Showing 313 items

matching stoneware

-

Federation University Art Collection

Federation University Art CollectionCeramic, Serving Dish with Handles by Christopher Headley, c1985, c1985

Wheelthrown hand decorated stoneware platter with Shino glaze.christopher headley, ceramics, jan feder memorial ceramics collection, gippsland campus -

Federation University Art Collection

Federation University Art CollectionCeramic, Set of Four Mixing Bowls

Four Domestic Bowls, Stoneware fired Temaku Glazejilliby pottery, jan feder memorial ceramics collection, mixing bowls, russell thorpe -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Demijohn, n.d

A demijohn is a large, narrow necked bottle for containing liquids such as wine or olive oil. The word is French in origin.Stoneware demijohn with woven cane covering, handle each sidecontainer, liquid, wine -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumJar

Brought to the Ovens Goldfields by Chinese men working in the area in the 19th century. Most likely made in China.Aldo Gios recorded the location of where most pieces in his collection were found. Some maps drawn by Aldo Gios, also give more detail. This detail is rare as most pieces of broken crockery were discarded and complete items were usually collected with no thought to recording the location where they were found. This object is part of one of the largest collections of Chinese ware found in the Upper Ovens area and the only one recording the location where found.Stoneware ginger jar, glazed except base. Green /bluestoneware chinese jar ginger glaze goldfields -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Mortar and Pestle

Stoneware mortar and pestle used for grinding seeds, nuts, etcdomestic items, food preparation -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Wheel Thrown Stoneware Bowl

Belltower Pottery was established by Rudolf Dybka in Kyabram, Victoria, in around 1977 with the help of John Stroomer. Stroomer later took over the pottery, employing as many as 23 workers and apprentices. After a fire in 1988 destroyed the building, Stroomer moved the pottery to the old Kyabram butter factory, where it operated until the late 1990s. Works may be marked with an impressed 'Belltower Pottery' or, after the move to Kyabram, 'Belltower Pottery, Handmade, Kyabram, Vic.'Wheel thrown stoneware bowl with the word 'Nuts' on one side. Stamped "'Belltower Pottery, Handmade, Kyabram, Vic"pottery, belltower pottery, kyabram, australia studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Image, Belltower Pottery, Lidded Wheel Thrown Bowl, c1995

Belltower Pottery was set up by Rudolf Dybka in Kyabram, Victoria, in around 1977 with the help of John Stroomer. Stroomer later took over the pottery, employing as many as 23 workers and apprentices. After a fire in 1988 destroyed the building, Stroomer moved the pottery to the old Kyabram butter factory, where it operated until the late 1990s. Works may be marked with an impressed 'Belltower Pottery' or, after the move to Kyabram, 'Belltower Pottery, Handmade, Kyabram, Vic.'Wheel thrown stoneware bowl with the word 'Nuts' on one side. pottery, belltower pottery, rudolf dybka, john stroomer -

Federation University Art Collection

Federation University Art CollectionArtwork - Ceramic, Kealy, Ruth, 'Tenmoku Jar' by Ruth Kealy, 1994

This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Wheel thrown stoneware lidded jar. Decorated with tenmoku glaze. art, artwork, ruth kealy, ceramics, tafe ceramics collection, available -

Federation University Art Collection

Federation University Art CollectionArtwork - Ceramic, Drew, Sam, (Lidded Urn) by Sam Drew

This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Wheel thrown, stoneware vessel with lid decorated with tin glaze.art, artwork, ceramics, sam drew -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumJar

Brought to the Ovens Goldfields by Chinese men working in the area in the 19th century. Most likely made in China.Aldo Gios recorded the location of where most pieces in his collection were found. Some maps drawn by Aldo Gios, also give more detail. This detail is rare as most pieces of broken crockery were discarded and complete items were usually collected with no thought to recording the location where they were found. This object is part of one of the largest collections of Chinese ware found in the Upper Ovens area and the only one recording the location where found.Stoneware ginger jar, wide opening, glazed except base. Green Chinese writing on base.stoneware chinese jar ginger glaze goldfields -

Hume City Civic Collection

Hume City Civic CollectionStorage jar

This object was used for storage mostly in a domestic situation.A large stoneware storage jar with coloured graduated glaze around neck.containers, domestic items, george evans collection -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Ceramics, Ceramic Canister by NPCP

Photograph of a hand thrown glazed stoneware canister with 'Gum Leaf' design. ceramics, gumleaf decoration, studio pottery, australian studio pottery -

Federation University Art Collection

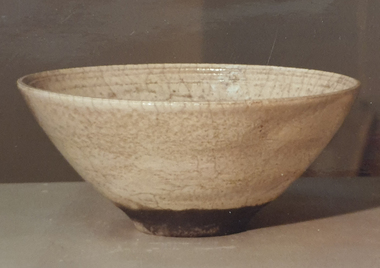

Federation University Art CollectionCeramic, Raku Fired Bowl with White Crackle Glaze by Robin Welch, 1980

Robin WELCH (1936- ) Born Nuneaton, Warwickshire, England Robin Welch is one of the most highly respected contemporary British potters. The full range of his work includes large vessels with related paintings, fine drawings, and distinctive bowls and vases which explore colour, surface texture, form, detail of edge, and line. Initially studying at Penzance School of Art and the Central School of Art, London Robin Welch then worked part-time at the Leach Pottery between 1953 and 1959 before opening his own pottery in London's west end (1960 to 1962). After a couple of years of world travel, including working in Australia from 1962 to1965 helping Ian Sprague set up his Mungeribar Pottery and exhibiting in Melbourne, Robin Welch returned to England setting up Stadbroke Pottery in Eye, Suffolk in 1965. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.Raku Fired stoneware bowl with White Crackle Glaze by Robin Welch Robin Welch stamped on baserobin welch, ceramics, jan feder memorial ceramics collection, gippsland campus -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramic, Moore, Craig, 'Poppy Jar' by Craig Moore, 1993

This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007. See '3rd Year Exhibition 1992' Program (005803)Wheel thrown stoneware lidded jar, decorated with incised and glazed poppies. Signed on base. art, artwork, ceramic, craig moore, ceramics -

![Ceramic - Artwork - Ceramics, Untitled [Jar] by Owen Rye, c1985](/media/collectors/530576742162ef0fa09a2288/items/56b7f40d2162f11c0c8c028a/item-media/59d0cf1e21ea6a0cc8a40145/item-fit-380x285.jpg) Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Untitled [Jar] by Owen Rye, c1985

Owen RYE (05.11.1944 - ) Born Cooma, New South Wales Internationally recognised in the field of Ceramics, Owen Rye was a lecturer at the School of Visual Arts, Gippsland Institute of Advanced Education (incorporated into Monash University 1992), 1985-91 and senior Lecturer at the Gippsland Centre for Art and Design, Monash University (later Federation University) from 1992-2003. Proficient in the use of the wood-fired Anagama kilm, the surface of his work is dependant upon the placement of the item in the kiln, with ash glaze developing where ash and embers coat the form. Wheelthrown Anagama [woodfired] stoneware. Jan Feder Memorial Ceramics Collectionjan feder memorial collection, jan feder, owen rye, ceramics, gippsland campus, artwork, artist, gippsland centre for art and design -

Mont De Lancey

Mont De LanceyStoneware Crock pot

Two toned brown stoneware crockery pot with lid. (1 quart)cooking equipment, cooking pots -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Ceramics, Ceramic Teapot by Ken Hovenden, c1980s

Ken HOVENDEN Working at Bendigo Pottery from April 1972 at the age of 17, Ken Hovenden was also involved in the Lillydale Pottery venture. He worked at Cannie Ridge Pottery for a time, exhibiting work there in 1979. Known as a great thrower, his work featured beautifully fitted lids and quantities of mugs of identical size. In the 1980s, he set up his own pottery at Malmsbury and sold his work through Bangles Gallery at Cobargo. From late 1988 to 1997, he worked under the business name Shiloh Pottery in Castlemaine. His work often features a unique gum leaf design on individually thrown work. Marks used include KH on Bendigo Pottery Epsom Ware, Kevin Hovenden on Badger Creek Pottery, KH on Lillydale Pottery and his own impressed KH initials.Stoneware teapot with beige glaze and handpainted gumleaves, and stamped 'KH' on the footrim.australian studio pottery, ceramics, ken hovenden, teapot -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Vase, c1910

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This item is from the Haeusler collection. It is a stoneware, urn-shaped vase. The mark "V210" underneath the vase identifies it as an Antique Majolica Green Glazed Victorian Mantle Vase. Majolica is an earthenware pottery decorated with a clear lead glaze. It became very popular during the Victorian era. This item is from the Hauseler Collection which documents social life of early settlers in the Wodonga community.A stoneware, urn-shaped vase. It has a waisted square foot, urn shaped body, trumpet neck and two curved side handles. It is decorated with scrolling leaves on the body and leaves on the foot, glazed with a monochrome dark green glaze.Underneath Base V210household items, decorative arts, ceramics, haeusler collection -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaDecorative object - Nativity, Mid - Late 20th C

Group of Polychrome matte glazed stoneware nativity figures - Group of 8 (Incomplete)nativity, mary, joseph, shepherds, kings, animals, jesus, angel, sheep, christmas -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

Very Large Stoneware Jar. Wooden Lid made by R Altman Stawellstawell -

Federation University Art Collection

Federation University Art CollectionMixed media - Artwork, 'Tile I & Tile III' by Caitlin Lowe, 2010

Caitlin LOWE (1990- ) Born Townsville, Queensland Caitlin Lowe completed a Bachelor of Fine Arts (Visual Arts) degree at the University of Ballarat (later Federation University) This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Two framed mixed media artworks consisting of 5 x 5 cm LGH tiles, glazed using Speckled Blue Stoneware and Celadon Stoneware glazes. Presented on handmade paper using cotton hand stitching.art, artwork, mixed media, caitlin lowe, ceramics, available -

Greensborough Historical Society

Greensborough Historical SocietyContainer - Jar, Hoffman Australia, Earthenware storage jar, 1930s

This is an unmarked earthenware storage jar possibly made by the Hoffman's Pottery of Brunswick Victoria. It displays a dark treacle glaze typical of Hoffman's Pottery in the 1930s. this jar would have been used to store foods such as biscuits, flour or rice away from rodent attack. it has a wide mouth to enable easy withdrawal of produce. Originally it would have had a large cork stopper or cloth fastened with a string to seal it.This item was recovered from the abandoned barn of the Pope family in 1971, when the property was sold to the Shire of Diamond Valley. This barn was located on the northern side of Pope Place and sketched by Ron Reynolds for the book "Greensborough and Greenhills".Glazed stoneware jar with dark treacle glaze to top, wide neck. Stopper missing.hoffman pottery, stoneware jars -

Greensborough Historical Society

Greensborough Historical SocietyContainer - Jar, Hoffman Australia, Earthenware storage jar, 1930s

This is an unmarked earthenware storage jar possibly made by the Hoffman's Pottery of Brunswick Victoria. It displays a dark treacle glaze typical of Hoffman's Pottery in the 1930s. this jar would have been used to store foods such as biscuits, flour or rice away from rodent attack. it has a wide mouth to enable easy withdrawal of produce. Originally it would have had a large cork stopper or cloth fastened with a string to seal it.This item was recovered from the abandoned barn of the Pope family in 1971, when the property was sold to the Shire of Diamond Valley. This barn was located on the northern side of Pope Place and sketched by Ron Reynolds for the book "Greensborough and Greenhills".Glazed stoneware jar with light treacle glaze to top, wide neck. Stopper missing.hoffman pottery, stoneware jars -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Alexander Hall and Son, ca. 1855

Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England to Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with a general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in south west Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite the public stir particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime museum that also displays ship fittings and equipment, personal effects. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia.Stoneware Bottle, wide mouthed, covered in white encrustation, recovered from the wreck of the Schomberg. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, stoneware bottle, james baines, black ball, container, clay bottle -

