Showing 325 items

matching hand made tools

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spirit Level, 1937-1955

... , is collectable and highlights a time when tools were made by hand and how ...Initially Elvicta was known as Elliot Lucas (hand tools)Ltd, and was established around 1937 based at 38 Summer Row, Birmingham. Around 1950 the firm relocated to Cannock, Staffordshire and by 1965 had moved again to their Church bridge Works also at Cannock. The Elliot Lucas Ltd Elvicta Cabinet and Tool factory as it was known employed over a hundred people and operated from the company's satellite works in Crickhowell southeastern Powys, Wales, near Abergavenny, in the county of Brecknockshire during the 1950s. The company manufactured a range of specialist pliers, nippers and pincers including the brands Elvicta, Electoy and Elect.A tool that is now regarded today as vintage, is collectable and highlights a time when tools were made by hand and how wood was predominately used to manufacture such items. It gives a snapshot of the time before the use of plastics and other synthetic materials which are now used to produce every day objects and tools such as this spirit level.Elvicta brand wooden spirit level made by Elliott-Lucas Ltd England. Level has two levels one vertical one horizontal . Has 2 brass corner protectors Has 530 marked on plate denotes model No and an original label 610 mm long x 60 mm x 30 mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCaulking tool

Caulking iron (hand made) narrow pointed jerry iron used to jerry or chip out the old pitch and oakum from corked seams. It was held at 45 degree angle to the seam and hit with mallet. 265mm long, 22mm wideflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, caulking iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, A Mathieson and Son, 20th century

Plane, moulding type, made by A Mathieson and Son. 3/8th no blade Stamped; "A MATHIESON & SON / GLASGOW & EDINBURGH" around a symbol [Crescent and star]flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, a mathieson & son, glasgow, edinburgh, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, James Hastie, Late 19th to Early 20th Century

... was made predominately by hand and with tools that were themselves ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane with metal blade attached. Made by J Hastie. Inscriptions stamped into wood. "J Hastie" "E G" "W.M" "EG" "11"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j hastie, plane, wood working tool, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, R Kelly & Sons Ltd, 20th century

Plane, Rebate type, with stamped inscriptions. It has no blade. Made by maker R Kelly & Sons Ltd Liverpool.Stamped; within oval "KELSON" "R KELLY & SONS LTD / LIVERPOOL / & MANCHESTER"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, rebate plane, r kelly & sons ltd, kelson, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

... furniture was made predominately by hand and with tools that were ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1844-1860

... sought after by collectors of vintage tools. A vintage tool made ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about John Ames is that he was a tool maker and retailer that operated a business in London early to mid 18th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools.A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Complex Moulding Plane J Heath (owner) stamped. No 6 opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, ames -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Early to Mid 19th Century

... predominately by hand and with tools that were themselves hand made ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Moulding Plane T S Richards & Co. J Heath owner stamped. No 4/8 opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, t s richards & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

... and tools continued to be made in London until 1904 when ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

... of the master who guided it. A vintage tool made by an unknown company ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane 4 screws attached to wood bottom plateJ Heath. 1/2 inch on opposite end.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

... of the master who guided it. A vintage tool made by an unknown company ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Circular moulding Rabbet Plane Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, circular rabbet plane, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to late 19th Century

... of the master who guided it. A vintage tool made by an unknown company ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane H Heathflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1832-1864 made in London

... sought after by collectors of vintage tools. A vintage tool made ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 4 opposite end flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, 1770-1809

... of cutting edged hand tools. Tools that were themselves hand made ...The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Side Rabbet Plane Stamped Maker Gabriel (owner M Hobling).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, 1832-1864

... sought after by collectors of vintage tools. A vintage tool made ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Plane Moulding type maker J Budd London also stamped J Heath (owner) & No 2 opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Federation University Historical Collection

Federation University Historical CollectionTool - Electrical Instrument, Electric Belt Sander, c1960s

