Showing 1499 items

matching water use

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSoda Syphon, 1900-1930’s

... pressurised, effervescent soda water. It was often used... to dispense pressurised, effervescent soda water. It was often used ...This soda syphon (or siphon) was distributed by John Fletcher of Warrnambool, and made by the British Syphon Mfg. Co. Ltd. of London between the 1900s-1930s. It comprises a multi-sided clear glass bottle, an internal glass tube and a metal release valve and spout on the top. It was used to dispense pressurised, effervescent soda water. It was often used as an alternative to water or added to fruit juices and cordials. The text on this bottle states that it remains the property of the retailer, John Fletcher, and must be returned to him. Customers were asked for a deposit on the bottle, which would be refunded when the bottle was exchanged or continued as the deposit on a fresh bottle. Returned bottles would be cleaned and recharged with the gas and sold again. Soda syphon are bottles, glass or metal, with a release valve and spout on the top. The valve lever on the top of the syphon, when depressed, causes the gas in the syphon to force the water up through the tube and out of the spout. The bottle’s mechanism gives the water an effervescent quality to make bubbly drinks such as sparkling mineral water, soda water and sparkling water. ABOUT JOHN FLETCHER John Fletcher bought the Union Cordial Factory in Koroit Street, Warrnambool that was previously owned by John Davis. Fletcher operated the factory as J Fletcher, John Fletcher and Fletcher’s. He eventually sold his business and stock in 1930 to Ralph Reeves, who may have continued using Fletcher’s supply of drink containers before renewing them with stock showing his own brand. The soda syphon is representative of drink containers used in the later 19th and early 20th century. It also represents the system of returnable, recyclable containers. Soda syphon (or siphon). Glass bottle, clear, multi sided, tapered from a heavy glass base to a narrower shoulder, with glass tube at centre connected to metal pump mechanism at the top. Has elaborate frosted label for J. Fletcher of Warrnambool. Made by the British Syphon Mfg. Co. Ltd. London. Bottle remains the property of John Fletcher, Warrnambool.Metal syphon has impressed "J FLETCHER" and logo "S S" in centre of two concentric circles with text between circles "BRITISH SYPHON MFG. CO. LTD. LONDON". Etched into glass "J. FLETCHER / WARRNAMBOOL", "TRADE "[stylised] F" / MARK", "SODA WATER", "THIS SYPHON IS THE PROPERTY / OF JOHN FLETCHER / WARRNAMBOOL AND CONNOT BE / AND CONNOT BE LEGALLY USED BY OTHERS / BRITISH SYPHON CO. TLD. LONDON / - - - - "flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john fletcher, fletcher, john fletcher of warrnambool, soda siphon, soda syphon, british syphon mfg co ltd of london, soft drinks, soda drinks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Sculling Oar, Mid to late 19th century

... An oar is an implement used for water-borne propulsion... Warrnambool great-ocean-road An oar is an implement used for water ...An oar is an implement used for water-borne propulsion. Oars have a flat blade at one end. Rowers grasp the oar at the other end. The difference between oars and paddles is that oars are used exclusively for rowing. In rowing the oar is connected to the vessel by means of a pivot point for the oar, either an oarlock, or a hole. The oar is placed in the pivot point with a short portion inside the vessel, and a much larger portion outside. The rower pulls on the short end of the oar, while the long end is in the water. By contrast, paddles, are held in both hands by the paddler, and are not attached to the vessel. Rowers generally face the stern of the vessel, reach towards the stern, and insert the blade of their oar in the water. As they lean back, towards the vessel's bow, the blade of their oars pivots in the oarlock, and the end in the water moves towards the stern, providing forward thrust. There also is another way of propelling a small craft it's called a sculling oar which is attached to the transom and used to propel a small vessels rather than using two oars as previously described. It is believed the subject item is just such an oar given it’s long blade associated with a sculling oar. For thousands of years vessels were powered either by sails, or by the mechanical work of rowers, or by paddlers. Some ancient vessels were propelled by both oars and sail, depending on the speed and direction of the wind. Wooden oars, with canoe-shaped pottery, dating from 5000–4500 BC have been discovered in a Hemudu culture site at Yuyao, Zhejiang, in modern China. The history of man using wooden oars to propel a boat has a considerable record in marine archaeology going back many centuries. The item is significant for marine archaeology as it gives a snapshot into how a small row boat was powered using a wooden sculling oar. A method of propelling a small boat still used today an example is the gondoliers in Venice using a sculling oar in a circular motion to propel his craft. Single sculling oar with long flat blade, two copper bands, on blade with rowlock fittingNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, boat oar, sculling oar, row boat -

