Showing 183 items

matching machine tool

-

Tatura Irrigation & Wartime Camps Museum

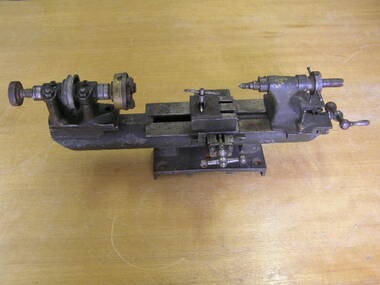

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach -

Clunes Museum

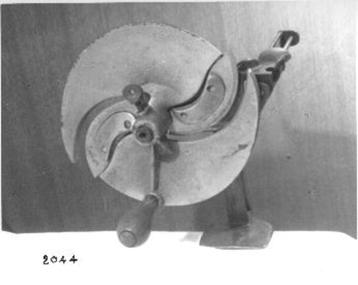

Clunes MuseumTool - BOTTLE CORKING MACHINE, R. MONTGOMERY & CO. MELBOURNE

... ON THREE-LEGGED WOODEN STAND Tool BOTTLE CORKING MACHINE R ...CORKING MACHINE WAS USED AT THE EBERHARD & CO. CORDIAL FACTORY IN CLUNESCORKING MACHINE WITH PUMP ACTION HANDLE, ADJUSTABLE STAND TO FIT BOTTLE SIZE. MACHINE MOUNTED ON THREE-LEGGED WOODEN STANDR. MONTGOMERY & CO. AGENTS MELBOURNElocal history, food technology, bottling, eberhard & co. -

Friends of Kurth Kiln

Friends of Kurth KilnChisel Tool,mid 1940

... Chisel shaped tool for a machine with a 3.5cm hole at one... Chisel shaped tool for a machine with a 3.5cm hole at one end ...found amongst the tools at Kurth Kiln Part of wood harvesting machineryChisel shaped tool for a machine with a 3.5cm hole at one end. 3cm thick and 6cm wide at the thick end. Could be part of a slasher or hammermillrural industries -

National Wool Museum

National Wool MuseumSpanner

Tool associated with the Wertheim "Preciosa" Knitting Machine.Tool associated with the Wertheim "Preciosa" Knitting Machine.knitting, jepson, mr keith -

National Wool Museum

National Wool MuseumSpanner

Tool associated with the Wertheim "Preciosa" Knitting Machine.Tool associated with the Wertheim "Preciosa" Knitting Machine.knitting, jepson, mr keith -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine - Treadle type

Home sewing machine - pre electric.Black Metal - Remains of gold leaf. Cotton reels attached Inlayed case with handle. Tool box has more parts in it."RThe" -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Singer Sewing machine Treadle type

Home Sewing machineBlack - Floral Design - crackled. Wooden curved top case. Case with handle metal turned wood - keyhole. key on black wool no box for tools and parts. Empty bobbin in slot. Foot Pedal'Singer" Trade mark Stamp " The Singer Maine co" fastened to the machine "Y8089019" "Simarco 193017" -

National Wool Museum

National Wool MuseumTool - Sickle, Pre. 1988

Feed for sheep farming is crucially important. Whether growing a sheep for breeding, wool or meat, it is vital to ensure that all sheep at whatever stage of life are maintaining or growing in weight. Sheep are often pictured grazing in paddocks; however, the grass available in a paddock is often not enough to maintain a sheep’s weight. In addition, if a sheep eats grass too low in a paddock then corrosion can affect the soil preventing any grass from growing in this location. For these reasons, supplementary feed is introduced to sheep’s diets. In most occasions’ food high in protein such as Lupins is sought. In times such as drought or to makeup a sheep’s roughage; feed such as silage, hay and straw may be required in the feeding of sheep. This is where the sickle is introduced to sheep farming. Although modern-day machines are used to harvest cereals, in times past the sickle was used for harvesting these crops. Once harvested, these crops can be fed to sheep freshly cut or dried. This sickle has been on display for 30 years at the National Wool Museum. It was at the entrance to Gallery One in the “A New Europe” wood hut display case. It was taken off display in 2021 with the “On the Land” redevelopment of this gallery space.Curved Metal serrated blade extending from carved dark wooden handletools of the trade, sheep feed, sheep farming -

National Wool Museum

National Wool MuseumFunctional object - Typewriter, Remington Typewriter Company, c.1925

