Showing 264 items matching " woodworking tools"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

... that today is a rare and collectable example of woodworking tools ...The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Drill Brace metal with socket and thumbscrew, varnished wooden head and handleNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, 1911 - 1970

... for those enthusiasts that collect vintage woodworking tools ...Ward & Payne was founded in Sheffield by David Ward, an edge-tool manufacturer in 1803. The company had the name, David Ward. David Ward's son Edward joined the company around 1837 and the company name was changed to David Ward & Sons or David Ward & Co. Perhaps both names were used in succession it is unclear. Henry Payne appears as an edge tool maker in 1837 and joins the company before 1845. Perhaps he joined in 1837, as a result, this caused the name change to David Ward & Co. In 1843 Henry Payne registered the trademark name of Ward & Payne consisting of the crossed hammers above an anvil with W to the left and P to the right. Henry Payne became the junior partner in 1845 and died in 1850 and ownership of the company then reverted to the Ward family. After 1845 the firm built a large business in edge tools concentrating on carving tools, chisels, and gouges. Another David Ward (1835 - 1889), possibly the son of Edward Ward, took over the company in 1855 and was an aggressive young executive with the company before that. He grew the company's fortunes in both the sheep shearing scissor and carving tool businesses. The company grew and expanded its factory to a full city block and published a 501-page catalog in 1911. The company was still in business up to around 1970.A tool made by a well-known company and regarded today as a collector's item for those enthusiasts that collect vintage woodworking tools. However for further details regards provenance see the note in the provenance section this document.Socket chisel cast steel "Ward Cast steel" inscribed on blade flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hand tool, ward chisel, woodwork chisel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, Ward, 1855 - 1911

... for those enthusiasts that collect vintage woodworking tools ...Ward & Payne was founded in Sheffield by David Ward, an edge-tool manufacturer in 1803. The company had the name, David Ward. David Ward's son Edward joined the company around 1837 and the company name was changed to David Ward & Sons or David Ward & Co. Perhaps both names were used in succession it is unclear. Henry Payne appears as an edge tool maker in 1837 and joins the company before 1845. Perhaps he joined in 1837, as a result, this caused the name change to David Ward & Co. In 1843 Henry Payne registered the trademark name of Ward & Payne consisting of the crossed hammers above an anvil with W to the left and P to the right. Henry Payne became the junior partner in 1845 and died in 1850 and ownership of the company then reverted to the Ward family. After 1845 the firm built a large business in edge tools concentrating on carving tools, chisels, and gouges. Another David Ward (1835 - 1889), possibly the son of Edward Ward, took over the company in 1855 and was an aggressive young executive with the company before that. He grew the company's fortunes in both the sheep shearing scissor and carving tool businesses. The company grew and expanded its factory to a full city block and published a 501-page catalog in 1911. The company was still in business up to around 1970. A tool made by a well-known company and regarded today as a collector's item for those enthusiasts that collect vintage woodworking tools. However for further details regards provenance see the note in the provenance section this document.Socket chisel with 1 inch blade end of handle has been sawn off.Has "E" stamped on bladeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hand tool, ward chisel, woodwork chisel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Blade, A Mathieson & Son, late 19th to early 20th century

... Museum and Village Warrnambool woodworking tool plane blade hand ...Blade for a woodworking plane. Maker's name moulded into metal in arch configuration. Made by A Mathieson & Son."ALEXANDER MATHIESON &o SON." flagstaff hill, flagstaff hill maritime museum and village, warrnambool, woodworking tool, plane, blade, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, 1905-1913

