Showing 874 items matching "irons"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWrench Coleman, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. This hand held wrench was provided exclusively for the Coleman self heating kerosene (KVHS 0347A) iron and used for the regular changing the kerosene used in it. The iron was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation. Kerosene supplies were cheaper than electricity but also more inconvenient than electric. Electrical appliances become cheaper to buy and maintain in the later part of the 1900's and the now older kerosene iron was faded out.This wrench was required to open the fuel container which stored kerosene in the Coleman hand iron(see KVHS 0347A). This item was part of the maintenance requirement of this particular hand iron. In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival(use of this wrench was a part of rural life). The ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This item is a flat cast iron wrench, which has been specifically made for KVHS 0347A (kerosene iron). The wrench has four specific forms cut into the steel which fit firmly around their targeted nut and other fixtures. Also see See KVHS 0347B- Instruction sheet; and KVHS 0347D Fuel can.ironing, iron maintenance tool, domestic appliances, household -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

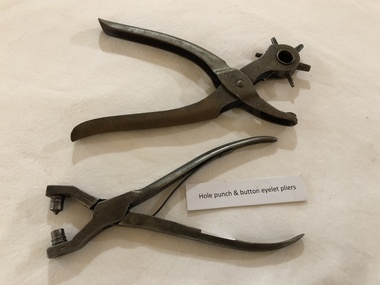

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

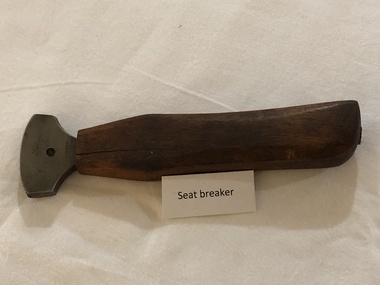

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

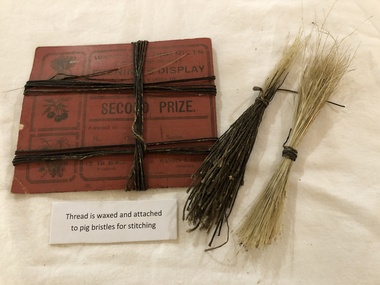

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 pairs of handmade, adult brown leather boots, with decorative stitching, eyelets and stitched with waxed thread. Soles covered with hob nails in a decorative pattern. 1 handmade child's brown leather boot, with decorative stitching, metal eyelets, heel has patterned nails.bootlaces, boots -

Bendigo Military Museum

Bendigo Military MuseumEquipment - BREAST BAND & COUPLINGS, c. 1915

Examples of the harness used on WW1 horse drawn vehicles.There are 6 pieces of leather strappings, for hourse drawn with heavy metal fittings. .1 Leather strap 23 cm x 3 cm wide. 3 pieces of iron link fittings. .2 Leather strap large. 55 mm wide 77 cm long 5 metal links. A 23 cm smaller piece of leather strap is attached to the links. .3 Piece large leather strap. 77 cm long. One end has opened up. Links missing - other end has 31 cm x 3 cm strap sewn on. the smaller strap has stamped into it - E + A Noir it 1915. .4 Large leather strap 77 cm long width 5 cm. One end has 5 iron links. Other end has smaller strap sewn on. 48 cm long width 3.5 cm .5 + .6 Very large strap. Avg 12 cm wide - length 103. 4 sets iron couplings with smaller connections strap and irons at each end. .3) Stamped on smaller strap: 'E + A Noirit 1915'ww1 - horse harness, military equipment, transport - horse, trades - leatherwork -

Bendigo Historical Society Inc.

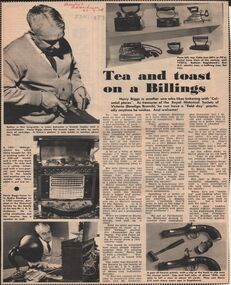

Bendigo Historical Society Inc.Newspaper - LYDIA CHANCELLOR COLLECTION: HARRY BIGGS

A newspaper article from the Bendigo 'Advertiser' titled 'Tea and toast on a billings.' This article tells of Harry's love of collecting colonial pieces and his voluntary job as treasurer of the Royal Historical Society of Victoria (Bendigo Branch). 30/7/1969.person, individual, harry biggs, lydia chancellor collection, collection, harry biggs, bendigo, history, male, person, individual, bendigo historical society, royal historical society (bendigo branch), arms, firearms, clubs and associations, heritage, recreations, societies, irons, collection pieces, antiques, antique -

Tarnagulla History Archive

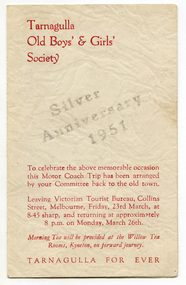

Tarnagulla History ArchiveCard: Tarnagulla Old Boys' and Girls' Society Centenary Anniversary 1952, Tarnagulla Old Boys' and Girls' Society Centenary Anniversary 1952, 1952

Donald Clark Collection. Card relating to commemoration of Tarnagulla Old Boys' and Girls' Society Centenary Anniversary in 1952. Inside is list of names, a roll of those who returned for reunion.tarnagulla, reunions, tarnagulla old boys' and girls' society, centenaries, anniversaries, busst, castleman, dyer, fitzgerald, fletcher, foers, harding, irons, monichan, mccorkelle, paris, pratt, radnell, smith, spencer, stagoll, tucker, zeigler -

Tarnagulla History Archive

Tarnagulla History ArchiveCard: Tarnagulla Old Boys' and Girls' Society Centenary Anniversary 1952, Tarnagulla Old Boys' and Girls' Society Centenary Anniversary 1952, 1952

Murray Comrie Collection. Card relating to commemoration of Tarnagulla Old Boys' and Girls' Society Centenary Anniversary in 1952. Inside is list of names, a roll of those who returned for reunion.tarnagulla, reunions, tarnagulla old boys' and girls' society, centenaries, anniversaries, busst, castleman, dyer, fitzgerald, fletcher, foers, harding, irons, monichan, mccorkelle, paris, pratt, radnell, smith, spencer, stagoll, tucker, zeigler -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1930s

Scales such as the subject item were used in a domestic situation. Salter has been a name long associated with weights and measures especially in the home kitchen. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011."Scale Salter's Spring Balance brass cylinder with ring at one end and a hook at the otherSalter trademark stamped on front. Made in England stamped on back. Weighs 0 to 4LBS showing ¼lb increments.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods, domestic object, kitchen scale -

Puffing Billy Railway

Puffing Billy Railway14A Number Plate

Number Plate 14A Loco: 14A In service Thursday, 25th June 1914 Withdrawn April 1962 Livery Red Owner Puffing Billy Gauge 762 Status Preserved - Operational 14A Built in 1914 and painted Canadian red & dark brown, this locomotive was issued to the Colac to Crowes line and saw service on all four lines, but mostly on the Colac to Crowes line. It was withdrawn from service in 1962 at Colac and sent to Newport Workshops for storage where it remained, except for a brief time at Bendigo North Work-shops in 1963. After overhaul, it was brought to Belgrave in 1965 where it has seen almost continuous service since. In 1978, it became the first of the preserved NA’s to trial a historic colour scheme for which the Canadian red & dark brown was chosen, but ended up mistakenly being painted a “London Tan” & dark brown. In 1996 it received a more correct Canadian red livery. This “temporary” trial livery has now given way to 14A’s designated livery of all-over black. Its physical configuration will match the late 1940s era with the extended bunker, guard irons, etc.Historic - Victorian Railways Locomotive Number Plate used on Steam Locomotive 14ANumber Plate 14A Rectangular black and brass number plate. Cast brass number board.14Apuffing billy, 14a, number plate -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Airzone Vacuum Cleaner, 1950

Standard Telephones and Cables Pty Ltd was a telecommunications company that began as part of Western Electric, a telephone manufacturing company set up by Alexander Graham Bell. Following the First World War, Western Electric diversified to include electric generators and wireless receivers, all still imported. In 1925, Western Electric was sold to the International Telephone and Telegraph Company. In Australia, it became known as Standard Telephones and Cables (Australasia) They worked closely the Postmaster Generals department to set up telephone and radio networks throughout Australia. Its first factory was in Chippendale, New South Wales but ut developed to have branches in all stated of Australia. By the end of the Second World War STC was Australia's biggest manufacturer due to its critical role in producing telecommunications equipment, domestic radio receivers, telecom cables, military equipment and electron tubes. The company returned to peacetime manufacture. Rather than reduce staff it used its excess capacity to produce electric irons and other domestic appliances including vacuum cleaners and floor polishers. This model was produced at the beginning of the 1950s. It was once owned by Mr. Stiff from Stiff and Gannon, Wodonga.This item has local and national significance. It was used in a local Wodonga business and is representative of domestic appliances used in the 1950s. It also has national significance as it is an excellent example of good produced by the manufacturing industry in Australia during that period.Model 30 Airzone Vacuum Cleaner and accessories. Manufactured in AustraliaMetal logo for Airzone including engine specificationsdomestic appliances, standard telephones and cables pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Robert Sorby, First half of the 20th Century

A scotch eye auger is perfect for quickly making holes in dry or wet wood for making chairs, stools, and any number of woodworking projects. The scotch eye serves as a peg gauge and whatever peg you make to go into the hole should fit into the augers eye. Robert Sorby & Sons: The forbearer's of Robert Sorby had been cutlers in the Sheffield region of England, dating from the mid 17th century. Robert Sorby and Sons were registered in Sheffield in 1828 as a manufacturer of edge tools, saws, scythes and hay knives. In addition to manufacturing tools, they also diversified into the manufacture of crucible steel for tool manufacture. From circa 1860-1967, the Sorby factory in Sheffield was known as the “Kangaroo Works”. The Kangaroo Brand of tools was made by Robert Sorby & Sons. During the 19th century, they had a large trade in Australasia. By the early 20th century, they were manufacturing carving tools, planes and plane irons, circular saws, wood saws, butchers saws and cleavers, garden tools, pruning knives, coopers’ knives, bricklayers tools and joiners tools. In 1923 Robert Sorby & Sons was bought by Sheffield company Hattersley and Davidson. They are today one of the few remaining British tool manufacturers.The company has a long tradition of making edged tools for various uses and exporting them to Australia, however the subject item was probably made from the early 20th century up until 1967 when the company stopped exporting to Australia.Scotch Eye Auger, Double Twist with Lead Screw, square shaft, socket set at right angleRob Sorbey Sheffield stamped on shaft with Kangaroo trade markflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger, carpenders tools, hole drilling, rob sorby & sons