Showing 443 items matching "american made"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Lamp Burner, Isaac Sherwood & Son Ltd, 1904-1920

Sherwood Ltd. Was a manufacturer of oil lamps and burners at the Nechells Park Works Birmingham UK and regarded at the time as a renowned name in the oil lamp and burner manufacturing industries in Birmingham during the early part of the 20th century. They started selling as ‘Isaac Sherwood & Son Ltd.’ in 1904, later around 1920 they merged with Linley and Co makers of American pattern lamps and became ‘Sherwood-Linley” moving to 44-50, Granville St. Birmingham. They became one of the largest manufacturers of lighting devices and burners in England. They produced all sorts of illumination devices and became famous for their oil burners. Apart from oil burners, they produced table and floor lamps, sconces, lanterns and chandeliers that made Sherwood unique. A Significant item as part of a kerosene lamp that was commonplace in homes and other premises during the early 20th century as a means of lighting before electric lighting became the standard. These types of items give a snapshot into domestic and social life during this period.Lamp Burner housing, brass with wick-screw (no wick). Made in England Sherwoods LTD Birminghamwarrnambool, flagstaff-hill, shipwreck-coast, flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp burner, sconces, kerosene lamp, wick adjuster, sherwood & son ltd, sherwood-linley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTimer, 1940s

Australia's first telephone exchange was opened in Melbourne in August 1880. It was operated by the Melbourne Telephone Exchange Company. Owned by W. H. Masters and T. T. Draper, the Manager of the Company was H. Byron Moore. This was only two years after the world's first exchange in the United States, and just four years after Bell first spoke on a telephone. The exchange was located in the old Stock Exchange building at 367 Collins Street, a site now occupied by the Commonwealth Bank. In 1884, the operations of the Company, by then known as the Victorian Telephone Exchange Company, had grown considerably and were transferred to Wills Street, Melbourne. Private ownership of this company continued until 1887 when it was bought out by the Victorian Colonial Government. Other colonial governments followed this example. By 1910, the growth in telephone services made additional accommodation necessary. This could not be provided in the existing building in Wills Street and arrangements were made for a new exchange in Lonsdale Street. Alexander Graham Bell visited Australia in 1910 to advise the Federal Government's Postal Commission. Telephone exchanges were established in Adelaide with (48 subscribers), Hobart (10 subscribers) and Launceston (35 subscribers). The first exchange in Western Australia was established in 1887 and located in a small three-room cottage in Wellington Street, Perth with 17 subscribers. The year 1888 marked the opening of the Fremantle exchange in a small room at the rear of the Town Hall. There were nine subscribers. Australia's first automatic exchange was installed in the GPO in Sydney, in 1911, for internal use. But the first automatic exchange for public use was opened at Geelong in Victoria in the next year July 1912 with 800 subscribers. Melbourne's first automatic exchange was opened in the suburb of Brighton in 1914; the first public automatic exchange in NSW began operating at Newtown, Sydney in 1915; and Queensland's first was installed at South Brisbane in 1925. 1929 saw the opening of Tasmania's first automatic exchange in Hobart. an automatic telephone service. In June 1977, the manual telephone exchange at Swansea was replaced with an automatic service and made Tasmania the first State in Australia to have a fully automatic net work. The half-century following Federation saw the growth of the automatic operation; a great extension of trunk line services; The automatic telephone contributed greatly to the early popularity of telephones in Australia. It was a quicker and more convenient way of communicating with another person on the same exchange — instead of having to go through tedious processes with the operator. From its introduction, the number of automatic telephones in operation grew to a remarkable extent. In 1886, the first trunk link of 16 km was connected to the exchanges of Adelaide and Port Adelaide in South Australia. Then, in 1907, the first inter-capital telephone trunk line was opened between Sydney and Melbourne. It was followed by a line between Melbourne and Adelaide in 1914. Sydney and Brisbane were linked in 1923, and Perth and Adelaide in 1930. In 1930, the first overseas calls from Australia came possible with the introduction of a radio telephone service to England, and through there to Europe and America. A similar service opened to New Zealand in the same year. Initially, trunk channels linked different manual trunk exchanges. It was necessary for a succession of trunk operators to connect the appropriate channels, one after the other until the connection was made. As trunk traffic grew. the system became increasingly unsuitable. More trunk operators had to be employed and so labour costs increased. It was a tedious and slow way of making a long-distance call, and it was sometimes hard to hear, particularly when several exchanges were linked With technical advances, trunk switching moved from manual operation through a partly automatic phase. Automatic transit switching equipment was used and only a single operator was required to connect a trunk call to a wanted automatic subscriber. Until well beyond the middle of this century, the majority of trunk traffic went through this single telephonist control. In 1953, the number of telephones in use in Australia passed the one million mark. By then, the need for improvement in the automatic exchanges was be coming well recognised. The need was for a telephone switching system which would do a better job more economically than the conventional step-by-step ex-change. This led to the adoption of the Crossbar system as the standard in automatic telephone exchanges in 1960. The introduction of Crossbar switching was a big step forward in the automation of trunk calls. It substituted automatic switching and charging equipment for the originating trunk operator, and improved the quality of the system radically. Before the introduction of the Crossbar system there were often very long delays in obtaining a booked trunk call, and the quality of sound was often very poor. With Crossbar, Subscriber Trunk Dialing (STD) became a reality. A trunk call by STD was as easy to make and almost as fast to connect as a local call.The item was made around the 1940s and used up until the 1970s in manual cord telephone exchanges as a way to time and charge users for trunk calls made over the telecom system of the time. Post Master General dept. - Trunk Call Timer.Inscribed PMG, C. of A, 37. Bell chimes at 3 min increments.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, timer, trunk call, telephone, cord exchange -