Victorian Aboriginal Corporation for Languages

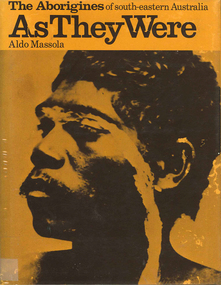

Victorian Aboriginal Corporation for LanguagesBook, Aldo Massola, The Aborigines of south-eastern Australia : as they were, 1971

... foods, plant foods, water resources; manufacture &? use... foods, plant foods, water resources; manufacture &? use ...Contents: p.1-3; Origins, arrival in Australia; p.4-9; How they lived - camp sites, dating (including carbon dating); p.10-27; Physical appearance, skin colour, hair, clothing, body ornaments, cicatrization; exchange system, distribution of food, marriage &? sexual relations; the tribe - structure, relationship to land, territory, gives map showing locations of tribes, New South Wales, Victoria &? eastern South Australia, leadership, government, division of labour, status of women, estimated population at white settlement, density of population (Victoria); p.28-31; Language - names &? naming, reproduces Wembawemba vocabulary, notes use of secret languages, gives 12 rules for pronounciation; p.32-53; Religion, spirit beliefs, totemism, moieties, phratries, marriage rules; mythology, gives eaglehawk &? crow myth from Lake Victoria &? other myths illustrating origins of fire &? natural rock formations, mythical beasts (Bunyip, Mindie), stellar beliefs; magic, medicine men, powers, native remedies for sickness, describes ceremony held in Melbourne, 1847 to avert evil, sorcery, pointing bone, love magic, rain makers; messengers, appearance, etiquette, message sticks; p.54-71; Rock art, motifs, colours, decorative art, engraving of utensils, rock engravings, manufacture &? use of pigments, engraving techniques; trade system, objects bartered, meeting places for trade (Victoria), map shows possible routes (south east Australia); corroborees, purpose, body ornaments &? decorations, musical instruments; p.72-93; Ceremonial life, marriage, punishment for infidelity, birth, childhood, games &? amusements, initiation, etiquette of visiting tribes, details of ceremony, womens role, earth figures &? ground designs, bull roarers, female puberty ceremonies; p.94-133; Shelters, fire making, cooking, construction of canoes, wooden implements, use of reeds, animal skins &? sinews, shells; stone tools, cylindro conical stones, scrapers, knives &? microliths; hunting weapons, spear, other methods pits, nets; fishing methods &? spears, traps; food sharing, womens responsibilities for collecting, digging stick, cooking methods, insect foods, plant foods, water resources; manufacture &? use of spears, spear throwers, shields, clubs, boomerangs; inter- &? intratribal fighting; p.134-147; Death, disposal of body - eating of the dead, burial, cremation, platform exposure, dendroglyphs (N.S.W.), Aboriginal burial grounds (Darling &? Murray Rivers), mourning, widowhood, kopi caps (N.S.W.), causes of death, inquest ceremonies, revenge expedition, after death beliefs; p.148-157; The end of the tribes white settlement &? its impact on Aboriginal life, friction between natives &? settlers, establishment of Protectorates; copiously illustrated throughout.maps, b&w illustrations, b&w photographswemba wemba, murray river, darling river, lake victoria -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Strainer

... of the drinking water. However, using a tea tool to keep run away tea... (such as small bugs) out of the drinking water. However, using a tea ...Take a stroll through the average beverage aisle in your supermarket, and you might get the impression that tea has always come in small boxes with disposable tea bags. But before those easy to come by boxes, there was the rich and intriguing history of the tea strainer, a beautiful little tool that has helped our ancestors enjoy loose leaf tea for hundreds of years. Enjoying loose-leaf tea, and becoming familiar with this tool, can help spark an appreciation for your tea strainer and infuser collection, or simply inspire you to grow one. Documentation of tea tools such as the tea strainer appear in ancient history, the earliest models were likely made of bamboo, and later evolved into stainless steel, sterling silver, china, porcelain, silicon, and linen. During the Tang Dynasty in China, a small book called “Classic of Tea” was written describing tea utensils, and they were made to help Buddhist monks keep living things (such as small bugs) out of the drinking water. However, using a tea tool to keep run away tea leaves out of a cup did not become a cited use of the strainer until the 17th century when Dutch merchants made tea more readily available to those outside of the Chinese dynasty. British royals then increased the popularity of tea as their preferred beverage, and it was not long before a newfound fanaticism for tea in Great Britain spread to the American colonies, as did a growing demand for products that could separate loose tea leaves from liquid with ease and flair. Why did people use a strainer to separate out tea leaves in Great Britain and not in China? While the method of serving tea from a teapot with the tea loose in the pot was a practice used in both countries, the reason China may not have required a tool to remove leaves from their cup likely had to do with the types of tea leaves they were producing. The British owned tea plantations, in countries such as India, produced finer black tea leaves that did not require as much space to expand inside of a tea pot, where as the leaves prepared on the Chinese plantations would expand far more in the pot, and were therefore less likely to land or be bothersome inside a tea cup. This common approach to serving tea with smaller tea leaves required a solution to avoid ending up with a cup, and mouth, full of tea leaves. The obvious solution was a strainer basket. In the Victorian era, tea strainer baskets, similar to those still used in tea parlors today, were made to sit on top of the cup to capture the leaves when pouring the tea from a tea pot into the individual cups. Another solution was a tea-removing device called a mote spoon. Mote spoons act as search and rescue spoons to remove tea leaves from individual teacups. The tea would be brewed loose in the teapot, so any tea that ended up in the cup could be removed with a long handled spoon with holes in the spoon to remove rogue tea leaves and keep the steeped water in the cup. The handle also helped keep the teapot spout free of leaves and could help unclog any leaves trapped when pouring. Stainless steel tea strainers and tea infusers gained popularity in the late 19th century. Big name tea strainer producers, such as Tiffany and Gorham, could use fine silver to create quality, heavy, and sturdy strainers, for those who could afford it. There were many varieties of strainers at that time, but it was more likely that smaller designers who could not afford to mass-produce these quality strainers out of silver made them into unique shapes to attract consumers with lighter wallets. And borne was the tea strainer we are accustomed to today. Things took an unexpected turn for the tea strainer in the early 1900s when Thomas Sullivan, a tea merchant, shipped out tea samples in small silk bags. Customers did not realize that they were supposed to remove the tea from the bags, and instead boiled the tea, bag and all! The convenience of tossing out the leaves is obvious, and the popularity of tea bags is still seen today. Most premium bags of tea we are accustomed to today are frequently packaged loose for consumption, and when they are available in bags, the leaves are often crowded and do not have enough space to expand. While pyramid tea bags have become a more recent solution to this problem, due to the additional space at the top of the bag, enjoying a variety of quality tea is easier with a tea strainer in your arsenal. Besides, with the wide variety of strainers for your cup or pot in versatile materials such as mesh, silver, or a novelty silicone cartoon shape, loose tea can still reign supreme. Tea strainers sometimes do require more cleanup and measuring, but the experience and quality is always worth the effort. Besides, strainers also allow for mixing favorite tea blends together for an extra dose of delicious creativity! https://www.teamuse.com/article_170413.html The strainer provided the convenience of separating the tea leaves for disposal later.Metal strainer, bowl shaped, with mesh and twisted wire handle.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strainer -

Mission to Seafarers Victoria

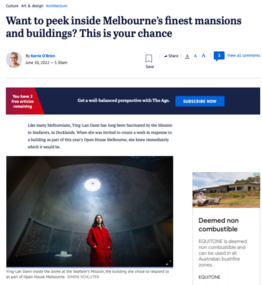

Mission to Seafarers VictoriaArticle, Kerrie O'Brien, Want to peek inside Melbourne’s finest mansions and buildings? This is your chance, 30 June 2022

... often uses water as a theme. When she started spending time... often uses water as a theme. When she started spending time ...Open House 2022: "Like many Melburnians, Ying-Lan Dann has long been fascinated by the Mission to Seafarers, in Docklands. When she was invited to create a work in response to a building as part of this year’s Open House Melbourne, she knew immediately which it would be. Taking a peek behind the closed doors of some of Melbourne’s finest and most interesting buildings is a core premise of the weekend event, now in its 15th year. During that time, the program has grown from half a dozen buildings to a 200-plus strong list that extends to Ballarat and Bendigo. “[It’s] much more expansive and citizen-led,” says Fleur Watson, Open House Melbourne’s executive director. “As a public festival, it has always had a spirit of generosity, this gesture of opening up and allowing visitors to come and look and experience things.” Swinging open their doors at the end of the month will be some of the city’s finest mansions, including Villa Alba in Kew and Brighton’s Billilla, the Cairo flats in Fitzroy, the newly renovated Jewish Museum designed by Kerstin Thompson, the Melbourne Quakers Centre, the Albanian Mosque in Carlton North and many more. Considering how to approach the event this year, held remotely for the past two, Watson decided to explore beyond the traditional, with associate professor and director of curatorial practice at Monash University Tara McDowell. The two have co-curated an exhibition of works to run concurrently with the Open House program, called Take Hold of the Clouds. That’s where Dann’s work, Circular Temporalities, comes in, one of seven commissions around town in which local and international artists respond to chosen buildings or sites. A lecturer in interior design at RMIT as well as an artist, she is interested in time and finding different mediums to show things in flux and, having grown up on Phillip Island, she often uses water as a theme. When she started spending time at the Mission, Dann found there was an oculus at the top of the dome, known as the Norla Dome. She thought about how that small but significant opening related to where sailors spent so many months of the year, the sky being the only thing they would see much of the time, stars guiding the way in times gone by, and of the recent stories she’d heard about sailors being trapped at sea during COVID. Built in the Arts and Craft style between 1916 and 1919 and designed by architect Walter Butler, the Mission includes a chapel, clubroom, Chaplain’s house, a small cottage and the Norla Dome, which was apparently inspired by the Pantheon. The Mission was funded by the government and the Ladies Harbour Lights Guild, who Dann was also intrigued by. “One of the things those women identified is that life at sea is very dangerous [and they] wanted to give them a space of sanctuary and support,” she says, adding that for many years, the dome was used as a gymnasium. Her work inside the dome includes a 35-minute loop film, recorded from the ferry during the crossing from Queenscliff to Sorrento. The horizon takes up about a third of the shot and moves as the waves rise and fall, mirroring the journeys made by the sailors who found refuge at the mission over the years; it will be projected onto a gauze-like fabric, allowing glimpses of the building behind. Dann also plans to activate the site over the course of the weekend and will read a poem by Justin Clemens.The articles gives an insight of the création of the artwork by Ying-Lan Dann. digital copy of an article with photographs published in the Ageopen house melbourne, 2022, ying-lan dann, take hold of the clouds, norla dome, exhibition, the age, cultural events -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Jim Connor, Main Road, Eltham, 14 Jan 2017

... are two bath rooms in which hot and cold water can be used. All... are two bath rooms in which hot and cold water can be used. All ...The Eltham Hotel is the oldest continually operating hotel in the Eltham district. Initially referred to as the Little Eltham Hotel, it has been known as the Eltham Hotel since the 1850s through to present time with a very brief period as the Eltham Tavern in the late 1980s. Benjamin Oliver Wallis was a prominent Eltham resident, publican and Councillor during the second half of the nineteenth century. He owned the house that is now the Nillumbik Living and Learning Centre at 739 Main Road Eltham and one stage the Eltham Hotel. Wallis migrated to Melbourne in 1853 but his wife and children remained in Cornwall for a further 10 years. Later in 1853 Richard Warren engaged Wallis to build the Eltham Hotel and it opened in 1854. The hotel was constructed of hard basaltic blue stone quarried in the Eltham district and cemented together with mud, and partly of bricks made at Eltham. The Fountain of Friendship Hotel on the opposite side of Maria Street (Main Road) opened shortly after. The hotel was a well-known resting place for gold diggers during the gold rush at Woods’ Point and Warren would buy the gold from the diggers. In 1858 Warren fell into financial difficulties and had to sell the hotel. Wallis bought the hotel and obtained a publican’s licence in 1861. In the 1850s the Fountain had been the more popular hotel but after that the Eltham Hotel became more popular. It is understood that in about 1857 Wallis probably built the “Living and Learning house” for tanner John Pearson. In 1868 Pearson became bankrupt and Wallis acquired the house and he lived there until his death in 1896. For some of this time the house was in the name of Benjamin’s son Richard but he died in 1888 and ownership reverted to his father. Wallis was a member of the Eltham Jockey Club and in 1867 his wife Anna rode her horse Charlotte in the Annual Races. Anna was also an angler and is reported to have caught a large perch in the Yarra River. She died in 1887. On 16th September 1886 Wallis sold the hotel to Christopher Watson (Snr). Watson died in 1887 and the hotel passed to his son Christopher Watson (Jr) who owned it until his death in 1909 at which time his wife Emily took over the license. Upon her death, their son Herbert applied for the license in January 1915. In July 1925, Herbert Watson demolished the original building and, in its place, erected a modern hotel which remains the foundation of the present Eltham Hotel. The contractors at the time commented on how well the original building had been constructed. A description of the new building was detailed in the Advertiser newspaper of January 8, 1926: “The new building consists of. two stories. designed in English tavern style, and contains-all told, 24 rooms. On the second floor, in front uninviting the two gables is a deep balcony, which will be much appreciated by visitors. The lower story is wholly of brick, and the upper one of wood and fibrous cement plaster. The rooms are spacious and lofty, and the windows are large and of latest style, and light the rooms splendidly. The entrance hall is 8 feet wide. The bar is a very commodious room and is furnished in the most up-to-date and convenient manner. The dining room, a very attractive apartment, is 30 feet by 15 feet 6 inches, and the bar parlor is also a large and well furnished room. A large cellar, an indispensable adjunct to an hotel, has been excavated beneath the bar. On the upper story are 12 bedrooms, and among other conveniences are two bath rooms in which hot and cold water can be used. All the rooms have been supplied with the necessary appliances for electric lighting, which will be one of the progressive evidences which Eltham will shortly enjoy.” “In the yard a brick garage to accommodate three cars at once, has been erected. This, as well as the hotel, is roofed with tiles.” “From the front of the hotel (especially the balcony) a lovely view of the country west and, north may be obtained.” “It may be added that it Is intended to have an ornamental garden, a tennis court. and a kiosk in connection with the hotel, and the property will have a rustic fence round it.” The hotel has since undergone several modifications and extensionsTomorrow's history documented todayeltham, jim connor collection, main road, eltham gateway, eltham hotel, pitt street -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Jim at "The Pub" Eltham; Reed's Eltham Hotel, c.1948

... are two bath rooms in which hot and cold water can be used. All... are two bath rooms in which hot and cold water can be used. All ...Olive Elsie May Reed was licensee of the Eltham Hotel from April 1948 to January 1950. The Eltham Hotel is the oldest continually operating hotel in the Eltham district. Initially referred to as the Little Eltham Hotel, it has been known as the Eltham Hotel since the 1850s through to present time with a very brief period as the Eltham Tavern in the late 1980s. Benjamin Oliver Wallis was a prominent Eltham resident, publican and Councillor during the second half of the nineteenth century. He owned the house that is now the Nillumbik Living and Learning Centre at 739 Main Road Eltham and one stage the Eltham Hotel. Wallis migrated to Melbourne in 1853 but his wife and children remained in Cornwall for a further 10 years. Later in 1853 Richard Warren engaged Wallis to build the Eltham Hotel and it opened in 1854. The hotel was constructed of hard basaltic blue stone quarried in the Eltham district and cemented together with mud, and partly of bricks made at Eltham. The Fountain of Friendship Hotel on the opposite side of Maria Street (Main Road) opened shortly after. The hotel was a well-known resting place for gold diggers during the gold rush at Woods’ Point and Warren would buy the gold from the diggers. In 1858 Warren fell into financial difficulties and had to sell the hotel. Wallis bought the hotel and obtained a publican’s licence in 1861. In the 1850s the Fountain had been the more popular hotel but after that the Eltham Hotel became more popular. It is understood that in about 1857 Wallis probably built the “Living and Learning house” for tanner John Pearson. In 1868 Pearson became bankrupt and Wallis acquired the house and he lived there until his death in 1896. For some of this time the house was in the name of Benjamin’s son Richard but he died in 1888 and ownership reverted to his father. Wallis was a member of the Eltham Jockey Club and in 1867 his wife Anna rode her horse Charlotte in the Annual Races. Anna was also an angler and is reported to have caught a large perch in the Yarra River. She died in 1887. On 16th September 1886 Wallis sold the hotel to Christopher Watson (Snr). Watson died in 1887 and the hotel passed to his son Christopher Watson (Jr) who owned it until his death in 1909 at which time his wife Emily took over the license. Upon her death, their son Herbert applied for the license in January 1915. In July 1925, Herbert Watson demolished the original building and, in its place, erected a modern hotel which remains the foundation of the present Eltham Hotel. The contractors at the time commented on how well the original building had been constructed. A description of the new building was detailed in the Advertiser newspaper of January 8, 1926: “The new building consists of. two stories. designed in English tavern style, and contains-all told, 24 rooms. On the second floor, in front uninviting the two gables is a deep balcony, which will be much appreciated by visitors. The lower story is wholly of brick, and the upper one of wood and fibrous cement plaster. The rooms are spacious and lofty, and the windows are large and of latest style, and light the rooms splendidly. The entrance hall is 8 feet wide. The bar is a very commodious room and is furnished in the most up-to-date and convenient manner. The dining room, a very attractive apartment, is 30 feet by 15 feet 6 inches, and the bar parlor is also a large and well furnished room. A large cellar, an indispensable adjunct to an hotel, has been excavated beneath the bar. On the upper story are 12 bedrooms, and among other conveniences are two bath rooms in which hot and cold water can be used. All the rooms have been supplied with the necessary appliances for electric lighting, which will be one of the progressive evidences which Eltham will shortly enjoy.” “In the yard a brick garage to accommodate three cars at once, has been erected. This, as well as the hotel, is roofed with tiles.” “From the front of the hotel (especially the balcony) a lovely view of the country west and, north may be obtained.” “It may be added that it Is intended to have an ornamental garden, a tennis court. and a kiosk in connection with the hotel, and the property will have a rustic fence round it.” The hotel has since undergone several modifications and extensions Pages from a scrapbook belonging to Heather Jenkins (nee Sargeant) who lived as a child in the Police Residence at 728 Main Road, Eltham in the 1920s.Heather Sargeant was the daughter of Constable W.C. Sargeant, the local police officer in residence at Eltham, 1922-1927Glued on a brown paper scrapbook page (torn from scrapbook) with 8 black and white/sepia photos of varying sizes, 1 newspaper clipping and one greeting card with printed sketch and handwritten captions in ink. On back of page is 1 black and white photo and a large newspaper clipping.eltham, police residence, heather jenkins (nee sargeant), walter withers, constable w.c. sargeant, eltham hotel, jim jenkins, reed's eltham hotel, olive elsie may reed -

Eltham District Historical Society Inc

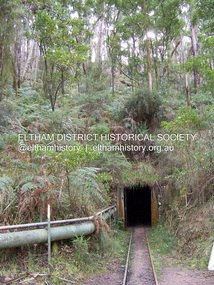

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, One Tree Hill Mine, Smiths Gully, 8 June 2006

... to the Black Cameron Mine for crushing. There he uses water from... to the Black Cameron Mine for crushing. There he uses water from ...Gold was discovered on One Tree Hill in 1854. The site has been worked intermittently until fairly recent times. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p53 Though still a working mine, One Tree Hill Mine at Smiths Gully, now stands in a tranquil reserve surrounded by bush and native animals - in contrast to its heyday. In the mid 19th century, when the mine was part of the Caledonia Goldfields, hundreds of men in search of their fortune worked the alluvial gold in the Yarra River, its tributaries and the reefs that made up the goldfields. Miner Stan Bone, assisted by Wilfred Haywood, is the last of the independent gold miners in the area and still uses the quartz crushing battery as miners did when gold was first discovered in the area in 1851.1 Stan, who is the last of six generations of miners in his family, was aged 17 when he began mining on his father Alex’ mine, The Golden Crown in Yarrambat. These days, after blasting the gold-bearing rock in Mystery Reef, one of the four reefs at One Tree Hill, Stan transports it around five kilometres by tip truck to the Black Cameron Mine for crushing. There he uses water from the waterlogged mine, (which still contains gold), as the Happy Valley Creek at One Tree Hill is usually dry.2 The One Tree Hill Mine has been worked for close to a century since it opened around the late 1850s.3 The Swedish Reef was its most productive reef and one of the largest in the area. Around 1859, extractions included 204 ounces (5.8kg) of gold, won from 57 pounds (26kg) of stone.4 Then during World War Two, Stan’s uncle, Bill Wallace, and Alex Bone, closed the mine. In 1973, Stan, with his Uncle Bill, reopened the Black Cameron Mine and worked there until 1988. Stan resumed mining One Tree Hill in 1998. As late as the 1920s gold was picked up by chance! When crossing a gully on his way to vote at the St Andrews Primary School, Bill Joyce picked up some quartz containing gold. This site was to become the Black Cameron Mine. The Caledonia Diggings, named after Scotland’s ancient name by local Scots, began around Market Square (now Smiths Gully) and included Queenstown (St Andrews), Kingstown (Panton Hill) and Diamond Creek. There were also poorer bearing fields in Kangaroo Ground and Swipers Gully (now Research). * None of these compared in riches to the Ballarat and Bendigo fields5, but the Caledonia Diggings continued intermittently for close to 100 years. Gold was discovered in Victoria following a bid to stem the disappearance of much needed workmen to the New South Wales diggings. Several businessmen offered a reward of £200, for the discovery of gold within 200 miles (322 km) of Melbourne. Late in June 1851, gold was first discovered at Andersons Creek, Warrandyte. Then in 1854, George Boston and two other men discovered gold at Smiths Gully. Gold transformed the quiet districts, with a constant flow of families and vehicles on the dirt tracks en route to the Caledonia Diggings. Three thousand people worked the gullies in Market Square, including about 1000 Chinese miners. The square established its own police, mining warden, gold battery, school, shops and cemetery and grog flowed. Market Square flourished until the middle 1860s. Bullocks transported quartz from the Caledonia Goldfields to the crushing machinery at the Queenstown/St Andrews Battery, near Smiths Gully Cemetery. It was destroyed by bushfire in 1962. By the late 1850s, most early alluvial fields were in decline, but minor rushes continued until around 1900 and some until the early 1940s. Some miners did well, although most earned little from their hard labour in the harsh and primitive conditions.6 But according to historian, Mick Woiwod, the gold fields helped to democratise society, as individuals from all walks of life were forced to share experiences, and the ability to succeed, depended less on inherited wealth or social rank.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, gold mining, one tree hill mine, smiths gully -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Hourglass

... the water. They were also used to regulate ringing the ship’s... the water. They were also used to regulate ringing the ship’s ...An hourglass or sandglass is an instrument for measuring a defined time and can be used perpetually by simply turning it over immediately the top bulb empties. The clear blown glass is shaped into two equal sized bulbs with a narrow passage in the centre and contains uniform sized sand or glass particles in the lower bulb. The width of the neck regulates the constant flow of the particles. The glass is held in a stand with top and bottom of equal shape and size. Hourglasses can measure an infinite variety of time by gauging the size of the particles, the shape and size of the bulbs and the size of the passage between the bulbs, thus measuring hours or minutes or even seconds. Generally an hourglass sits between discs of wood at the ends, which are joined by long wooden spindles between the ends and tightened by screw caps. The length of time can be adjusted by adding or removing sand particles. The use of the marine sandglass (or hourglass) has been recorded in the 14th century in European shipping. A one minute sandglass was used in conjunction with the ship’s log for ‘dead reckoning’, (see below) that is, for measuring the ship’s speed through the water. They were also used to regulate ringing the ship’s timetable; for example a 4 hour sandglass was used for the length of the sailors’ watch, and a half hour timer for taking of readings for the ship’s log; the ship’s bell would be rung every half hour. It was usually the role of the cabin boy to watch and turn the sandglasses over at the exact time of them emptying their upper chambers and to ring the ship’s bell. Hourglasses have been used historically for many hundreds of years. Some have been used for timing church sermons, in cooking, in industry and at sea. Even today they are used for measuring the cooking time of eggs and timing a player’s turn in games such as Boggle and Pictionary. The sandglasses at sea were gradually replaced in the late 1700’s to early 1800’s by the more accurate chronometers (marine clocks) when they became reliable instruments. DEAD RECKONING (or Deduced Reckoning) Dead reckoning is the term used to describe the method of calculating the ship’s position from its speed and direction, used in early maritime travel, mostly in European waters. Both the (1) speed and the (2) direction of travel were recorded on a Traverse Board at half-hourly intervals during a helmsman’s watch of 4 hours. The navigator would record the readings in his ship’s log, plot them on his navigational chart and give his updated course directions to the next helmsman on watch, along with the cleared Traverse Board. This was a very approximate, but none-the-less helpful, method of navigation. The wooden Traverse Board was a simple pegboard with a diagram of a compass with eight peg holes along the radius to each of the compass points, plus a grid with ascending half hours in the left column and increasing ship’s speed in knots in a row across the column headings, with a peg hole in each of the intersecting cells. A number of wooden pegs were attached to strings on the board. By placing one peg consecutively in the direction’s radius hole, starting from the centre, and the speed holes when the half hourly reading was taken, a picture of speed and direction for the whole 4 hour watch was created. (1) To measure the ship’s speed a one minute hourglass timer was usually used to measure the ship’s speed through the water and help to calculate its longitude. A rope, with knots at regular standard intervals and a weight such as a log at the end, would be thrown overboard at the stern of the ship. At the same time the hourglass would be turned over and a seaman would start counting the number of knots on the rope that passed freely through his hands as the ship travelled. When the timer ran out the counting would be stopped. A timer of one minute (one-sixtieth of an hour), knots spaced one-sixtieth of a nautical mile apart, and simple arithmetic easily gave the speed of the ship in nautical miles per hour ("knots"). This would be recorded every half hour. The speed could however be inaccurate to the travel being affected by ocean currents and wind. (2) To calculate the ship’s direction a compass sighting would be recorded each half hour.Marine hourglasses or sandglasses were used from around the 14th to 19th century during the time of sailing ships. This hourglass is representative of that era, which is during the time of the colonisation of Australia. Hourglass or sandglass; an instrument used to measure time. Two equal sized clear glass bulbs joined with a narrow passage between them, containing equal sized particles of sand grains in lower bulb. Glass sits in a brass collar at each end, in a frame comprising 3 decorative brass columns or posts, each attached top and bottom, using round screw-on feet, to round brass discs. Disc have Roman numerals for the numbers 1 - 12 pressed into their inner surfaces and hieroglyphics on the outer surfaces. Roman numerals on inner surface of discs " I II III IV V VI VII VIII IX X XI XII " Hieroglyphics impressed on outer surface of discsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, horology, hourglass, hour glass, sandglass, sand glass, timing instrument, dead reckoning, deduced reckoning, finding latitude at sea, sandglass with hieroglyphics and roman numerals, hourglass with hieroglyphics and roman numerals, brass hourglass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Syringe, Late 19th - early 20th century

... be performed with a large syringe (20 mL) and warm water. The use.... The use of sterile water or saline as opposed to tap water ...How to safely syringe ear wax Irrigation, or ear syringing, should be performed only after taking a full history, doing an ear examination and explaining the potential complications to the patient. It is also important to ensure appropriate assembly and use of equipment. Gentle irrigation of the ear canal can be performed with a large syringe (20 mL) and warm water. The use of sterile water or saline as opposed to tap water or bacteriostatic agent (eg dilute hydrogen peroxide) can decrease the risk of infection. Direct visualisation of the ear canal is not necessary for safe and effective syringing. The tip of the syringe should not pass the outer one-third of the ear canal (approximately 8 mm) – the use of a rounded nozzle may assist with this. The jet of water should be aimed towards the edge of the cerumen to enable the debris to flow out of the ear canal. Cease immediately if the patient experiences pain or if bleeding occurs. Mechanical jet irrigators are available and some allow better control of water pressure and direction of spray. After syringing, examine the external canal and tympanic membrane. Document the patient’s consent, procedure, and pre- and post-examination findings. https://www.racgp.org.au/afp/2015/october/ear-wax-management This ear syringe was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. Ear wax is an ongoing problem for many people, and its safe and easy removal is important. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Ear syringe from the W.R. Angus Collection with barrel, plunger and tip. Inscription on oval shaped plaque on barrel. Inscription on oval shaped plaque on barrel "10th / UNIVERSITY COLLEGE HOSPITAL" & "MAYER & MELTZER / MAKERS, LONDON" & " TO THE / HOSPITAL OF DESEASES (SIC) OF THE THROAT"" & "TO THE / HOSPITAL / FOR WOMEN" & "TO THE / MIDDLESEX / HOSPITAL" plus "R" inscribed on each side of the handlewarrnambool, shipwreck coast, great ocean road, flagstaff hill maritime village, maritime museum, dr angus, w.r. angus, dr t f ryan, medical instrument, surgical equipment, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, medical treatment, syringe, ear syringe, ear wax -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

... keep a record of the water used ?— Yes, the water in this case... keep a record of the water used ?— Yes, the water in this case ...Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century