Showing 875 items

matching irons

-

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumFlat Iron, Metters

This flat iron was one of two flat irons donated by Mr Max Millsteed in 2000. Mr Millsteed died in Dec 2004 No. 7 Metters Flat Iron made from cast iron.Good Condition" No7 /Metters /Sydney"flat iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron

Before the introduction of electricity, irons were heated by combustion, either in a fire or with some internal arrangement. An "electric flatiron" was invented by American Henry Seely White and patented on June 6, 1882. It weighed almost 15 pounds (6.8 kg) and took a long time to heat. The UK Electricity Association is reported to have said that an electric iron with a carbon arc appeared in France in 1880, but this is considered doubtful. Two of the oldest sorts of iron were either containers filled with a burning substance, or solid lumps of metal which could be heated directly. Metal pans filled with hot coals were used for smoothing fabrics in China in the 1st century BC. A later design consisted of an iron box which could be filled with hot coals, which had to be periodically aerated by attaching a bellows. In the late nineteenth and early twentieth centuries, there were many irons in use that were heated by fuels such as kerosene, ethanol, whale oil, natural gas, carbide gas (acetylene, as with carbide lamps), or even gasoline. Some houses were equipped with a system of pipes for distributing natural gas or carbide gas to different rooms in order to operate appliances such as irons, in addition to lights. Despite the risk of fire, liquid-fuel irons were sold in U.S. rural areas up through World War II. In Kerala in India, burning coconut shells were used instead of charcoal, as they have a similar heating capacity. This method is still in use as a backup device, since power outages are frequent. Other box irons had heated metal inserts instead of hot coals. From the 17th century, sadirons or sad irons (from Middle English "sad", meaning "solid", used in English through the 1800s[4]) began to be used. They were thick slabs of cast iron, triangular and with a handle, heated in a fire or on a stove. These were also called flat irons. A laundry worker would employ a cluster of solid irons that were heated from a single source: As the iron currently in use cooled down, it could be quickly replaced by a hot one. https://en.wikipedia.org/wiki/Clothes_ironThis iron is typical of the clothes iron used before electric irons superseded it.Salter iron no. 6, painted black but with rust showing through. Salter iron no. 6.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, iron, clothes, laundry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - TILLEY Paraffin Pressure Iron, Tilley Lamp Company, 1950s to 1970s

Irons such as this were very popular prior to the widespread introduction of electricity in Australia. It was manufactured by the Tilley Lamp Company Ltd. In 1818 John and William Henry Tilley established W. H. Tilley, in Stoke Newington, London, England. During WW1 they started to use paraffin as a lamp fuel in pressurised containers. A production plant was established at Hendon, just north of London, and the first commercial lamps were produced after World War 1. During the 1920s the company diversified into domestic lamps. This expanded to other appliances such as heaters and eventually to irons. The use of paraffin or kerosene as a fuel was a much cleaner form of heat, especially when compared to older flat irons which used coal.This item is significant because it is representative of domestic appliances used in the Wodonga District prior to the introduction of electricity throughout the area.Cream coloured iron with a black Bakelite handle which attaches to the fuel tank. It has a steel sole plate. The heat of the iron is provided by a paraffin burner.On Metal plate: Model D.N. 250 Made in England British Pat. 524719 Australian Pat. 114305 On Knob at rear: ON/OFF TILLEYdomestic appliances, tilley paraffin iron, tilley lamp company ltd. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageIron

This iron used its own fuel to heat up the iron rather than earlier flat irons that required heating on top of the stove."Comfort Self Heating" clothes iron. Spirit iron with wooden handle and metal tank for spirit fuel (probably benzene.). Different fuels were used, some with dire resultsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, spirit iron, self, heating iron, comfort iron, comfort self heating iron -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hotpoint Electric Iron, Hotpoint under Licence to Edison Elelectric Appliance Co. Inc, c1930s

Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains. 'Hotpoint' electric irons were first sold in Australia around 1914 and remained a popular product for many decades. From the late 1920s they were manufactured in Australia by the Australian General Electric Co. Ltd.This iron is representative of early electrical appliances manufactured under licence in Australia from the late 1920s onwards.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a power cord is plugged. The iron has a wooden handle.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W200."domestic appliances, early electric appliances, hotpoint australia -

Ringwood and District Historical Society

Ringwood and District Historical SocietySchool Council List, Arthur Lunt, East Ringwood Primary School no. 4180: School Council members list 1978, 1978

Arthur Lunt was chairman of the East Ringwood Primary School Council and prepared this list.List of members of the 1978 School Council of the East Ringwood Primary School no.4180. For list refer key associations. +Additional Keywords: Adams, Tony / Campbell, Jan / Cook, Robert / Darke, Ruve / Davine, Kevin / Hogg, Dennis / Irons, Philip / Kenny, Trevor / Little, Francis / Lunt, Arthur / McEnaney, Laurie / Meehan, Ron / Morris, Jeffrey / Philip, Shirley / Propsting, Gerry / Robins, Norman / Rymar, Joseph -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bees wax

This is a lump of beeswax that has been used to polish and clean old flat irons. Beeswax is a natural product made by bees to form the honeycomb in their beehives. It was used historically in many areas, including candle making, bow making, cosmetics production, bullet-making and modelling. It still has many commercial uses today. Flat irons were metal objects that had a flat polished surface and were heated to iron material and garments. The beeswax assisted in keeping the polished surface clean and shiny. This piece of beeswax comes from a local source but the full provenance is not known. It is important to keep it in the collection as an adjunct to the Historical Society’s collection of sad and flat irons from the past. This is a lump of beeswax in a round shape with one end broken across to reveal the inner part of the beeswax. The outer part is somewhat stained. flat and sad irons, household items from the past, history of warrnambool -

Orbost & District Historical Society

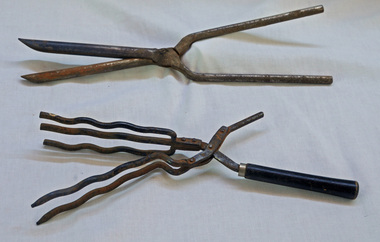

Orbost & District Historical Societycurling and crimping tongs, late 19th early 20th century

Used by women and girls to wave or crimp their hair, for styling their hair, hairdressing. The irons are heated and then applied to the hair and wound to form curls. Pre-dates electrically heated curlers.One set of curling tongs made of iron/steel, rusted. The tongs are two shaped metal pieces which clamp together over a tress of hair. One set of crimping tongs. These have two wavy iron shaped metal pieces which clamp over a tress of hair to produce crimpy waves.hair-crimpers-curlers hairdressing heated-curlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Blacksmith Anvil

This anvil is typical of the type used by Blacksmiths in Moorabbin Shire c1850 - 20thC Blacksmith were needed to make machinery, tools, farm and household equipment, wheels and wagons, horseshoes and saddle irons.This anvil is an example of the type used by blacksmiths in Moorabbin Shire 1840- 20thC as early settlers developed the land. built homes, shops and schoolsSolid steel single horn shaped block used by a Blacksmith to make tools, horseshoes, kitchenware, farm equipment, wagon wheelsmarket gardeners, early settlers, moorabbin shire, dendy special survey 1841, bentleigh, moorabbin, cheltenham, tools, anvils, steel, horses, wagons, washing pots, cooking pots, blacksmiths, county of bourke -

Anglesea and District Historical Society

Anglesea and District Historical SocietyClothes Iron, Coleman Lamp Stove Co Ltd, Spirit-fuelled Clothes Iron, Estimated circa 1936

Coleman Lamp Stove Co Ltd possibly making irons by arrangement with Coleman Lamp & Stove Co Ltd in Canada. Origin of these companies - started by William Coleman of Oklahoma and Kansas, USA. Iron has chrome plated sole - blue enamel body with white speckles and hemispherical tank (probably copper - has typical green verdigris appearance) for the lighting fluid that would have supplied the heat. The wooden handle is painted blue. Top screw is missing from the fuel tank.clothes iron -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Household, Trouser stretcher & press x2, Early 20th century

These two boards were clipped on to the creased edge of trousers and the item stored in this way. They were used in lieu of irons in the days before electric irons. These items come from the household of the Angus family in Warrnambool. Dr William Roy Angus (1901-1970) studied medicine in Adelaide and Edinburgh. He practised medicine in South Australia and at Nhill before coming to Warrnambool in 1939. In later years he specialized in ophthalmology. The Angus family lived at ‘Birchwood’, a house now demolished. Dr Angus was very civic-minded and was active in a great number of community groups.These items are retained because of their connection to past years and because of their association with the well-known local Warrnambool doctor, Dr Angus. These are two rectangular pieces of wood with three metal clips on each. Two of the metal clips are badly rusted. Both pieces have printed material etched into the wood. A piece of string is attached to the end of each board.The Aveca (Patented) Trouser Stretcher and Presser The Aveca (Pat. Appd. For) Trouser Stretcher and Presser men’s accessories, history of warrnambool -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumIron

Used at Camp 13, Italian compound, Murchison. Recovered from there in 1989. Iron would have been heated before use on a wood fired stove top/hot plateBlack flat iron with shaped handleiron, camp 13, murchison, tatura, domestic, items, irons -

Hume City Civic Collection

Hume City Civic CollectionDomestic object - Damping bottle with top, Schweppes

The damping bottle was filled with water and used to moisten starched clothes and linen before garments were ironed. The introduction of steam irons into households in the early 1960's resulted in damping bottles becoming superfluous.A glass 'Schweppes' bottle has yellow and black graphics on it. It has been recycled and used as a damping bottle. The metal stopper has been inserted into a cork. There are spray holes on the top of the stopper. The word 'Schweppes' has been embossed around the base of the bottom.13 FL. OZ / SCHWEPPESlaundering, ironing, starching, schweppes, domestic items, george evans collection -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Hotpoint, Electric Iron, 1930s

Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a separate power cord is plugged. The iron has a wooden handle.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W200."hotpoint -- australia, electric irons -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Hotpoint, Electric Iron, 1930s

Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a separate power cord is plugged. The iron has a wooden handle. Missing cord.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W230."electric irons, hotpoint australia -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Household, Travel Iron, 1920s

This iron would have been used mostly by women either travelling, in hotel rooms etc, or on an occasion when only one or two small items were needed to be ironed. It has been superseded by electric irons. This is an attractive item and is retained as a fine example of a travel iron used about 90 years ago. This has a rectangular-shaped metal base with pointed ends (in the shape of a conventional ironing plate). The top of the plate is indented. A piece of metal (chrome-plated), with a hinged lid, partially slides out from the top of the plate and this is used to hold the meta tablets (methylated spirits) or coal. The top of this plate is used to extinguish any coals or flames. This piece of metal is partially enclosed in an open metal container. The wooden handle of the iron is affixed to the top of this container. ‘British Boudoir Iron’ ‘World Pats Granted or Appd for BCM WS4C’ household items, history of warrnambool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Electric

From c1950s electrical irons were used. The thermostatic iron followed the electric iron used with a container that enabled water to be sprayed onto the cloth. Damp cloth was more easily pressed. This thermostatic electric iron was one of the early models.This iron was used by residents of the Kiewa Valley including those living at Mt Beauty where there was electricity and an SEC shop from c1950.This is a "General Electric" iron. It has a steel base with a chrome upper and black plastic handle. It is thermostatically controlled with water spray. The electric cord is permanently attached, at right angels, to the handle base. A red button activates the water spray when pushed. A white button slides to enable fabric selection. A metal hole in the front of the handle is used to fill the iron with water.General Electric; Wash and Wear / Wool / Cot / Lin; Australian General Electric Appliances Pty Ltd.; Notting Hill Victoria. 1100 Wats 240 Volts AC only. V/A2F Cat. No. 10 FS10iron;, electrical appliance, laundry, domestic, pressing clothes -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Kerosene

Kerosene irons were used c1930 - 1950 especially where electricity wasn't available. Shelite was another fuel that could be used instead of kerosene. The advantage of the kerosene iron was that it didn't require a stove to be lit (especially in summer) to heat the iron and it didn't require electricity.Residents in the Kiewa Valley used kerosene irons.This black iron is made of cast iron with a steel base and a black wooden handle. This Comfort iron has a ball shaped container with a screw-on lid to hold the fuel (kerosene or Shelite). At the bottom of this ball is a pipe going down then meeting another pipe at right angles to it leading into the iron. At the pipe junction there is a handle on a screw to limit the amount of fuel. The Kerosene would flow through this pipe. There is a filler plug air stem on top. This is a self-heating iron.Comfort iron / Self Heating Comfort Iron MFD by / National Stamping and Electric Works / made in U.S.A. Chicago iron, domestic, laundry, pressing clothes, household, kerosene, shelite -

Melbourne Legacy

Melbourne LegacyDocument - Document, list, Property of Mr. and Mrs. Frank, 1943

Undated list of personally owned furnishings at Holmbush found in a file next to letters dated 1943. The piano, musical cabinet, card tables, fire fender and fire irons, wireless, and kerosene refrigerator give an indication of how homes were furnished at the time. Mr Bert Frank was appointed to the role of manager of the Legacy Club Hostel in March 1943 (see 00355.1) and details of his application for the role is also in the archive at 00351. As were the times the wife of the successful applicant was automatically assumed to be working as well but without the acknowledgement of a hired position. As it was a live-in position perhaps this list recorded their personal contents to avoid disputes later on. Legatee Carleton is mentioned as who supplied the fender and fire irons.Demonstrates the frugality with which the first Melbourne Legacy hostel was furnished. Faded white copy paper, black carbon imprint, two holes punched for filing.holmbush, residences, staff, holmbush administration -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPie Iron Camping, circa mid to late 1900s

This Pie Iron was used in the mid to late 1900's when stock, both cattle and sheep, were grazed on the Bogong High Plains. Providing meals for stockmen over open fires, even in log cabins in the Victorian Alpine region, was usually by a "camp cook" or a stockman designated "cook" from the Valley station/property. The use of "camping cooking utensils were a necessity and not a "weekend" affair. Stockmen could spend up to six weeks on the plains and all their cooking needs required had to "pack horsed" from the valley below. A scientific study started in 1947, to study the impact of grazing cattle on the natural Alpine and sub Alpine vegetation found grazing cattle had an adverse affect on the natural Alpine and sub alpine vegetation, and grazing on the plains was stopped by the Victorian Government in 2005.This item is highly significant to the Kiewa Valley as it demonstrates the kind of cooking utensils that were required for camp drafts in the Bogong High Plains environment. As the control of cattle and sheep in the High Plains was very demanding upon horse and rider, good "tucker" was a pre- requisite for a successful operation. As the time spent in this remote location was governed by the climatic condition maximum utilisation of the very good pastures in the High Plains was crucial to a successful and profitable season.This pie iron has two pie forms in horizontal configuration and both top and base rounded forms are connected at one end (Top) with pop rivet application. This application allows for the "opening" up of the two halves. The bodies are made from cast iron in a "cup" form and a metal rod and wooden handle extend to permit the opening of the two sides. The inner side of the "cups" are smooth which relates to pie requirements and not the jaffle/sandwich irons. A clasp metal "D" ring is installed at the end of one wooden handle (to keep the iron in the close/cooking position).camp fire cooking utensils, hot plate, cast iron cooking appliances, pie irons, jaffle irons, drovers kitchen -

Melbourne Legacy

Melbourne LegacyDocument - Document, list, Legacy Club Hostel. List of Equipment to 3/3/43, 1943

List of equipment for setting up Holmbush with prices, not including items bought from Thomson's or under terms of Contract. Including prices and applicable sales tax. Included items such as teapots, irons, toasters, buckets, cutlery, brushes, carpet sweeper, trays, garden tools, rugs, mattresses, pillows and linen. A record of written correspondence regarding purchasing furniture and items for the first hostel established by Legacy in 1943.List of equipment and prices for Holmbush on white quarto copy paper x 4 pages, with black type, two hole punched.Tick marks or crosses in pencil alongside some items.holmbush administration, residences -

Orbost & District Historical Society

Orbost & District Historical Societyiron

Iron was heated on top of stove. Often the person ironing had two irons - one to iron with and the other heating on stove ready to use when the other cooled down. They were heavy to use and were generally cleaned with bees' wax and a cloth before use. Wooden handles were patented in 1865.This item is an example of a domestic appliance in common usage before the advent of electricity.Small rusty flat iron.domestic iron flat-iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Hair Tongs, Marcel Grateau, 1900 +

Marcelling is a hair styling technique in which hot curling tongs are used to induce a curl into the hair. Its appearance was similar to that of a finger wave but it is created using a different method. Marcelled hair was a popular style for women's hair in the 1920s and 30s often in conjunction with a bob cut. For those women who had long hair, it was common to tie the hair at the nape of the neck and pin it above the ear with a stylish hairpin or flower. Accounts vary about the invention of the style, but Marcel Grateau (1852–1936) is widely credited with inventing the hair styling technique in the 1870s. He started with a small salon in Montmartre, Paris where his clients were the poorer classes. As he developed the waving method that would later become the Marcel wave, using heated curling irons, The inventor and stylist emigrated to the United States and changed his name to François Marcel Woelfflé, sometimes reported as François Marcel. He was granted U.S. patents for implements for performing the technique; the first, U.S. patent 806386, entitled "Curling-Iron", was published in 1905, and the second, entitled "Hair-Waving Iron", for an electric version, under the name François Marcel, was published in 1918. His obituary appeared under the name Francois Marcel Grateau in 1936. Originally the irons had to be heated in the fire, but hair easily got burnt until 1924 when electric irons were invented and the temperature could be regulated. A significant item that gives us a snapshot not only into women's hairstyles of the 1920s and 1930s but a look into the social norms of that era. Therefore the item is of social interest in regards to the story it tells and the development of women's fashion in hair styling.Marcel Tongs, metal, used to impart a hair wave by heating and crimping the hairNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tongs, curling tongs, hairdressing -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Electrical, fittings 3 bakelite 1 brass c1930, c1931

As supply of electricity became available in the Moorabbin Shire c 1920 homes gradually changed from Gas lighting to Electrical lighting and bakelite was used for fittings. Bakelite was a safe non-conductor of the electric current. Housewives, who had ironed clothes with flat irons heated on the hearth of open fires, were delighted to be able to stand on a chair and remove the light globe and plug in their new clean and efficient electric iron. The supply of electricity to homes in the City of Moorabbin in the early 20th Century brought many welcome changes to domestic and commercial life 3 Electrical, fittings c 1931 a) a bakelite plug and socket Made in Australia b) a bakelite bayonet fitting Made in England ;c) Bakelite screw type with no markings d) A large brass and porcelain screw type with no markings L8 a) Australian Made / PIMI b) British Made in England c) No marks d) no marks electricity, electric lights, electric irons, bakelite, market gardeners, early settlers, moorabbin shire, mechanics institute cheltenham, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, clark judy, reed gladys, reed george -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Flat

This iron was used to press clothes prior to the spirit and electrical irons becoming available circa 1930s - 1950s. The main body of the iron was placed on a flat heated surface of a stove (wood, coal or gas fired). It was mainly used by women in their domestic role, ironing the family's clothes and linen. In the Kiewa Valley the supply of coal or gas was not available or too expensive than the locally cut hard wood trees. Ironing was time consuming as the iron had to be heated, used and then reheated to the required level of application. Kiewa Valley farmers' wives used these irons having heated their stoves with local timber from their farms. This iron is made of cast iron. The handle is a hollow cylinder and is 70 mm above the solid 30 mm base. Presumably the handle was wrapped and/or threaded with cloth to protect the hand from the heat of the iron. The iron would have been heated on the top of a stove.6 Metters KFB Victoriairon, laundry, domestic, antique, pressing clothes, household -

Mont De Lancey

Mont De LanceyBall and Ring Bunion Stretcher

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron ball and ring bunion stretcher.boot stretchers -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP, Unknown

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, and nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together and neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A pair of handmade, adult brown leather work boots, with brown leather laces, decorative stitching, metal eyelets and are stitched with waxed thread. The soles are covered with hob nails in a decorative pattern. They have metal caps on the heels. bootlaces, boots, footwear, clothing -

Falls Creek Historical Society

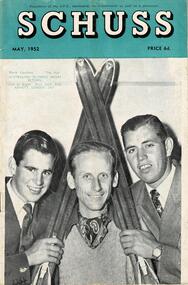

Falls Creek Historical SocietyJournal - Schuss Vol. 18. No. 3 May 1952

Schuss was advertised as Victoria’s Official Ski Journal It was issued monthly from 1935 to 1961 except during the war when summer issues covered two months. This continued after the war, but it averaged 10 issues annually over its 25 year life. Schuss was published by the Ski Club of Victoria which had a membership of 38 Ski Clubs and demanded to be recognised as the prime authority on skiing in the state. The other 30 ski clubs with 85% of the members disagreed and the politics of skiing became heated. These clubs formed the Federation of Victorian Ski Clubs with their own journal, Ski Horizon. With the establishment of the Victorian Ski Association, Ski-Horizon published its last issue in Nov - Dec. 1955 and the role of the official journal was fully taken over by “Schuss”. This item is significant because it contains stories, images and information documenting the development of the ski industry in Victoria.The journal features stories and events chronicling developments in Victoria and internationally. Items related to the Falls Creek Area in this issue include:- Cover - Australian Olympic Skiers Return Left to Right: Bill Day, Bob Arnott, Gordon Day. Page 111 - FRONT-SPRING CABLE BINDINGS - A note from Bob Hymans advises that he has for sale a number of Front- Spring Cable Bindings made by Ramy, the well-known French maker. In This pattern the spring is attached to the ski in front of the toe-irons and eliminates the weight of the spring around the heel fitted to most cables. It is very popular with ski-racers in Europe for its comfort and control. Bob also advises that his Ski School at Fails Creek will be open during the weekends of June, and from June 30 onwards till the end of the season. schuss journal, bob hymans, front-spring cable bindings -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village