Federation University Art Collection

Federation University Art CollectionCeramic, Bowl by Robin Welch, 1980

Robin WELCH ( 23 July 1936-5 December 2019) Born Nuneaton, Warwickshire, England Robin Welch is one of the most highly respected contemporary British potters. The full range of his work includes large vessels with related paintings, fine drawings, and distinctive bowls and vases which explore colour, surface texture, form, detail of edge, and line. He is one of small group of significant British potters who expanded the language of throwing pots on the wheel through post-wheel additions and alteration. This gave his generally cylindrical forms a more organic and sculptural aspect, but their heavily coloured and textured surfaces were as much about painting, too, as Robin sought an integration of the visual disciplines he enjoyed. As he once wrote: “There’s no divide between art or craft. You decide to be an artist and you’ll use anything. If marooned on a desert island you’d use driftwood.” (https://www.theguardian.com/artanddesign/2019/dec/27/robin-welch-obituary, accessed 23 March 2021) When not in his Suffolk studio Robin Welch spent much time in Australia where he appreciated the outback’s arid earth and brilliant light, its grittier textures and luminous colour, qualities he sought to convey in-the-round and on canvas. Apart from his studion work Robnin Welch was a skilled designer for industry including Wedgwood, Midwinter and Denby. Initially studying at Penzance School of Art under Michael Leach (son of Bernard Leach) and the Central School of Art, London Robin Welch then worked part-time at the Leach Pottery between 1953 and 1959 before opening his own pottery in London's west end (1960 to 1962). After a couple of years of world travel, including working in Australia from 1962 to1965 helping Ian Sprague set up his Mungeribar Pottery and exhibiting in Melbourne, Robin Welch returned to England setting up Stadbroke Pottery in Eye, Suffolk in 1965.Stoneware bowl with split flange, glazed with matt white, black and a touch of copper red Tobin Welch stamped on basejan feder memorial ceramics collection, ceramics, robin welch, gippsland campus, jan feder -

Federation University Art Collection

Federation University Art CollectionCeramic, Jillaine Hurrell Hurrell, Collection of Small, dry glazed Bottles by Jillaine Hurrell, 1982

Jillaine HURRELL This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. A collection of raku-fired stoneware, wheel thrown and altered bottles with dry glaze decoration. jan feder memorial ceramics collection, raku, bottles, ceramics, gippsland campus -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - A collection of assorted stoneware and ceramic canisters

Stoneware or pottery canisters were widely used throughout the late 19th and early 20th centuries for storing and preserving a wide range of kitchen food ingredients. Bendigo Pottery was established in 1858 and is Victoria's oldest working pottery. It was founded by George Duncan Guthrie (1828–1910) who abandoned his potter’s wheel in Scotland to join the Australian gold rush. He found a clay deposit perfectly suited for the production of ceramics, so returned to his former profession as a master potter. The population explosion created by the Australian gold rush resulted in an increased demand for all kinds of locally manufactured goods. The Bendigo Pottery became one of regional Victoria’s most important industrial enterprises. By the late 1800s the Pottery was making all kinds of household wares. One of its most popular lines was the mass produced, affordable and functional earthenware such as these canisters.These items are significant on a state and national level due to the importance of Bendigo pottery as a major Victorian manufacturer whose products were widely used in Australian homes.A group of 3 stoneware and ceramic canisters of assorted sizes. The tallest canister bears the Bendigo Pottery makers mark. The flour canister with the lid and the third canister are unmarked. Similar canister were produced by several companies in the early to mid 20th century. They were commonly used for storing flour, salt and other commodities.At bottom of largest canister "BENDIGO POTTERY" above straight linebendigo pottery, earthernware, kitchen utensils -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Bowl, 1910 to 1950

A mass produced unbranded utilitarian item made for domestic use no history or provenance currently available, design indicates item made before 1950Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as made prior to 1950.Stoneware mixing bowl round cream with pouring lip and decorative scallop relief around bodyNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, bowl, ceramic bowl, pouring bowl, kitchen ware, cooking ware, ironstone bowl, salt glazed, mixing bowl -

Federation University Art Collection

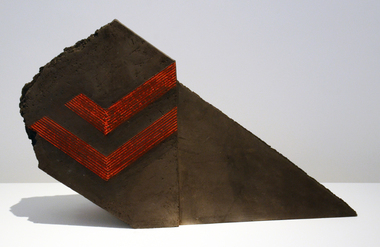

Federation University Art CollectionCeramic - Artwork - Ceramics, Alan Watt, 'Blackfired Form' by Alan Watt, c1985, c1985

Alan WATT (1941- ) Born Melbourne, Victoria Alan Watt studied at RMIT from 1961 to 1965, and he completed a Fellowship Diploma in 1973-4. Alan Watt travelled and studied pottery in Europe and Japan, and lectured in three State a Colleges in Victoria since 1964. in 1984 Alan Watt was a guest lecturer at Spotkanie held at the Gippsland Campus of Advanced Education.Slab built blackfired stoneware. The sculptural form is inspired by the cuts in open cut coal fields. alan watt, ceramics, jan feder memorial ceramics collection, gippsland campus, spotkanie, strezlecki spotkanie