967 .26) ? .27) Entrance gate to Novar, Webster Street, Ballarat .28) Interior of Ballarat Railway Station, c1967 .30) Pratt's Warehouse, Camp Street, Ballarat, c1967 .31) Entrance gate to Novar, Webster Street, Ballarat .32) Cast Iron Gate .33) Cast Iron Gate .34) Cast Iron Gate .35) Ballarat New Cemetery Gates .36) Cast Iron Post Cap .37) Cast Iron lamp .38) Cast Iron lamp .39) Ballarat Botanical Gardens Statuary Pavilion .40) 'Flight of Pompeii' statue in the Ballarat Botanical Gardens Statuary Pavilion ballarat city council logo on ballarat botanical garden gates, ballarat botanical garden gates, ballarat railway station, ballarat town hall, ballarat fire station, ballarat east, interior of ballarat railway stations, ballaarat municipal libraries barkly street branch, formerly ballarat east library, entrance to ballarat presbyterian church?, former ballarat baptist church, dawson street, church with small steeple, erected ad 1860, brick church with steeple, gates of the former ballarat gaol, craig's hotel, nominee brian d. foley, brian d. foley, interior of her majesty's theatre, ballarat, bailey's mansion, later used as the st john of god convent, lal lal blast furnace, gates of st patricks cathedral ballarat, looking towards the cathedral hall, gates of st patricks cathedral, lenaghan's tourello, ballarat terrace,, entrance to ballarat terrace, entrance gate to novar, webster street, ballarat, interior of ballarat railway station, c1967, pratt's warehouse, camp street, ballarat, c1967, cast iron gate, ballarat new cemetery gates, cast iron post cap, cast iron lamp, ballarat botanical gardens statuary pavilion, 'flight of pompeii' statue, architectural features -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stand, Unknown

A stand or support for utensils before or on the fire. Usually made of wrought iron, the most common variety, from the 17th century, stands on three legs and has a circular plate with perforated decoration, often in the form of a date. Another early type, short-legged, stood in the fire to support a cast-iron pot. Later, in the second half of the 18th century, trivets designed to be hung from fire bars were made. These were of two types: an oblong, standing trivet with a handle at one end and projections to fit over the fire bars at the other, and a plate that could be attached to the fire bar. Some of the latter were hung inside the grate supporting a vessel over the fire. Large quantities of cast-brass fender trivets were manufactured at Birmingham, in England, in the last quarter of the 18th century; these were suspended from the top rails of the fender as muffin and kettle stands. Four-legged trivets that stood under the spit holding the dripping pan were made in the 18th and 19th centuries. The cat, an entirely different type of plate stand that was made in the 18th century, consisted of six spokes, three at the top and three at the bottom; it could be used either way up. The term trivet is also used in reference to a metal stand with short feet, used on a table to support a hot dish. https://www.britannica.com/topic/trivet Trivets have been used since the invention of iron and are essential for placing hot items on surfaces.Metal stand for hot items, black painted metal. Heart-shaped with three supports. Now quite rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wrought iron, trivet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Pulley Sheave, Russell & Co, 1888

This ship's pully sheave was part of the Antares rigging. A pulley sheave is a circle on a shaft that is manufactured to hold up movement and change of way of a cable or/and rope, or transfer of power between the shaft and cable or/and rope. A pulley is a unique mechanism that is used to leverage the lifting of heavy loads to required heights. The Italian barque Antares was an iron three-masted sailing clipper built in 1888 by Russell & Co of Port Glasgow originally named the “Sutlej” and renamed in 1907 the “Antares” when sold to the Semider Bros of Genoa Italy. The vessel left Marseilles on the 18th of December 1913 with its master captain Gazedo destined for Mullaly & Byrne of Melbourne with a cargo of roofing tiles but failed to arrive. The wreckage was found near the Bay of Islands twenty-two miles east of Warrnambool after a body had washed ashore. Some of the timbers washed up were charred by fire, and a small boat's stern board with the name "Sutlej" led to the identification of the wreck as Antares which had been reported missing. According to later reports, the Antares wrecking was overshadowed by war news at the time. A young local boy had remarked that the Germans had arrived off the coast as he had seen them firing off shells and rockets, but his story was passed off as a joke. These rockets were most likely the distress signals from the stricken ship. The Italian barque/clipper Antares was sometime later reported as overdue. The wreck of the ship was later found at the base of a cliff at the Bay of Islands near Warrnambool in November 1914, there were no survivors.The Antares is significant as it was a sail trader carrying an international inbound cargo during the early part of the 20th century. It is part of the Great Ocean Road Historic Shipwreck Trail and as such is registered as a protected wreck in the Victorian Heritage Database VHS S34.Pulley sheave; brass, with recesses full of concretion. The metal has some blue-green colouration due to exposure to sea water. Recovered from the wreak of the Antares. Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pulley sheave, antares, tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, bay of islands, pully sheave, pulley, lifting equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ship's Fitting, circa 1825