... ocean road shiopwreck coast woodworking tool crosscut saw ...This crosscut saw was originally part of the equipment on the barque Marjorie Craig, which brought New Zealand timber into Warrnambool from about 1908 to 1912 for the local merchants P J McGennan & Co. The toolbox was donated by a member of a local family connected with the La Bella rescue in 1905. The toolbox has carvings and markings that make it unique and connect it to the Marjorie Craig. The Craig Line of sailing ships was from Auckland, New Zealand, and traded in timber and some coal from New Zealand ports to Australia, including Sydney, Adelaide, Melbourne and Warrnambool. They returned with produce from Australia as ballast. In 1912 the Craig fleet included the Ihumata, Inga, Jessie Craig, Marjorie Craig, Louisa Craig and Joseph Craig. The steel barque Marjorie Craig, 500 ton, was built in 1891 as the 'Hirotha', in Ardrossan, Scotland for Norwegian owners. The ship was sold to Auckland’s Donald Ross and others in 1900, then in 1905 it was sold, registered by J.J. Craig in Auckland, New Zealand and renamed Marjorie Craig. Marjorie Craig’s commanders included Master R A Campbell in 1907, J MacFarlane in 1909 and Master R.G. Holmes in 1913. From February 1908, the Marjorie Craig was regularly seen in the Port of Warrnambool with loads of timber for merchants P J McGennan & Co. In February 1912 Marjorie Craig delivered white pine for P J McGennan & Co. In April of the same year, she brought 500,000 feet of timber for McGennan & Co and again in May 1912. On May 12 1912 Marjorie left the Port of Warrnambool with 500 tons of flour for New Zealand; it seems that this was her last time at Warrnambool. Prior to 1908, the vessel Speculant brought in timber from New Zealand for the McGennan firm. The Marjorie Craig had a strong reputation for being a ‘Fast Flyer’, breaking the sailing records for voyages between New Zealand and Australia. It was reported that she made passages with a speed equal to steamboats on several occasions. One of her records was from Warrnambool to Hokianga, NZ in eight-and-a-half days. The ship broke the record in October 1913 for the time from Adelaide to Auckland, sailing in 28 days, even with a damaged ship, and the owner presented Captain Holmes with a gold watch and chain. By the end of December 1913, the Craig Line’s last two surviving sailing ships, Marjorie Craig and Jessie Craig, had been purchased by Huddart, Parker & Co. Ltd. to work as coal hulks, one in Melbourne and one in Hobart.The saw is significant for being created for use in 1905 when the steel barque Marjorie Craig was purchased by J J Craig and given that name. The saw would be part of the sip's equipment and could have been used for the timber carried as cargo on the Marjorie Craig. The saw is significant for its association with the well-known Marjorie Craig, a frequent visitor to the Port of Warrnambool 1908 to 1912, a supplier of New Zealand timber for the local firm P J McGennan & Co, and one of the fastest inter-colonial sailing ships that broke numerous records for its speed including the fastest sailing from Warrnambool to Hokianga. Crosscut saw; blade attached to wooden handles by wingnut each end. The saw has 63 teeth. Also has a tag attached with an inscription. The saw was ship's equipment on the barque, Marjorie Craig.Handwritten on tab: "From sailing ship Marjorie Craig early 1900 Port of Warrnambool"flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shiopwreck coast, woodworking tool, crosscut saw, shipwright tool, saw, marine trade, carpenter, marjorie craig, j j craig, craig line, 1905-1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Toolbox, 20th century

The owner of this toolbox was J Burden.The toolbox is an example of the equipment used by people in the woodworking trade to store and transport the equipment in an orderly and secure manner. Similar toolboxes are used today but are often made of metal.Box; wooden toolbox marked J Burden. The box has removeable shelves inside with drawers and lid. The box has two rope handles on the ends and has a key lock in front."J Burden"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j burden, wooden tool box -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 20th century

... Plane plane W Goodell JB hand tool woodworking Woodworking Tool ...Moulding plane, round type, with a formed hole drilled through it. Stamped with owner's name and inscriptions. Varnish has partly obscured the name.Stamped; "W GOODALL" "JB" "JB"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, moulding plane, plane, w goodell, jb, hand tool, woodworking, woodworking tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, late 19th to early 20th century

... Village Warrnambool Great Ocean Road woodworking tool plane rabbit ...Plane Rabbet type, no blade no markings.flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, woodworking tool, plane, rabbit plane, hand tool -

Federation University Historical Collection

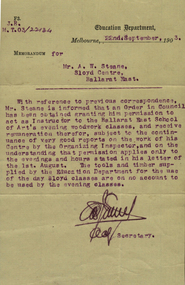

Federation University Historical CollectionCorrespondence, Education Department Memorandum: A W Steane, 1903, 22/09/1903

... woodwork tool equipment Signed; A James on behalf of the Secretary ...Cream coloured paper with Education Department letterheadSigned; A James on behalf of the Secretary Markings on top left corner: 'F3' 'J.B' 'M.T.03/22134 education department, sloyd centre, ballarat east, a w steane, a james, order in council, ballarat east school of arts, evening classes, woodwork, tool, equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Spokeshave steel ornate, c1900

... with Record Ridgeway Ltd. woodwork tools spokeshave moorabbin ...A spokeshave is a tool used to shape and smooth wooden rods and shafts - often for use as wheel spokes, chair legs . Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. Spokeshaves can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, whilst the body and handles were wood. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached. Like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth century metal handles and detachable blades had become the most common. Preston Tools was an English tool making company also known as E.P. Tools and Edward Preston Tools. Edward Preston Sr. (1805-1883) was first listed as a plane maker at 77 Lichfield Street in the 1833 Birmingham Directory but it is believed he may have started business there as early as 1825. Around 1850 his son, Edward Preston Jr. (1835-1908) left school to join his father's business and he later started up his own "wood and brass spirit level manufactory" at 97-1/2 Lichfield Street by 1864. By 1866 Edward Jr. had added planes, routers, joiners, coach, gun, cabinet and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to a much larger premises at 22-24 Whittall Street. This later became the office and factory of Edward Preston and Sons, who were forced to liquidate in 1934, due mainly to the Great Depression and mismanagement of the company. The plane making concern was sold to the Sheffield firm of C. & J. Hampton, who had subsequently merged in 1932 with Record Ridgeway Ltd.An ornate steel spokeshave wood plane with an adjustable screw.PRESTONS PATENTwoodwork, tools, spokeshave, moorabbin, cheltenham, bentleigh, early settlers, pioneers, market gardeners, woodplanes, craftwork, bicycle wheels, furniture, cabinetmaking, cartwheels, wagons, drays, preston edward, preston tools ltd -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

... flat edges. tools, woodwork, metalwork, welding, carpentry ...A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel hacksaw 'Marples', 20thC

... used over 100 years ago. tools, woodwork, metalwork, carpentry ...A hacksaw is a fine-toothed saw, originally and principally for cutting metal. They can also cut various other materials, such as plastic and wood; for example, plumbers and electricians often cut plastic pipe and plastic conduit with them. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vice, hacksaw blades should be set to be facing forwards. Joseph Marples & Son Pty Ltd Traditional Craftsmans Hand Tools made in Sheffield. The finest quality hand made tools, backed by over 170 years of manufacturing heritage. .In the 1840’s Joseph Marples was one of several ‘Marples’ (most of which were related) in Sheffield manufacturing joiners tools, such as brass inlaid rosewood & ebony braces, boxwood spokeshaves, beech planes, gauges and squares. The business has remained within the family to this date, and has been based in Sheffield since those early days. Although modern technology has been used in some instances, many of the traditions of manufacturing fine hand tools has remained the same using selected materials and hand finishing, indeed the same threads are used in the gauges as were used over 100 years ago. A steel hacksaw. 'Marples' with bladeMARPLEStools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond, joseph marples & son pty ltd, sheffield , england, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Coping saw, c1900

A coping saw is a type of hand saw used to cut intricate external shapes and interior cutouts in woodworking or carpentry. It is widely used to cut mouldings to create coped rather than miter joints. It is occasionally used to create fretwork though it is not able to match a fretsaw in intricacy of cut, particularly in thin materials. Coping saw blades are always thicker and much coarser cutting than typical fretsaw blades. A coping saw consists of a thin, hardened steel blade, stretched between the ends of a square, c-shaped, springy-iron frame to which a handle is attached. The blade is easily removed from the frame so that the blade can be passed through a drilled hole in the middle of a piece of wood. The frame is then re-attached to the blade and the cut starts from the middle of the piece. Long cuts perpendicular to the edge of the material are possible but the shallow depth of the frame rather limits how far from the edge one may cut. The much deeper frame of the fretsaw is more useful for cutting well away from the edge but conversely cannot manage the thicker materials commonly cut by the coping saws. The coping saw blade is installed with the teeth pointing towards the handle. Unlike a hacksaw, which has the teeth pointed away from the handle, the coping saw cuts on the pull stroke. The coping saw blade is removable by partially unscrewing the handle. The blade is prevented from rotating by means of the short, steady bar provided where the blade is attached. Loosening the handle also allows the blade to be rotated relative to the frame as desired. Carefully aligning the finger steady bars at the top and bottom of the blade ensures that the thin blade is straight and not twisted along its length. Re-tightening the handle tensions the blade and locks it at the desired angle relative to the frame. The short steady bar nearest the handle is held securely between finger and thumb while the handle is tightened to ensure the blade remains at the desired angle. Unlike the fretsaw the coping saw blade has holding pins which lock securely into the angled slots of the rotatable blade holders. Gentle curves are achieved by slowly turning the whole frame by means of the handle while continuing to cut steadily. A coping saw with wooden handle but no bladetools, saws, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, fretsaw, coping saw, bowsaw, blacksmiths, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel vice, c1900

Perak or State of Perak one of the 13 states of Malaysia, is the second largest state in Peninsular Malaysia. It borders Kedah and the Thai Yala Province to the north; Penang to the northwest; Kelantan and Pahang to the east; Selangor to the south, and the Straits of Malacca to the west. The state's administrative capital of Ipoh was known historically for tin-mining activities until the price of the metal dropped, severely affecting the state's economy. A vice is a tool with 2 jaws between which an object is gripped, usually by tightening a screw, so as to leave the hands free for working upon it. The vice is usually firmly attached to a bench . A steel vice THE PERAK TIN MINING COMPANYtools, vice, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, blacksmiths, perak tin mining co. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, hammer upholstering, c1900

A hammer is a tool with a heavy head and a handle, often made of shock absorbent wood or fibreglass, that is used to strike an object. The most common use for hammers are to drive nails, fit parts, forge metal and break apart objects. Hammers vary in size, shape and structure, depending on their uses. Hammers are basic tools in many trades. A hammer is composed of a head, most often made of steel and handle also called a helve or haft. Most hammers are hand tools. A traditional hand-held hammer consists of a separate head and handle, fastened together by means of a special wedge made for the purpose, or by glue, or by both . This 2 piece design is often used to combine a dense metallic striking head with a non-metallic mechanical shock absorbing handle - to reduce user fatigue from repeated strikes. If wood is used for the handle, it is often ash or hickory, which are tough and long lasting materials that can dissipate shock waves from the hammer head. This upholsterer’s hammer has one end of the steel head rounded for knocking nails into wood furniture. The other end is divided to form a 2 pronged claw for withdrawing nails. . An upholsterer's hammer with a steel head and wooden handle, The steel head has one rounded end and a clawed endpioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, cabinet makers, blacksmiths, builders, woodwork -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher, at one time mostly used in chair making.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. Curved Spokeshave with metal handlesNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, hand plane, joiners tools, wagoner's tools, spokeshave -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane, wagon making, joiners tools, carpenter tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Inside Shave Plane, Prior to 1950

A plane used by a cooper to smooth the inside of barrels can also be used for smoothing other curved surfaces like chairs etc.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Inside Shave Plane for curved surfacesNoneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, curved smoothing plane, coopers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Inside Shave Plane, Prior to 1950

A plane used by a cooper to smooth the inside of barrels can also be used for smoothing other curved surfaces like chairs or round poles etc.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Round shave also known as Coopers In-shave, metal curved blade with two wooden handles. Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, curved smoothing plane, coopers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, late 19th to early 20th Century

... as a collectors item and is an example of vintage woodworking tools used ...A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the Bismark pattern made by Henry Boker the this plane is now regarded as a collectors item and is an example of vintage woodworking tools used in the manufacture of wooden products.Smoothing Plane Bismark design. Blade marked Henry Bokerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw knife, C Johnson (Christopher Johnson), 1855-1879

A draw knife is a hand tool that has a long straight blade between two handles. As implied by its name. it is drawn like a knife across the wood. It is used to prepare the timber for the next step of the process, removing loose wood and bark and giving a start to making the wood into a round or cylindrical shape. Then a finer smoother finish is given with a spokeshave, which has a shorter, curved blade. A draw knife could be used for the wooden spokes for cart, wagon and carriage wheels as well as for ladder staves and ship wheels. Features of a good draw knife include tight handles, a blade with plenty of metal to it and a blade length of 20 to 24 centimetres. This draw knife was likely made at least 150 years ago by C Johnson of Sheffield, who used the Trade Mark “C.J.” within a flag. Christopher Johnson began work as a cutler, making knives, pocket knives and tableware in his works at Howard Street in Sheffield. In the book ‘Hand-Saw Makers of Britain by Schaeffer and McConnel, Johnson is listed in 1855 as a saw maker. A later reference has the business name of Johnson & Company, Sheffield in 1879-1882. Australia was one of the company’s markets. The company continued until its closure in 1955.This draw knife is significant for being made in Sheffield, a location famous for steel and silver manufacturers. It is significant because of its age, being made no later than 1879, which is the time period of our maritime Village. It is a tool most suitable for the blacksmith's or a ship' smith's workshop for making spokes for the wheels of wagons and carts, and for making ship's wheels.. It is also significant for being made by C Johnson, who was well known for his good workmanship. Draw knife; flat cast steel fixed blade with rotating wooden handles each end. Round bulbous handles have two parallel scored lines around the end furthest from the blade and a brass collar between the handle and blade. A logo and inscription are cast into the centre front of the blade. Made by C Johnson. of Sheffield.Cast into steel blade: Sideways Image “C.J.” within {flag}, “JOHNSON / CAST STEEL”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, spokes, wagon maker, blacksmith, cart maker, cart wheel maker, blacksmith tool, wagon wheel, c johnson, sheffield, wheelright, craftsman, woodwork, carriage wheel, ship wheels, shipwright, wooden spokes, ladder staves, draw knife -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marking Gauge

... such as a cabinet maker, woodworker or carpenter. The hand tool shows signs ...This mortice marking gauge has an adjustable sliding arm. The gauge is used for scribing two lines on a flat surface such as timber for measuring and cutting. It is a hand-powered tool that would have been used by a tradesperson such as a cabinet maker, woodworker or carpenter. The hand tool shows signs of much use. The ‘W. Maples & Sons, Hibernia’s catalogue of 1867 had a very similar tool, called a Mortice Gauge, column 2, page 15. W. MARPLES & SONS- William Marples Snr. had a business on the Sheffield Moor in 1773/74. In 1821 his son William Jnr. At 12 years old began in his father’s joinery business. 1833 the firm was known as a tool manufacturer. In 1838 Marples called his business Hibernian Works and moved to 67-69 Spring Lane, Sheffield. When he moved to Westfield Terrace in 1856, he called his business Hibernia Works (no ‘n’ on the end). The business remained at this address for 116 years. In about 1859 the firm began using the Lyre (Irish harp) mark. In 1860 or so the two brothers, Edwin and William Marples, became partners and the firm became William Marples and Sons. The firm introduced the single shamrock symbol in 1860-61. The boys’ brother Albert joins the firm in 1863. In 1875 the company registered both the name ‘Hibernia’ and the trade mark symbol of a Triple Shamrock and the use of these trademarks continued for many decades, into the 1940 and the firm, with many changes, was still in business in the early 21st century. About Shamrock and Hibernia, both are related to Ireland and W. Marples named his products the Shamrock brand.The marking gauge is an example of a hand powered woodworking tool used over the past few centuries. Its maker was well known for his good quality tools and his business grew because of his reputation.Mortice marking gauge: wooden staff with block and green, adjustable sliding arm within the staff. The end of the staff has a facility for holding the scribe marker. The block has a hole into which a peg or wedge would be inserted to hold the sliding arm in place. Inscription with maker's name and almost indecipherable mark is stamped onto one side of the block. Made by W Marples & Sons, Sheffield.Stamped into block “W. MARPLES & SONS / HIBERNIA WORKS” above Logo of ‘Trefoil’ image [three, three-leafed clovers on the same stem]flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, hand tool, woodwork, marking gauge, measuring tool, mortice gauge, mortice marking gauge, william marples, w marples & sons, hibernia, shamrock, trifoil, tripple shamrock, carpenter's tool, cabinet maker, woodworking tool, drawing, planning, tool, wooden scribe, vintage, carpenter, marking tool, antique, marking out, joiner -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wooden Screw Clamp, Late 19th to early 20th century

... produced today in many sizes by many woodworking tool companies ...A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel, screw or surgical clamp. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. In the field of animal husbandry, using a clamp to attach an animal to a stationary object is known as "rounded clamping." A physical clamp of this type is also used to refer to an obscure investment banking term, "fund clamps." Anything that acts to hold two surfaces together may be called a clamp, so this gives rise to a wide variety of terms across many fields. The subject item is a wooden-handled screw clamp used in cabinet or woodworking projects to hold two surfaces together while glueing or fixing. An item that has not changed in shape or use since its inception hundreds of years ago. These types of clamps are still produced today in many sizes by many woodworking tool companies.Wooden hand Screw Clamp two lengths of wood each beveled at one end and standing parallel. Two long wooden screws with handles and predominant thread that fits through wood lengths.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden screw clamp, carpenters tools, cabinet makers tools, clamp -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: AWL

Pittock coach builder's box: woodwork awl * steel awl with timber handle * awl 143 mm L * located in assigned location at front of box, extreme left corner Item stored in Pittock coach builder's box, reference 13000.1. -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Handle, 1940's

Made by internee at Camp 3, Tatura workshopWood turned handle, unpolished, unfinished handle, wood, bissinger g, wied g, camp 3, tatura, ww2, handcrafts, woodwork -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Handle, 1940's

Made by internee in Camp 3, Tatura workshopWood turned handle, polished, with metal end piece/shaft. Opening for inserting blade/chiselhandle, wood, bissinger g, wied g, camp 3, tatura, ww2, handcrafts, woodwork