Showing 1262 items matching "sheep and wool"

-

National Wool Museum

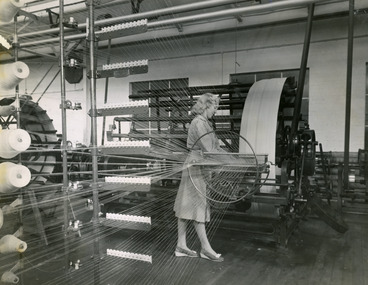

National Wool MuseumPhotograph - Warping Machine, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a woman working at a warping machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W24 / W24. Warping.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumPhotograph - Dyeing Wool, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a man working at vats dyeing wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W28 / W28. Dyeing Wool.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

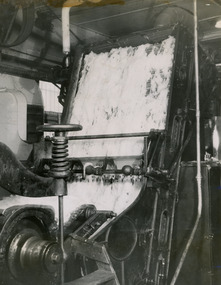

National Wool MuseumPhotograph - From Scourer to Dryer, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a wool moving through machinery.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W11 / W11. From Scourer to Dryer.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumPhotograph - Mending, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing close up of a hand mending wool textiles.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W39 / Mendingwool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumMillion Dollar Bale Wool Sample, 1995

The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at $600/kg and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at $10,300/kg, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labeled Kadinia.Wool sample from the Million Dollar Balewool sales, million dollar bale -

National Wool Museum

National Wool MuseumCloth sample, 1816-1821

Cloth sample from an opera cloak made in England c. 1820 from wool clipped from Macarthur's merino sheep in 1816. The cloak was passed down through the family to Harold Lethbridge with whom the main part of the cloak resides, in Narrandera. The fragment was passed to Lethbridge's niece who gave it to the donor's mother who passed it onto him and then it was donated to the National Wool Museum. The cloth fragment was tested by Gordon Institute of Technology in 1974 showing the wool to be very fine (15-16 microns) which is consistent with the pure lineage of Macarthur's sheep. The cloth fragment was framed in 1952 and remains in the original frame to this day. Cloth sample form an opera cloak made in England c. 1820. Wool for the cloak was clipped from John Macarthur’s merino sheep in 1816. Macarthur is recognised as the pioneer of the wool industry that was to boom in Australia in the early 19th century and become a trademark of the nation. Macarthur was responsible for the first bale of Australian wool to be exported. The British woollen mills were desperate for wool at the time because of the Napoleonic blockade, and the Australian bale sold for a record price. Australia needed a product to sell in European markets which did not perish during long sea-voyages and which offered high value per unit of weight. Wool also had a ready market in England because the Napoleonic Wars had increased demand and cut English cloth-makers off from their traditional source of quality wool, Spain. Australia's first $2 banknote featured John Macarthur thanks largely to his establishment of wool as the backbone of the early Australian economy. Red fabric sample folded in half and mounted in the centre of a brown metal frame.'ARCO' MADE IN ENGLANDmacarthur, wool industry, australian economy -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 26, Dec. 1962

"Sheep Liaison Notes" no. 26, December 1962. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W.R. MONTGOMERYwool growing, csiro agricultural research liaison section -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 27, Feb. 1963

"Sheep Liaison Notes" no. 27, February 1963. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W.R. MONTGOMERYwool growing, csiro agricultural research liaison section -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 28, April 1963

"Sheep Liaison Notes" no. 28, April 1963. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W.R. MONTGOMERYwool growing, csiro agricultural research liaison section -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 30, Oct. 1963

"Sheep Liaison Notes" no. 30, October 1963. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W.R. MONTGOMERYwool growing, csiro agricultural research liaison section -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 32, May 1964

"Sheep Liaison Notes" no. 32, May 1964. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W.R. MONTGOMERYwool growing sheep - parasites, csiro agricultural research liaison section, wool growing, sheep - parasites -

National Wool Museum

National Wool MuseumJournal, Sheep Liaison Notes no. 37, June 1967

"Sheep Liaison Notes" no. 37, June 1967. 'Wool Production' issue. Produced by the Agricultural Research Liaison Section of CSIRO. Limited circulation publication produced for extension officers in State Departments.W. Montgomerywool growing, csiro agricultural research liaison section -

National Wool Museum

National Wool MuseumPhotograph - The Australian Eleven, 1935

"The Australian Eleven", from the display board which hung in the Geelong Wool Exchange, Corio St, Geelong until the building was sold in 1985. Sheep were from the "Wanganella" station in Victoria.Panoramic black and white photograph of eleven merino rams in full fleece, standing in a row in front of a wire fence. The photograph has a dark, tree-lined background and each side has been blackened out. Photograph is glued to cream cardboard. Bands of glue are visible where photograph has been fixed to mounting board. Grey paper pieces glued to the back of the cream board.merino sheep, sheep australian, pastoral industry history, geelong woolbrokers' association geelong wool exchange, western district, victoria, 'wanganella' victoria, sheep - australian, pastoral industry - history -

National Wool Museum

National Wool MuseumShearer's Tally Book

Used for keeping record of sheep shorn by individual shearers. The final number of sheep shorn by each shearer are used to calculate payment. Provides wool grower with statistical information about how many sheep on property and where they are. Depends how many people on site who keeps the shearers tallies eg the contractor, property owner, station hand. Used also to keep shearers honest about their totals and therefore their pay.Booklet with image of man shearing a sheep.Shearer's Tally Book. Eldersshearers, tally book, shearing, sheep -

National Wool Museum

National Wool MuseumSlide, Medium Merino ram

Slide of a medium Merino ram. Medium or Peppin merinos are found in the vast inland of Australia where rainfall varies between ten and twenty inches annually. Peppin-type sheep produce the greatest quantity of wool of any breed or type of sheep in Australia. Formerly stored in presentation folder as part of "Merino & Australasian Breeds of Sheep Set No. A866" series by the Audio Visual Education Centre, Education Department of Victoria.Merino & Australasian Breeds / of Sheep / Set No. A866 / No. 3 / Medium Merino Ram VISUAL EDUCATION CENTRE / EDUCATION DEPT. OF VICTORIAmerino sheep, peppin merino sheep, peppin-merino sheep -

National Wool Museum

National Wool MuseumLetter

Letter from F D McMaster, "F D McMaster Pty Ltd", Dalkeith, Cassilis, 1941 to W.R. Lang, Gordon Institute of Technology, Geelong re. wool samples and sheep breedingsheep breeding wool - testing merino sheep - history world war ii, f d mcmaster pty ltd, lang, dr w. roy mcmaster, f d, sheep breeding, wool - testing, merino sheep - history, world war ii -

National Wool Museum

National Wool MuseumTaxidermy Sheep, Blossom, c1980

The success of any flock is through the strength of its females and Blossom, a Border Leicester/Merino Cross ewe is an excellent example. Border Leicester rams are mated with Merino ewes to produce fat lamb mothers. These first cross ewes are mated with meat sheep, such as Dorsets to produce hybrids that pass on quality wool characteristics to their offspring. The Border Leicester/Merino crosses produce good quantities of wool which, despite being of stronger micron than most Merino fleece wool (34 to 38 microns), is still in demand in the marketplace. The Border Leicester sheep takes its name from the border country between England and Scotland, the area in which the breed was first developed in the late 18th century.Border Leicester/Merino Cross ewe. Long body with white fleece. The nose is black and she has large ears, upright and alert. The head and legs are free of wool.drysdale, sheep, new zealand -

National Wool Museum

National Wool MuseumSculpture - Bollard, Jan Mitchell, The Lost Bollards, 1999

Geelong is famous for its bollards. Created by local artist Jan Mitchell, the colourful bollards spot the foreshore, representing a fascinating and fun chronicle of the city’s past. Few people know that Mitchell planned for a flock of sheep to be part of her public art project. The wool industry is an important part of Geelong’s history, so Mitchell thought what better than a flock of sheep to welcome people to the city. The flock (and a Shepard) were to be placed out on the Melbourne-Geelong highway, near Lara, to welcome travellers to the city. The sheep would then be scattered along the road as a wayfinding signal to bring people to Geelong. When traffic authorities heard the plan for bollard sheep along the road, they squashed the project as a potential distraction for drivers. Another flock was also suggested for the hills of the eastern gardens, overlooking the bay. This was also disapproved; so Mitchell only ever partially completed four sheep bollards. The bollards are remnants of Jan Mitchell’s flock of sheep. The sheep also show the evolution of one of Geelong’s most iconic art installations. From the first sheep showing the raw timber of the old Yarra Street pier, to the sheep without a face, through to the completed sheep, it is possible to trace Mitchell’s process in the preparation of the bollards. The lost bollards form part of the National Wool Museum’s unique collection. The first bollard is the least complete, still in its original timber colour. From the central cylindrical shape, an additional wedge protrudes. This unpainted wedge forms what would have been the face of the sheep, with an ear present on either side that would have been painted white. Presently they are a bare metal. No legs are present on this bollard. The second and third bollard are completed to a similar level. They have a central cylindrical shape with an additional wedge protruding from the front of the timber. This wedge forms what would have been the face of the sheep, with an ear present on either side. The face and ears have been painted white but the finer details such as the eyes have not been added. These bollards bodies have also been painted white and have their legs attached. The legs are thin metal cylinders, approximately 50mm in diameter and 500mm long. The fourth bollard Is complete. It has the same central cylindrical shape with an additional wedge protruding from the front of the timber. This wedge forms the completed face of the sheep, with an ear present on either side that has been painted white. The face also features completed painted eyes. This bollard has its legs attached. The legs are thin metal cylinders, approximately 50mm in diameter and 500mm long. geelong, bollards, geelong's bollards, jan mitchell -

City of Greater Bendigo - Civic Collection

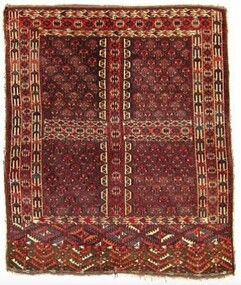

City of Greater Bendigo - Civic CollectionTextile - Yomut Turkmen Islamic Rug, c 1880

This rug was a gift and gesture of friendship from the local Muslim community to the City of Greater Bendigo. It was presented to Mayor, Cr Rod Fyffe on behalf of the people of Bendigo at a 2016 'Thank You Bendigo' dinner. In 2014 approval for a planning application from the Bendigo Islamic Association to build a community centre and mosque in East Bendigo prompted a series of public protests that captured widespread media attention. During this tumultuous period the Council identified the need for a community-wide plan to promote diversity and help address potentially divisive cultural issues. These events led to the COGB becoming the first local government area (LGA) formally accredited under Australia’s Welcoming Cities Standard. Community leaders emerged who wanted to show that the anti-mosque protesters did not reflect the views of the majority of Bendigo residents. The community lead ‘Believe in Bendigo’ movement gained momentum, and the Council and other local organisations joined forces to present a unified message that Bendigo residents do not tolerate racism. Muslims have made Central Victoria their home since the Goldrush, contributing to the community and the economy for the past 120 years. Traditional Islamic rugs, especially their patterns and motifs are intrinsically linked with the design of the Bendigo Mosque and Bendigo Islamic Community Centre providing important points of reference for the architects of the project. Typically, mosques are linked with specific cultural groups but not in the case of Bendigo where the Muslim community is made up of multi-ethnic groups. This meant the building's design was not fixed to a specific style or cultural iconography but instead needed to encompass many. The small local Muslim community selected a specific Australian architect because of their interest and knowledge of Islamic design and iconography gained through family collection of Islamic textiles. In thinking about the design of the mosque and community centre the architects wanted to acknowledge the role of Afghans in Australian history, especially tribal Afghans who helped build connections across the interior of Australia between First Nations communities, European settlers and Central Asian migrants. The gift of this Turkmen rugto the Bendigo community thus symbolises collaborative partnerships across faith and cultural groups based on friendship and mutual benefit. A Turkman rug was specifically chosen as it is the pinnacle of nomadic arts of the Islamic world. It was also important to the architects and the local Muslim community that the gift was a female artistic product as it was mainly a female Muslim architecture team that designed the mosque in Bendigo and there was a desire to select something that celebrated female artistry. This hand-woven rug is an engsi, made for a woman in preparation for marriage. Design work and weaving is a shared experience, between many generations of women and each rug hold the personal story of the woman it is made for and her family and thus holds deep symbolic meaning. There are often songs and poetry that are recited as the rug is made – helping the makers to memorisze the mathematical structure of the design. An engsi is put on the doorway to a yurt as part of a wedding ceremony. During the ceremony the groom turns the engsii upside down to check the quality of the rug makers weaving skills. The nomadic lifestyle of Yomut Turkman tribes determines the size of the rug as the loom can’t be carried. Its size is also restricted by the dimensions of the doorway of the yurt. This rug is dated as c 1880 because of the types of patterns used, the use of natural dyes (synthetic dyes were introduced to the area in 1890s) and with the smoother weaving on the back indicating the quality of craftsmanship dating to this time period. The Yomut engsi rug was made in Turkmenistan c1880 by Yomut Turkmen Tribes people and is designed to fit over the doorway of a yurt during a wedding ceremony. The main field motif is related to Turkoman jewelery design. The women and girls of the tribe spin the wool and design and weave the rugs. The men shear the sheep, dye the wool and clip the rug after it has been woven. The word “Turkoman” is thought to have been derived from Turk-iman, meaning the first nomadic Turkic tribes that began to follow Islam. Dyes used are natural including orange from madder root. bendigo mosque, bendigo islamic association, city of greater bendigo community partnerships, city of greater bendigo community groups -

National Wool Museum

National Wool MuseumPhotograph - Armed Guards with Million Dollar Bale, 11 January 1995

This photograph shows armed guards and Wool Manager Keith Jackson posing with the million dollar wool bale after it was sold by auctioneer Michael Crooks on the 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men with a bale of wool in front of an armaguard truck. Two of the men are armed guards standing either side of the wool bale, one is holding a shotgun. Another man in a suit and tie is crouching near the bale.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, armed guards, armaguard -

Warrnambool and District Historical Society Inc.

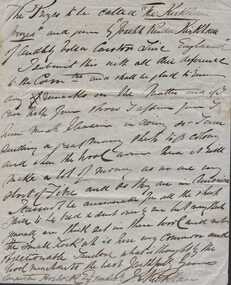

Warrnambool and District Historical Society Inc.Document, Letter J Kirkham, 1873

From other correspondence in this collection of letters we have established that Mr Kirkham is a breeder of long wool Lincoln sheep who was eager to establish the breed in Australia and New Zealand. Augustus Bostock is mentioned at the bottom of this letter To that end, he speaks of establishing a number of prizes called the Kirkham prizes with the emphasis being on the quality of the wool. He states as an aside at the end of the letter,” I have now determined to export my best sheep leaving the home ** to my father and nephew, I would like to number ** amongst my customersThis letter shows the link between wool breeders in England and their efforts to establish connections and supplies in Australia.Large cream sheet of paper with black ink hand writing .Back of sheet is blank. Folded in half.Signed Kirkham.warrnambool, j kirkham, augustus bostock, long wool lincoln sheep, long wool lincoln -

National Wool Museum

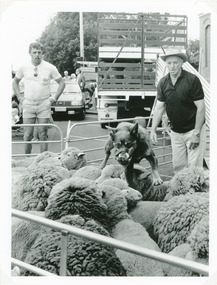

National Wool MuseumPhotograph

Depicts a dog with owner working sheep in pen at official opening of National Wool Museum held on the 21st December 1988. (Contact: Kevin Boyle, editor, Weekly Times, for permission for any further display).sheep dogs, national wool museum, photographs -

National Wool Museum

National Wool MuseumTool - Pullover

Chrome plated pullover used to close wool bales. In early use at Strachans (a lighter, simple long handled hook was used later). Chrome plated tool with wood handle. Tool pivots at two points and has hooks on the end. The wood handle also has string binding. chrome, baling hook, pullover, tool, sheep, wool, industry -

Great Stupa of Universal Compassion

Great Stupa of Universal CompassionClothing - Tibetan hat with fur flaps

Tibetan felt hats, typically made from wool felt crafted from sheep or yak wool, are well-suited to the harsh, cold climate of the Tibetan Plateau. A lining and decorative elements, such as embroidery or patterns, are often added. The fur flaps, made from rabbit or fox fur, provide extra warmth. Felt hats are worn by both men and women.Tibetan hats (also known as ‘chuba hats’ or ‘tsamtha’) are rich in cultural significance. They are often worn during religious ceremonies, festivals, and other important occasions. The design and quality of a hat can indicate the wearer's social status or role within the community.Traditional Tibetan hat with silk brocaded crown in dark and light brown colours, with orange and green flower pattern, and large fur flaps.everyday life, clothing, hats -

Great Stupa of Universal Compassion

Great Stupa of Universal CompassionClothing - Tibetan hat with fur flaps

Tibetan felt hats, typically made from wool felt crafted from sheep or yak wool, are well-suited to the harsh, cold climate of the Tibetan Plateau. A lining and decorative elements, such as embroidery or patterns, are often added. The fur flaps, made from rabbit or fox fur, provide extra warmth. Felt hats are worn by both men and women. Tibetan hats (also known as ‘chuba hats’ or ‘tsamtha’) are rich in cultural significance. They are often worn during religious ceremonies, festivals, and other important occasions. The design and quality of a hat can indicate the wearer's social status or role within the community.Traditional Tibetan hat with silk brocaded crown in blue, red and golden colours, and large fur flaps. The TFG initials written in ink inside.everyday life, clothing, hats -

Great Stupa of Universal Compassion

Great Stupa of Universal CompassionClothing - Tibetan hat with fur flaps

Tibetan felt hats, typically made from wool felt crafted from sheep or yak wool, are well-suited to the harsh, cold climate of the Tibetan Plateau. A lining and decorative elements, such as embroidery or patterns, are often added. The fur flaps, made from rabbit or fox fur, provide extra warmth. Felt hats are worn by both men and women.Tibetan hats (also known as ‘chuba hats’ or ‘tsamtha’) are rich in cultural significance. They are often worn during religious ceremonies, festivals, and other important occasions. The design and quality of a hat can indicate the wearer's social status or role within the community.Traditional Tibetan hat with silk brocaded crown; it has dark brown background, and silver and beige flower pattern, the fur flaps are of ruse colour.everyday life, clothing, hats -

Great Stupa of Universal Compassion

Great Stupa of Universal CompassionClothing - Tibetan hat with fur flaps

Tibetan felt hats, typically made from wool felt crafted from sheep or yak wool, are well-suited to the harsh, cold climate of the Tibetan Plateau. A lining and decorative elements, such as embroidery or patterns, are often added. The fur flaps, made from rabbit or fox fur, provide extra warmth. Felt hats are worn by both men and women.Tibetan hats (also known as ‘chuba hats’ or ‘tsamtha’) are rich in cultural significance. They are often worn during religious ceremonies, festivals, and other important occasions. The design and quality of a hat can indicate the wearer's social status or role within the community.Traditional Tibetan hat with silk brocaded crown in blue and purple colours, with red and white flower pattern, and large fur flaps.everyday life, clothing, hats -

National Wool Museum

National Wool MuseumFunctional object - Auctioneer's Gavel, c. 1950s

Michael Crooks was the auctioneer responsible for selling Australia's million dollar wool bale on the 11th January, 1995 in Geelong, using this gavel. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Small wooden hammer, with handle and double sided face.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore -

National Wool Museum

National Wool MuseumPhotograph - Appledore Family, Growers Gallery, National Wool Centre, Geelong, 11 January 1995

This photograph depicts people gathered in the Growers Gallery on the 11th January, 1995 at the National Wool Centre, Geelong. It shows the emotions of Murray, Ian and Kaye Appledore while bidding took place for the million dollar bale. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of rows of people seated and standing in room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

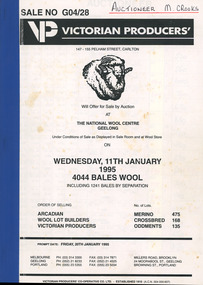

National Wool MuseumDocument - Victorian Producers' Sale Catalogue, National Wool Centre, Geelong, Victorian Producers' Co-operative Limited, 11 January 1995

This sales catalogue was the one used by Auctioneer Michael Crooks on 11th January 1995 when the million dollar bale was sold at the National Wool Centre, Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Bound paper booklet, approximately 35 pages, with printed and handwritten text.Front: [handwritten] AUCTIONEER M. CROOKS Front: [printed] SALE NO G04/28 / VICTORIAN PRODUCERS' / 147-155 PELHAM STREET, CARLTON / Will Offer for Sale by Auction / AT / THE NATIONAL WOOL CENTRE / GEELONG / Under Conditions of Sale as Displayed in Sale Room and at Wool Store / ON / WEDNESDAY, 11TH JANUARY / 1995 / 4044 BALES WOOL / INCLUDING 1241 BALES BY SEPARATIONmichael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre