Showing 193 items

matching sharpening

-

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt. This is able to withstand repeated impact making it suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of a stone tool used by the early Indigenous people of Eastern australia.A handmade stone Aboriginal axe head.axe-head aboriginal tool stone-artefact -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyRazor Personal Vintage, circa 1940s to 1950s

This item(razor) was used by men, only before fashion dictated that women should shave their legs and underarms. There is information that this razor was first used circa 1922 and it lasted up until circa 1958. It permitted the user to have a compact shaving apparatus at hand in any environment. It provided a safe and easy way of sharpening the more permanent blade. This type of razor replaced the straight, open, or cut-throat razors. The mobility of this item was further enhanced by Gillette with their double bladed disposable razor. Time taken(shaving) and costs involved where crucial factors in the ever growing pace of domestic lifestyle in the post 1920s.This historical item presents that, even though the Kiewa Region was an inland rural settlement which in the 1920's was not as close to "modern" fashions and "gadgets", the basic living conditions where still maintained at city levels. This particular razor was in its heyday a sophisticated safety razor and brought down the demand for the services of the "professional" barber(shaver). One of the problems of the superseded straight razor was the high levels of cuts and nicks to the face. As this particular razor was fairly expensive it would have been used by men who were in the middle to upper socio-economical position in Kiewa Valley before the late 1950'sThis item is a Sheffield steel(stamped inside) metal box(Viscount model) containing a red leather fine shaving strap and in its lid a grey honing stone. Both bottom and top lids are removable to allow for replacements of strap and stone. On the bottom lid appears "The Whetter" trade mark, registered in the U.S.A. in 1950.Three bands of a Greek key pattern has been pressed on the lid. A circled identification inscription. " ROLLS RAZOR Ltd, MADE IN ENGLAND" and patented information appears within this inscription. "Patented in England and Abroad. English patents numbers 467383. 284428. 242718. 242717" On the outside of the base lid within a circle are "ROLLS RAZOR" and the sketch of a long haired naked man (side view), crouched, with both hands stretched forward operating the razor. On a slab underneath are the words "The Whetter"safety razor, non disposable, men's shaving implement -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008 Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and so is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of an early axe head used by the Indigenous people of East Gippsland.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, hand made wood plane, c1880

A hand plane is a tool for shaping wood Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle to the cutting edge, render the planed surface very smooth. A cutter which extends below the bottom surface, or sole, of the plane slices off shavings of wood. A large, flat sole on a plane guides the cutter to remove only the highest parts of an imperfect surface, until, after several passes, the surface is flat and smooth.The family of Mr Lamb were early settlers in Moorabbin Shire and had to be self reliant and made their own clothes and tools as they established homes and farms for their families.c1880 A hand made wood planeearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher, at one time mostly used in chair making.A tool of the joiner and other woodworking tradesmen that has been in use since the making of furniture for hundreds of years without much change to the design or how the tool is used to smooth and shape timber.Spokeshave, Marked AH, (believed to be owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Federation University Historical Collection

Federation University Historical CollectionTool, Handshears

Hand shears needed to be very sharp and often had a leather strap or ‘driver’ which passed over the hand. Others had sheepskin bound around the grip. Blades had to be regularly sharpened on a grinding stone. Most hand shears were made in Sheffield, England, with various models produced offering wide or narrow blades, sharp or rounded points, and various grips and bows. The technique of Australian hand shearing gradually developed from the 1830s using the old English method of cutting the flank with hand shears in a series of circular cuts from the sheep’s neck to the tail. In the early 1930s the Ballarat School of Mines introduced a wide-ranging Wool Classing Course as jobs were in extremely short supply during the Great Depression. Metal handshears used for shearing sheep.ballarat school of mines, shearing, woolclassing, sheep -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Education kit - School Writing Slate early 20thC, 20thC

School children learned to write using a slate From 1880’s to mid 1950’s in most schools, very young children first learned to write their letters in sand trays using their fingers or a stick. When about 6, they progressed onto writing on slates . The board was made from a piece of quarry slate set in a wooden frame. A slate pencil (not chalk) was used to form the letters. This slate pencil was often sharpened on the school wall. The advantage of slates over paper was that they could be wiped clean and used again and again. Until the mid 20thC paper was expensive . After the pupil wrote on the Slate, the work was checked by the teacher and then erased for a new task Children had to bring a dampened cloth or sponge to school so that they could clean the slate and start again. The pioneer settlers in the Moorabbin Shire area valued education and established schools for their children in Cheltenham and East Brighton c1860's This writing slate is typical of the type used up to the mid 20th Century in preparatory classes.A writing slate in a wood frame used by school children from c1880s to c1950sschools, education, writing equipment, slate writing boards, victoria melbourne, market gardeners, pioneer, settlers, cheltenham state school no. 84., bentleigh east state school no. 2083, st stephens c of e school tucker road east brighton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher, at one time mostly used in chair making.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. Curved Spokeshave with metal handlesNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, hand plane, joiners tools, wagoner's tools, spokeshave -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane, wagon making, joiners tools, carpenter tools -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - L-30 Chain saw, Lombard, 1962 - 1964

This chainsaw was one of the earliest models sold in Australia. It was manufactured by the Lombard company which was established in 1894 when Nathaniel Lombard developed the first practical water wheel governor in Roxbury, Massachusetts, USA. In 1904, the company moved to Ashland, Massachusetts. During the first World War, Lombard Governor produced hydraulic lathes for the manufacture of artillery shells At the conclusion of the war, Lombard expanded into the areas of chain saws and plastic molding injection machines. This model, the L-30 was only produced for 2 years from 1962 - 1964, primarily due to safety concerns and the fact that it did not have any way to sharpen or tighten the chain. This chainsaw was sold by Mann of Wodonga and donated to the Wodonga and District Historical society by David Mann, owner and manager of Mann Wodonga.This item is significant as it was produced for a limited time. It was also sold by a prominent Wodonga business.A single operator chain saw from Lombard, Ashland, Massachusetts, USA. The chainsaw was relatively lightweight but had no safety features such as a chain brake. It was made primarily of sand cast magnesium. The main cylinder was constructed of aluminium with a cast iron sleeve. It had a manual oil pump, the crankshaft operated on ball bearings and it had a maximum rpm of 4,500. See the Model profile in the accompanying Media item for details.On side of fuel tank: "ONE HALF PINT/SAE-30 OIL/ FOR EACH/ GALLON GASOLINE/ MIX WELL IN SEPARATE CONTAINER/BEFORE FILLING" On opposite side: "STARTING INSTRUCTIONS 1: FILL FUEL TANK WITH PROPER FUEL MIXTURE ( AS NOTED ON TANK) 2. FILL OIL RESERVOIR WITH #30 MOTOR OIL 3. CLOSE CHOKE, MOVE LEVER BACK TOWARDS AIR FILTER 4. HOLD THROTTLE WIDE OPEN 5. PULL STARTER HANDLE SLOWLY UNTIL STARTER ENGAGES, THEN GIVE IT A SHARP YANK 6. AS ENGINE WARMS UP, EASE CHOKE LEVER TO OPEN POSITION"hand tools, vintage chainsaws, david mann, mann wodonga -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, safety razor blade 'King Gillette'', 20thc

King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. Gillette's safety razor retailed for a substantial $5 half the average working man's weekly pay — yet sold by the millions. The most difficult part of development was engineering the blades, as thin, cheap steel was difficult to work and sharpen. This accounts for the delay between the initial idea and the product's introduction. To sell the product, Gillette founded the American Safety Razor Company on September 28, 1901 (changing the company's name to Gillette Safety Razor Company in July 1902). Gillette obtained a trademark registration (0056921) for his portrait and signature on the packaging. Production began in 1903, when he sold a total of 51 razors and 168 blades. The following year, he sold 90,884 razors and 123,648 blades, thanks in part to Gillette's low prices, automated manufacturing techniques and good advertising. By 1908, the corporation had established manufacturing facilities in the United States, Canada, England, France and Germany. Razor sales reached 450,000 units and blade sales exceeded 70 million units in 1915. In 1918, when the U.S. entered World War I, the company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. The company continues in the present day as the Gillette brand of Procter & Gamble, USA. Throughout the 20thC most men used this type of safety razor with disposable stainless steel razor blades to shave their beards prior to the introduction of affordable electric razors in 1960'sA blue packet of unused 'King Gillette' safety razor blades.on top of packet; Press with thumb / and snap end open / GILLETTE QUALITY THE / SAME THE WORLD OVER / FACTORIES IN / USA / CANADA , GREAT BRITAIN / MEXICO , FRANCE / COLUMBIA, GERMANY / BRAZIL, SPAIN / ARGENTINA, AUSTRALIA / GILLETTE TRADE MARK / KING C GILLETTE / RED. TRADE MARKS / GILLETTE (AUST.) PTY. LIMITED / MELBOURNE / DE 2023 / MADE IN AUSTRALIA / shaving equipment, safety razors, gillette king, proctor & gamble, moorabbin, bentleigh, cheltenham, -

Bendigo Historical Society Inc.

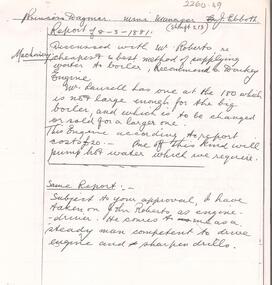

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: PRINCESS DAGMAR MINE, GARDEN GULLY LINE

4 page handwritten document, (copy) detailing some of the Mine Manager's reports for Princess Dagmar mine 1881 - 1914. Example: Reportof 8.3.1881, shaft 213, Mine Manager J. Ebboth. 'Discussed with Mr. Roberts re cheapest and bst method of supplying water to boiler, recommend a donkey engine. Mr. Lansell has one at the 180 which is not large enough for the big boiler and which is to be changed or sold for a larger one. This engine according to report costs 20 pounds. One of this kind will pump hot water which we require. Subject to your approval I have taken on John Roberts as engine driver. He comes to me as a steady man competent to drive engine and sharpen drills.'bendigo, mining, princess dagmar -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

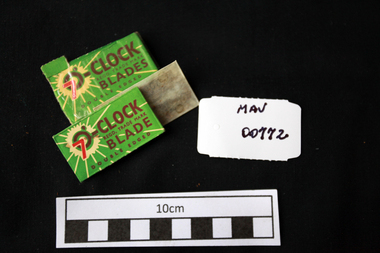

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, man's razor blade in box, 20thC

Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor. Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. In 1918, when the U.S. entered World War I, the Gillette company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. An unused, wrapped, man's razor blade in a box. 7 O'clock brand '7 O'CLOCK / REGD. TRADE MARK / BLADES / DOUBLE EDGED shaving equipment. razorblades, safety razors, cheltenham, moorabbin, bentleigh, pioneers, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers’ Equipment, hair clippers steel, c1950

Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. A set of hand held barbers’ hair clippers with an adjustable screw. Chrome plated, in good condition, c1950 barbers, hairdressing, hair clippers, grooming, horse clippers, steel manufacture, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, metal scythe, c1880

A scythe is an agricultural hand tool for mowing grass or reaping crops. It was largely replaced by horse-drawn and then tractor machinery. A scythe consists of a wooden shaft and a long, curved blade is mounted at the lower end, perpendicular. Scythes always have the blade projecting from the left side when in use. Mowing is done by holding the handle , with the arms straight, the blade parallel to the ground and very close to it, and the body twisted to the right. The body is then twisted steadily to the left, moving the scythe blade along its length in a long arc from right to left, ending in front of the mower, thus depositing the cut grass to the left. Mowing proceeds with a steady rhythm, stopping at frequent intervals to sharpen the blade. The correct technique has a slicing action on the grass, cutting a narrow strip with each stroke Mowing grass is easier when it is damp, and so hay-making traditionally began at dawn and often stopped early, the heat of the day being spent raking and carting the hay cut on previous daysEarly settlers and market gardeners used these scythes as they established their farms in Moorabbin Shire c1880A large metal scythe with a wooden handle x 2early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionCrosscut saw set gauges

The tips of each cutting tooth of a saw are bent (set) slightly away from the plane of the saw. Alternate teeth are set (and sharpened) in opposite directions. The set helps prevent the saw binding in the wood by cutting a kerf (the slot in the wood) that is slightly wider than the saw's thickness. Too little set and the saw binds; too much set results in more work to cut the wider kerf and could lead to too much side movement of the saw and a curving cut. The saw set gauge is used to measure the set of the saw tooth. The amount of set can be from almost nothing in dry hardwood to perhaps 1mm for some softwoods. The spider has three legs of the same length and a longer fourth leg. On a flat surface, the three short legs contact the surface while the long leg is just shy of the surface by the degree of 'set'. The spider is placed such that the three short legs are on the face of the saw with the longer leg touching the tip of the tooth - the tooth is bent to match the gauge.metal spiders used to set the teeth of crosscut sawsforests commission victoria (fcv), hand tools -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Household, Shaving Strop and Brush, Early 20th century

These items are of a high quality and would have come from a household where the occupants had considerable means. It was not common to have silver plating on both of these items. Shaving brushes and strops were essential items for men shaving their faces regularly until the mid to late 20th century when electric shavers became more common. These two items are attractive ones and are retained because they represent a household item of the past and they are a rare example of a shaving strop enclosed within a case. They will be useful for display. .1 This is an extending razor strop made of brown leather. It has a heavily patterned silver handle attached to the leather by metal studs and it is contained within a cylindrical case of plated silver. The case has a heavily-patterned curved base and top and on one side there is an oval outlined space in which to put initials or an inscription. The case has a handle on one end to match the strop handle but this handle is for hanging the item on a hook to keep it upright and stable. This would then enable the user to pull hard on the other handle to use the strop to sharpen a razor .2 This is a shaving brush made of horsehair or other animal hair. It has a silver-plated handle with a double ridge in the middle. It was used to lather a person’s face or skin with cream or soap to lessen chafing during and after shaving. The silver on both items is a little tarnished. ‘British Made Ziff Sterilised’ ‘Falcon Silver Plate Co. Made in England 3533’ household items, history of warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor, Joseph Allen & Sons, 1883-1933

The razor was made between 1883 and 1933 by Joseph Allen & Sons of Sheffield, England. It is a form of shaving equipment used for many years, and still by some today. The shaver would prepare for shaving by lathering the skin and hair with soap and a purpose-made bristle brush before carefully stretching the skin and running the razor over it. The razor's blade would be sharpened with a 'strop' strap. JOSEPH ALLEN (C. 1829-1893) Joseph Allen was born in Dromfield, in the Sheffield district of England in around 1829. He was trained as a razor smith and razor back forger. His business grew and he moved to several addresses. By 1883 his firm was named Joseph Allen & Sons and was exporting his products overseas. In 1883 he paid to use the 'NON-XLL' mark to stamp on his metal products. Joseph's tow sons, Joseph and James, were managing his business by 1900, operating at Ecclesall Works, 245 Rockingham Street in Sheffield. They expanded the range of products to include cutlery as well as razors and bought the use of other trademarks. In 1919 it became a Limited company, trading until 1933. This vintage razor represents men's grooming equipment in use over many decades, and even today. The maker is well-known for its quality workmanship and materials.Razor, metal blade with synthetic handle. Blade has steel handle. Razor is contained in black cardboard box. Made by Joseph Allen & Sons of Sheffield, England. On blade "NON - XXL" "Joseph Allen & Sons, Sheffield, England"flagstaff hill, warrnambool, shipwreck-coast, shipwreck coast, flagstaff hill maritime museum & village, maritime museum, joseph allen & sons, sheffield, raxor, shaving equipment, personal grooming, men's toiletries, shaving aid, ecclesall works, non-xll, vintage razor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Numurkah & District Historical Society

Numurkah & District Historical SocietyCarpentry Tools & Storage Box

These carpentry items were owned and used by Archibald (Mick) Blackley, a local long-time resident of Numurkah. Born 1912 in Numurkah, Mick was the son of Archibald (Senior) and Grace Blackley, also residents of Numurkah. Archie Senior was a carter, horse-breaker, conducted a livery stable and worked at Brown Corke & Co for a number of years. Archie also served in the Veterinary Corps in WW1. Some of the tools donated belonged to Archie Senior eg wooden hand planes. Mick Blackley used his dad’s tools (and also added some of his own) when he worked in various carpentry jobs during the 1930’s and 1940’s. One particular carpentry job was during the depression when Mick relocated to the Wonthaggi State Coal Mines building stables for the horses, and also completing some building works inside the mines. Returning to Numurkah, Mick joined a Mr Murray as carpenter and painter to build and repair houses. He then joined another builder for 4 years (We think this was Jim Tuttle). Mick then went on to work at the Butter Factory (originally called Holdenson & Nielsen) where some of his carpentry skills were still used. Item list: • Wooden box for carpentry tools • 1 x steel pliers • 2 x wooden hand planes • 1 x tin snips • 1 x wooden spirit level in canvas bag • 1 x small wooden spirit level • 5 x wooden handled hand-saws • 1 x wooden handled right- angle square • 1 x wooden handled tenon-saw • 1 x steel plumbers wrench • 1 x wooden handled hedge-clippers • 1 x cloth & leather measuring tape • 1 x wooden mallet • 1 x narrow wooden plane • 1 x plastic handled hand-saw • 1 x plane blade sharpening stone • 1 x brace hand drill • 1 x compass for marking wood • 1 x cold chisel • 1 x set of various chisels and hand drill bits in a canvas bag • 1 x steel sike • Various other drill bits, chisels, files • 1 x wooden handled trowel • • 2 x steel garden secateurs • carpentry, building, wood, tools, planes, levels, chisels, hammers, saws, drills, drill bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Bendigo Military Museum

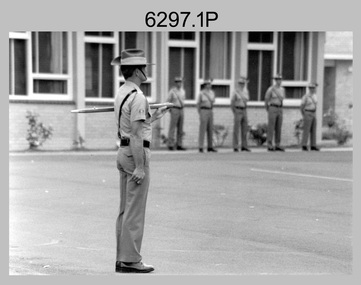

Bendigo Military MuseumPhotograph - Army Survey Regiment – RSM Handover at CO's Parade, Fortuna, Bendigo, 1995

These 15 photographs were taken in 1995 during a CO’s Parade at the Army Survey Regiment, Fortuna, Bendigo in 1995. On this occasion outgoing RSM WO1 Phil Meagher handed over to incoming RSM WO1 Ken Johnston OAM MM. WO1 Phillip Nicholas Meagher served in the Australian Regular Army (ARA) from Jan 1971 to Jun 1997. He was RSM of the Army Survey Regiment from 1992 to 1995. He was succeeded by WO1 Ken Johnston OAM MM from the Royal Australian Infantry Corps, who was RSM for the remainder of 1995. WO1 Johnston served in the Citizens’ Military Force and the ARA from Feb 1966 to Mar 2002. A tribute in the Army Newspaper on the 14 May 2014 and discoverable on the Trove website, stated he passed away on 12 May 2014. In this tribute it stated he was a Vietnam War Military Medal recipient, known as a “Digger’s Digger” and for his direct no-nonsense approach. As RSM of the Army Survey Regiment, WO1 Johnston was instrumental in shaping and sharpening the military skills and behaviours of personnel who chose to continue in their reallocation to other corps in the ARA or the 1st Topographic Support Squadron in Enoggera, QLD. His tenure is covered in more detail on page 164 of Valerie Lovejoy’s book 'Mapmakers of Fortuna – A history of the Army Survey Regiment’ ISBN: 0-646-42120-4. On this occasion CO LTCOL Duncan Burns presented MAJ Mick Banham the Defence Force Service Medal for 15 years of efficient remunerated service in the Australian Army. This is a set of 15 photographs taken of a RSM Handover at a CO’s Parade at the Army Survey Regiment, Fortuna, Bendigo, 1995. The photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, black & white, 1995. Outgoing RSM WO1 Phil Meagher. .2) - Photo, black & white, 1995. L to R: MAJ Mick Banham, outgoing RSM WO1 Phil Meagher. .3) - Photo, black & white, 1995. L to R: CO LTCOL Duncan Burns, MAJ Mick Banham. .4) - Photo, black & white, 1995. L to R: ADJT CAPT Brenton McDonald, RP SGT Peter Coles, CO LTCOL Duncan Burns, MAJ Mick Banham receiving Defence Force Service Medal. .5) - Photo, black & white, 1995. L to R: ADJT CAPT Brenton McDonald, CO LTCOL Duncan Burns, MAJ Mick Banham (background), outgoing RSM WO1 Phil Meagher, incoming RSM WO1 Ken Johnston OAM MM, CAPT Bin Fashar Sutiman (Indonesian Army). .6) - Photo, black & white, 1995. L to R: SGT Perry Langberg, MAJ Dave Stephenson, SPR Trevor King, SPR Craig Smith, CAPT Colin Davidson, LCPL Mark Fedden, SPR Donna Grayland. .7) - Photo, black & white, 1995. L to R: unidentified (x3), RSM WO1 Phil Meagher, SGT Darren Wilkinson, SSGT Steve Drummond, unidentified, SPR Donna Grayland, SPR Allison Ottaway, unidentified, back of ADJT CAPT Brenton McDonald, unidentified (x4), CPL Darren Maher, SGT Laurie Justin. .8) - Photo, black & white, 1995. Outgoing RSM WO1 Phil Meagher, remainder unidentified. .9) - Photo, black & white, 1995. L to R: WO2 Peter Imeson, CPL Darren Maher, unidentified, SSGT Steve Winner. .10) - Photo, black & white, 1995. L to R: MAJ Mick Banham, ADJT CAPT Brenton McDonald, CAPT Doug Arman, WO1 Phil Meagher, CAPT Bin Fashar Sutiman (Indonesian Army), WO1 Ken Johnston OAM MM, CAPT Bill Griggs, unidentified. .11) - Photo, black & white, 1995. L to R: WO1 Ken Johnston OAM MM, ADJT CAPT Brenton McDonald. .12) - Photo, black & white, 1995. Outgoing RSM WO1 Phil Meagher. .13) - Photo, black & white, 1995. L to R: Outgoing WO1 Phil Meagher, incoming RSM WO1 Ken Johnston OAM MM. .14) - Photo, black & white, 1995. L to R: Incoming RSM WO1 Ken Johnston OAM MM, outgoing WO1 Phil Meagher. .15) - Photo, black & white, 1995. L to R: MAJ Mick Banham, RP SGT Peter Coles, outgoing RSM WO1 Phil Meagher..1P to.15P – There are no annotations.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Federation University Historical Collection

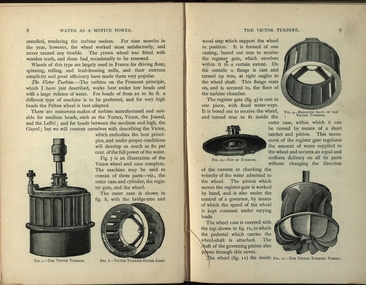

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Set of desks & benches, Unknown

The following are the recollections of John Elkins, who started school in February, 1945 at Maryborough in Queensland, Australia. 'I think in Prep 1 that we had some paper to write on with pencils, but my memory of the routine use of slates is much more vivid. Each slate was framed in wood and one side was inscribed with lines to guide the limits for the upper and lower extremities of letters. The slate "pencils" were made of some pale gray mineral softer than slate which had been milled into cylinders some one-eighth of an inch in diameter and inserted into metal holders so that about an inch protruded. Each student was equipped with a small tobacco tin in which was kept a damp sponge or cloth to erase the marks. Sharpening slate pencils was a regular task. We rubbed them on any suitable brick or concrete surface in the school yard. Teachers also kept a good supply of spares, all writing materials and books being provided by the school. It is possible that the retention of slates stemmed from the political imperative that public education should be free. I do recall being given a Copy Book for home practice of letter formation, a typical practice until Grade 6. The tables at which we used to sit in the Infant School were replaced in the primary Grades by long desks seating five or six pupils. These had slots into which the slates could be inserted vertically. When the teacher asked the class to clear their desks, the command issued was "slates away!" This was an occasion for a noisy expression of relief as we dropped the slates producing a sound not unlike a volley of rifle shots, and usually brought a request from the teacher to repeat the process with no noise by holding the frames throughout. Thus, I suspect we may still have used slates in Grade Three, though by then paper, which may have been scarce during the War, seemed to be used more routinely.' The full context of John's account of writing during his primary school days can be found at: https://www.readinghalloffame.org/sites/default/files/history_of_literacy_22slates_away22_penmanship_in_queensland_australia.pdfSchool desks and benches/chairs have been in use in schools since formal group education started.Eight long school desks (five higher three lower), each with four inkwells and groove along length. eight school benches (five higher three lower). Each desk and bench accommodates four children.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Spokeshave steel ornate, c1900

A spokeshave is a tool used to shape and smooth wooden rods and shafts - often for use as wheel spokes, chair legs . Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. Spokeshaves can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, whilst the body and handles were wood. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached. Like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth century metal handles and detachable blades had become the most common. Preston Tools was an English tool making company also known as E.P. Tools and Edward Preston Tools. Edward Preston Sr. (1805-1883) was first listed as a plane maker at 77 Lichfield Street in the 1833 Birmingham Directory but it is believed he may have started business there as early as 1825. Around 1850 his son, Edward Preston Jr. (1835-1908) left school to join his father's business and he later started up his own "wood and brass spirit level manufactory" at 97-1/2 Lichfield Street by 1864. By 1866 Edward Jr. had added planes, routers, joiners, coach, gun, cabinet and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to a much larger premises at 22-24 Whittall Street. This later became the office and factory of Edward Preston and Sons, who were forced to liquidate in 1934, due mainly to the Great Depression and mismanagement of the company. The plane making concern was sold to the Sheffield firm of C. & J. Hampton, who had subsequently merged in 1932 with Record Ridgeway Ltd.An ornate steel spokeshave wood plane with an adjustable screw.PRESTONS PATENTwoodwork, tools, spokeshave, moorabbin, cheltenham, bentleigh, early settlers, pioneers, market gardeners, woodplanes, craftwork, bicycle wheels, furniture, cabinetmaking, cartwheels, wagons, drays, preston edward, preston tools ltd