Showing 3961 items matching " machining"

-

Bendigo Military Museum

Bendigo Military MuseumPostcard - POSTCARDS, PHOTOGRAPHIC WW1, c.1914 - 1918

Black & white photos of WWI battle scenes in Europe. Seven Daily Mail battle pictures, black & white. Official war photos, Series VIII. No 57 Wounded. Tommy to Photographer: I'm not a German! No 58 Black Watch Pipers Playing to the Captors of Longueval. No 59 The Burial of two British Soldiers on the Battlefield. No 60 A Fag After a Fight. No 62 British Machine Gunners Wearing Gas Helmets. No 63 Tommy at Home in German Dugouts. No 64 A Big Mine Exploding.postcards - photographs, military history, passchendaele barracks trust -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchDress Jacket Army Reserve, Fletcher Jones & Staff, 1998

This jacket is part of the dress uniform of a Major in the Army Reserve. Major Bernard Farley who owned this jacket wore it to official functions in the Mess dining room. He served in this capacity from 1998-2001.Bernard also served in the RAAF for a number of years.This jacket has significance as it is typical of dress requirements which were worn to official Army functions.Short white jacket with wide front lapels epaulets at the shoulders and a small V shaped downward peak at the back. The sleeves have a stitched over section at the cuff with a point in line with the shoulder. On each epaulet from the collar edge side there is a brass coloured button with the Rising Sun in low relief and on the lower edge of the epaulet a brass coloured crown with red nsert and a circular shaped badge with the word Australia. There is a badge on each lapel two crossed rifles holding a crown in brass colour over the top of a silver VLabel states ,' Fetcher Jones Victoria 1998 NSN 8405-NIC Name....... Service No......... Polyester / Viscose Dry Cleanable ( A) Warm Gentle Machine Wash Rinse well. Warm iron. ZC785 BR1689 425267911.ZC785 107 R 347 044 05037649 cloth br 1689 17. J10129 OW Wwarrnambool, army reserve, dress jacket -

Federation University Historical Collection

Federation University Historical CollectionCostume, Perhaps made internally at Alfred Hospital, Nurses Apron, Cap and Collar, 1960s

This nurse's collar, cap and apron would have been worn by student nurses at the Alfred Hospital in Melbourne in the 1960's. Although the style did not change much from earlier years the length of the skirt had shortened. The white semi circular collar has a single row of drawn thread work 1.5 centimeters from the outer edge and is made of starched cotton fabric. The cap is made of a half circle of fine white cotton lawn with a turn back front edge bearing the Alfred Hospital emblem. It has a tape casing about 1.5 centimeters from the edge which contains a thin tape for gathering up the edge of the cap. The white cotton apron has a 5 panel skirt, a waistband with four covered buttons and a bib front which went over the shoulders and buttoned at the back of the waistband.The collar has written in black marker - D.L.Ross E.37; Also written in black marker - E980; A tape printed and machine stitched on - L.A. Holberton The cap has a printed emblem - Alfred Hospital Incorp. Melbourne, Service and Care The apron has written in black maker - M Taylor; E877; J. Williamsalfred hospital, nursing, nurse uniform, student nurse uniform, nurse apron, nurse cap, nurse collar, apron, costume, textiles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Desk, Foy & Gibson, Circa 1880s

The design of this small disc is from the Australian Colonial period. The cedar wood desk was made in Australian by Foy & Gibson in the 1880s, most probably in the business’s works in Collingwood, Victoria. The heavy brass locks fitted into the desk drawers were made by the famous Hobbs & Co of London, mid-late 19th century. In 1860 the business changed hands but the locks were still branded Hobbs & Co. The desk is branded with the symbol of Victoria’s Public Works Department. There is currently no information on when, where and by whom this desk was used. However, a very similar desk with Hobbs & Co. locks is on site at the Point Hicks Lightstation in Victoria and was formerly used by the Point Hicks head light keeper there. Other light stations also have similar desks from the P.W.D. (see also ‘Desk, Parks Victoria – Point Hicks Lightstation, Victorian Collections’.) HOBBS & CO., LONDON Alfred Charles Hobbs, 1812-1891, was American born. He became an executive salesman in 1840 for renowned lock manufacturer Day & Newell. His technique of exposing the weaknesses of people’s current locks was very successful in generating sales. He represented Day & Newell at London’s Great Exhibition of 1851, competing with other lock makers. Through the Exhibition he became famous for picking the best trusted Bramah and Chubb locks. Hobbs’ fame led him to found his own company in 1851 then register it in 1852 as Hobbs & Co., London. Hobbs was awarded the Telford Medal by the British Institution of Civil Engineers in 1854 for his paper 'On the Principles and Construction of Locks'. In 1855 the very successful company added partners and became Hobbs, Ashley and Co. In 1860, it traded under the name of Hobbs, Hart & Co. and was based in Cheapside London, where the business remained. Hobbs then returned to America, having sold the complete company to John Mathias Hart. He briefly returned to attend the 21st anniversary celebrations of the successful business in 1872. Hobbs kept himself busy in America, inventing and manufacturing firearm ammunition, for which he held several patents. He passed away there in 1891, a month after his 70th birthday. FOY & GIBSON Mark Foy wan an Irish draper who migrated to Bendigo, Victoria in 1858, attracted by the gold rush. He lived and worked in the area, establishing a drapery business. In the 1870s he moved to Melbourne where there were better prospects for expansion. He chose a place in Smith Street, Collingwood, a suburb of Melbourne, and started his business at the rear. In 1883 Foy retired, bringing in William Gibson as a partner, and then transferred his own share of the company to his son Francis Foy. Not long afterwards Francis sold his half share to Gibson, and the business continued under the name of Foy & Gibson. Francis Foy and he and his brother Mark Foy (junior) moved to Sydney. They established a business there in 1885, named after their father, Mark Foy. Gibson added to his business by starting his own manufacturing works from 1887, producing clothing, millinery, furniture, bedding and hardware for his stores. The factories, warehouses and stores complex became one of Victoria’s largest employers. He set up branches of his stores in Perth, Brisbane and Adelaide and two more branches in Melbourne. Foy & Gibson (usually referred to as Foys) became one of Australia’s largest retail department stores. In 1931 Foy’s little house in Collingwood was still part of the entrance to Foy & Gibson Emporium. In 1955 the company was bought out by Cox Brothers. Later on the stores were sold to various businesses such as David Jones, Woolworths and Harris Scarfe. In 1968 Cox Brothers went into receivership, ending almost 100 years of the business known as Foy’s. The former Foy & Gibson Complex is registered by Heritage Council Victoria. “Designed by William Pitt, this magnificent 19th and early 20th century complex of factories, warehouses and showrooms saw the production of a remarkable range of goods for Foy & Gibson, Melbourne’s earliest department store chain”. (Quoted from the Plaque erected by the Collingwood Historical Society 2007) P.W.D. – Public Works Department, Victoria The desk is stamped “P.W.D,” signifying that it is from the Public Works Department in Victoria, which operated from 1855-1987. The department was responsible for, among other things, the design and supply of office furniture and equipment for public buildings and organisations. This desk is significant historically as it originated from Foy & Gibson, a colonial Australian company that had a positive and strong impact on employment, manufacturing and retailing in Melbourne, Victoria and Australia. The significance of Foy & Gibson to Victoria’s and Australia’s history is marked by the Collingwood Complex being registered in both Heritage Victoria Register (H0755, H0897 and H0896) and National Trust Register (B2668). This locks on this desk are significant for their connection with their manufacturer, Hobbs & Co, who invented a lock that surpassed the security of any other locks produced in the mid-19th century. Desk; Australian Colonial cedar desk, honey coloured. Desktop has a wooden border with a rolled edge and a fitted timber centrepiece. The four tapered legs are tulip turned. Two half-width drawers fit side by side and extend the full depth of the desk. The drawers have dovetail joints. Each drawer has two round wooden knob handles, a keyhole and a fitted, heavy brass lever lock. Inscriptions are on the desktop, drawers, desk leg and lock. Made in Australia circa 1880 by Foy & Gibson, lock made by Hobbs & Co, London.Impressed into timber frame of one drawer “FOY & GIBSON” Impressed into lock “HOBBS & CO / LONDON”, “MACHINE MADE”, “LEVER” Impressed along the front edge of the desktop [indecipherable] text. Impressed into the timber of right front leg “P. W. D.” below a ‘crown’ symbol Handwritten in white chalk under a drawer “206” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, desk, cedar desk, colonial desk, 1880s desk, australian colonial furniture, furniture, office furniture, office equipment, australian made furniture, colonial furniture, colonial hardware, foy & gibson, alfred charles hobbs, hobbs & co london, hobs & co lever lock, cabinetry lock, machine made lever lock, p.w.d., public works department victoria, day & newell, great exhibition of 1851, bramah lock, chubb lock, telford medal 1854, cheapside london, mark foy, mark foy – bendigo draper, smith street collingwood, william gibson, foy & gibson emporium, foy & gibson complex, cox brothers -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Board, Wash board child, Early 20th century

This child’s wash board, a play item, is possibly home-made. Wash boards for rubbing and washing clothes were common household clothes- washing items in Australia until the mid 20th century, along with wood coppers, washing troughs, copper sticks and simple wringers. By the 1950s and 60s washing machines were becoming more prevalent and the wash board was no longer a common item in households. This item is retained as an interesting example of a twentieth Century child's toy.This is a rectangular-shaped unpainted wooden wash board with clear rippled glass inserted in the centre and held in by four metal screws. The top of the board has a piece of the wood missing. household items, children’s toys -

Lara RSL Sub Branch

Lara RSL Sub BranchStereograph, The Rose Stereographs

George Rose was well known Australian photographer and postcard maker in the first half of the 20th century. This sterograph shows recruits training at Geelong during the First World War. Soldiers were trained to attack in short rushes rather than advancing in line due to the lethal power of the machine gun. The stereograph was an early technology that used double images to achieve a three dimensional image. Rectangular piece of cardboard with a stereograph image attached to the front. The image is a double reproduction of a black and white photograph. the photograph depicts a line of soldiers lying on the ground. AUSTRALIAN EXPERDITIONARY FORCE, GEELONG. Training Recruits in the Art of Attacking in Short Rushes. Copyright by Geo. Rose.wwi, rose series, postcard, lara, geelong, rsl, training, stereograph -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Nail

This historic bronze nail dates back to 1790s to 1890s. Nails such as this one were used for ship building, as deck fasteners and many other uses. This nail was made at a time when the shanks of nails were usually machine cut but the heads were hand formed by blacksmiths. The nail was recovered from a shipwreck along the coast of Victoria in around 1968 and is part of the John Chance Collection. The nail is significant historically as an example of hardware used when building wooden ships in the early to mid-19th century. The nail is historically significant as an example of the work and trade of blacksmith. The nail is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value.Nail; bronze, deck nail. Rounded rectangular head, rectangular shank cross-section, tip flattened to a rounded wedge shape. The surface is pitted and rough and has blue-grey, green and orange concretion and degradation on the nail's surface. Recovered from an unspecified shipwreck along the coast of Victoria. Part of the John Chance Collection. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, fastener, nail, square nail, machine cut mail, blacksmith, historic nail, bronze nail, hand forged, coastal shipwreck, victorian shipwreck -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Nail

This historic bronze nail dates back to 1790ss to 1890s. Nails such as this one were used for ship building, as deck fasteners and many other uses. This nail was made at a time when the shanks of nails were usually machine cut but the heads were hand formed by blacksmiths. The nail was recovered from a shipwreck along the coast of Victoria in around 1968 and is part of the John Chance Collection. The nail is significant historically as an example of hardware used when building wooden ships in the early to mid-19th century. The nail is historically significant as an example of the work and trade of blacksmith. The nail is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value.Nail; bronze, deck nail. Rounded rectangular head, rectangular shank cross-section, tip flattened to a rounded wedge shape but cut straight down at the end instead of a point. The surface is pitted and rough and has yellow and orange concretion and degradation on the nail's surface. Recovered from an unspecified shipwreck along the coast of Victoria. Part of the John Chance Collection. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, fastener, nail, square nail, machine cut mail, blacksmith, historic nail, bronze nail, hand forged, coastal shipwreck, victorian shipwreck -

Tatura Irrigation & Wartime Camps Museum

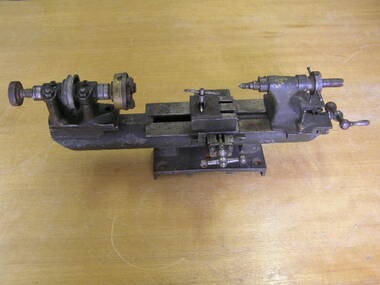

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach -

Ballarat Tramway Museum

Ballarat Tramway MuseumEphemera, Victorian Railways (VR), Set of railway tickets - Bungaree, 1970s

Tickets used by passengers to Bungaree: First class single - Ballarat to Bungaree - 10 August 1975 - brown - No. 1453 Second class single - Melbourne to Bungaree - 22 January 1975 - light blue - No. 5064 Second class single - Melbourne to Bungaree - 27 January 1978 - blue - machine printed - No. 6350 Platform ticket - Bungaree - undated - white card two halves - No. 0004Bungaree station has a location link to the activities of the Ballarat Tramway Museum.Set of four Edmondson type card railway tickets - printed for use at Bungaree Railway Station, various colours in accordance with the ticketting manuals.railways, tickets, bungaree, platform ticket -

Kew Historical Society Inc

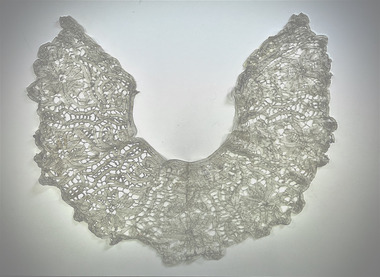

Kew Historical Society IncAccessory - Tape lace collar, 1890-1910

One of a group of items including lace and crochet collars and pelerines, a jabot, a chid's dress and a wedding dress donated by KHS member, Kathryn (Kate) Gwynne Reeve (nee Marx) that belonged to members of her family. Tape lace is either a hand made (with a bobbin) or a machine woven tape. The tape is folded into the required design and then fixed and embellished with connecting lace or embroidery stitches of various kinds.Tape lace collar. L 17 cm / W 39 cm / Circumference 98 cmaccessories, tape lace, lace collars -

Vision Australia

Vision AustraliaMachine - Object, APH (American Printing House for the Blind), APH Talking book machine, 1980-1990's

APH began producing it's own line of products to satisfy it's clients, outsourcing the manufacturer to overseas companies. This talking book machine, had an optional carry case, and dials to control tone, volume, speed, front buttons to record, rewind, forward, play, and stop tape. Playing both 2 and 4 track tapes, it also had Braille signs next to some of the buttons.Plastic rectangular light brown audio player with buttons for navigational controls, power cord, outlets for ear or head phones and black vinyl protective zip up cover Model no. 3-5194A.audio equipment, royal victorian institute for the blind -

Melbourne Tram Museum

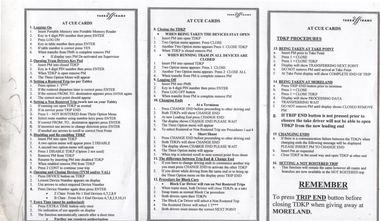

Melbourne Tram MuseumDocument - "AT Cue Cards", Yarra Trams, c2000

The documents provided information to Yarra Trams drivers on setting up the Myki ticket machine controllers on trams with the Portable Memory modules - see item 7681 for an example and further notes. Included instructions when changing ends of a tram, logging off, being taken at depots, non rostered trips etc. Based on item 14, "Being taken at Moreland", used at Brunswick depot.Demonstrates a set of instructions for crews in the operation of the Myki ticket machine controllers on a tram.Three pocket size sheets printed.trams, metcard, ticket machines -

Bendigo Historical Society Inc.

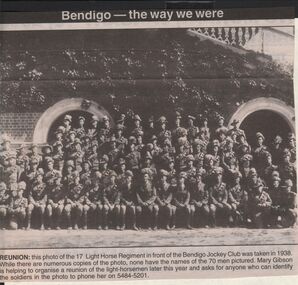

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: REUNION

The 17th Light Horse was a militia unit between the wars. Members were drawn from Kyneton, Castlemaine and Bendigo areas. In 1936 the regiment, including 100 horses, camped at the Bendigo Racecourse so it is possible this photo was actually 1936.From Dec 1941 this regiment became the 17th Light Horse (Machine Gun) Regiment and was disbanded in April 1943. Members were absorbed into other units.Bendigo Advertiser ''The way we were'' from 2003. Reunion: this photo of the 17 Light horse regiment in front of the Bendigo jockey Club was taken in 1938. While there are numerous copies of the photo, none have the names of the 70 men pictured. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Melbourne Tram Museum

Melbourne Tram MuseumMachine - Ultimate Ticket Machine - MMTB No. 9, Bell Punch Co, c1950

Manufactured by the Bell Punch Company Ltd of London as the "Ultimate Fare System", for issuing bus and tram tickets. Used by the MMTB for street sellers at Safety Zones in Melbourne. See items 7504 for a roll of 10c MMTB tickets and 7889 for a circular regarding their introduction in 1951. The machine was received from the donor with five rolls of NSW bus tickets - 3 Section, 25c, 45c, 60c and $1.00. Demonstrates a ticket machine used at Melbourne tram stops by "Safety Zone sellers".Complex apparatus consisting of metal parts, grey frame, levers, numbering counters, fitted with a cloth strap with clips and brown plastic backing. Contains five rolls of paper tickets. Strap 25mm wide x 1100 long leather with clips.Engraved on the top part "MMTB No 9"tickets, ultimate, mmtb, machine issued tickets, ticket machines -

Vision Australia

Vision AustraliaAdministrative record - Text, Braille Writers Association of New South Wales: annual report year ending December 31, 1955, 1949-unknown

Annual report outlining the achievements of the Braille Writers Association of N.S.W. including the presentation of certificates of recently qualified members, transcription of public exams, acquisition of 2 Stainsby machines, list of authors of contributed articles to 'Boomerang' magazine, Eisteddfod Braille reading contests, production of a programme for ABC Youth Concerts, Paramatta gaol transcribers and book binders, and a list of books transcribed by transcriber and number of volumes.1 printed volume of 15 pages with photographsbraille writers association of new south wales, annual reports -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Forest Green Childrens jumper with geometric ‘alpine’ pattern with long sleeves and ribbed cuffs and round neck collar. Textured geometric pattern is created with purl stitches and extends both on the front and back of the jumper, as well as down the sleeves.[white label at back neck printed with blue ink] KATHRYN REGD SIZE 1 / LENGTH 84cm / WEIGHT 12kg / Made in Australia ACRYLIC/WOOLchildren's knitwear, knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Lace Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream short sleeved jumper with overall open lace design, front yoke with accent lacework and applied lace ruffle edging .2 is a retail tag with style code and size, reverse has washing instructions for acrylic and cotton.1) [white tag back neck, printed blue letters] KATHRYN REGD POLYESTER/VISCOSE MADE IN AUSTRALIA .2 [retail swing tag, numbers handwritten in blue ink] KATHRYN Children’s Knitwear STYLE [handwritten] 363 PRICE SIZE [handwritten] 6children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, machine lace -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White lacework baby romper suit with long sleeves and legs, and enclosed feet. Closes at centre back with two plastic buttons. Zips open around leg inseam. Size 00 .2 is a retail tag marked with the price and size, and refers to the label sewn into the garment for washing instructions..2 [Retail Swing Tag] [Obverse] KATHRYN Children’s Knitwear STYLE PRICE [handwritten] $18 SIZE [handwritten] 00 [Reverse] WASHING INSTRUCTIONS Refer to label sewn in Garment Designed and manufactured by ROBERT BLAKE PTY. LTD., Melb., Aust.children's knitwear, children's clothing, baby clothing, baby knitwear, clothing, knitwear, romper, jumpsuit, manufacturing, fashion textile production, machine knitting, machine lace, baby clothes -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Long sleeved cream baby romper suit with patterned stitch on bottom half and diamond emblem on chest. Closes with two pearlescent plastic buttons at centre back and with three pearlescent plastic buttons at crotch.Kathryn Reg’d / 100% orlon / 20 [handwritten]children's clothing, children's knitwear, clothing, knitwear, romper, jumpsuit, baby clothing, baby clothes, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Baby Swimwear, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White baby’s swimming shorts with stripes on front in navy, cyan and yellowchildren's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, colourwork, swimwear, baby swimwear -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1962-1964

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Pink three piece legging suit, consisting of cardigan, lettings and beanie. Cardigan is knitted with textured stitch and has stocking stitch panel bordered with garter stitch at centre front. Two rows of buttons on garter stitch tab, with a fifth button under left collar. Leggings are plain garter stitch with an elastic waistband and a flap that extends onto the top of the foot with elastic to keep it held under the sole. Hat is in same patterned stitch as cardigan, has ear flaps with ties and a white pompom.1) [Label at back neck with blue lettering woven into label] KATHRYN REGD ORLON / 20 /CREATED BY ROBERT BLAKE [sample label] [OBVERSE] STYLE LS/PWO – 3 PCS – LEGGING SUIT – PEARL PATT. – 80% ORLON 20% WOOL SIZE 18” 20” PRICE 48/6 51/6 COLOR BLUE. LEMON. PINK. WHITE. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Dress, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream baby dress with long sleeves, blue stripe and cream faux cable textured details at yoke and hem. Body is gathered and attaches at yoke. Dress has a drawstring tie at neck accented with cream pompoms and closes at centre back with three pearlescent plastic buttons. Back opening is reinforced with grosgrain ribbon. .2 is a sample tag with manufacturing information, including sizes and colours available .3 is a retail tag with style, care instructions and brand marketing[label stitched into back neck] KATHRYN 100% Orlon .2 [sample label] [Obverse] 802/F – BABIES ORLON FROCK. 16” – LENGTH 24/6 BLUE/WHT LEMON/WHT PINK/WHT WHT/BLUE WHT/LEMON WHT/PINK .3 [Obverse] KATHRYN Children’s Knitwear STYLE [handwritten] 802/F SIZE PRICE [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLYclothing, children's clothing, knitwear, children's knitwear, manufacturing, fashion textile production, colourwork, pom-pom, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s two-piece outfit set, consisting of a top and leggings. Knitted in colour blocks of navy, red and white. Top has ribbed navy bodice section with white stripe separating red skirt and closes at back neck with two navy plastic buttons. Leggings are primarily red, with a white stripe at the ankle and navy-blue feet. Leggings are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece..1) [tag stitched into back neck of top] KATHRYN REGD 100% ACRYLIC FIBRE SIZE 0 WEIGHT 10 LENGTH 76 MADE IN AUSTRALIA .3) [blue sample label] STYLE 574/ Pop Top and B’tts S.26. Acrylic. SIZES: 00 0 PRICE: $8.95 COLORS: Navy/Wht/Red Red/Wht/Navy P.Blue/Wht/Navy Dec on Del.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Second half of 19th Century or first half of the 20th Century

Although glass containers for wine and beer are probably 1,600 years old, much of their use began only in the late 17th century. In the United States, large-scale production of bottles was pioneered by Caspar Wistar in 1739 at his New Jersey plant. In the 1770s the carbonation process for producing soft drinks was developed, and so began an entirely new bottling industry. At the Great Exhibition of 1851 in the Crystal Palace in London, one million “pop” bottles were consumed. The first beer pasteurised in glass was produced in Copenhagen in 1870. Pasteurisation of milk followed soon after. The moulding of a screw thread on a container was invented by John Mason in 1858. The principles of the “press-and-blow” process for making wide-mouth jars were shown in the United States by Philip Arbogast in 1882, and the “blow-and-blow” process for making narrow-neck containers was demonstrated by Howard Ashley in England in 1885. These processes employed manual delivery; fully automatic jar forming by a suction-and-blow process was perfected by Michael Owens over the period 1895–1917 at the Toledo (Ohio) Glass Company, which subsequently became the Owens Bottle Machine Company. The automatic single-gob feeder was developed in 1919–22 by Karl Peiler at the Hartford-Fairmont Company in Connecticut. Fully automatic machines followed, but the true rugged survivor, utilising fully automatic gob delivery to the maximum versatility, was the Individual Section, or IS, machine invented by Henry Ingle at the Hartford Empire Company in 1925. Source: https://www.britannica.com/topic/glass-properties-composition-and-industrial-production-234890/History-of-glassmakingUnlike item 4018, this is a much smaller ink bottle, and was probably used by an individual, as against the supply of ink to pupils from a much larger bottle.Cotton Reel Ink Bottle, green glass, small, chipped around the lip, bubbles in glass.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, bottle, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Melbourne Tram Museum

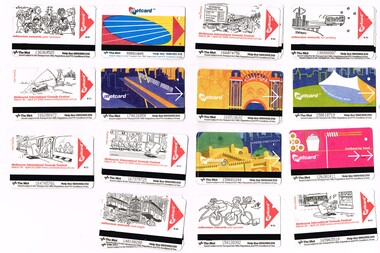

Melbourne Tram MuseumEphemera - Ticket/s, The Met, Set of 15 Metcard tickets, 2000

Set of 15 Metcard tickets, used during the Metcard era. Has the Metcard logo on it, along with other Metcard, information. All of the tickets appear to have been used. .1 - Millennium Metcards cartoon by Ron Tandberg (3 copies) .2 - Melbourne Comedy Festival - Matt Golding cartoon - estimated travel time (3 copies) .3 - standard Metcard (3 copies) .4 - Millennium Metcards cartoon by Peter Nicholson (3 copies) .5 - Metcard featuring a stylised image of the Sidney Myer Music Bowl (3 copies) .6 - ditto of Luna Park (4 copies) .7 - ditto Melbourne Exhibition Centre (3 copies) .8 - as for 2 - but with a fish line - trolley wire - theme. ( 3 copies) .9 - featuring Melbourne food. ( see also Reg Item 1466 for the same theme) .10 - Metcard featuring a stylised image of the Flinders St Station (3 copies) .11 - Melbourne Comedy Festival - Matt Golding cartoon - Metcard Machine tapping his foot (3 copies) .12 - ditto - Metcard Machine following a passenger onto a train (3 copies) .13 - ditto - Metcard Machine and an ATM ( 3 copies) .14 - Millennium Metcard - cartoon by John Spooner (3 copies) .15 - ditto - cartoon by Mark Knight. ( 3 copies) See also Reg item 1465 for other cartoons cards. Additional copies added 3/5/16 from donation of G. Warburton - see Reg Item 1463.1 for other examples and details of donation.trams, tramways, tickets, metlink, metcard, luna park, cartoons, flinders st station -

Bendigo Military Museum

Bendigo Military MuseumUniform - SHIRT, ARMY, Australian Defence Industries, 1989

Shirt, khaki cotton polyester, short sleeve with shoulder epaulettes. Plastic buttons. Cotton manufacturer's label back, below collar with black print information. Size stamp on inside collar. handwritten owner's label - bottom back of shirt.Cotton label information - black ink print. "ADI P/I /1989/^/size 40/R405.66.093.8019/Service No./Name/ DO NOT BOIL OR WRING./ MACHINE WASHABLE/ DRIP DRY, IRON LIGHTLY/ WITH WARM IRON" Black ink stamp on collar "SIZE 40". Bottom back shirt - black ink handwritten "320 4573 GREEN".uniform, army, shirt -

Ringwood and District Historical Society

Ringwood and District Historical SocietyNewspaper, Scrapbook Clipping, Library Collection, Ringwood, Victoria, `

``Newspaper clipping from "The Mail", 17/2/98, P 1. Gamblers lose $27 million. By Faye Michelson Maroondah gamblers lost just over $27 million on the city's 477 poker machines during the last financial year. Victorian Council on Problem Gambling spokesman, Rob Wootton said research showed that most money spent on gambling came from the household budget. Welfare agency budgets have been stretched to the limit.` -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageKnife Cleaner, 1877-1916

Knife cleaner, round wooden manual machine with 4 holes in top, each surrounded by metal fitting, handle attached to side of barrel, decorative metal stand with holes for fixing to banch. Black brush bristles are fitted inside, surrounding each hole (some bristles have been worn away. Inscribed "DAVIES PATENT EXCELSIOR LONDON", manufactured by Davis's Excelsior Knife Cleaning Company. Ltd, London. c.1877-1916Inscribed "DAVIES PATENT EXCELSIOR LONDON",flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, knife cleaner, knife cleaning machine, davis's knife cleaning machine co., domestic equipment, butchery, cleaning equipment