This attractively patinated artefact was raised from the wreck site of the CHILDREN (wrecked January 1839, recovered February 1974) and was quite reasonably catalogued as a portion of a ships porthole. This identification is unlikely however, because the CHILDREN was built at Liverpool in 1824, and round portholes were not in common use until the 1850s. The catalogue identification has since been changed to "Ship's Fitting" Prior to the appearance of round portholes in the middle of the nineteenth century, the function of introducing light to lower decks was performed by square half-glassed ‘ports’ in the side of the hull (known as a port-sash) , or ground-glass ‘bullseyes’ inserted in the deck (scuttles). In historical terms, ports were always square, cut into the timber originally to allow the firing of a ships guns, and were closed in weather by a tight fitting square hatch. Flagstaff Hill Shipwreck Museum has three portholes on display that illustrate the gradual development and adoption of circular brass portholes. First in sequence is a small 12.5cm diameter window (with a deep frame for thick wooden hulls) from the 1855 wreck of SCHOMBERG. The second and third are larger 25cm diameter windows (with a shallower frame for thinner iron hulls) from the 1892 wreck of the NEWFIELD and the 1908 wreck of the FALLS OF HALLADALE . Once the apparently obvious use of the brass object is discounted, an accurate and reliable alternative classification is difficult to specify. One artefact register notes it was ‘found in about the centre of the wreck site’. This would mitigate against the possibilities of (1) ‘horseshoe frame’ joining pieces of the keel and hull at the bow of the vessel, or (2) ‘deckseat’ for a binnacle at the stern. It may support the idea of a ‘head frame’ on a cooped companionway or a ‘deckseat’ for a mainmast pump. But this is only speculation. The actual identification is not known. The wreck of the CHILDREN is of State significance - Victorian Heritage Register S116Ship's fitting, of heavy gauge brass circle, previously classified as section of ship's fitting, which was raised from the wreck of the Children. One end is broken off at an original bolt hole and the other is severed or cut at an acute angle from the inner rim. The artefact is 6cm across and 1cm deep, indicating strength and function as a substantial and finished item of moulded metal. The upper face bears sedimentary accretion stained red/brown. The rear face has been gouged by hard or corrosive materials and bears brilliant blue/green oxidisation.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, the children, brass flange, brass rim, shop fitting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon Ball, Victorian era

A cannon ball, made of iron, is used as ammunition for a cannon and fired at a target.Cannons with cannon balls as ammunition were installed at Warrnambool for protection from possible invasion in the mid-to-late 19th century and early 20th century.Cannon ball, iron, painted black. Originally marked "16"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, cannon ball, ammunition, cannon, fortifications, military equipment, firearm -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Pump, Goulds Manufacturing Co, 1915-1925

Gould manufacturing company was founded in 1848 at Seneca Falls, New York when Seabury S. Gould purchased an interest in Downs, Mynderse & Co. and the firm became Downs & Co. Wooden pumps were produced at the time in an old cotton factory building. In 1869, the name of the company was changed from Downs & Company to Goulds Manufacturing Company. Seabury S. Gould was regarded as a man of unusual vision, and as the founder of Goulds Manufacturing Company he was keen to start producing cast iron pumps. An iron pump, he believed, would overcome all the disadvantages of a wooden pump. It would be strong and efficient and provide fresh flowing water for the pioneers. He ran the company until after the American Civil War and because Goulds Manufacturing had a foundry, they also produced all kinds of cast iron products such as corn shellers, bells, sad irons, sinks, tools, and a line of fire engines. From 1848 to 1964 a Gould family member had always been President of the company. However, the company ownership in 1964 was transferred from family-owned stock to public offerings and employee ownership of stock. The subject item called the "N e w Deluge" was an improved bilge pump for vessels having not more than 25 feet depth of hold. It was also used by contractors for pumping out excavations and was well adapted for irrigation use. This hand pump was designed to be used where a hand pump of large capacity was desired. Goulds made many different types of pumps to suit differing pumping situations such as. Well Pumps, Hydraulic Rams, Diaphragm Pumps, Tank Pumps, Sprayers and Small Capacity Power rumps. Goulds Triplex, Centrifugal, Rotary and Deep Well Power Pumps The subject item was first introduced to the market in the Goulds catalogue of 1915 and became a very popular pump used in Australia and the USA. It is manufactured by a company still trading today with offices in Australia and many other countries.Hand Pump cast iron with long reversable pumping lever and cylindrical casing there are 4 metal holes for fastening to floor surface. Painted black. Embossed "NEW DELUGE" "- - -" and "No 16" or "No 18".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pump, hand pump, goulds manufacturing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Carronade