This Remington No.12 typewriter is of the typebar, front-strike class. It was made by the Remington Typewriter Company of Ilion, New York, U.S.A. in about 1925. The Model No. 12 was introduced in 1922 and was one of the first 'visible writer' machines, in which the typed characters were visible to the operator. Previous models were of the upstrike class in which the characters were typed on the underside of the platen. To see what had been typed the operator had to raise the platen, meaning the typist was typing blind much of the time. This machine was used by Margaret Ganly née Burn in the 1930s. It was purchased for her by one of the sons of William Pride, a famous saddle maker in Geelong, William was Margaret’s grandfather. The typewriter was donated with original sales receipt and servicing tools. Margaret worked at Dennys for 7 years during the 1930s. The typewriter is accompanied with a story written by Margaret about her time working at the company. Margret married Jack Ganly, a fellow employee of Dennys. The Ganly name was well known within Dennys, with three generations of the Ganly family working at the company. WORKING CONDITIONS & OFFICE WORK DUTIES. Written by Margaret Burn in 2021. Worked at Dennys Lascelles in the 1930s. In the 1930s coming out of the Depression, jobs were hard to come by and had to be clung to by efficiency and subserviency. There was no union to protect workers – bosses could be tough and rough. Dennys Lascelles revolved around fortnightly wool sales in the “season” – September to May. Sale day was always a day of suppressed excitement. Preparation from a clerical point of view was complete and we now awaited the aftermath of the actual wool auction. The building teemed with people. There were country people down to see their wool sold, buyers of many nationalities, or from the big cities, who were coming in and out of the building all day. Their role was to inspect the acres of wool bales displayed on the show floors; however, caterers were present to feed clients, and there was plenty of social interactions on top of business. The office staff did not go home but waited until the first figures came back from the wool sales and the machines went in to action, both human and mechanical, preparing the invoices for the buyers’ firms. This comprised of lists of lot numbers, weights, prices per lb., and the total prices paid. A lot of this was done by old-school typewriters, making this work a big, heavy, tiring job. Before the finished lists could be dispatched, they were collated on an “abstract”. The lists had to balance with the catalogue from which the invoices had been prepared. This never happened automatically. All the paperwork had to be split up amongst pairs of workers and checked until discrepancies were found. This would happen until midnight but occasionally went until 2 or 3 am. Once complete, the invoices could then be rushed off to the buyers’ firms usually in Melbourne, and hire cars took the staff home. It was back on the job the next morning, usually around 8.30. The office hours varied according to the size of the sale and work involved. Some days started as early as 8 and could finish around 5.30. The second phase of work began with the account sales to be prepared for the sellers of the wool. These detailed all the weights, descriptions of wool, brands, and prices. One Sales account could have multitudes of lot numbers, all needing to be individually described. Various charges needed to be deducted such as finance for woolpacks, extra stock, or farmers who were given a loan to live on during the season. Details of how payment was to be made was also noted, whether the seller was to be paid by cheque, to a bank, or credited to their account with the company (which often left the seller still in debt). For a couple of months in the winter, things were quieter when staff took holidays and were sometimes given afternoons off. But there were still weekly skin sales and stock sales around the state. The annual end of June figures to be prepared for a big company like Dennys with branches all around the state also kept the staff busy. In good years there was sometimes a bonus. On sale days there was a bar open for the clients and wool buyers. This added to the excitement for the young girls, who were strictly barred from using it, but somehow managed to sneak a gin and tonic. This is how I had my first ever, before the evening meal. There was also the romantic notion in some minds, with all the influx of males, that some of us might end up on a wealthy station, or be noticed by an exotic buyer. To my knowledge, this never happened at Dennys Lascelles Limited. Group staff photo at Dennys Lascelles Limited. Margaret Burn. Age 18 or 19. Jack Ganly (Margaret’s future husband). 22.The typewriter has a black painted metal frame. The top section of the typewriter consists of a cylindrical platen on a carriage featuring plated metal fittings. A curved folding paper guide sits behind the platen and moves on the horizontal axis when the user types on the keyboard. A horizontal semicircular type basket with typebar links the top section to the lower keyboard. The ink ribbon is carried between two spools on a horizontal axis, one on each side of the type-basket. At the rear, a paper tray features gold lettering which reads ‘Remington’. At the front, a four-row QWERTY keyboard is found with 42-character keys total. 'SHIFT LOCK' and 'SHIFT KEY' are to the left of the keyboard, 'BACK SPACER' and 'SHIFT KEY' to the right. All keys are circular, white with black lettering. At the top of the keyboard are five circular red keys with the numbers 1-5 displayed behind their respective keys. A Spacebar is found along the front of the keyboard. The typewriter is accompanied by a cardboard box. This box contains the original sales receipt, on blue paper with grey lead handwriting. It also contains spare parts, a spare ribbon stretched between two spools, and cleaning tools such as brushes of differing sizes. Serial Number. Engraved. "LX45395" Gold lettering. Paper tray. “Remington” Gold Lettering. Behind keyboard. “Made in Ilion, New York, U.S.A. Gold Lettering. Mirrored both sides of type-basket. “12”remington, dennys lascelles ltd, worker conditions 1930s -

