Showing 220 items

matching plant and machinery

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Farm Machinery, Horse-drawn Plough Potato Digger, c1900

Circa late 1800s early 1900s a horse-drawn plough, potato digger, is one example of the implements that were widely used by early market gardeners in the Shire of Moorabbin. The flat plate, seen to the right of the photo, dug down into the ground below the potatoes and "scooped" them up. Behind the plate, two driving chains on cogs, (these chains are missing from our exhibit), then "rocked' the dug potatoes to loosen the soil from the "spuds". The potatoes were then harvested by hand. Very large tracts of land in the Shire of Moorabbin were planted with potatoes. Harvesting commenced in October, into November and on into December. Potatoes were a necessary food staple. The market gardeners were always in a rush to be first to get their potatoes to market, and hence the best price. Some market gardeners were so keen to be the first to market, (and get the most money), that they dug their potatoes "green" (or new). The only downside of this practice was that these early potatoes had to be handled with extreme care as their skins were very loose, and came off easily - so decreasing their profits.As well as taking their produce to the Melbourne and St Kilda markets, they also sent produce off to Sydney markets. It is interesting to note that a group of Chinese market gardeners were the first to access the Sydney market. .Following the 'Dendy's Special Survey' 1841 and the Crown Land Sale of 1852, land allotments were sold to pioneer settlers who established market gardens in the area of Moorabbin Shire. During the 1850s gold-rush population boom the number of market gardeners increased significantly spreading throughout the Moorabbin Shire. Potatoes were considered a staple foodstuff, so crops were regularly sown throughout the whole Moorabbin area. Circa late 1800s early 1900s. A horse-drawn plough potato digger is an example of the machines used by early market gardeners in Moorabbin Shiremelbourne, sydney, markets, vegetables, potato, dendy henry, st kilda, market gardeners, gold rush, moorabin, chinese gardeners, ploughs -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - BENDIGO SALEYARDS COLLECTION: PURCHASE REQUISITION BOOK

City of Bendigo Purchase Requisition, dated from 22/7/1988 to 17/7/1989. Numbered from 62301 to 62400. Book has a blue and white crocodile skin pattern on the cover and has Sale yards written in red pen at the top of the front cover The spine is bound with tan coloured tape. Pages are white with a blue carbon copy. A blue card attached to the back cover is used between each requisition. Purchases and repairs were authorised by J Richmond and J M Criminis. Purchase Requisitions were used for repairs, stationary, purchase of small equipment and tools.bendigo, council, cattle markets, bendigo saleyards collection - purchase requisition book, debbie smart, alan ritchie, city of bendigo, j richmond, brb electrics, n harris, hume & user, bolton's, fletcher & sons ballarat, w buries, bendigo mower service, bolts and fasteners, all ball?, cig, dalgety farmers, bendigo stainless steel, cattleguard, bp, robot plant, golden square small engines, sandhurst machinery power tools, cambridge press, sandhurst hire, all bull cattle colour, w d mason, data land, rover grip industries, charlie mason, northern seed supply, j m crimmins, beaurepaires, golden triangle, telecom, awm electrical, bendigo bearings, repco, tubemakers, mcilwraith, abbotts, holls electrical, midland irrigation, h j reece, moss electric, bruce's discount house, v comer, paul postema, andrew rosen, peter berens, golden triangle, bbc hardware, all bull, ocean action pty ltd, beth or gill wedmore, compare australia, data land, bendigo computer co, bendigo data processing, j redmond, dalgety, repco -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CENTRAL RED, WHITE AND BLUE MINE - REPORT ON MACHINERY

Hand written notes on a winding engine, report date 16/1/1914. Winding engine will be installed by Messrs Jorgensen & Sons. Tender for winding plant to Messrs A Roberts & Sons. Gives description of engine and drums.mine, gold, central red, white and blue mine, central red, white and blue mine, report on machinery, messrs jorgensen & sons, messrs a roberts & sons, mr macaffer -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CENTRAL RED, WHITE AND BLUE MINE - OPENING OF NEW BATTERY

Hand written notes and a carbon copy of extracts from Bendigo Advertiser on the opening of New Battery Central Red, White and Blue Co. on Thursd. March 14th 1912. Mentions the machinery, aerial tramway and supports and flying foxes.mine, gold, central red, white and blue mine, central red, white and blue mine, opening of new battery, bendigo advertiser, aerial tramway, flying fox, mining plant -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Leisure object - WOODEN MODEL CYANIDE PLANT

Wooden model of a cyanide plant. A cyanide plant was used for dissolving gold from finely divided ores by means of dilute solutions of sodium or potassium cyanides. The model has five metal bins, there is some rust on the bins and scorch mark on the wooden base.mining, equipment, cyanide plant, gold cyanidation (also known as the cyanide process or the macarthur-forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. it is the most commonly used leaching process for gold extraction. the ore is comminuted using grinding machinery. depending on the ore, it is sometimes further concentrated by froth flotation or by centrifugal (gravity) concentration. water is added to produce a slurry or pulp. the basic ore slurry can be combined with a solution of sodium cyanide or potassium cyanide, however many operations utilize calcium cyanide, which is more cost effective. to prevent the creation of toxic hydrogen cyanide during processing, slaked lime (calcium hydroxide) or soda (sodium hydroxide) is added to the extracting solution to ensure that the acidity during cyanidation is maintained over ph 10.5 - strongly basic. lead nitrate can improve gold leaching speed and quantity recovered, particularly in processing partially oxidized ores. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: CENTRAL DEBORAH GOLD MINE NL INVOICES, 1945-1946

Documents: Buff coloured heavy card folder, containing invoices for materials purchased for reconstruction of gold mine. Written on outside front cover ' Central Deborah GM NL, plant and building reconstruction, copies of invoices for materials purchased.'organization, business, central deborah gold mine, mccoll, rankin & stanistreet collection: central deborah gold mine nl, goldmining, plant and machinery -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph-colour, LJ Gervasoni, Jubilee Mine Scarsdale Victoria, 19/03/2011

The Jubilee Mine at Scarsdale was started by Thomas Greenwood of Italian Gully.Jubilee Company Quartz Gold Mine has one of the most comprehensive range of quartz mining foundations in the State. The brick and concrete foundations cover pumping, winding and crushing operations, as well as cyaniding of mine tailings. The machinery foundations are the remnants of large scale quartz mining operations carried on at the site between 1899 to 1912. During this time the mine produced over 125,000 ounces of gold and was the district's most important gold mine. (Source Victorian Heritage Register http://vhd.heritage.vic.gov.au/vhd/heritagevic/?timeout=yes#detail_places;5517)colour photograph in digital format showing the brick foundations of the stamping plant at the Jubilee Mine in Scarsdale, Victoria.gold mine mining scarsdale -

El Dorado Museum Association Inc.

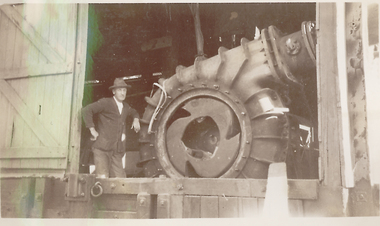

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer Engine c1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, gold mining, tin mining, machinery, engines, men, cocks pioneer, el dorado, eldorado -

Clunes Museum

Clunes MuseumPhotograph - PHOTOGRAPHS, INTERKNIT KNITTING MILL

.1 TANKS AT REAR OF FACTORY TO FILTER AND PURIFY WATER .2 MR. F. ANNEAR OPERATING A LARGE PLANT OF HOSIERY MACHINES .3 SOUTH CLUNES SCHOOLinterknit, tanks, machinery, south clunes school, mr f annear -

Hume City Civic Collection

Hume City Civic CollectionPhotograph

A section of the machinery in the former Sunbury Power House which was used to generate the town's electricity supply. The power house was situated on the the corner of Jackson and Shields Street. B/W photograph of the Producer Plant (gas) at Sunbury Power Supply.Handwritten on back: Section of the Producer Plantsunbury power supply, gas, george evans collection -

National Wool Museum

National Wool MuseumPamphlet, Independence Better Shearing Bigger Profits

Pamplet advertising Cooper shearing plants.shearing machinery, cooper engineering company pty ltd -

National Wool Museum

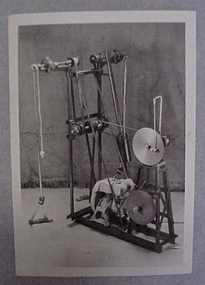

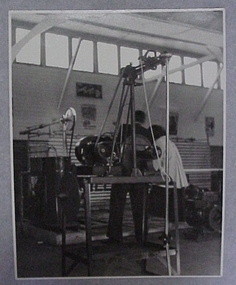

National Wool MuseumPhotograph, Cooper 2-stand semi-poratble sheating plant

Photograph of Coooper shearing plant.Photograph of Coooper shearing plant.Cooper 2-stand semi-poratble sheating plant powered by pilot air cooled petrol engine circa 1949 Photography by Athol Shmith Pty Ltd 125 Collins St. Melbourne No. ......shearing machinery, cooper engineering company pty ltd athol shmith pty ltd -

National Wool Museum

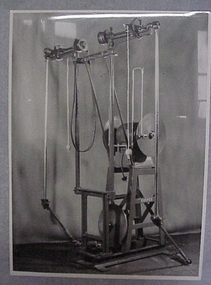

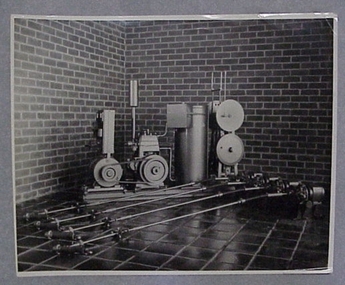

National Wool MuseumPhotograph, Cooper 2-stand self contained shearing plant

Photograph of Cooper shearing plant.Photograph of Coooper shearing plant.Cooper 2-stand self contained shearing plant powered by 1 H.P. electric grinder motor circa 1948 Athol Shmith Studio Illustrative Photography 125 Collins Street Melbourne C.I. Cent. 27 No. ..... Position ....... 2/F/18512shearing machinery, cooper engineering company pty ltd -

National Wool Museum

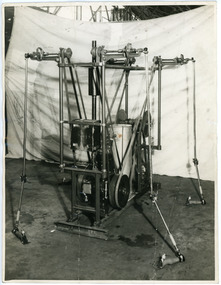

National Wool MuseumPhotograph, Cooper Model "A" contractors portable electric shearing plant

Photograph of Cooper shearing plant.Photograph of Cooper shearing plant.Cooper Model "A" contractors portable electric shearing plant capable of operating up to 4 stands of 220 volt D.C. electric shearing gear circa 1948shearing machinery -

National Wool Museum

National Wool MuseumPhotograph, Cooper small flock 1-stand shearing plant

Photograph of Cooper shearing plant.Photograph of Cooper shearing plant.Cooper Model "A" contractors portable electric shearing plant capable of operating up to 4 stands of 220 volt D.C. electric shearing gear circa 1948shearing machinery -

National Wool Museum

National Wool MuseumPhotograph, 4-stand self contained shearing plant

Photograph of Cooper shearing plant.Photograph of Cooper shearing plant.4-stand self contained shearing plant powered by 4 H.P. Cooper petrol engine designed for use in South Africa circa 1950shearing machinery, cooper engineering company pty ltd -

National Wool Museum

National Wool MuseumPamphlet, Independence Better Shearing Bigger Profits

Pamplet advertising Cooper shearing plants.Pamplet advertising Cooper shearing plants.shearing machinery, cooper engineering company pty ltd -

National Wool Museum

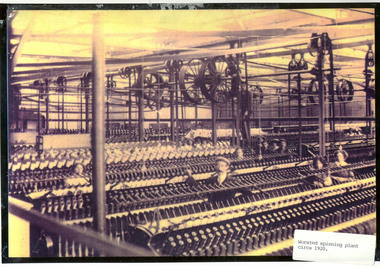

National Wool MuseumPhotograph, Worsted spinning plant circa 1920

Acquired when "Classweave Industries" closed down.Worsted spinning plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

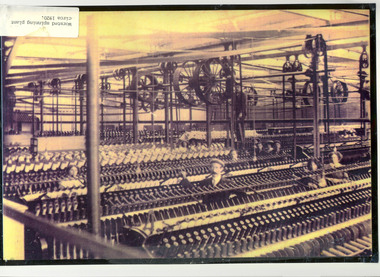

National Wool MuseumPhotograph, Worsted spinning plant circa 1920

Acquired when "Classweave Industries" closed down.Worsted spinning plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills -

National Wool Museum

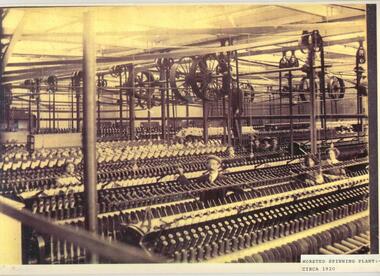

National Wool MuseumPhotograph, Worsted spining plant circa 1920

Acquired when "Classweave Industries" closed down.Worsted spining plant circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, spinning machinery, textile mills, woollen mills, textile mills - staff -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

National Wool MuseumBooklet - Wool Topmaking Training Hints for Operators, Stuart Ascough, 1990s

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.Printed booklet bound with plastic black ring binder consisting of approximately 32 pages. Image on front cover shows textile machinery.front: Wool Topmaking / Training Hints for Operators / Prepared by: / IWS International Pty. Ltd. / Melbourne / Australiastuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, training, technical advice, mills -

National Wool Museum

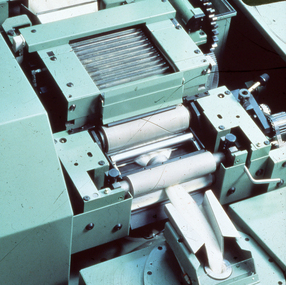

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Box NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of gill box machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

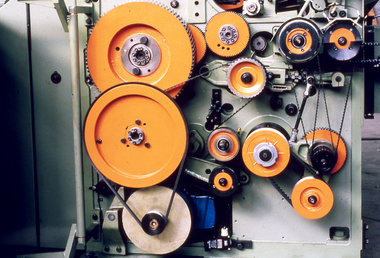

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of combing machinery with orange and black cogs.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

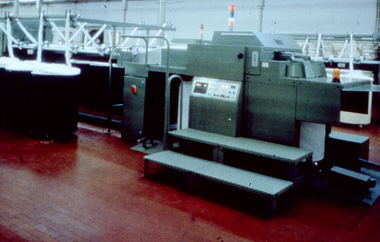

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Box, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing an exterior view of machinery, relating to Gill Box, NSC Schlumberger.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Machinery, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a part of machinery with number keypad, key, lights and buttons.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

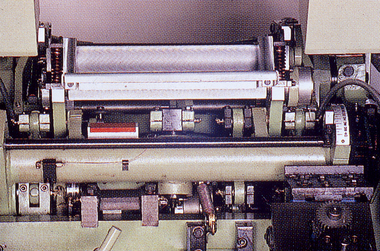

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Box, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing an exterior view of machinery, a Gill Box from NSC Schlumberger.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Boxes, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of a factory, depicting gill box machinery. Staff are shown standing next to machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Tops Used in Laboratory, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a woman using scientific machinery in a laboratory.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Boxes, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of factory, depicting gill box machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box