This deck cannon is believed to be a replica Carronade as it has no foundry mark, year of manufacture, proof marks or weight of carronade on it. However, its design matches the design of Carronades used in the early to mid 19th century. History: The carronade was designed as a short-range naval weapon with a low muzzle velocity for merchant ships, but it also found a niche role on warships. It was produced by the Carron iron works and was at first sold as a complete system with the gun, mounting, and shot altogether. Carronades initially became popular on British merchant ships during the American Revolutionary War. A lightweight gun that needed only a small gun crew and was devastating at short range was well suited to defending merchant ships against French and American privateers. Its invention is variously attributed to Lieutenant General Robert Melville in 1759, or to Charles Gascoigne, manager of the Carron Company from 1769 to 1779. In its early years, the weapon was sometimes called a "mellvinade" or a "gasconade". The carronade can be seen as the culmination of a development of naval guns reducing the barrel length and thereby the gunpowder charge. The Carron Company was already selling a "new light-constructed" gun, two-thirds of the weight of the standard naval gun and charged with one-sixth of the weight of the ball in powder before it introduced the carronade, which further halved the gunpowder charge. The theory of its design was to use less powder and had other advantages that were advertised in the company's sales pamphlet of the time, state. The smaller gunpowder charge reduced the barrel heating in action, also reduced the recoil. The mounting, attached to the side of the ship on a pivot, took the recoil on a slider, without altering the alignment of the gun. The pamphlet advocated the use of woolen cartridges, which eliminated the need for wadding and worming, although they were more expensive. Carronades also simplified gunnery for comparatively untrained merchant seamen in both aiming and reloading that was part of the rationale for adopting the gun. Other advantages promoted by the company were. The replacement of trunnions by a bolt underneath, to connect the gun to the mounting, reduced the width of the carriage that enhanced the wide angle of fire. A merchant ship would almost always be running away from an enemy, so a wide-angle of fire was much more important than on a warship. A carronade weighed a quarter as much as a standard cannon and used a quarter to a third of the gunpowder charge. This reduced charge allowed Carronades to have a shorter length and much lighter weight than long guns. Increasing the size of the bore and ball reduces the required length of the barrel. The force acting on the ball is proportional to the square of the diameter, while the mass of the ball rises by the cube, so acceleration is slower; thus, the barrel can be shorter and therefore lighter. Long guns were also much heavier than Carronades because they were over-specified to be capable of being double-shotted,(to load cannons with twice the shot, for increased damage at the expense of range). Whereas it was dangerous to do this in a carronade. A ship could carry more carronades, or carronades of a larger caliber, than long guns, and carronades could be mounted on the upper decks, where heavy long guns could cause the ship to be top-heavy and unstable. Carronades also required a smaller gun crew, which was very important for merchant ships, and they were faster to reload. Additional notes: Cannon cast in England, Wales and Scotland had their imperial weight chiselled or engraved in the format of 4-2-0 on the bottom of the cascabel, indicating the weight of the cannon as 4 hundredweight, 2 quarters and 0 pounds. Since a hundredweight equals 112 pounds and a quarter weight is 28 pounds the total weight is 504 pounds or about 228 kilograms. The small bore replica carronade and carriage is part of a collection of nineteenth Century Flagstaff Hill Guns and cannons, and is a representation of carronades used from the early 18th up to the 1850s on merchant and military ships particularly the British Royal Navy until 1850. This example is not significant in the historic sense but demonstrates the type of artillery used aboard vessels of the time for protection & offensive military actions. Cannon, cast iron, small smooth bore cannon on the stepped wooden carriage with wooden wheels. It appears to fire a 12-pound cannonball. The Cannon barrel can have its elevation adjusted via a sliding sloped block at the rear of the cannon. Gun carriage has loops for locating and holding the carriage in position with the use of ropes. It is believed this carronade is a replica of a mid-to-late 19th-century Carronade cannon.Cast into metal; [Royal emblem of Queen Victoria (VR "Victoria Regina")]warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannon, naval cannon, cannon on carriage, 19th century cannon, fortifications, smooth bore cannon, 12 pounder, carronade, artillery, replica, deck cannon, cannon in carriage, ship cannon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pot

Modern iron cooking ‘ranges’ were being introduced from the late 18th century, however a vast number of people cooked in open fireplaces, well into the 1800s. Generally they were fitted with iron rods suspended above the fire or ‘cranes’ that could be swung in and out for easier and safer access to the pots that hung from them. These cooking systems may seem rudimentary, but a skilled cook knew how to manage pots, pans, cauldrons and pokers and expose them to the right type of heat by positioning them in various parts of the fireplace. They were also very versatile, enabling multiple cooking techniques – boiling, stewing, frying, roasting, toasting – all at the same time, using different types of vessels and utensils. https://blogs.sydneylivingmuseums.com.au/cook/hearth-fire-cookery/This type of item was used extensively over the centuries over open fires. It is still used in camping.Metal cooking pot with handle designed to hang the pot over an open fire.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchenware, cooking, open hearth cookery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTile, c 1914

This clay roof tile was part of the ANTARES cargo, a large consignment of tiles on its way to Melbourne. THE ANTARES In mid-November 1914, after the beginning of the First World War, a young local man went one evening to fish near the Bay of Islands, west of Peterborough. He later arrived home hurriedly and in an agitated state declaring: "The Germans are coming!" His family laughed and disbelieved him, as this young fellow was prone to telling fictional tales. About a month later, on December 13th 1914, local farmers Phillip Le Couteur and Peter Mathieson were riding in the vicinity, checking on cattle. Phillip Le Couteur saw what he “thought was the hull of a ship below the cliffs.” He rode to Allansford and contacted police. The next day, two Constables and Phillip Le Couteur returned to the site, where they dug a trench near the top of the cliff and sank a log in it. To this they attached a rope, which they threw down the cliff face. Constable Stainsbury and Phillip Le Couteur then made the dangerous descent down the rope on the sheer cliff face. They found wreckage strewn around a small cove and a portion of a man's body under the cliffs. The hull of the ship could be seen about 300 metres out to sea. Some of the wreckage revealed the name Antares and the remains of the ship's dinghy bore the name Sutlej. During the next two weeks and with the help of the Warrnambool lifeboat and crew, two more bodies were found. Later investigations proved that the tragic wreck was indeed that of the Antares, reported overdue on the 207th day of her voyage from Marseilles, France, to Melbourne. She was a three masted, 1749 ton iron clipper, built in Glasgow in 1888 and originally named and launched as the Sutlej. Bought in 1907 by Semider Bros. from Genoa, Italy, she was refitted and renamed Antares. It was later realised that the local lad who a month earlier had declared he had seen German guns being fired, had probably seen distress flares fired from the deck of the Antares the night she was wrecked. She was last sailed under Captain Gazedo and wrecked at what is now known as Antares Rock, near the Bay of Islands. She had been carrying a large cargo of roof tiles from France to Melbourne, consigned to Mullaly & Byrne. Many of them are now to be seen amongst the battered and scattered remains of the wreck. Some of the timbers were found to be blackened by fire. An Information Board has been erected on the cliff top near to the site of the Antares wreck, at the end of Radfords Rd, west of Peterborough. (Ref: Flagstaff Hill Maritime Village’s “Antares” fact sheet, Victorian Heritage Database, Information Board at Peterborough, Flagstaff Hill Significance Assessment 2010) The Antares was one of the last of the 'tall ships' to be lost along the south west coast of Victoria, and is the only wreck that took the lives of all people on board. She is listed on the Victorian Heritage Register VHS S34. The Antares is significant as a sail trader carrying an international inbound cargo. It is part of the Great Ocean Road Historic Shipwreck Trail. Piece of a clay roof tile recovered from the wreck of the Antares. Has a relief of a horse on back. Artefact Reg No A/7.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, antares, tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, antares rock., bay of islands, clay tile, roofing tile, roof tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin