Showing 1572 items matching "blades"

-

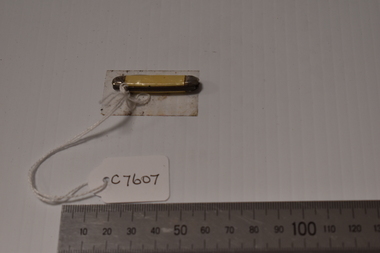

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchFunctional object - Letter Opener, Circa 1918

Made by Albert Henry Rogers who served in the British Army during WW1, the grandfather of the donor. It was made as a symbol of hope as receiving letters from home gave them hope. Hence the bullet made into a letter opener is a symbol of something made to kill into something to give hope. (Transcribed from the donor's description)Small letter opener consisting of a handle made from a .303 bullet and a blade made from an unknown metal. The projectile has been split in half lengthways and the blade soldered in. The markings on the cartridge indicate that it is a Mk VII cartridge manufactured by the Royal Laboratory in 1917.Both sides of the blade have decorative engraving on them. The left side has "ARRAS" engraved on it and the right side has "1918 YPRES" engraved on it. The base of the cartridge is marked R^L 17 and VII.ypres, arras, world war 1 -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionWeapon - 303 Bayonet, Pattern 1907 bayonet without hooked quillon

Bayonet type used by Australian forces in the first and second world warsBritish Pattern 07 bayonet and scabbard. The hilt has a straight crossguard with a muzzle ring and the grips are plain wood held to the tang with two screw bolts. The pommel is missing its push button locking bolt The polished blade is straight having a single fuller to each side and the riccasso is stamped with MA 1907 over 1. '. The brown leather scabbard has a blued steel chape and tear drop locket. The locket throat edge is stamped 3MD35564. The leather body is marked on the reverse MANGROVITE '44.blade -1907 1 Scabbard -MANGROVITE '44.5/6 rvr -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. Although the item is marked J Dixon no reference can be found at this time for a maker of complex moulding planes J Dixon of London. The plane could have been made by an unknown maker and sold through a merchandising agent of which there was one in London at the time. It is this agent J Dixon that could have stamped his mark on the item and then sold the plane on giving the impression J Dixon was the maker, this practice was quite common in the 18th & 19th centuries. This item is still regarded as a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Panel Plough Plane white wood, blade missing. Stamped "J Dixon London" also has the letter "B" stamped flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood working, cabinet making, complex moulding plane, j dixon london, mouldings -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Neville-Barnes obstetric forceps used by Dr Lorna Lloyd-Green

Neville Barnes Obstetric Forceps have a cephalic and pelvic curve and are used for delivery of babies presenting as occipitoanterior. The left blade being put on first followed by the right blade – the baby is then pulled down until the occiput is under the symphysis, then pulled around. (RACGP)Neville-Barnes forceps with traction attachment and pouch. The forceps are nickle plated, and consist of two blades and an attachable axis traction handle. Pouch is made of denim and has a full length pocket insert. The edges of the pouch are bound with a narrow satin binding and machine sewn. The pouch is fastened with a press stud.obstetric delivery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Knife

From the early days of our race, the knife represented one of the first and most important tools that enabled rise of our technology, military, culture, science and all other things that brought us to this point of modern civilisation. As a vital tool for survival, combat, construction and food preparation, the knife quickly became the most basic tool from which all others were born. In those ancient times, 500,000 years ago, sharpened stones started slowly evolving, becoming more and more like their modern counterpart. Before the time when fire enabled the melting of the various metals, and forging them into modern knives, their stone counterparts received several visual upgrades. Double bladed knives were most popular, and their wooden or stone hilts were decorated with animal skins and feathers. Those knives represented a great deal of pride for the warriors and elders who owned them, and that tradition continued to be practised with the arrival of the Bronze Age. The appearance of metallurgy brought the ability to create knives from softer types of metal. Even though knives from bronze did not provide durability over longer periods of time [easily dulled, and susceptible to corrosion), their sharpness and slim designed proved to be superior to any stone knife tool. As the centuries went on, iron and then steel became commonplace across the entire world. Knives created from those materials were much more durable and easier to maintain their sharpness after prolonged use. During medieval times in Europe, steel metallurgy managed to evolve knives from small single or double-bladed edges to larger sizes - swords, spears and axes. Even with all those advancements, the use of knives as an eating utensil continued to be used in some small circles. Even as early as the 15th century, wealthy circles of people started carrying personal knives, intended for double use - both eating and defending against threats. During those times the host were not obliged to provide their guest with any kind of eating utensil in addition to plates, so wealthy males used their eating knives for cutting their own meals, and the meals of nearby female guests. Slim double-bladed knives were good for cutting and piercing foods. As the use of forks became widespread in the whole of Europe by the late 17th century, most people used this kind of small knife on a regular basis (a combination of two knives, one for stabilising and other for cutting the meal). http://www.eatingutensils.net/history-of-cutlery/knife-history/The knife is one of the most important items that has enabled the development of civilisation over thousands of years.Carving knife with wooden handle and rusted slender metal blade.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, knife, kitchen equipment, dining -

Orbost & District Historical Society

Orbost & District Historical Societypaling knife, c. 1890s to 1960s

Used in the timber industry for making split palings. The palings are shaped by hand with the bottom edge put onto the timber and a mallet hit onto the top of the blade. This pre-dates sawn palings. Associated with the timber and household building industry in the Orbost region.A rectangular flat iron blade attached to a wooden handle. The cutting edge of the knife is along the bottom (rather than the end as with an axe). The wooden handle appears to be made from a small tree branch.paling-knife splitting-timber -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Screw Driver, F G Pearson & Co, First quarter of the 20th century

A very unique screwdriver or turn screw possibly used by a Ship Builder, Railroad Engineer or other tradesman in need of a long reach. The handle shape or pattern indicates it could have been made by G Pearson later F G Pearson Sheffield at the Hope Works. This company was established in 1854 and by 1914 the company was manufacturing many differing types of edge tools, joiners' tools, forks and garden tools. Their specialities were hay, manure and coke forks, punches, armourers' tools etc. In 1938 the Company was styled F. G. Pearson and Co (Sheffield) Ltd and they were still making plane and other sharp edged blades as late as 1957, but by the 1970s they had gone out of business. A significant company based in Sheffield England and making tools of all types and exporting same to various countries around the world. This particular item is a vintage and unusual screwdriver possibly used by a local Warrnambool tradesman. Screw driver wooden handle. Straight blade attached with brass ferrule.Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, screwdriver, tools, f g pearson sheffield -

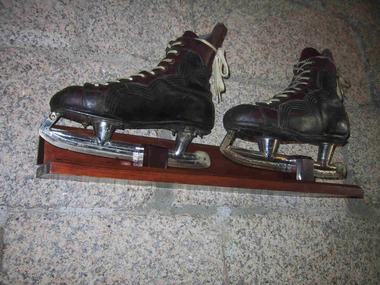

Parks Victoria - Mount Buffalo Chalet

Parks Victoria - Mount Buffalo ChaletSkates

Ice skates used to skate on Lake Catani. Ice skating was a popular activity for guest and visitors to Mt Buffalo. Ice skates were provided for hire by the the first Lessee of the Chalet, John Newton and also Norwegian born Hilda Samsing, who took over from him in 1919 and did much to pioneer and promote winter sports in the Victorian Alpine region . Ice cover on the Lake has not been sufficient for safe skating for many decades. 'After its initial popularity, skating at Mount Buffalo dwindled in the post-war years. According to Museum Victoria curator, Michelle Stevenson, few collections hold historic ice-skates, so any early examples identified in the Chalet collection will be important for their rarity." (Pg 94. Historica) 'Ice-skating was a popular recreational activity in the later nineteenth and early twentieth centuries...According to Michelle Stevenson, Australian Collections hold little material culture relating to its practice other than images and film. The few pairs of ice skates in the Chalet collection, which are in good condition, are important for their rarity as well as for illustrating the popularity of skating on Lake Catani prior to WW2.' Pair of black leather ice scates, mounted on wall. Skates feature white laces, metal blades and brown leather reinforcing area around laces and ankles.Boots are stffed with 1993 newsprint.On skate blade, "Made in Canada 11 1/3 CCM / Senior A" On boot sole , "Made by J Molony " plus worn name label. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, large Saw, 2 man, c1900

Early settlers had to clear the land of trees and shrubs to establish and maintain their farms and market gardens. Some settlers worked in the Gippsland region felling timber for transport by bullock wagons to Melbourne. Two-man crosscut saws were primarily important when human power was used. Such a saw would typically be 1 to 4 m (4 to 12 feet) long, and sometimes up to 5 m (16 feet), with a handle at each end. The technique in using a two-man saw involved a sawyer standing at each end and together the sawyers would alternate pulling the saw through the wood. If the kerf -slit- began closing, causing the saw to bind, wedges would be inserted behind the saw blade in order to keep the kerf open.Two-man saws were designed to cut in both directions. Careful tooth design was necessary to clear the sawdust during the cut. This is a typical two-man tree felling saw that was necessary to clear the land when the pioneers were establishing their market gardens and farms in Parish of Moorabbin c1850A long steel blade saw with 2 wood handles c1900tools, saws, axes, early settlers, pioneers, market gardeners, dairy farms, orchards, vineyards, timber mills, bullock wagons, tree felling, timber mills, city of moorabbin, county of bourke, moorabbin roads board, parish of moorabbin, shire of moorabbin, henry dendy's special survey 1841, were j.b.; bent thomas, o'shannassy john, king richard, charman stephen, highett william, ormond francis, maynard dennis, -

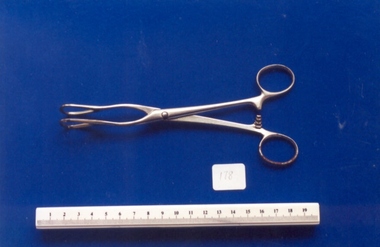

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Tool - Guy's tongue forceps used by Dr Mitchell Henry O'Sullivan, 1930 (approximate)

During surgery under general anaesthetic, these forceps were used to pull the tongue forward to keep the patient's airways clear from obstruction. This tool was in general use from the 1930s onwards in teaching hospitals, and became a standard piece of equipment on all anaesthetic trolleys. In the majority of teaching hospitals, the blades of these forceps were smooth and wide to cause less trauma to the tongue. This particular style of tongue forceps is known as Guy's tongue forceps.Dr Mitchell Henry O'Sullivan worked in the Victorian country town of Casterton as a general practitioner from 1919 until his death in 1977. He also practiced obstetrics. His son, Dr David More O'Sullivan donated his obstetric bag and its contents to the College in 1999. The bag and contents are a unique time capsule of the type of instruments and pharmaceuticals used in the inter-war period.Pair of metal forceps. Similar in appearance to a pair of scissors, and other surgical forceps, but with rounded teardrop shaped tips. There is also a notch clip for the handle to keep the forceps open. Inner aspect of both forceps blades engraved with the number '3'. The left hand blade is also engraved with a 'P'.anaesthesia -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, cut-throat razor “Kings Crown’, 20thC

KING RAZOR MFG. CO.Pittsburgh, Pennsylvania; moved to Indiana, Pennsylvania in 1911.ca. 1904 - 1919 Marked "Made in Germany", although the company's offices were located at 118 E. 28th Street, New York City. ca. 1934-1943 Used the "THE KING OF RAZORS REGISTERED TRADEMARK" trademark. 47-1/2 and Trademark: Crown and Wolf. For 500 years the Weyersberg family has been producing the finest blades in the world. For centuries the King’s Crown™ mark has been synonymous with exacting precision, hand-craftsmanship and quality. For the first few hundred years the blades, made in Solingen, Germany (the “City of Blades”), were for swords. As times changed, the Weyersberg family transitioned into making cut throat razors. The Greb. Weyersberg™ family business.continue to place our mark on each and every product sold as we have done since first being able to register it in 1774. For over a 100 years, the straight razors continue to be produced in Solingen (Germany). King's Crown™A folding cut-throat razoron blade ; KING'S / CROWN 'a crown trademark' RAZOR / EXTRA HOLLOW GROUND around 'trademark' ; SET READY FOR USE on steel handle; MADE IN GERMANYcut-throat razors, straight razors, shaving equipment, steel blades, swords, weyersberg family, king crown pty ltd., solingen, germany, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Laryngoscope

Metal laryngoscope in two parts. A round hollow handle with a textured grip and a screwed in base for holding batteries. The metal blade screws in to the handle and has a moulded section for a small light bulb. Engraved in to top of blade, D.A. Engraved in to base of handle, B.T.S. / R.W.H. D.A. Stamped in top of the handle, PAT.NO.683731 Stamped in top of the handle, BRITISH [indecipherable]laryngoscope, light bulb, battery -

Orbost & District Historical Society

Orbost & District Historical Societymortising axe, late 19th - early 20th century

A mortise axe is a specialist axe designed for hewing sills and notches in joints. The axe has a long, narrow head, making it easier to work on large logs. The shape enables the user to hew a long way down into the notch, where otherwise a chisel would be used. This tool has one blade, which may be pushed, swung or struck with a mallet. Others, have two, one of which is used for separating the fibres, and the other for levering out the waste.This is an example of a common woodworking tool used by the early settlers in the Orbost district.A long wooden handled axe used to cut mortises in posts for post and rail fences. The blade is made of iron and is quite long.axe mortise-axe fencing timber farm-tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, James Hastie, Late 19th to Early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane with metal blade attached. Made by J Hastie. Inscriptions stamped into wood. "J Hastie" "E G" "W.M" "EG" "11"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j hastie, plane, wood working tool, hand tool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Wooden Spokeshave

A spokeshave was made with a wooden (usually beech wood) body and metal cutting blade. With industrialisation metal bodies displaced wood in mass-produced tools. The name 'spokeshave' reflects the early use of the tool by wheelwrights.Used by carpenters and/or cabinet makers and/or wheelwrights in the Kiewa Valley in the 1800s and 1900s. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. It is a shaping and smoothing tool eg. curves and rounding and used after cutting with chisels or saws. Ref. Pg 28 Tools for all Trades Cataloguewoodworking tool, spokeshave tool -

Bacchus Marsh & District Historical Society

Bacchus Marsh & District Historical SocietyTool, Pocket Knife

This pocket knife is believed to have been used by an employee of the Bacchus family and possibly given to the employee by the Bacchus family. It is therefore an object with a probable linkage to one of the earliest European colonist families in the Bacchus Marsh area.A pocket knife with mother of pearl handle and a silver blade.On the handle on one side there is an engraved decorative design featuring a bird, leaves and flowers. Along the middle of the handle there is a blank cartouche of silver, intended for the name of the owner. On the other side there are two engraved starbursts. On the blade there are five hallmarks, a crown, a lion passant, head of Queen Victoria, letter G and the letters JM. The crown represents Sheffield. The lion passant indicates the knife was made in England, the image of Queen Victoria is a Duty Mark, the letter G indicates that the year of manufacture was 1850. JM indicates one of two manufacturers - JM or Mappin & Son.knives, bacchus family -

Woodend RSL

Woodend RSLBritish WWII RAF and Special Forces Survival Knife, Late WWII?

A rare example of a Type D Survival Knife issued to British RAF during the latter part of WWII.Heavy duty survival knife with single edged oval shaped broad blade and wooden handle contoured for grip. Two large screws secure the grips. The pommel end has a wrist cord hole (cord not present). See also item 2020.000034-2 (leather sheath). Blunt end of blade near grip there is engraved '27C/2360', reverse side is the makers mark 'Rodgers Sheffield England'.british airforce, survival knife, ww2, wwii, type d -

Nillumbik Historical Society Incorporated

Nillumbik Historical Society IncorporatedTool - Jack Plane

Example of carpententers tools from late 19th to early 20th centuryWooden "Jack Plane" with shaped handle, blade, blade holder and wooden blade wedge. #carpentersplane, #wooden, #jackplane, #carpentry -

Waverley RSL Sub Branch

Waverley RSL Sub BranchFolding knife

Carried by C. Felstead during WWI Thought to be British Army IssueFolding metal knife with 3 blades and a copper loop for attachment to a lanyard Blade 1 is an edged blade cor cutting Blade 2 is a "can opener" Blade 3 is a "Marlin spike"(defense dept arrow) WEknife pocket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scythe, 1930-1960

A Scythe was one of the most important of all agricultural hand tools, consisting of a curved blade fitted at an angle to a long, curved handle and used for cutting grain. In modern scythes the handle has a projecting peg that is grasped by one hand, facilitating control of the swinging motion by which grass and grain are cut. The exact origin of the scythe is unknown, but it was little used in the ancient world. It came into wide use only with agricultural developments of the Carolingian era (8th century AD) in Europe, when the harvesting and storing of hay became important to support livestock through winters. Scythes can still be found in use today by hobby farmers and permaculturists. ( producing food, by using ways that do not deplete the earth's natural resources) to cut grass in a more eco-friendly way as opposed to using a machine.A hand tool used for the cutting of crops and grain, modern versions are still being produced today in Europe. The subject item gives us a snapshot into agricultural practices in times past.Scythe with long wood Snath (curved handle) with 1 hand holding piece & curved blade. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Whaling Spade, n.d

Part of the collection purchased from Brendan Kurtze by the City of Portland. From the Kurtze Museum. Spades were used primarily for cutting up a whale. They were flat-bladed implements (except the gouge spade) with a chisel cutting edge and were mounted on wood poles by means of a socket at the aft end of the spade. The blades of later spades, after the 1850's, were usually made of cast steel, while the sockets and shanks were wrought iron. Cast steel held a cutting edge far better than the earlier wrought iron, and was necessary for repeated cutting. The sockets of spades were forge welded closed, without an open seam, for added strength. They were secured to the pole with a nail, screw or pinWhaling implement, iron, painted gloss black. Flat blade and handle sleeve on either end of shaft, no handle. Spades were used primarily for cutting up a whale. They were flat-bladed implements (except the gouge spade) with a chisel cutting edge and were mounted on wood poles by means of a socket at the aft end of the spade. The blades of later spades, after the 1850's, were usually made of cast steel, while the sockets and shanks were wrought iron. Cast steel held a cutting edge far better than the earlier wrought iron, and was necessary for repeated cutting. The sockets of spades were forge welded closed, without an open seam, for added strength. They were secured to the pole with a nail, screw or pinkurtze museum, whaling, tools, industry, maritime -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, William Marple & Sons, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. William Marples junior joined his father's joinery making business in 1821. In 1860 William's sons joined him and the firm became William Marples and sons. Over the years they acquired John Moseley & Sons a London plane maker and Thomas Ibbotson & Co a Sheffield edge tool maker. Growing to become the most prolific and best known Sheffield tool maker. Their large factory was known as the Hibernia Works. Their trademark was a shamrock that appeared on some of their tools, in 1961 they had about 400 employees. In 1962 the record Tool Company and William Ridgway acquired a fifty percent interest in the company and in 1972 the companies merged with several others to form Ridgway Tools Ltd. After 116 years at its Hibernia Works, the company was moved to Dronfield. A 1982 takeover by A G Bahco of Sweden was short-lived and in 1985 Record Ridgway returned to British ownership first as Record Marples Woodworking Tools Ltd. In 1988 then as Record Holdings PLC in 1993. In 1998 the company accepted a bid from American Tool Corporation, subsequently trading as Record Irwin. The Irwin company itself was acquired by Newell Rubbermaid in 2002 and renamed Irwin Industrial Tool Co. Both the Marples and Record names were re-branded "Irwin" However the name has since been resurrected as Irwin/Marples and applied to wood chisels and table saw blades now made at their new facility in Udine, Italy. As a footnote, William Marples was the uncle of Robert Marples and Joseph Marples, both of whom established competing tool making businesses in Sheffield. The Robert Marples firm disappeared early in the 20th century. After several changes in the company's ownership tools are now made under the Ridgway name but in China. A tool made by a company with a long family history of tool making in Sheffield England, with a member of the Marples family, Joseph Marples establishing a competing tool company which continues today to manufacture quality products for the joinery and shipwrights trades.Caulking tool straight wide blade, Stamped "W Marples & Sons" & James S Steele tool box.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking tool, caulking iron, james s steele -

Lara RSL Sub Branch

Lara RSL Sub BranchShort Sword, French 1831 Pattern Artillary Shord Sword

French 1831 Pattern Artillery Short Sword A French 1831 pattern brass handle dismounted artillery mans short sword, marked Talabotts Paris with black leather brass mounted scabbard. Blade, length 49cm, total length 64cm The French 1816-1831 sword was based on ancient sculptural depictions of the Roman gladius, the standard sword of the Roman legionaries. Both sword and scabbard are in very good condition.Short Sword Brass Handle with 26 cm Blade French 1831 Pattern Artillery. Based on ancient sculptural depictions of the Roman gladius, the standard sword of the Roman legionaries.Stamped number on center of the guard of the hilt is 770. There is some marks also on center of the guard on the opposite side but not readable.french short sword 1831, brass handle, metal blade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGouge

John Heath tool boxGouge with Ward stamped on blade. Handle is wood octagonal. Blade is v shaped Blade is 94mmL x 6mmW.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

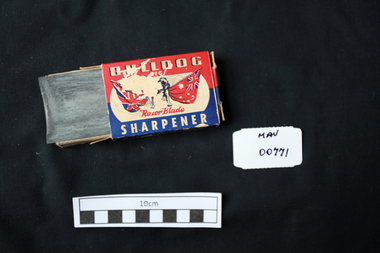

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, man's razor blade sharpener, c1940

A box containing abrasive paper for sharpening a man's razor blade. Box has directions for use on base of the sliding insert.Front :BULLDOG / REG. / a Bulldog with a British and an Australian Flag / Razor Blade / SHARPENER. Back: BULLDOG / REG./ :Gives / longer life" / SHARPENER/ Sides: A CLEAN SHAVE ENSURES / THAT FEELING OF CONTENT. Insert Top : FOR BEST RESULTS USE / VERY LIGHT PRESSURE. Sides:FINISH OFF BY WIPING EDGES / ON PALM OF HAND. / Made in Australia .razor blades, gillette company, razor sharpeners, bulldog company, toiletries, personal effects, shaving equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1869-1920

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type Marked Routledge No.8 Blade Stamped JAS Burden (owner). flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumFunctional object - Knife - pocket

Mother of pearl finish on pocket knife blade. Knife blade.pocket knife, mother of pearl -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 20th century

A special version of the rebate plane, the keel and stem rabbet plane. This was a wider than the usual rebate or rabbet plane, and the blade was set askew to the side to give a slicing action. It was used for cleaning out the rabbet cut from the head of the stem, and along the keel, to take the ends and edges of the planking - its angle varied according to the ship.Rabbet plane. Has a makeshift piece of wood screwed to base to protect it. Made by Sherman Nth York. Blade size 2". A square piece of leather is tacked to top of plane. Red paint markings are on one side.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rabbet plane., wood working, wood working tools, hand tool -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchWeapon - Edged weapon, Edged sword, Circa WW2

Asian sword. Bone handle with wooden handle with shark skin covering. Brass fittings.Ornate blade