National Wool Museum

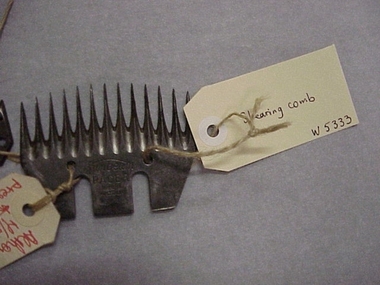

National Wool MuseumShearing comb

Shearing machine comb inscribed "Sunbeam PACER".Sunbeam PACER/ MADE IN AUSTRALIA Although the L/H/pce appears to have been presented complete/with combs and cutter/ I feel the tools are modern/ TC.3/11/93shearing animal health sheep stations - management, shearing, animal health, sheep stations - management -

National Wool Museum

National Wool MuseumShearing cutter

Shearing machine cutter inscribed "Sunbeam ARROW".Sunbeam ARROW Although the L/H/pce appears to have been presented complete/with combs and cutter/ I feel the tools are modern/ TC.3/11/93shearing animal health sheep stations - management, shearing, animal health, sheep stations - management -

National Wool Museum

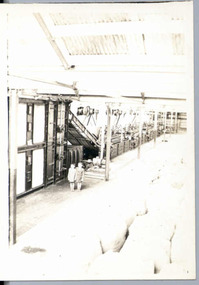

National Wool MuseumPhotograph

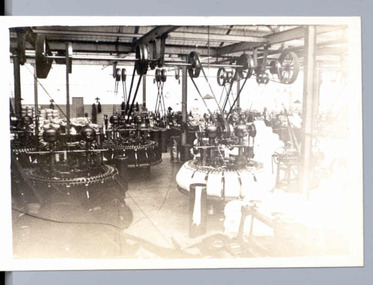

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the carding machine. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, carding -

National Wool Museum

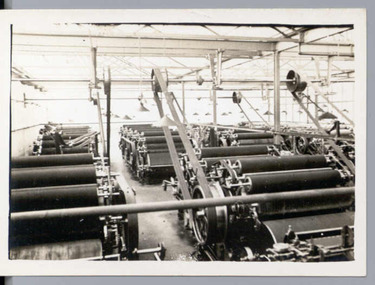

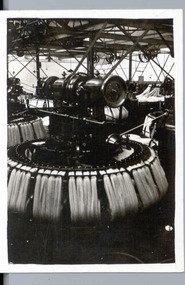

National Wool MuseumPhotograph - Noble Combs, Valley Worsted Mill, 1923

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. "These 12 machines ended their working life in 1981 when the mill switched from the Bradford system of wool combing to the Continental system, the reason being was that the cost of maintaining them became too high, also the replacement rectilinear combs production rate was far greater and achieved higher yields although it could be argued that the Noble combs quality was superior". - Greg AldridgeBlack and white image showing the interior of a textile mill with machinery. Slightly overexposed on the right side.valley worsted mill, combing, noble comb, geelong -

National Wool Museum

National Wool MuseumPhotograph, Noble Combing Machine, Valley Worsted Mill

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile mills, valley worsted mill foster valley mill pty ltd, combing, noble comb -

National Wool Museum

National Wool MuseumTool - Finishing machine

... , used for shipping. Tool Finishing machine ...Variable speed cloth puller, used for tightening and smoothing blanket edges, prior to them being sewn or bound. Used at Collins Bros Mill.Textile finishing machine. Horizontal, made from grey steel with a small encased gear box and two attached rollers. Separate belt drive and nine other rollers. Enclosed in original brown cardboard box, used for shipping.SUISIE / VARIABLE SPEED / VERSATILE CLOTH PULLERtextile machinery, collins bros mill pty ltd, blankets -

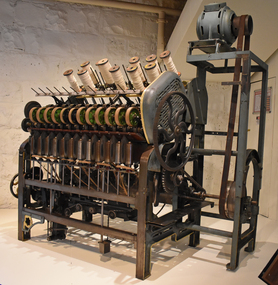

National Wool Museum

National Wool MuseumMachine - Cap Spinner, 1925

This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Pamphlet, Stanley-Titan Pty Ltd, 1960s?

Hand tool catalogue.Hand tool catalogue: wood chisels, auger bits, eyed augers, machine bits, masonry drills, linoleum or leather knives, handsaws, plane irons, woos screw pilot bits and flat power bits.Hand tool catalogue.stanley-titan pty ltd, woodworking tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Needles

Needles are part of a collection of sewing tools donated by Betty McPhee.Packet of sewing needles - no. 6. Presumed it they were purchased from 'The Trimming Shop' 11-13 Grainger Street Newcastle (Printed on packet).Use W' m Allwood & Son Sewing Machine Needle.handcrafts, equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Cotton Reel

Reel is part of a collection of sewing tools donated by Betty McPhee.A 40 0z spool of machine sewing thread. Cream Cotton on wooden reelExtra Superior 'The Badger Machine Thread' 40|Finlayson Bousfield & Co, Johnson, Scotland.|4 oz spooldomestic items, sewing, handcrafts, equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Cigarette Maker

Nickel plated cigarette tin with the Crest of Jersey. Also contains a cigarette making machine. It has two rollers to take the cigarette papers and the tobacco to make a cigarette. Also included is a packet of Tally Ho cigarette papers and the direction for making cigarettes.EVANCON OD No.548003 Made in England.personal effects, smoking accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Kitchen Cutter

The donor stated that the machine is about 100years old.Metal food cutter with rotary blade and handle. Base has lower shaft with screw to attach to table.Sterling Slicer No.10 NRS&Co Rochester New Yorkdomestic items, food preparation -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchMemorabilia - Pack Saddle

Believed to have been made 1939/43. In 1904 the British Army adopted a new General Service (GS) pack saddle with an adjustable tree, known as the Mark V pack saddle. The main innovation was the adjustable tree created by having the front and back steel arches jointed to the wooden sidebars, which allowed them to turn to adjust to the size of the back of whatever animal carried the saddle, from the largest horse to the smallest donkey, and eliminated the need to manufacture saddles in different sizes. The saddle could be adapted, by the addition of hanging bars, or universal slats, to carry a wide variety of stores, tools and equipment, and also wounded men. The GS pack saddle was used in both world wars by both the British and Australian armies. The use of pack saddles was especially important in the campaign in Palestine during the First World War where wheeled transport was often not an option. Each machine gun carried by light horse units was transported on a pack saddle, and was accompanied by a second pack animal carrying spare ammunition. During the Second World War pack animals were routinely used by patrols, and larger units such as Norforce, in remote areas of northern Australia. The saddle shown here has two separate girths, which crossed under the animal's belly. Most later versions of the saddle used a shorter single girth buckled to a 'V' attachment, which was in turn buckled to the sidebars. Use of the 'V' attachment gave greater strength and stability to the saddle, and decreased 'rocking' of the load. -

Whitehorse Historical Society Inc.

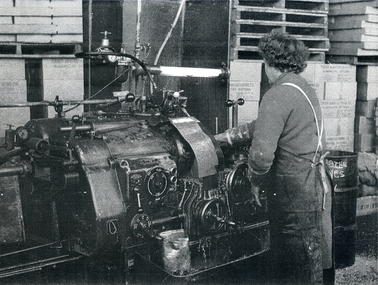

Whitehorse Historical Society Inc.Photograph, Stanley Works Pty Ltd, C1970

In 1970 Stanley Works took over Turner Industries in Nunawading. They manufactured hardware for doors and windows, lawnmowers and tools.Black and white photograph of a man standing to the left of a large machine called a vibratory finisher. Stanley Works Pty Ltdstanley works pty ltd tools machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Stanley Works Pty Ltd, 1970+

In 1970 Stanley Works Pty. Ltd. took over toolmaker, Turner Manufacturing Company, who were situated in Whitehorse Road, Nunawading.Coloured photograph of a male worker in a blue boiler suit in a Stanley Works machine room.tools, stanley works pty. ltd, manufacturing industry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sewing Machine needles

... 5 needles. One packet 4 needles. Tool Sewing Machine needles ...Two packets of sewing machine needles wrapped in pink paper with White Vibrator name, assorted sizes. One packet 5 needles. One packet 4 needles.White Vibrator Antony Hordern & Sons Lts Brickfield Hill Sydney -

Australian Army Museum of Western Australia

Australian Army Museum of Western AustraliaDiorama, 2015

This diorama is the introductory feature in the World War 1 Gallery - 1918 experience. The figure shows details of the Lewis gun and webbing including the documented but irregular positioning of the entrenching tool.The diorama text discusses the transition from manpower to firepower with the restructure of infantry battalions to incorporate more light machine guns and to give the platoon an all round versus specialist capability. The increase in firepower and the reduction to three from four battalions in an infantry regiment in part offset the decline in voluntary recruitment. The offensive capabilities of an infantry battalion was therefore generally maintained but with 700 men instead of 1100 when fully manned .1:1 scale diorama showing a Lewis gunner of 44th Battalion, 11th Brigade, 3rd Division, Australian Imperial Force in May 1918amiens, last 100 days, lewis gun, spring offensive -

Moorabbin Air Museum

Moorabbin Air MuseumPamphlet (Item) - Ansett The Tools Of Our Trade Drilling Machines

... Moorabbin melbourne Ansett The Tools Of Our Trade Drilling Machines ... -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (Item) - Ansett Jones Shipman Machine Tools No.39

... Moorabbin melbourne Ansett Jones Shipman Machine Tools No.39 Booklet ...