Used in Building Studies at Ballarat School of Mines. The sander used to sand rough timber smooth, remove old finish from wood, put a bevel on a door, reduce the thickness of timber, dress up a poor saw cut. Also used for back cutting miter cuts for neater joints and for polishing and cutting.Stainless steel with rollers and sanding plate. Hand held. Continuous loop of sandpaper would be mounted.Maker's Plate: MILLER FALL TOOLS CATALOG 830 3 INCH BELT SANDER MODEM "C" USE 3" X 21" BELT 230/250 VOLTS 3 AMPS 25-60 CYCLES MADE IN USA PATENT 2,991,595 MILLER FALLS COMPANY, GREEFIELDS, MASS. TO CHANGE BELT PULL LEVER DIRECTION OF BELT ballarat school of mines, building studies, david flintoff, timber, smooth, miter cuts, polishing, buffing, thinning -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Education, Pen Nibs ' R. Esternbrook Co. Ltd, 20thC

Dip pens emerged in the early 19th century, when they replaced quill pens. They were generally used prior to the development of fountain pens in the later 19th century, and are now mainly used in illustration, calligraphy, and comics. A nib pen usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted on a handle or holder, often made of wood. Other materials can be used for the holder, including bone, metal and plastic. Generally speaking, dip pens have no ink reservoir; therefore the user has to recharge the ink from an ink bowl or bottle in order to continue drawing or writing. Birmingham, England was home to many of the first dip pen manufacturers. John Mitchell pioneered mass production of steel pens in 1822; prior to that the quill pen had been the most common form of writing instrument. His brother William Mitchell later set up his own pen making business in St Paul's square. The Mitchell family is credited as being the first manufacturers to use machines to cut pen nibs, which greatly sped up the process. Germany 1842 began at the factory of Heintze & Blanckertz in Berlin By 1860 there were about 100 companies making steel nibs in Birmingham, but 12 large firms dominated the trade. Dip pens are rarely used now for regular writing, most commonly having been replaced by fountain pens, rollerball pens, or ballpoint pens. However, dip pens are still appreciated by artists, as they can make great differences between thick and thin lines, and generally write more smoothly than other types of pens. Dip pens are also preferred by calligraphers for fine writing. Richard Esterbrook was a Cornish Quaker from England who saw an opportunity in the United States to manufacture Steel Pens. In 1856 R.Esterbrook traveled to the US to set up shop as 'The Steel Pen Manufacturing Company' where Richard made these steel pens by hand using special tools and machines (mostly that Richard had to invent). In 1858 he was able to establish himself as the sole pen manufacturer in the USA and he changed the company name to 'The Esterbrook Steel Pen Mfg. Co.' The company settled down in Camden, New Jersey. Quality was a key factor in his success. His steel pens were versatile, long lasting, and came in many different styles to fit the varied writing styles of the public. Sadly, Richard Esterbrook didn't see the 'empire' his company was to become as he passed away in Atlanta on October 12th 1895 . in 1896 they started an Esterbrook branch in England to join the ranks of the other main pen manufactures in Birmingham . In 1912 the company had gotten so large that they erected a 5 story building, just to continue manufacturing pens. By 1920 the fountain pen was fast becoming more popular amongst people who were tired of 'dipping.' To meet this demand the company manufactured its first fountain pen. In 1930 the company sought less expensive means of manufacturing pens because gold and 'jewel' tips were too expensive and in this same year they began selling fountain pens in England . The Esterbrook Company began using the metal Iridium which they called 'Durachrome.' To meet the fountain pen demand the company reformed as 'The Esterbrook Hazel Pens Ltd.' In 1940 war had come to strike a blow at the Esterbrook company. On November 19th 1940 their England location was hit by an incendiary bomb destroying half of the location! To make matters worse, when putting out the fire using a human water bucket chain, someone accidentally grabbed a bucket of paraffin and set the place further ablaze. Oddly enough, the company was able to rebuild the structure during the war. However, the government had placed a stipulation that 50% of its capacity was to be used for government related purposes. In 1947 the company bought out John Mitchell and the American branch had already acquired Hazel Pen Co. The company re-formed again as 'The Esterbrook Pen Company.' This is the last company name the dip pen nibs were manufactured under. A box of Steel dipping nibs for writing pensOn Box; Photo of man / R. Esternbrook Co. / PENS / PROBATEsteel nibs, writing pens, education, schools, writing, caligraphy, artists, moorabbin, bentleigh, cheltenham, dip pens, inkwells, fountain pens, mitchell john, birmingham england, esternbrook richard, maple barbara -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

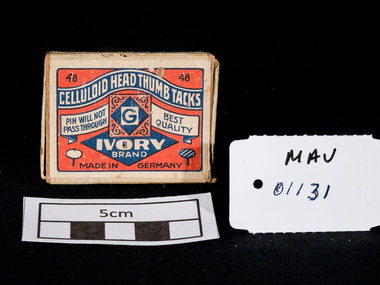

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Thumb Tacks 'Ivory', 20thC

A thumb tack, push pin or drawing pin is a short nail or pin used to fasten items to a wall or board for display and intended to be inserted by hand, generally without the assistance of tools. A variety of names are used to refer to different designs intended for various purpose. Edwin Moore invented the "push-pin" in 1900 and founded the Moore Push-Pin Company. Moore described the push-pin as a pin with a handle. Later, in 1904, in Lychen, German clockmaker Johann Kirsten invented flat-headed thumb tacks for use with drawings. A thumb tack has two basic components: the head, often made of plastic, metal or wood, and the body, usually made of steel or brass. The head is wide to distribute the force of pushing the tack in, allowing only the hands to be used. Many head designs exist: flat, domed, spherical, cylindrical and a variety of novelty heads.Cardboard box with sliding insert that contained 48 'IVORY' Brand celluloid head Thumb Tackson Box ; 48 / 48 / CELLULOID HEAD THUMB TACKS / 'G' / PIN WILL NOT / PASS THROUGH / BEST / QUALITY / IVORY / BRAND / MADE IN GERMANYdrawing pins, thumb tacks, brass tacks, moore edwin, kirsten johann -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

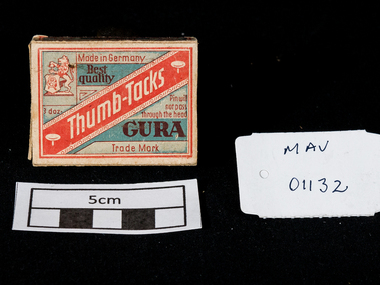

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Thumb Tacks 'GURA', GURA Pty Ltd

A thumb tack, push pin or drawing pin is a short nail or pin used to fasten items to a wall or board for display and intended to be inserted by hand, generally without the assistance of tools. A variety of names are used to refer to different designs intended for various purpose. Edwin Moore invented the "push-pin" in 1900 and founded the Moore Push-Pin Company. Moore described the push-pin as a pin with a handle. Later, in 1904, in Lychen, German clockmaker Johann Kirsten invented flat-headed thumb tacks for use with drawings. A thumb tack has two basic components: the head, often made of plastic, metal or wood, and the body, usually made of steel or brass. The head is wide to distribute the force of pushing the tack in, allowing only the hands to be used. Many head designs exist: flat, domed, spherical, cylindrical and a variety of novelty heads. Cardboard box with sliding insert that contained 3 Doz. GURA Brand Thumb Tacks On box ; MADE IN GERMANY / BEST / QUALITY / 3 doz. / THUMB-TACKS / Pin will / not pass / through the head / GURA / Trade Mark -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Farm Equipment, Rake, large Hay c1900, c1900

A hay rake is an agricultural rake used to collect cut hay or straw into windrows for later collection (e.g. by a baler or a loader wagon). It is also designed to fluff up the hay and turn it over so that it may dry. The next day it is spread again, so that the hay dries more quickly. Early settlers established productive market gardens, poultry,. pig and dairy farms , orchards and vineyards on the land in the 'Henry Dendy Special Survey Brighton 1841' - now Ormond, Bentleigh, East Bentleigh, Brighton, This hay rake is typical of the type used by early settlers in Moorabbin Shire c1900Large wooden Hay rake , hand made c1900farm equipment, hay rakes, hammers, early settlers, market gardeners, blacksmiths, tools, building equipment, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Tools, blacksmith's tongs, c1900

... century. Large pair of forge-made blacksmith's tongs. Tool Tools ...Whilst each town's blacksmiths played an essential part in the colony of Victoria, the early settlers frequently had their own small forge and a few blacksmith's tools to attend to smaller day to day repairs. A long-handled pair of blacksmith tongs were essential for handling red-hot metal that was being repaired.As only a handful of settlers were present in the Moorabbin district from the 1840s. These early colonists were required to use their ingenuity and skill to undertake the "running repairs", including some basic blacksmithing, required around their property or leasehold.Circa 19th century. Large pair of forge-made blacksmith's tongs. Nilblacksmiths, forges, metalwork, craftwork, fireplaces, early settlers, pioneers, moorabbin, bentleigh, cheltenham, market gardeners colonists, 1840s -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Spokeshave, hand plane, c1880

The pioneer farmers and market gardeners in Moorabbin Shire had to be self sufficient and made their own tools and clothing and grew their own food. Some had been farmers in England and brought with them tools that would help them establish homes in the new countryAn example of the typical tools used by pioneers in Moorabbin Shire as they built homes and established farms. c1880 This spokeshave, is a wooden hand - plane that has a very short flat metal sole, used for smoothing curved surfaces.moorabbin, brighton, cheltenham, market gardeners, pioneers, farmers, tools, planes wood -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, mallet wooden square, c1880

Early settlers in Moorabbin Shire had to be self reliant and made their own clothes and tools as they established homes and farms for their families. An example of the tools used by pioneer settlers in Moorabbin Shire c1880c1880 A well used, hand made, square, wooden mallet with wooden handlepioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, tools, farming -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, mallet, wooden cylindrical, c1880

... moorabbin brighton cheltenham tools farming c1880 Hand made, wooden ...Early settlers in Moorabbin Shire had to be self reliant and made their own clothes and tools as they established homes and farms for their familiesAn example of the tools used by pioneer settlers in Moorabbin Shire c1880c1880 Hand made, wooden mallet with cylindrical head, reinforced at ends with tin bands, and a wooden handlepioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, tools, farming -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, 2x Gimlet, boring screw, c1900

A gimlet is a hand tool for drilling small holes, mainly in wood, without splitting. A gimlet is always a small tool made of a piece of steel of a semi-cylindrical form, hollow on one side, having a cross handle at one end and a worm or screw at the other. A similar tool of larger size is called an auger. Early settlers in Moorabbin Shire had to be self reliant as they established their farms and built their homes using tools like this gimlet. 2 x small hand tool with a screw point, grooved shank, and cross handle for boring holes early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, marker wooden gauge, c1900

... brighton cheltenham tools c1900 A hand made wooden marker gauge ...A marking gauge, also known as a scratch gauge, is used in woodworking and metal working to mark out lines for cutting or other operations. The purpose of the gauge is to scribe a line parallel to a reference edge or surface. It is used in joinery and sheet metal operations.The gauge consists of a beam, a headstock, and a scribing or marking implement, typically a pin, knife, pen or wheel. The headstock slides along the beam, and is locked in place by various means: a locking screw, cam lever, or a wedge. The marking implement is fixed to one end of the beam.Early settlers in Moorabbin Shire had to be self reliant and made their own clothes and tools as they established homes and farms for their familiesc1900 A hand made wooden marker gaugeearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools