Showing 2109 items matching "fittings "

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Basic Training Manual 1-9 Metal Trades Fitting Hand Tapping and Thread Cutting, Department of Employment, Education and Training Ansett

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Basic Training Manual 1-7 Metal Trades Fitting Drilling, Department of Employment, Education and Training Ansett

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Basic Training Manual 1-5 Metal Trades Fitting Filing, Department of Employment, Education and Training Ansett

-

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - British Standard 341 Part 1 - Specification for Valve Fittings for Compressed Gas Cylinders - Valves with taper stems (excluding valves used for breatrhing and medical purposes)

-

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - The Development of Sheet Metal Detail Fittings by WSB Townsend

-

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Aviation fittings catalogues, Weatherhead Aviation Catalog Engineering Data and Handbook

The Weatherhead Company -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Metal trades fitting - training, Basic Training Manual 1-9 Metal Trades Fitting Hand Tapping and Threal Cutting

Ansett Techni;cal Training -

Moorabbin Air Museum

Moorabbin Air MuseumDrawing (Item) - Air Portable Workshop Type 1 Structural Fitting Out Department of Air DA67.1001.058 Sheet 1 of 2

-

Ballarat Tramway Museum

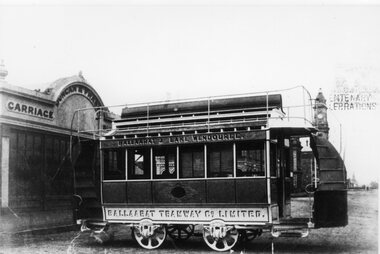

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, 1887

Yields information about the pattern tramcar, built by Duncan & Fraser in Adelaide with a view of the factory and the location behind. Shows the tramcar prior to the fitting of modesty panels.Black and White copy photograph of a State Library of South Australia SLSA B37169, of the Ballaarat Tramway Co horse tram pattern tramcar outside the factory or carriage works of Duncan and Fraser Adelaide. Has the Adelaide Town Hall in the background. Tram has the destination board (under the upper deck) "Ballaarat & Lake Wendouree". Modesty boards not fitted. Photo taken on building date - 1887. Collected by Alan Bradley from the State Library of South Australia early 1980's. Used in The Golden City and its Tramways - page 15.tramways, trams, horse tram, duncan fraser, adelaide -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Basic Fitting for Aircraftmen, Defence Trainees and Machinists, John D Cash

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Fitting for Defence Trainees, Department of Labour and National Service Industrial Training Division

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (Item) - Instruction Booklet For Fitting And Adjusting The S.U.Carburettor

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Fitting for Defence Trainees, Department of Labour and National Service Industrial Training Division

-

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s - set of 2, Wal Jack, 28/02/1962 12:00:00 AM

Yields information about Bendigo trams, the Golden Square route in the early 1960's prior to fitting dash canopy lighting.Black and white print of the Ballarat Scrubber tram, at the Bell Street loop, 28/2/1962, Photo by Wal Jack. Two copies. Photo print courtesy of Port Dock Railway Museum, now the National Railway Museum. See worksheet 4311 for letter and details of prints sent to Bill Scott, 19/10/2001. Any photo credit to mention NRM Collection. .1 - same photograph with Doug Colquhoun stamp on rear - see image i2..1 - On rear of copy 1"SEC Ballarat / Scrubber car /Bell St loop / 28/2/62 2125 / Wal Jack " In the top right hand corner "74)" .2 - On rear has Douglas Colquhoun stamp with photograph details - see image i2 trams, tramways, scrubber tram, bell st, tram scrubber -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Photocopy, State Electricity Commission of Victoria (SECV), "Tramways Advertising", 22/06/1959 12:00:00 AM

Yields information about the fitting of external roof advertising racks to SEC trams in Ballarat and Bendigo.Photocopy of a "file note" of a Conference at Bendigo on Thursday 18 June 1959, to discuss roof advertising signs on trams. Gives a list of those present, discussions, type of advertising and what could be done on each car type and general instructions. Has the word "Workshop Overseer" on the top of the poster. Photocopy provided by Andrew Cook 15-1-2015. See Reg item 3815 for a photo of tram 25 fitted with blank advertising boards.trams, tramways, advertisements, sec, bendigo, ballarat, meetings -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, The Courier Ballarat, 29/11/1979 12:00:00 AM

Yields information about the ESCo tram fleet after the initial operations, fitting of destination signs, tramcar numbers, crew uniforms and appearance of Wendouree Parade, c1906, Black and White photograph of No. 40 being lifted onto a truck in Wendouree Parade, at the old loop, 29/11/1979, to go to Melbourne - see page 2 of November 1979 Fares Please! and email (Other information) from Peter Winspur dated 24/07/12 for further details. The Courier Ballarat photo. See December 1980 Fares Please!Has The Courier stamp on rear.trams, tramways, btps, moving trams, tram 40 -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFunctional object - Skylight from the SS Shandon

Timber and glass skylight from the 'SS Shandon'.skylight, ships fittings, 'ss shandon' -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumEquipment - Fire Hose Nozzles

Two brass fire hose nozzles and a fire hydrant lever.fire fighting, fire hose fittings -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFunctional object - Spectacle Rings

Part of a collection of maritime artefacts donated by Wilfred [Bill] Libby These items were used on sailing ships.Two metal spectacle rings or ironsspectacle rings, shackels, spectacle irons, sail fittings, sailing -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFurniture - Bunk, sailor's, 1918 - 1928

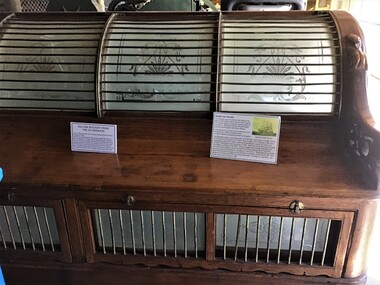

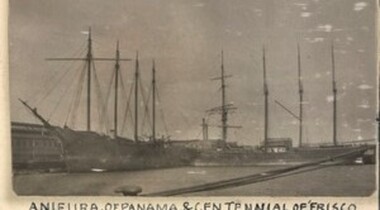

Anieura. Four-masted wooden schooner, 1328 tons. Built California, 1918 as the Oronite. Reg. Melbourne, 1928. Lbd 236.5 x 42 x 29. Last captain, de Carteret. Stripped of anything of value at the Yarra Street Pier, Geelong, in 1932; burnt to recover her copper and brass, and sunk off Avalon Bach, two kilometres east of Point Lillias. She had been seized for debt. @ Her wreckage is scattered and overgrown, covered in light silt in 4 metres. [NWR],[LC],[NSC]A relic from the broken up Barque 'Anieura' in 1932/33: BARQUE ANIEURA. Left to Sink in Mud. GEELONG Monday -The hulk of the barque Anieura, which has been idle in Corio Bay for more than four years, was towed to a spot near Bird Rock on the northern shores of the outer harbour on Monday. The Anieura was built for the timber trade and made a journey to Australia. The owners then decided that the vessel was unsuitable for this trade, and she was sold to an Australian firm. The ship was placed in Corio Bay, and remained at anchorage for about three years before an effort was made to sell her. This being unsuccessful most of the fittings, were disposed of, and the hulk was taken to Fletcher's pier to be out of the way of shipping. The Victorian Salvage Co's offer to the Geelong Harbor Trust to dispose of the hulk was accepted. The 300 tons of road metal ballast was removed, and a quantity of timber taken out. The vessel was towed through the channel this morning and run aground near Bird Rock just outside of the north-east extremity of the bar where it is away from shipping. More timbers will be stripped from the vessel, and it is likely that she will be allowed to sink into the mud. The Argus Tuesday 4 April 1933. A wooden bunk from the 'Anieura', drawers underneath with brass handlesanieura, bunk, port phillip -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFunctional object - Door and Locker

Obtained form the wreck of the Time on Corsair Rock and was collected by Norman Hunt who was a lighthouse keeper at Point Lonsdale. Door and Locker from the wreck of the Timeships fittings, lighthouse keeper, norman hunt, point lonsdale lighthouse -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFunctional object - Signal Lamp

This signal lamp was originally fitted on the steam tug 'Wattle'RAN Career 1932 to 1969: Wattle's construction and career as a non-commissioned vessel of the Royal Australian Navy. Saved from the Scrapyard 1969 to 1979: Sydney-based enthusiasts rescue Wattle from the scrapyard, forming an association with Sydney Heritage Fleet. Melbourne Pleasure Steamer 1979 to 2007: A volunteer group brings Wattle to Melbourne to restore, then sails Port Phillip on outings and excursions. Restoration Journey 2007 to 2015: Wattle is hoisted onto the hard to undergo major restoration work. Back in the Water, 2015 to present: Wattle returns to the water for further restoration, and in 2019 sails again on Port Phillip.Brass candle powered signal lamp with a lens circumference of 14cm, mounted on a timber plinthSundercombes Patent Eclipsesignal light, marine fittings, steam tug 'wattle' -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Fitting and machining texts, Fitting and Machining: Grade One

Technical guide for fitting and machining worknon-fictionTechnical guide for fitting and machining workfitting and machining -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Fitting and machining texts historical, Notes on the Theory of Fitting for Defence Trainees

Overview of theoretical aspects of fitting circa 1942Published in June 1942non-fictionOverview of theoretical aspects of fitting circa 1942 -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Former Kew Police Station : Ceiling light and fitting, 1930-1945

A civic campaign for new public offices developed in Kew in the 1880s. After much deliberation, the location chosen was the junction of Bulleen and Cotham Roads. The buildings were designed by George Watson and John Henry Harvey, architects within the Department of Public Works (Victoria). Building was commenced in 1887, and after one year, the buildings were opened. The Post Office was transferred to the new Commonwealth Government in 1901. The Police Station and Court House, sold by the Victorian Government to the City of Boroondara in 2007, are now a community cultural centre and performing arts venue.The buildings were listed on the Victorian Heritage Register Register (HO885) in 1991. They are historically and architecturally significant to the State of Victoria because Watson and Harvey's designs exhibit diversity in integrating civil offices, they accommodate the apex of road junctions, and they demonstrate a departure from the contemporaneously favoured High Victorian Classical to the Queen Anne style in the design of civic buildings.Ceiling fixture, chain, metal cap and large white glass shade from the former Kew Police Station, removed during renovations in 2007-11, and presented to the Kew Historical Society by the City of Boroondaralight fittings, kew police station -

Kew Historical Society Inc

Kew Historical Society IncDecorative object - Former Kew Police Station : Ceiling rose, 1888

A civic campaign for new public offices developed in Kew in the 1880s. After much deliberation, the location chosen was the junction of Bulleen and Cotham Roads. The buildings were designed by George Watson and John Henry Harvey, architects within the Department of Public Works (Victoria). Building was commenced in 1887, and after one year, the buildings were opened. The Post Office was transferred to the new Commonwealth Government in 1901. The Police Station and Court House, sold by the Victorian Government to the City of Boroondara in 2007, are now a community cultural centre and performing arts venue.The buildings were listed on the Victorian Heritage Register Register (HO885) in 1991. They are historically and architecturally significant to the State of Victoria because Watson and Harvey's designs exhibit diversity in integrating civil offices, they accommodate the apex of road junctions, and they demonstrate a departure from the contemporaneously favoured High Victorian Classical to the Queen Anne style in the design of civic buildings.Metal ceiling rose from the Kew Police Station, removed during renovations, 2007-11. From original, now concealed ceilings.kew police station, ceiling roses, architectural fittings -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Former Kew Police Station : Slates, 1888

A civic campaign for new public offices developed in Kew in the 1880s. After much deliberation, the location chosen was the junction of Bulleen and Cotham Roads. The buildings were designed by George Watson and John Henry Harvey, architects within the Department of Public Works (Victoria). Building was commenced in 1887, and after one year, the buildings were opened. The Post Office was transferred to the new Commonwealth Government in 1901. The Police Station and Court House, sold by the Victorian Government to the City of Boroondara in 2007, are now a community cultural centre and performing arts venue.The buildings were listed on the Victorian Heritage Register Register (HO885) in 1991. They are historically and architecturally significant to the State of Victoria because Watson and Harvey's designs exhibit diversity in integrating civil offices, they accommodate the apex of road junctions, and they demonstrate a departure from the contemporaneously favoured High Victorian Classical to the Queen Anne style in the design of civic buildings.Two pieces of broken slate from the roof of the Kew Court House / Kew Police Station, formerly the Kew Public Offices. The slate roof was replaced during renovations between 2007-11.kew police station, architectural fittings, slates, kew court house -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Former Kew Court House : Iron pin, 1888

A civic campaign for new public offices developed in Kew in the 1880s. After much deliberation, the location chosen was the junction of Bulleen and Cotham Roads. The buildings were designed by George Watson and John Henry Harvey, architects within the Department of Public Works (Victoria). Building was commenced in 1887, and after one year, the buildings were opened. The Post Office was transferred to the new Commonwealth Government in 1901. The Police Station and Court House, sold by the Victorian Government to the City of Boroondara in 2007, are now a community cultural centre and performing arts venue.The buildings were listed on the Victorian Heritage Register Register (HO885) in 1991. They are historically and architecturally significant to the State of Victoria because Watson and Harvey's designs exhibit diversity in integrating civil offices, they accommodate the apex of road junctions, and they demonstrate a departure from the contemporaneously favoured High Victorian Classical to the Queen Anne style in the design of civic buildings.Rusted iron pin, the sole remaining example that held the iron finial atop the flèche on the ceiling of the Kew Court House. The pin dates from the building's construction by the Department of Public Works. It was replaced during renovations between 2007-11.architectural fittings, kew court house, iron pin -

Parks Victoria - Mount Buffalo Chalet

Parks Victoria - Mount Buffalo ChaletBarometer

"A number of specific items, which have been useful in the day to day operations of the Chalet, remain in the building with each complementing the other to provide context, meaning and character to their setting. Items such as the hall porter bell, the many signs providing information to the guests, the wall clock, barometer and dinner bell point to the Chalet being a well-run social institution with a pleasant environment for rest, recreation and congenial company." (Pg 81 Historica, MBCC) "The barometer mounted on an ornately carved backing was presented by flour miller John Spencer Brunton (1861-1937), son of Thomas Brunton who founded the Brunton & Co. flourmills. John had responsibility for the New South Wales arm of the company and lived in Sydney.' (Pg 82 Historica MBCC) " Fig 80. It was presented by John Spencer Brunton on 9 December 1930."(Pg83, Historica. MBCC) Listed in Draft Inventory of Significant Collection items A.3.. Fixtures and Fittings (Pg 165.Historica, MBCC)Barometer and thermometer with carved decorative leaf pattern wooden surround.On plaque below barometer:"PRESENTED BY / JOHN SPENCER BRUNTON / 9.12.30" (further inscriptions on face) -

Parks Victoria - Mount Buffalo Chalet

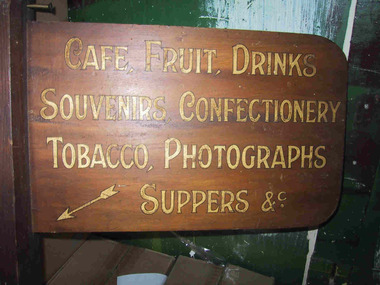

Parks Victoria - Mount Buffalo ChaletSigns

Original directional signs from Chalet interior. Dated to pre 1960's. "A number of specific items, which have been useful in the day to day operations of the Chalet, remain in the building with each complementing the other to provide context, meaning and character to their setting. Items such as the hall porter bell, the many signs providing information to the guests, the wall clock, barometer and dinner bell point to the Chalet being a well-run social institution with a pleasant environment for rest, recreation and congenial company." (Pg 81 Historica, MBCC) Listed in Draft Inventory of Significant Collection Items. Appendix A.3 Fixtures and Fittings. (Pg 165 Historica MBCC) Varnished wooden directional signs with painted gold lettering to direct guests through the chalet to the cafe and the guests drying room. Signs have rounded edges and are attached to a vertical post.1. "Cafe, fruit, drinks, souvenirs, confectionary, tabacco, photographs, suppers etc." 2. "GUESTS DRYING ROOM"