Showing 197 items

matching domestic food preparation

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Cookbook, The Kandy Koola Cookery Book, 1898

This is a cookbook of family recipes and promotes products available for purchase at that time. The products include Kandy Koola, Nestle, Usher’s Whiskey and O.K. Kandy Koola ran an advertisement in the West Gippsland Gazette on 2 May 1911 promoting its tea as perfect for a picnic. The text reads “Picnicking. All as hungry as hunters – made a fire of small twigs – put on our billy of fresh spring water – and waited. Soon bubble, bubble, bubble and the billy boiled. In goes the pure Kandy-Koola Tea. Tea! Tea is not the word – it tasted like nectar! One cup, two cups, three cups – then had to make a fresh billy full. Lazed away the rest of the day sipping our Kandy Koola and chatting. How good indeed! “All grocers sell Kandy Koola Tea. It is pure leaf, selected and blended with the greatest care and skill. Ask your grocer for Kandy Koola . Sold in three grades, i.e. red, blue and green packets” A copy of this cookery book is in the Monash University Library’s Rare Books Collection and has a cover with red printing on a cream background. The price stamp on the corner of the cover is “One Shilling” and is under an image of a crown. The book has 71 pages. It is listed as being published in Melbourne, 1898. The comment given is “This is an early example of an Australian cookbook printed as a product promotion, ‘published by the proprietors of Kandy Koola Tea for presentation to the ladies of Victoria, with compliments.’ “ Flagstaff Hill also has a green Kandy Koola Tea tin in our Collection This Kandy Koola Cookery Book is an example of the recipes, foods, manufacturers, advertisements available and used in the late 19th century in Australia’s colonial times. Food types, preparation and cooking methods show those available to housewives in those times.Book, cookbook, The Kandy Koola Cookery Book and Housewife’s Companion. Small book, pages bound with staples, contained in a black card cover (original outer covers is missing). Pages start at number 11, which is an advertisement for Kandy Koola Tea. The book includes a wide variety of recipes promoting products of Kandy Koola, Nestle, Usher’s Whiskey and O.K. There are pages of line drawings of a ‘Chinese Tea Plantation’ and ‘Natural Bridge in Virginia U.S.A.’ Advertisements include a drawing of a kangaroo. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cookery book, cookbook, australian cookbook, 19th century cookbook, colonial cookbook, domestic, book, promotional cookbook, o.k. preserves manufacturer, nestle, usher’s whiskey, image of chinese tea plantation, image of natural bridge in virginia u.s.a., cook book, kandy koola cookery book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, McKenzies Foods, circa 1930s

This tin once contained McKenzie’s baking powder, a cooking ingredient. It was donated with other similar tins that were used by the donor’s mother who was married in 1932. It those times in Australia all manner of household items, including food and drink, were sold by hawkers (salesmen) who travelled from door to door in both suburban and rural areas. The donor remembered the bicarb soda tin on her mother’s pantry shelf. The McKenzie’s Baking Powder label adds the information that the ingredients were “Prepared with Aerophos, Regd. Trade Mark, the finest raising ingredient. A product of Albright & Wilson, Australia Pty. Ltd.” It also says that it “Excels all others in use”. The Australian family business, McKenzie’s Foods, began in Melbourne in 1852 and continues today, now run be the fifth generation of descendants from the original owners. Its baking and cookery products are well recognised by Australians. This tin originates in the early 1900s from an Australian company that is now managed by fifth generation descendants of the original family after its inception in 1852. The tin increases in significance for its use as a recognised object found in many Australian kitchens since early days. It gives a snapshot into domestic life and social norms of the pre and post war period in Melbourne The tin is significant for its association with a local family in the 1930s for the preparation of family meals. Tin container, cylindrical, with cream paper label with gold highlights, motif and text. Used for selling McKenzie’s Excelsior baking powder. Container has push-on lid. Quantity of 1/2 LB. NETT. Made in Australia by Jas. F. McKenzie & Co. Pty Ltd. Text includes “JAS. F. McKENZIE & CO. PTY. LTD. / AUSTRALIA“ “McKENZIE’S EXCELSIOR / BAKING POWDER”. Motif: man’s portrait within oval frame with wheat sheaf border, placed below figures of sun, moon and stars. Information and instructions. flagstaff hill asset, baking powder tin, container, flagstaff hill museum, kitchen item, cookery, baking, grocery, mckenzie, rising agent, food container, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tin, cooking ingredient, baking powder, mckenqie -

Flagstaff Hill Maritime Museum and Village

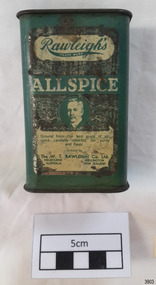

Flagstaff Hill Maritime Museum and VillageContainer - Tin, W T Rawleigh, Circa 1930s

This tin once contained Rawleigh's Allspice, a cooking ingredient. It was donated with other similar tins that were used by the donor’s mother who was married in 1932. It those times in Australia all manner of household items, including food and drink, were sold by hawkers (salesmen) who travelled from door to door in both suburban and rural areas. The donor remembered the tin on her mother’s pantry shelf. The Rawleigh Nutmegs label stated “Selected whole nutmegs not ground but granulated to preserve full strength and flavour.” The company had operated in Melbourne, Australia, and Wellington, New Zealand. W.T. Rawleigh & Co. was established by William Rawleigh in America in 1889 and later expanded into Australia. The company made a variety of household products in a factory in Collins Place, Melbourne, between 1930 and 1935. It specialised in medicines and remedies, food additives, cleaning products and toiletries. The company in Melbourne expanded into their factory in Dawson Street, Brunswick, in the mid-1930s. Independent salesmen, often referred to as ‘The Rawleigh’s man’, sold Rawleigh products door-to-door between the wars and after the Second World War in the Melbourne suburbs. Rayleigh’s products are still produced today. The tin is significant for its association with W.T Rawleigh, one of Melbourne’s strong growing manufacturers in period particularly between the World Wars. Rawleigh’s was, and still is, well known for its household and cleaning products, medicines, food additives and toiletries. The tin increases in significance for its use as a recognised object found in many Australian kitchens since early days. It gives a snapshot into domestic life and social norms of the pre and post war period in Melbourne The tin is significant for its association with a local family in the 1930s for the preparation of family meals. Rawleigh's rectangular Allspice spice tin, green, with directions for use on back and sides of container.Text “Rawleigh’s ALLSPICE” “The W.T. RAWLEIGH Co. Ltd.” “MELGOURNE / AUSTRALIA” “WELLINGTON / NEW ZEALAND” Motif: Man’s portrait in a circle. Other text includes information about spices.flagstaff hill museum, container, spice container, rawleigh company, tin container, kitchen item, tin, cooking ingredient, food container, grocery, allspice, rawleigh co. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, George Salter & Co, Circa 1921

The Hughes’ Family Scale No. 48 is a spring balance scale. It uses the Imperial measurements of ounces and pounds. There are 16 ounces (OZ) in one pound (LB), and each pound equals approximately 454 grams in Metric measurements. Scales have been used to measure and compare items for value for centuries. A weight was placed on one side of a balance and the object was placed on the other. Adjustments were made to either the weight or the object until the balance was horizontal, which meant that each side was the same weight. The Salter family business began in 1760 with spring makers, Richard and William Salter. In the late 18th century, Richard Salter invented the spring scale, where the weight of an object on the tray of the scale causes pressure on a spring in the scale. The pressure caused by gravity was then measured to calculate the weight of an object. Spring scales are still used today along with the more recent and accurate digital scales. The company began manufacturing in West Bromwich, England, in 1770. The firm was taken over by William’s sons, John and George. In 1824, after the death of John, the firm became George Salter & Co. The company produced a wide variety of products, including Britain’s first bathroom scale and the first English typewriter. In 1884 the Salter Trademark of a Staffordshire knot pierced by an arrow was registered. After over 100 years of manufacturing, the company was bought out by Staveley Industries, which was bought by Weigh-Tronix, and then that company was bought by HoMedics Company in 2004.This scale was made by Salter, the company that invented the balance scale, the first British bathroom scale and the first English typewriter. The scale represents the domestic equipment used for measuring in food preparation over 100 years ago. Modern kitchen scales are still using the same principal, along with scales used in business and industry.Scale; a domestic spring balance scale for measuring weight from 0 to 20 pounds. The scale’s grey metal case has a round white dial on the front with black markings, an arrow indicator and a round shallow metal bowl on a pedestal at the top. The scale is raised on a rectangular metal base with outward-sloping sides. An adjustable screw is on the dome top. The scale is marked from 0 to 20 pounds, with each pound marked in 1-ounce increments. The scale is named the Hughes Family Scale No. 48 and was made in Britain by Salter.“HUGHES’ / FAMILY SCALE / No. 48” “BRITISH MADE” “TO WEIGH 20 LBS BY 1 OZ” “SALTER” above logo [knotted rope with an arrow through loops]flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, hughes, salter, british made, family scale, no. 48, spring balance, scale, weighing instrument, weights and measures, weighing machine, kitchen utensil, baking accessory, domestic equipment, cookware, bakeware, kitchen scale, kitchen accessory, food preparation, recipes, cooking, measuring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, W T Rawleigh, Circa 1930s

This tin once contained Rayleigh's Nutmegs, a cooking ingredient. It was donated with other similar tins that were used by the donor’s mother who was married in 1932. It those times in Australia all manner of household items, including food and drink, were sold by hawkers (salesmen) who travelled from door to door in both suburban and rural areas. The donor remembered the tin on her mother’s pantry shelf. The Rawleigh Nutmegs label stated “Selected whole nutmegs not ground but granulated to preserve full strength and flavour.” The company had operated in Melbourne, Australia, and Wellington, New Zealand. W.T. Rawleigh & Co. was established by William Rawleigh in America in 1889 and later expanded into Australia. The company made a variety of household products in a factory in Collins Place, Melbourne, between 1930 and 1935. It specialised in medicines and remedies, food additives, cleaning products and toiletries. The company in Melbourne expanded into their factory in Dawson Street, Brunswick, in the mid-1930s. Independent salesmen, often referred to as ‘The Rawleigh’s man’, sold Rawleigh products door-to-door between the wars and after the Second World War in the Melbourne suburbs. Rayleigh’s products are still produced today. The tin is significant for its association with W.T Rawleigh, one of Melbourne’s strong growing manufacturers in period particularly between the World Wars. Rawleigh’s was, and still is, well known for its household and cleaning products, medicines, food additives and toiletries. The tin increases in significance for its use as a recognised object found in many Australian kitchens since early days. It gives a snapshot into domestic life and social norms of the pre and post war period in Melbourne The tin is significant for its association with a local family in the 1930s for the preparation of family meals. Rawleigh spice tin, rectangular, tall, used for storing Rawleigh's nutmeg. Tin has a flip-top lid, is coloured gold and comes with directions for use on front, back and sides of container.Text includes “W.T. RAWLEIGH Co. Ltd.”, “MELBOURNE / AUSTRALIA”, WELLINGTON / NEW ZEALAND” “Rawleigh’s / NUTMEGS” Motif: man’s portrait in a circle. Other text includes information about spices.tin container, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, food container, tin, kitchen item, container, cooking ingredient, grocery, spice container, nutmeg, rawleigh co. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, McKenzies Foods, circa 1930s

This tin once contained McKenzie’s baking powder, a cooking ingredient. It was donated with other similar tins that were used by the donor’s mother who was married in 1932. It those times in Australia all manner of household items, including food and drink, were sold by hawkers (salesmen) who travelled from door to door in both suburban and rural areas. The donor remembered the bicarb soda tin on her mother’s pantry shelf. The McKenzie’s Baking Powder label adds the information that the ingredients were “Prepared with Aerophos, Regd. Trade Mark, the finest raising ingredient. A product of Albright & Wilson, Australia Pty. Ltd.” It also says that it “Excels all others in use”. The company began in Melbourne in 1852 and continues today, now run be the fifth generation of descendants from the original owners. This tin originates in the early 1900s from an Australian company that is now managed by fifth generation descendants of the original family after its inception in 1852. The tin increases in significance for its use as a recognised object found in many Australian kitchens since early days. It gives a snapshot into domestic life and social norms of the pre and post war period in Melbourne The tin is significant for its association with a local family in the 1930s for the preparation of family meals. Tin container, cylindrical, with cream and green paper label with gold highlights, motif and text. Used for selling McKenzie’s Excelsior baking powder. Container has push-on lid. Quantity of 1LB. NET. Made in Australia by McKenzie Ltd.Text includes “CLIFFORD LOVE, McKENZIE PTY. LTD.” “McKENZIE’S EXCELSIOR / BAKING POWDER”. Motif: man’s portrait within oval frame with wheat sheaf border, placed below figures of sun, moon and stars. Information and instructions. flagstaff hill asset, baking powder tin, container, flagstaff hill museum, kitchen item, cooking ingredients, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tin, cooking ingredient, food container, grocery, cookery, rising agent, baking powder, mckenzie, mckenzie foods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant item giving an snapshot into how early industrial manufacturing became established in Australia in the production of domestic and industrial dairy equipment.Butter churn wooden manually operated made by Cherry and Sons with rotating lever curved plywood basin and parallel cross beamed horizontally spoken churning apparatus inside with wooden plug at lower side of churn. Label in block transfer "E CHERRY / MAKER / GISBORN / VICTORIA / 2" "IMPROVED PATENT"warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, wooden butter churn, e cherry & sons, dairy equipment, gisborne, food preparation -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyButter Stamp Block, Circa 1950

... domestic food preparations. shortbread stamp dairy butter ...At the time when this shortbread / butter stamp block was used, rural dairies and larger properties who manufactured their own butter used butter stamps blocks for identifying the source of the butter or for decoration.. The patterns stamped into the warmed butter provided for a range of decorative visual enhancement to the "plain" and "boring" straight leveled normal butter surface. Although the wooden surfaces could be hard to keep clean commercial usage would have been limited and eventually replaced by a non porous and hygienically cleaner material. Greater hygiene controls where introduced. from the late 1940s on. These controls were the result of high infectious illnesses due to contaminated milk and dairy handling methods.This shortbread / butter stamp was used by a Kiewa Valley dairy and it presents what the domestic butter beautification processes were available during the mid to latter 1900s was. Their was a pride by rural properties in their produce and its by-products.This shortbread / butter stamp is made from wood, round and fashioned from a flat bed to a dome top. The top has a round moulded hole with screw indentations for fastening a pressure pole. The pattern on the face of the stamp is of an eleven petalled flower pattern around a small circular flower head. Both the head and petals have indentations which are will produce raised points in the pressed butter. Enclosing the flower pattern is a pattern which when pressed against the butter would produce small ridges radiating outward.On the dome stamped in black ink "T. & W. Davies"butter stamp, domestic butter blocks, domestic food preparations., shortbread, stamp, dairy, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyShaker Spices, after 1895

This item was used at a time when there was a limited range of spices available and sought after by domestic and commercial kitchens. The taste buds of the average Australian diner were limited to the basic English style dishes which had been delivered by the early colonial days. Rural areas where slower in experimenting with Asian and European cuisine. The influx of European cuisine from refugees fleeing both World War I and world War II brought a different appreciation of gourmet food. The increase in Asian spices was brought about by Australians becoming more aware of the Asian "scene" through the conflicts of Korean and Vietnam military action. The "standard" type spices such as Cinnamon, nutmeg and similar spices offered by Robert Harper and later other Food and Spices whole sellers and processors where a direct result of a greater influx of migrants from spices rich societies and resulted in a greater range of "Asian" spices This became more visible after demise of the "White Australian Policy" on immigration and the great media revolution of Televised cooking shows from the 1950s on. The sustainability of containers such as this re-useable tin and cardboard spice holder, which could be replenished and not thrown away after it was empty was it a time period well before the "throw away" society had crept into the Valley.This spice container was used mainly in domestic kitchen within the Kiewa Valley. Those European construction workers of the SEC Kiewa Hydro Electricity Scheme had brought their continental cuisine into the valley and that was the beginning of a new era in highlighting different tastes. This rural valley had a greater interaction with people from other nation's cuisines and by association became more infused with a broader range of spices and food preparations.This item (spice shaker) is constructed by using a thick cardboard cylinder with both ends closed by tin plated light steel lids. The bottom lid is not removable however the top lid is removable to allow the contents (Cinnamon Spice) to be refilled. The lid has thirteen small holes which allow the contents to be shaken out. The outer side of the cylinder has been covered (glued on) by a printed black and yellow label detailing contents , weight, and supplier.On the front side of the printed label outside of the label boundary is "To make a shaker of this tin - take the lid off and remove the paper from inside the lid" Within the marked horse shoe shaped boundary is" HARPER'S ground spices star brand" underneath "CINNAMON" underneath this is printed "1 oz. NET WEIGHT" and under this, within its own frame " ROBERT HARPER COMPANY LIMITED (incorporated in Victoria) AUSTRALIA." On the back within its own box is "HARPER'S star brand GROUND SPICES" and underneath "These Pure Spices are packed in the following Varieties". Below this is a list (going down) "CINNAMON CARRAWAYS CAYENNE MIXED CLOVES CASSIA CORIANDER GINGER MACE TURMERIC NUTMEGS PIMENTO"kitchen spices, spice shakers, food preparation -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesA cast iron raisin stoner with a clamp. It has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societymincer, 1890's

This item was used by Helena Warren (nee McKeown), a well known photographer and local press correspondent. She lived at Newmerella. The meat mincer was a particularly popular kitchen gadget. By means of the mincer left overs and off cuts could be transformed into shepherd's pie or mince steak. Gadgets like this Universal food chopper are typical of domestic inventions designed to reinforce the principles of thrift and labour-saving. Many of these gadgets were imported from the United States. A cast iron metal hand mincer with a long metal body with an opening at one end, inside which is a circular spiral blade and a screw clamp attachment at the other end. On one side of the mincer is a curved metal handle held in place by a metal nut and a wooden bulb shaped knob at the end. There is a metal circular webbed blade held in place by a metal nut and bolt."Universal No. 2 brand; L.F. & C., New Britain, Conn., U.S.A."mincer chopper food-preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Enterprise Manufacturing Company, circa 1911

... by Silex Co. A mass produced early domestic item made for home food ...This particular food mincer was manufactured by Enterprise Manufacturing Company. Located in Philadelphia, this company specialized in making hardware products. The company was especially known for its cherry pitters, apple peelers, and coffee mills. The company was founded in 1864 and was located on the corner of Dauphin, 3rd, and American Streets. Enterprise Manufacturing Co. remained in business until 1956 when it was bought by Silex Co.A mass produced early domestic item made for home food preparation this item's first patent design was approved in 1897. Manufactured by a well known company in the USA the "Enterprise Manufacturing Company” up until 1956. They specialised in making kitchen appliances of various types for domestic use and for export. Food mincers of the subject items design are still being produced today under the brand name of "Universal" made by Universal Trading Inc USA.Food mincer, metal, clamp on bench style, with rotating wooden handle. Inscriptions stamped on metal.Marked "Enterprise tinned Meat Chopper" "No. 10" "Enterprise MF'G Co. PHILA. USA" "PAT. JAN.30.83" flagstaff hill, warrnambool, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mincer, food mincer, meat mincer, food preparation, kitchen utensil, domestic object, enterprise manufacturing company, kitchen appliance -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, 1900-1920

A colander, sieve or cullender is a kitchen utensil used to strain foods such as pasta or to rinse vegetables. The perforated nature of the bowl allows liquid to drain through while retaining the solids inside it is sometimes also called a pasta strainer or kitchen sieve. Conventionally, colanders are made of a light metal, such as aluminum or thinly rolled stainless or plated steel, colanders are also made of plastic, silicone, ceramic, and enamelware. The word colander comes from the Latin Colum meaning sieve.Early 20th century kitchen item possibly of French manufacture due to the design and shape of the bowl this design appears to have been favoured by the French around 1910 for smaller Colanders. This item gives a snapshot into domestic life around the late 19th and early 20th centuries and the types of kitchen equipment in use.Strainer or colander, metal, with concave base and wood handle, plated metal construction with welded or folded seams. Handle painted black, perforated base.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, strainer, food strainer, seive, food preparation, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fruit Press, 1890-1900

The fruit juice or lemon squeezer is a small kitchen utensil designed to extract juice from lemons or other citrus fruit such as oranges, grapefruit, or lime. It is designed to separate and crush the pulp of the fruit in a way that is easy to operate. Lemon squeezers can be made from any solid, acid-resistant material, such as plastic, glass, metal (usually aluminum) or ceramic. The oldest known lemon squeezers were found in Kütahya, Turkey and date to the first quarter of the 18th century. These ceramic presses are in the traditional style of Turkish pottery of the 18th century and have a superficial resemblance to today's press equipment with cones, though they are designed differently. These examples were individually made, and specially designed for making the then popular citrus drink sorbet. Lemons are not native to northern Turkey, though during the 17th and 18th centuries they were imported in bulk to Constantinople.The fruit juice press is an example of early 20th century kitchen utensils and is not associated with an historical event, person or place, provenance is unable to be determined at this time and the item is believed to have been made around 1900. This item is currently being used in Flagstaffs Hill village display and regarded as significant as it demonstrates domestic kitchen utensils used around the turn of the 19th century and today is a collectable item. Vintage lemon/citrus fruits squeezer cast iron juicer with two sections hinged together strainer on one section has holes for letting liquid escape.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, food press, food preparation, fruit juice press, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Funnel, Late 19th or early 20th Century

A funnel such as this is used to assist in pouring liquids into a narrow container such as a bottle or jar. An item like this could be commonly used in households for food preparation, cooking and soap making. It could also be used for pouring fuel, and medicinal purposes. Enamelware dates back to 1760 in Germany.This object is significant as an example of a type of item in common use in the 19th Century and that is still in use today.Funnel, white enamel with dark rusty metal rim. It has a triangular shaped hook on the top lip for hanging. The metal has been joined down one side.None.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, funnel, food preparation, beverage, laundry, fuel, food preservation, medicinal preparation, decanting, pouring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Knife

This knife would have been used for food preparation.Knife; wooden handle and shaped metal blade with serrated cutting edge.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen knife, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoon

An example of baking equipment used in Victorian times and still used to day.Spoon, wooden, blonde colour. Spoon section tapers to rounded point and handle is flat and shaped.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden spoon, food preparation, baking equipment, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Late 19th or early 20th Century

The colander is an extremely useful tool in the kitchen, as it allows food to be fully drained of liquids such as water or oil. Enamelware dates back to 1760 in Germany.This object is significant as an example of a type of item in common use in the 19th Century and that is still in use today.Mottled blue enamel colander with draining holes in the base and sides. Two thin handles on lip of bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, colander, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board. Wooden, octagonal, plain sanded light wood. Has decoration around edge and indented circular line to delineate round cutting board section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bread board, cutting board, pastry board, kitchen utensil, kitchen equipment, baking equipment, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

... equipment baking domestic cooking cooking equipment food preparation ...Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot

Domestic cooking itemLocal HistoryRound pot with long iron handle and tin lid with handle, grey metallic colour.Kenrick - FIRST QUALITY - 4 QUARTS-No 7 T & C CLARKE & Co. LTD A? 455879 domestic, cooking, kitchen, cast iron, food preparation, cast iron pot, clarke, foundry -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler, Early 20th Century

... preparation Local history domestic cast iron clark food preparation ...Domestic item used for cooking and food preparationLocal historyCast iron oval cooking pot. Hooked handle attached to lugs on side of pot. Tin lid has central handle.Clark & Co 2 1/2 G embossed on side of pot. domestic, cast iron, clark, food preparation, iron pot -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot, A.Kenrick, Early 20th century

... Marsh goldfields Food preparation This is a typical cast iron ...Food preparationThis is a typical cast iron cooking pot used on a wood stove. Used for food preparation.cast iron, oval boiler with centre hook in the handle, 3 gallon capacity, no lidA. Kenrick and sons. West Bromerickdomestic, kitchen, pot, boiler, cast iron -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot, Clark and sons, Early 1900's

Domestic cooking item used on a wood stove.Black oval cast iron pot with handle on one side Makers name embossed on one side.Clark and co. on one side. 6.G/ On bottom black and co. Patened St davids star with O in centrecooking, kitchen, pot, cast iron, food preparation -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler pot with lid, clark and co, early 1900's

... This is a domestic cooking pot used for food preparation. domestic kitchen ...Cooking pot used on wood stoveThis is a domestic cooking pot used for food preparation.oval shaped boiler with a handle and lid, cast ironClark and co. 2 1/2gallonsdomestic, kitchen, pot, boiler, cast iron -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeFork. Toasting

Used for toasting food items over fire.An example of home made ingenuity.Handmade from No. 8 fencing wire. Looped handle twisted together, then separating into 3 7.5 cm long prongs.Nonedomestic, wire, cutlery, fork, utensil, food preparation, toasting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mill, 1950s+

The Moulin Legumes No. 3 food mill is a useful manual kitchen utensil for milling, sieving, grating and pureeing various food types (legumes, vegetables, fruit and herbs). The food is placed in the chamber and the handle is turned to push the food through the holes in the blades and into a bowl placed below it. The various blades allow choice of consistency as they have different sized holes. It was in use before electric food processors were invented and is still used in modern times. The vegetable mill was invented by the French inventor and industrialist, Jean Mantelet, in 1932. Inspired by his wife, he invented the mill, which simply and quickly made cooked food into puree or mash. He said "My greatest pride is to rid women of a daily chore." The business started using the brand Moulinex in 1956 and today is it a household name linked to useful and good quality kitchen utensils and aids. The name comes from combining the words Moulin Express, which was an electric coffee mill. The embossed text "BREVETE S G D G" was a type of French patent without a government guarantee. It stopped being used in 1968. This Moulin is an example of a kitchen utensil used before electric food processors were invented, and had gained popularity to process foods such as vegetable's, fruit, nuts and herbs in a domestic or commercial kitchen. The first model of the Moulin Legunes was invented in 1932 by French industrialist Jean Mantelet to meet the reduce labour for housewives in the kitchen. Millions of this labour saving device have since been sold. Food mill, metal, for manually processing food. Conical-shaped food chamber, two U-shaped handles on opposite sides, two clips inside. Three interchangeable twelve-sided cutting blades, each with different sized holes. Made in France. Model is Moulin Legumes No. 3. Impressed into the side, within a circle "MADE IN FRANCE - BREVETE S G D C -" and in centre "2" (Brevete is French word for Patent)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, made in france, french kitchen utensils, moulin, food preparation, kitchen utensil, food mill, food processor, sieve, moule, mouli, grater, puree, hand operated, moulin legumes no. 3, vingage, kitchen gadget, moulineux, jean mantelet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1920s

Scales such as the subject item were used to measure commercial quantities, possibly grains and farm produce for quite large amounts of product, also in a domestic situation. Bags of grain or other dry goods would have been hooked up and weighed. Salter has been a name long associated with weights and measures. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011.Scale, Salter's improved spring balance, warranted. Brass and iron. Weighs 0 to 25LBS. Long rectangular brass instrument with ring attached to top and hook attached below. Centre of rectangle has long vertical slot with short, horizontal bar that slides down the slot when an object is suspended from the hook, showing its weight on the numbered scale beside the slot.Marked ""SALTER'S IMPROVED SPRING BALANCE" "Number 2". Weighs 0 to 25LBS. flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods, domestic object, kitchen scale, measure, weigh, measure ingredients, food preparation