Federation University Historical Collection

Federation University Historical CollectionBook, Modern Uses of Non-Ferrous Metal by F.M. Becket et al, 1935

This book was used by Charles BaconRed hard covered book of 427 pages in the A.I.M.E. Series (American Institute of Mining and Metallurgical Engineering Inc). It includes a presentation, or armorial, Bookplate from Seeley Wintersmith Mudd made out to Charles Bacon. Bookplatenon ferrous metal, american institute of mining and metallurgical engineering inc, aluminoum, stainless steel, gold, silver, nickel copper, bookplate, seeley wintersmith mudd, charles bacon -

Federation University Historical Collection

Federation University Historical CollectionBook, T.A. Rickard, Technical Writing by T.A. Rickard, 1939

Red hard covered book of 337 pages in the A.I.M.E. Series (American Institute of Mining and Metallurgical Engineering Inc). It includes a presentation Bookplate from Seeley Wintersmith Mudd made out to Charles Bacon.Bookplatecharles bacon, american institute of mining and metallurgical engineering inc, seeley wintersmith mudd, bookplate, grammar -

Federation University Historical Collection

Federation University Historical CollectionBook, A History of American Mining, 1932

This book was presented to Charles Bacon by Seeley Wintersmith Mudd.Red hard covered book of 419 pages in the A.I.M.E. Series (American Institute of Mining and Metallurgical Engineering Inc). It includes a presentation Bookplate from Seeley Wintersmith Mudd made out to Charles Bacon. Chapters include mining in the far north, Comstock Lode, Colorado, Mississippi Valley, Great Salt Lake, Black Hills of South Dakota, Cooper of Lake Superior, copper in Arizona, Bunker Hill Enterprise, Butte The great Diamond Hoax, Flotation Process. The book includes some simple maps and plans. The book was dedicated to 'The most distinguished of American mining engineers Herbert Hoover'.t.a. rickard, herbert hoover, seeley wintersmith mudd, bookplate, charles bacon, mining, america -

Federation University Historical Collection

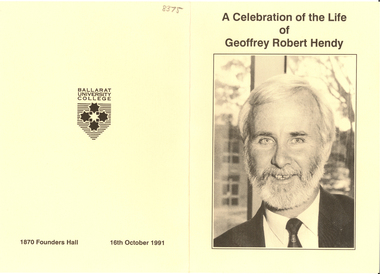

Federation University Historical CollectionProgramme, A Celebration of the Life of Geoffrey Robert Hendy, 1991, 10/1991

Geoff Hendy was born at Numurkah on 06 November 1945. In 1963 he was employed by the Victorian Education Department as an Administrative Officer. He moved to Ballarat in 1970 to take up the position of registrar at the Ballarat Teachers' College. In 1973 he resigned from the Education Department to become the Academic registrar at the State College of Victoria at Ballarat. He died on 08 October 1991 in Los Angeles, United States of America. The Federation University Hendy Award was established to support the professional development of the general staff of the University. The award is made biennially (in years with an odd number) The award is named in honour of the late Mr geoff Hendy, a long serving staff member of the University and its predecessor institutions. He joined Ballarat Teachers' College as Registrar in 1970, and in 1973 became the Academic Registrar for the State College of Victoria at Ballarat. In 1976 he was appointed Academic Secretary when the Ballarat College of Advanced Education was established, and later became Registrar of that institution. Geoff Hendy was still Registrar at the time of his death in 1991. A beige coloured card used at a service to celebrate the life of staffmember Geoff Hendy who died suddenly in America while representing Ballarat University College.hendy, geoff hendy, geoff hendy award, ballarat teachers college, ballarat college of advanced education, state college of victoria, ballarat university college, john sharpham, ian gordon, ken clements, gerardine christou, robert hook, anne beggs sunter, norman barling -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, S.J. (Joe) Czynski, Correspondence on S.J. Czynski letterhead, 1958, 04/06/2015

... Joe Czynski was an electrician who made contact... Czynski was an electrician who made contact with the American ...Joe Czynski was an electrician who made contact with the American Science Fiction (SF) editor Hugo Gernsback while undertaking his electrical apprenticeship in Chicago, USA. Some of Czynski's short stories were subsequently published in the SF periodical Amazing Stories in the 1920s and 1930s. He admitted to using a number of pseudonyms in Amazing Stories, but only acknowledged one, H. M. Crimp. On his return to Australia, Czynski's career as an electrician took precedence over his SF writing. He worked for some time on the Woomera rocket range and was an active member of the Ballarat Astronomical Society. (Austlit) In 1958 Joe Czynski was Secretary of the Ballarat Debating Association, and describes is electrical business as 'Ballarat Olympic Electricians'Correspondence on green letterhead for S.J. Czynski, registered electrical contractor. The letter relates to the Ballarat Debating Association of which Joe Czynski was the secretary. Ballarat School of Mines Principal, Dick Richards, responded with advice that he has publicised the event, but believes mid year exams with claim the full attention of Diploma students, czynski, s.j. czynski, joe czynski, debating, ballarat debating association, ballarat olympics, olympics, ballarat school of mines, r.w. richards, dick richards, letterhead -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, Foreign Service of the United States of America Correspondence, 1947, 1947-1955

The letters are regarding the Education of American Ex-servicemen at the Ballarat School of Mines and Industries as part of the Servicemen's Readjustment Act of 1944 - Public Law 346, the "G.I. Bill of Rights". The G.I. Bill was created to help rehabilitate American servicemen and re-integrate them into civilian society, focusing on and encouraging the education and training of ex-servicemen. The Act offered the payment of tuition, books, supplies and subsistence. Five letters of correspondence between the Foreign Service of the United States of America Consul General Richard F. Boyce, and the Ballarat School of Mines and Industries heads of staff between 1947 and 1955. Attached are other documents regarding the 'G.I. Bill of Rights' itself, veterans information records, amendments made regarding the payment of book, supplies and equipment charges, and receipts and records specific to student Allan C. Pitzen. Letterhead of the Foreign Service of the United States of America. Signature of Richard F. Boyce at the end of each letter. Intials of R.M.R, and a date in the top right corner of each letter.correspondance, usa, united states of america, foreign service, melbourne, ballarat school of mines and industries, ballarat, veterans administration educational and training provisions, servicemen's adjustment act of 1944, world war two, f.e. ferguson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrawing, c 1890's

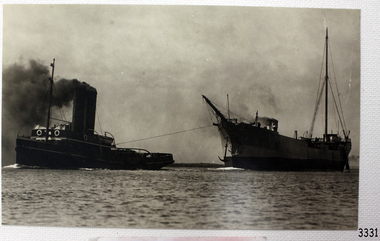

This drawing of the screw steamer SS Edina depicts the vessel in the period of service in Australia from the 1870's onward until the time when she was cut down to use as a 'lighter' to carry cargo in 1938. The artist is unknown. ABOUT THE S S EDINA The three masted iron screw steamer SS Edina was built in Glasgow, Scotland, in 1854 by Barclay and Curle. She was adorned with the figurehead of ‘fair maid of Judea’. The many years of service made SS Edina famous world-wide as the longest serving screw steamer. (The term screw steamer comes from being driven by a single propeller, sometimes called a screw, driven by a steam engine.) SS Edina’s interesting history includes English Chanel runs, serving in the Crimean Ware carrying ammunition, horses and stores to the Black Sea, and further service in the American Civil War and later, serving in the western district of Victoria as well as in Queensland and carried gold, currency and gold prospectors Australia to New Zealand. SS Edina had the privilege of being an escort vessel to H.R.H. the Duke of Edinburgh during his visit to Australia in 1867. In March 1863 SS Edina arrived in Port Phillip Bay, Melbourne and was bought by Stephen Henty, of Portland fame, to work the cargo and passenger run from Melbourne – Warrnambool – Port Fairy - Portland. After a short time of working the run from Australia to New Zealand, with passengers and cargo that included gold and currency, she returned to her Melbourne - Warrnambool – Port Fairy run, with cargo including bales of wool produced in the western district of Victoria. The Warrnambool Steam Packet Company purchased SS Edina in 1867; she was now commanded by Captain John Thompson and Chief Engineer John Davies. She survived several mishaps at sea, had a complete service and overhaul and several changes of commanders. In 1870 SS Edina was in Lady Bay, Warrnambool, when a gale sprung up and caused a collision with the iron screw steamer SS Dandenong. SS Edina’s figurehead was broken into pieces and it was not ever replaced. SS Edina was re-fitted in 1870 then was used as a coastal trader in Queensland for a period. She was then brought to Melbourne to carry cargo and passengers between Melbourne and Geelong and performed this service 1880-1938. During this time (1917) she was again refitted with a new mast, funnel, bridge and promenade deck, altering her appearance. In 1938, after more collisions, SS Edina was taken out of service. However she was later renamed Dinah and used as a ‘lighter’ (a vessel without engine or superstructure) to be towed and carry wool and general cargo between Melbourne and Geelong. In 1957, after 104 years, the SS Edina was broken up at Footscray, Melbourne. Remains of SS Edina’s hull can be found in the Maribyrnong River, Port Phillip Bay. This drawing of the SS Edina is significant for its association with the screw steamer SS Edina. The SS Edina is heritage listed on the Victorian Heritage Database VHR S199. She had endeared herself to the people of Port Phillip Bay as a passenger ferry, part of their history and culture. She played a significant role in the Crimean War, the American Civil War and the gold rush in New Zealand. She also served western Victoria for many years in her cargo and passenger runs. The SS Edina is famous for being the longest serving screw steamer in the world. After spending her first nine years overseas she arrived in Melbourne and her work included running the essential service of transporting cargo and passengers between Melbourne and the western Victoria ports of Warrnambool, Port Fairy and Portland. The SS Edina was purchased in the late 1860’s by local Warrnambool business, the Warrnambool Steam Packet Co. and continued trading from there as part of the local business community. The SS Edina’s original ‘fair maid of Judea’ figurehead was broken to pieces in a collision with another vessel (the SS Dandenong) in a gale off Warrnambool, Victoria, in 1870.Drawing in pen and ink, of screw steamer vessel SS Edina, framed in decorative timber and glass. View of bow of SS Edina with vessel's name on bow. SS Edina is in dry dock, background shows a power pole and roof. Ship configuration in the drawing was 1870's - 1938. Drawing dated c. 1890's.Drawn on bow "EDINA"warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, shipwrecked artefact, barclay & curle, figurehead 'fair maid of judea', centenary maritime exhibition 1934, a brief review of steam navigation in victoria, pleasure steamer edina, trade and travel late 19th and early 20th century, trade melbourne to geelong, screw steamer edina, coastal trader edina, lighter dinah, cargo carrying for cremean war, cargo carrying for american civil war, passenger and trade in western district of victoria, export gold and currency and gold diggers to new zealand, export vessel to h r h the duke of edinburgh, melbourne - warrnambool - port fairy - portland cargo run, warrnambool steam packet company, stephen henty, captain john thompson, chief engineer john davies, lady bay warrnambool, lighter edina, shipping victoria, port phillip bay steamers, steamship great britain, edina, vhr s199 victorian heritage database, drawing of ss edina, pen and ink drawing of ss edina, pen and ink drawing 1870's - 1938, maritime drawing of screw steamer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase/Trunk

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hatbox on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervation's to the design of luggage as it became a fashionable item.Suitcase/trunk with inner tray, brown canvas covered with 2 hinge clamps and a central Eagle lock, four wooden lateral buffer railed slats running around the case, leather handles each end. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Travel Trunk, 1890-1920

... have been made in America or Britain as the locks used in both ...Steamer trunks (named after their location of storage in the cabin of a steamship, or "steamer") which are sometimes referred to as flat-tops, first appeared in the late 1870s, although the greater bulk of them date from the 1880–1920 period. They are distinguished by either their flat or slightly curved tops and were usually covered in canvas, leather or patterned paper and about (36 cm) tall to accommodate steamship luggage regulations. Steamer trunks were originally called a cabin trunk. An orthodox name for this type of trunk would be a "packer" trunk, but since it has been widely called a steamer for so long, it is now a hallmark of the style. A trunk, also known as a travel trunk, is a large cuboid container designed to hold clothes and other personal belongings. They are most commonly used for extended periods away from home. Trunks are differentiated from chests by their more rugged construction due to their intended use as luggage, instead of storage. Among the many styles of trunks, there are Jenny Lind, Saratoga, monitor, steamer or Cabin, barrel-staves, octagon or bevel-top, wardrobe, dome-top, barrel-top, wall trunks, and even full dresser trunks. These differing styles often only lasted for a decade or two and along with the hardware can be extremely helpful in dating an unmarked trunk. Although trunks have been around for thousands of years in China and elsewhere, the most common styles seen and referred to today date from the late 18th century to the early 20th century when they were supplanted in the market by the cost-effective and lighter suitcase. There were hundreds of trunk manufacturers in the United States and a few of the larger and well-known companies were Rhino Trunk & Case, C.A. Taylor, Haskell Brothers, Martin Maier, Romadka Bros, Goldsmith & Son, Crouch & Fitzgerald, M. M. Secor, Winship, Hartmann, Belber, Oshkosh, Seward, and Leatheroid. One of the largest American manufacturers of trunks at one point the Seward Trunk Co. of Petersburg, Virginia still makes them for school and camp, and another company Shwayder Trunk Company of Denver, Colorado would eventually become Samsonite. Another is the English luxury goods manufacturer H.J. Cave trading since 1839. Their Osilite trunk was used by such famous customers as T.E. Lawrence and Ruth Vincent Some of the better known French trunk makers were Louis Vuitton, Goyard, Moynat, and Au Départ. Only a few remain with the most prominent US company being Rhino Trunk and Case, Inc who probably manufacture more trunks than any company in the world.A snapshot into our social history regards how travel was undertaken over a hundred years ago and how people travelled so differently than today as they often packed for extended travel on ships. Travel then was so different with people having to pack a very large wardrobe of clothes to last for some time possibly for months overseas. The subject item looks like it was of military issue and was used for travel during the first world war by a military man from Victoria and was one of six similar trunks. This assessment is based on the type of locks used the trunk itself could have been made in America or Britain as the locks used in both countries came from American lock makers.Trunk wooden large covered with leather wood cleats and brass locks, also unreadable tableIn white paint "H Onvett, 6 of 7 and bottom right of front the number 6 (Owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trunk -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bottle, Singer Sewing Machine Company, ca 1878

This Singer Sewing Machine oil bottle was made by hand, with the glass blown into a mould. Isaac M. Singer established his sewing machine company, I.M. Singer & Co. in America in 1851. A brief history of the Loch Ard (1873-1878): - The sailing ship Loch Ard was one of the famous Loch Line ships that sailed from England to Australia. Barclay, Curdle and Co. built the three-masted iron vessel in Glasgow in 1873. It had sailed three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of recently married, 29-year-old Captain Gibbs. It was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, and a heavier load of railway irons, cement, lead and copper. Other cargo included items intended for display in the Melbourne International Exhibition of 1880. The Loch Ard had been sailing for three months and was close to its destination on June 1, 1878. Captain Gibbs had expected to see land at about 3 am but the Loch Ard ran into a fog that greatly reduced visibility and there was no sign of land or the Cape Otway lighthouse. The fog lifted at 4 am and the sheer cliffs of Victoria's west coast were much closer to them than Captain Gibbs expected. He tried to manage the vessel but failed and the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. The top deck loosened from the hull, and the masts and rigging crashed down, knocking passengers and crew overboard. The lifeboat was launched by Tom Pearce but crashed into the side of Loch Ard and capsized. He clung onto its overturned hull and sheltered under it. He drifted out to sea and the tide brought him back to what is now called Loch Ard Gorge. He swam to shore and found a cave for shelter. A passenger, Eva Carmichael, had raced onto the deck to find out what was happening and was confronted by towering cliffs above the ship. She was soon swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He swam out and dragged her to the shelter of the cave. He revived her with a bottle of brandy from a case that had washed up on the beach. Tom scaled a cliff in search of help and followed some horse hoof prints. He came from two men from Glenample Station, three and a half miles away. He told the men of the tragedy and then returned to the gorge while the two men rode back to the station to get help. They reached Loch Ard Gorge and took the two shipwreck survivors to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome and was presented with a medal and some money. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy.The bottle is significant for representing an early innovation in domestic sewing, the treadle sewing machine. It is also significant for its connection with the Loch Ard shipwreck. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we are able to interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collection's historical significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Clear glass bottle, straight neck, broad shoulders tapering to slightly narrower indented base. Bottle once contained Singer Sewing Machine oil. Inscription embossed in the glass. Bottle was recovered from the wreck of the Loch Ard.Embossed in the glass "The Singer Manufacturing Company" on one side on the reverse "Extra Quality Machine Oil." flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, singer sewing machine, sewing machine oil, singer sewing machine oil, oil bottle, isaac m. singer, loch ard artifacts, loch ard -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pewter Dome Cloche, James Dixon & Sons, 1900-1940 as indicated by the design No 399 stamped in the cover

James Dixon & Sons were founded in 1806 in Sheffield and were one of the major British manufacturers of the Industrial Revolution. They were manufacturers of pewter ware, electroplated Britannia metal, silverware, and electroplated nickel silver. Their products included hundreds of items for use in the kitchen (e.g. bowls, cutting tools) and the dining room (e.g. tea services, cocktail shakers, and mixers) as well as items such as candlesticks. They were a world leader in manufacturing shooting accessories through the nineteenth century and exported powder flasks in large quantities to America, They were known as whistle makers, which like most of their products were of outstanding quality. They were located first at Silver Street (1806), Cornish Place (1822) Sheffield. Their registered trademark since 1879 was a Trumpet with a Banner hanging from it. Although registered in 1879, the "Trumpet with Banner" logo was used at times before registration and appears on some of their silver plate pieces. They were one of the foremost names in EPNS and sterling silver tableware including silver tea services and hollowware pieces. They also made silverware serving pieces and had a wide catalogue of patterns. Their tea sets and hollowware pieces produced in silver are now very valuable as antiques. The firm continued to be a family-run enterprise until 1976. The patterns are currently owned by another Sheffield firm that exports products mainly to the Middle East.An item made for domestic use late19th to early 20th century by a renowned maker of pewter and silverware products. These types of products give us a snapshot into domestic and social life during the time it was made.Pewter Cloche or cover for food ornate handle at top. Ring on one end. Number 399 inside lid & Dixon & Sons Sheffield.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pewter ware, james dixon, silver ware, kitchen cutlery, britannia steel, food cover, cloche -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Plate, Edward Challinor, Circa1862-1891

The pottery was at Fenton, Stoke on Trent, Staffordshire UK and was established in 1825, by C J & GM Mason, they were succeeded by Mr. Samuel Boyle from whom the works passed into the hands of E & C Challinor, formally E Challinor & Co. Of Sandyford and Tunstall. The partners in Sandyford and Tunstall works are recorded as Edward Challinor Jnr and Charles Challinor Jnr and is presumably they are the sons of the partners of the Fenton pottery business. They produced china of white granite, printed sponged common earthenware for the American, Australian, and other foreign and colonial markets. The main goods produced were tea, coffee, breakfast, dinner, and toilet ceramic sets as well as other earthenware goods. Their pottery marks were the Staffordshire rope knot with or without E & C Challinor or just E C. An early piece of earthenware pottery made in England for the Australian colonial market around the mid to late 19th century.Serving plate white body, smooth rim, and blue oriental designRope knot motif printed on back in blue with letters EC warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, earthenware, ceramic, willow pattern, serving plate, e & c challinor, potteries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Boiling Copper, Newberry & Walker, Boiling Tub, Circa1900

Francis John Newberry founded the Victoria Foundry and Enameling Works in 1890 with a workmate from the Humbles iron foundry in Lupton Street Geelong where he worked. Newberry & Walker Foundry & Enameling Works was built adjoining a cottage that was to be the home of the Newberry family during the ensuing years. Although Walker soon relocated to New Zealand, the Newberry and Walker foundry had become a local success. The foundry produced numerous cast iron products such as washing copper frames, and friezes, balustrades and verandah columns. Verandah posts are to be found in declining numbers, but the Newberry and Walker mark can sometimes be seen on the few which remain. A certain number of iron culvert posts were also made; some of them were still in place on the road to Cressy as late as 1961. Perhaps half the iron friezes on Geelong West verandahs came from the local firm’s foundry. A significant item made in Geelong giving a snapshot into the early beginnings of Victoria's industrial manufacturing of products that helped to replace previously imported items from England or America.Copper boiling tub, cast iron frame copper bowl inside of 14 gallon capacity Newberry & Walkerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, cast iron, newberry & walker, washing copper frame, laundry, dairy, butchering -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Standard avoirdupois weights, Avery Ltd, 1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weights, metal, silver electroplated, 1 x 2lb, 2 x 4lb, 1 x 7lb. (4) all government stamped, made by Avery Ltd.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, imperial weight, imperial standard weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase, 1930-1945

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hat box on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervations to the design of luggage as it became a fashionable item.Suitcase, brown canvas with three wooden reinforcing lateral rails running around the case, leather handle each end (one broken), two locks.. Maker Pettigrew & Stephens Ltd Glasgow. "A.T.Cox 354/3 Riversdale Rd Campberwell, Vic Australia" and "W.ON" painted over on each endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board wooden round with carved inner circle and carving an outer rim in old English lettering "Bread"None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chopping board, cooking, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

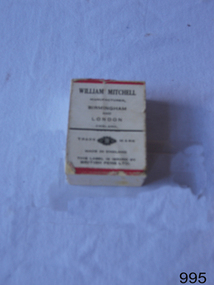

Flagstaff Hill Maritime Museum and VillageNibs & box, late 19th to early 20th century

Box of dip pen nibs made by William Mitchell Calligraphy dating back to late 19th or early 20th century when dip pens with steel nibs were the main writing instruments. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibs are stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. Email on file, from Mike Chappell, Sales and Marketing Manager, William Mitchell Calligraphy, “20161122 - William Mitchell re pen nibs” How to use a dip pen to create modern calligraphy, https://thepostmansknock.com/how-to-use-a-dip-pen-to-create-modern-calligraphy/ India Ink, Wikipedia https://en.wikipedia.org/wiki/India_ink birmingham Pen Trade, Wikipedia, https://en.wikipedia.org/wiki/Birmingham_pen_trade The Pen Museum, http://penmuseum.org.uk/ The early 19th century invention and later mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Box of patent Mitchell nibs containing 48 "Pedigree" nibs. Box depicts picture of William Mitchell on lid, and picture of nib pen on lid and side. Made in Birmingham, England. Nib “0505 Wm MITCHELLS PEDIGREE ENGLAND” Box “PEDIGREE / MAINFOLD SLIP”, “WILLIAM MITCHELL / BIRM - - - - - - LOND” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, william mitchell calligraphy ltd, pen nib, writing implement, writing accessories, dip pen, birmingham manufacturer, communication in writing, mass produced pen nibs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Steamer luggage Trunk, First quarter of the 20th century

Item used around the first quarter of the 20th century The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hat box on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th and early 20th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervation's to the design of luggage as it became a fashionable item.Suitcase/trunk leather reinforced at corners with wooden slats to strengthen the lid. Leather straps to close lid with metal lock in the middle of the lid. Closing strap missing.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Machinery Oiler Can, First half of the 20th century

An oil can or oiler is a can that holds oil usually motor oil for lubricating machines. An oil can can also be used to fill oil-based lanterns. An occupation, referred to as an oiler, can use an oil can (among other tools) to lubricate machinery. Oil cans were made by companies like Noera Manufacturing Company and Perfection in the late 19th and early 20th centuries and around this time, oil cans frequently leaked and contributed to fires. In 1957, aluminium oil cans were introduced, produced by companies like the American Can Company. Rocanville, Saskatchewan, Canada is home to a large-scale oil can industry because of the Symons Oiler factory which produced oil cans during World War II.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item a is believed to have been produced in the first half of the 20th century for marine use.Conical oiler can with spout, screw top lid and top hook for hanging, side handle missing.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, conical pot, pot -

Flagstaff Hill Maritime Museum and Village