Showing 298 items

matching farm tool

-

Churchill Island Heritage Farm

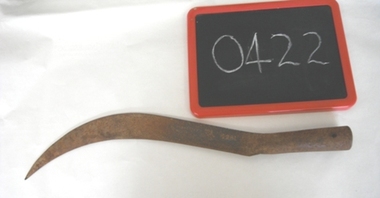

Churchill Island Heritage FarmTool - SICKLE

A Sickle is an agricultural hand tool used for harvesting or reaping grain crops using the sharp blade in a swinging or hacking motion. It was also used for cutting back forage and other plant growth. They have been used since early Iron Age times and many examples have been found in the Middle East dating back 18,000 to 8,000 BC. This is a bagging hook – a type of larger and heavier sickle used mainly for harvesting of grain. It continued to be used after industrialisation and the implementation of the mechanical reaper. Designed to be used by the right hand, its age is unknown. Right handed sickle. Blade painted black. Handle varnishedsickle, harvesting, churchill island heritage farm -

Churchill Island Heritage Farm

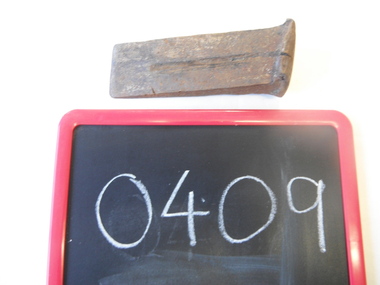

Churchill Island Heritage FarmTool - wedge

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.Used by the donor in clearing timber at Olinda and Shady Creek, Victoria. Forms part of a timber clearing tool collection including cross cut saws and Trewhella jack.wood cutting/splitting wedge. Steel. commercially made. Has relief groove.TROJAN [stamped on side]timber cutting;, timber splitting, olinda, shady creek, churchill island heritage farm, wilfred dungan collection -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - WEDGE

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.Timber splitting wedge; steel; commercially made; has relief groove.timber splitting, churchill island heritage farm, olinda, shady creek -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.wood splitting wedge; commercially made; steel; surface rust; with relief groovetimber splitting, churchill island heritage farm, olinda, shady creek -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.wood splitting wedge; commercially made; steel; relief groove; surface rusttimber splitting, churchill island heritage farm, olinda, shady creek, wilfred dungan collection -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge, HYTEST FORGED TOOLS

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.small wedge with substantial chip out of narrow end. Relief grooveHYTEST FORGED TOOLStimber splitting, churchill island heritage farm, olinda, shady creek, wilfred dungan collection -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.blacksmith made steel wedge with irregular relief groove; surface rustwilfred dungan collection, timber splitting, churchill island, blacksmith, olinda, shady creek -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge, Blacksmith made

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.blacksmith made; hand-hammered relief groove. Well used - top mushroomed out. timber splitting, blacksmith made, churchill island heritage farm, olinda, shady creek, wilfred dungan collection, wedge -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge, blacksmith made

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.one of three wedges cut from one piece of steel. No relief grooves.timber splitting, churchill island heritage farm, olinda, shady creek, blacksmith made, wilfred dungan collection, wedge -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge, blacksmith made

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.One of three wedges cut from one piece of steel. Blacksmith made.churchill island, wedge, wood splitting -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wedge, blacksmith made

An agricultural tool used by loggers, or farmers, the log splitting wedge has been used for thousands of years and was originally made from stone. They were either driven straight into the wood or into a previously made incision with the blade parallel to the grain. Using a sledgehammer or other tool hammered onto the flat end, the wedge is forced deeper into the log until the force splits the timber.one of three wedges cut from the same piece of steel. No relief groovestimber splitting, churchill island heritage farm, olinda, shady creek, wedge -

Churchill Island Heritage Farm

Churchill Island Heritage FarmFunctional object - Trewhella jack, c.1900

Used for clearing land in conjunction with wood cutting/splitting tools previously donated by Wilfred Dungan.The manufacturers claimed that the Wallaby jack could "assist with grubbing, root running, log rolling, lifting stone, pulling fences, raising waggon trucks or implements etc.". Benjamin and William Trewhella established a foundry in Trentham in 1888 which became the largest manufacturer of grubbers and jacks for industrial use in Australia and also supplied overseas markets. Trewhella Wallaby Jack: combination of commercially manufactured body and blacksmith made handleWALLABY TREWHELLA BROS PTY LTD TRENTHAM AUSTRALIAtrentham, trewhella brothers, blacksmith made, olinda, shady creek, timber work -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Fern hook, c.1920s

A fern hook is an agricultural tool used for slashing or reaping crops which are then gathered in sheaves and bundled together. Primarily used for penetrating and cutting through larger and heavier foliage, this example has a bored hole, probably used for attaching a longer wooden handle.fern hook with surface rust, but made from good steel. No handle."PARKER CAST" image of feet in first ballet position, with No 6 under left foot. "1281"parker tools, fern hook, agriculture, churchill island heritage farm -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Scythe

A scythe is an agricultural hand tool that cuts grass and is used by making large sweeping motions through the crop. Eventually replaced by horse-drawn or motorised machinery, they are occasionally still used as they are inexpensive and efficient. There are different types of scythes with larger or smaller blades. This particular scythe has a bored hole in the handle, probably for affixing a long wooden handle. Made by Trojans and Sons, a Melbourne based company that made a wide range of gardening and agricultural tools, this scythe formed an integral part of farming on Churchill Island. scythe with surface rust, no handle, good steel, rough welds on socket, hole for mounting handle (e.g. with screw)TROJAN/264scythe, hand tools, agriculture, churchill island heritage farm -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - wooden mallet

This mallet has a cylindrical head and would have been used to guide chisels for woodworking. The hammer end has a larger surface area than oblong mallets and gives greater control with less force. Wooden mallets don’t damage the metal head of the chisel as would an iron hammer. Wooden mallets would also be used to knock timber furniture together without damage.Wooden mallet with turned grooves around head - 2 double and 1 single. Oak handle. Head has cream paint remnants both sides.mallet, hand tools, wooden tools, churchill island -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Hand drill, c1960s

This hand drill was colloquially called an ‘egg beater drill’ due to its method of operation, and was aesthetically similar in appearance to the ‘breast drill’, with the former having a rounded handle instead of a concave bracing surface. Originally designed for drilling into metal, its gears allowed for higher rotation speeds and finer accuracy. This drill was probably manufactured in the 1960s by German company BECON. Distributed in Australia by Beck & Coram, it was widely used and easily accessible.Hand drill with red wheel, dark red paint remnants on handleBECON D129hand drill, hand tools, wood working tools, churchill island -

Churchill Island Heritage Farm

Churchill Island Heritage FarmPhotograph of two men, Unknown

Churchill Island Heritage Farm has a large photograph collection dating from the mid-nineteenth century to the last decade. This series of photographs show candid pictures taken by previous residents of the Island.Photograph of two men standing in front of a fence amongst the bush. One appears to be leaning over and inspecting the bus with a group of tools standing on the grass.Catalogue number written on the reverse in pencil.photograph, churchill island -

Churchill Island Heritage Farm

Churchill Island Heritage FarmPhotograph - Photograph of four people in Amess Barn

Churchill Island Heritage Farm has a large photographic collection dating from the nineteenth century. This series of photographs was probably taken around Churchill Island and shows the community engagement through the decades.Photograph of four people holding farming tools standing in Amess BarnCatalogue number written on reverse in pencil.churchill island, photograph -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - HARRIS Collection Metal Hooks

Jonathan Harris operated a winery on the banks of the Axe Creek, Axedale in the 1850s. Metal hook combination is made from one and a half centimetre diameter metal in two pieces, with four centimetre circles on each end 40 centimetres long. They are joined at the top by a threaded section with a square nut, a thin metal washer and a one centimetre thick four centimetre wide square metal piece. Part of the Harris Collectionagriculture, farm, hanging hooks -

Myrtleford and District Historical Society

Myrtleford and District Historical SocietyTobacco Cutter

This plug tobacco cutter was collected locally and displayed as part of the memorabilia display at the Tobacco Company of Victoria Ltd., Myrtleford. Plug tobacco could be acquired on tobacco farms or purchased at local outlets.Tobacco cutters were significant tools for pipe smokers until self-made or manufactured cigarettes began to dominate the tobacco sales market from the 1920s. Such cutters are a link to a previously common means of consuming tobacco.A small cast iron and wooden guillotine-style tobacco cutter. The metal cutter is mounted on the wooden base, with a wooden striker plate.Inscription "McMillan" appears on the striker plate.tobacco cutter -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncService Maunuals Case, Service Manuals in officially supplied Case, C. 1930s 1940s

Service manuals for the B-24D Liberator aircraft.These instruction mauals were officially issued from the Consolidated Aircraft Corporation, San Diego, California USASquare leather case with 2 handles and metal clasp, with gold inscriptions.E. Duplex SUMITON, ALA. CONSOLIDATED VULTEE with an eagle in gold circle. Service Manuals. 01618 i tooled into base of case. -

Clunes Museum

Clunes MuseumTool - METAL SCOOP, UNKNOWN

THIS TOOL CAME FROM WALTER COOK'S FARM AND WAS USED WHEN BLASTING ROCK DURING CONSTRUCTION OF SHEEP DIP. IT WAS THOUGHT TO BE USED MUCH EARLIER IN THE HISTORY OF THE FARM TO BLAST THE WELL WHICH IS THE MAIN WATER SUPPLY FOR STOCKTOOL USED TO CLEAN OUT HOLE FOR DYNAMITE WHEN BLASTING ROCKlocal history, trades, tools, cook family -

National Wool Museum

National Wool MuseumTool - Numnuts Prototypes, Numnuts

Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.Four prototype numnuts tools made from white plastic and stainless steel, each in varying stages of production. FInalised version made with black, orange and clear plastics.8097.2 - Mk4 8097.3 - Numnuts Tool V7; 20 10 0 8097.4 - On label - Numnuts NumOcaine 100ml 65 proceeduressheep, tools, castration, innovation, docking -

National Wool Museum

National Wool MuseumTool - Numnuts, Numnuts, 2020

Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.8098.1 - Numnuts tool made with stainless steel and black, orange and grey plastic. 8098.2 - Glass bottle with orange and grey plastic nozzle containing water for injection. 8098.3 - Yellow plastic case containing 12 stainless steel needles 8098.4 - 10 green plastic elastrator rings 8098.5 - Product cardboard box with the product image on the front8097.2 - on label - For animal treatment only WATER FOR INJECTION 100mL 8097.3 - On case - numnuts 12x Veterinary Hypodermic Needles On needdles - 18G 8097.5 - Numnuts targeted pain relief for tail docking and castrationnumnuts, tools, sheep, castration, docking -

National Wool Museum

National Wool MuseumTool - Water Pump, c.1960

A windmill may be considered one of the most iconic sights of Australian Farming life. A pump like this rest at the heart of all such windmills, turning wind energy into water for farmers both here in Australia and worldwide alike. The water windmills access is referred to as an aquifer, an underground layer of water trapped in rocks but accessible with use of water wells and windmills. Australia is home to an underground aquifer known as the Great Artesian Basin. It is the largest and deepest aquifer in the world. Stretching over 1,700,000 square kilometres, the Basin underlies nearly a quarter of the continent including most of Queensland, the south- east corner of the Northern Territory, the north-east part of South Australia and the northern part of New South Wales. The basin is 3,000 metres deep in places and is estimated to contain 64,900 cubic kilometres of groundwater. To try and give this number context, a megalitre is a million litres. The Great Artesian Basin contains 65,000 million megalitres of water. This would be enough to cover all the land on the planet in almost half a metre of water.Lift style piston pump typical of an Australian farm connected to a multi-bladed windmill. Bronze cylindrical construction coming up from removable wood base. Rotating lever is above outlet pipe which would send water to the storage tank.windmill, australian farming, great artesian basin, aquifer -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel, used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting