Showing 227 items matching "home manufacture"

-

Linton and District Historical Society Inc

Linton and District Historical Society IncLetter, Paper manufactured by T. Edmonds 1890 (watermark), Department of Lands and Survey, Argyle Common, Linton, 1897, 18.05.1897

Letter written on behalf of Tho. MacGibbon, Secretary for Lands, to C. Stratton, Secretary, Argyle Common, Linton. Acknowledging receipt of Argyle Common accounts for 1896, and informing of their passing by the Board of Land and Parks. Also requesting that in future the accounts should be prepared on the prescribed form, a copy of which was enclosed. Found in the home of Miss Margaret Gorman after her death. See form sent with letter - Registration No. 1617Handwritten letter on grey paper headed Department of Lands and Survey, dated 18th May 1897. Addressee C. Stratton Esq.-Secretary-Argyle Common-Linton.argyle common linton, animal grazing, agricultural activity -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale rib bone with advanced stage of calcification as indicated by brittleness. None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Phonograph Records

Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph. Beginning in 1889, pre-recorded wax cylinders were marketed. These have professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production under new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of home entertainment in the late 19th and early 20th century.Two phonograph cylinders in cardboard boxes. The first cylinder is an earlier 2 minute Edison Gold Moulded Record with Issue Number 9184. It features a recording of "Paddle your own Canoe" by Arthur F. Collins and Byron G. Harlan and was released in January 1906. The second cylinder is a 4 minute Edison Amberol Record (NO. 647) featuring the Levy-Athan Polka performed by Charles Daab on xylophone and accompanied by an orchestra. It was released in February 1911. The case is cylindrical in shape and made of cardboard. It is coloured green, white, and black on the outside, while the base is not coloured. The tube is open at the top, and sealed at the base. Inside the tube is a white fabric lining. The top section of the outside of the tube is dark green. Below this is an outer sleeve. The outer sleeve has a half white, half green background with a black stripe, with gold outline, running horizontally around the top and bottom. The words "Thomas A. Edison" are printed in green cursive along the band. In the centre of the sleeve is the text " EDISON AMBEROL RECORD FOUR MINUTE" in green ink. To the left of that text is a green-toned image of Thomas Edison in an ornate, gold border. This is surrounded by the words “Copyright 1900 by the National Phonograph Co. Orange N.J. U.S.A". To the right of the text is a rectangular text box with a black border, which contains patent information in green text. edison phonograph, home entertainment, music early 20th century -

![Equipment - Inhaler, Dr Nelson's improved inhaler, [ca1900's]](/media/collectors/50187a8f023fd7201471f198/items/52522b9a2162ef0d1c00cbd7/item-media/52522bde2162ef0d1c00cc45/item-fit-380x285.jpg) Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveEquipment - Inhaler, Dr Nelson's improved inhaler, [ca1900's]

Inhalation therapy has been used for over 2000 years, but it was from the early 19th century that different types of inhalers were developed. In 1865, Dr Nelson developed the improved Nelson inhaler. It is still manufactured today with very few modifications. The efficiency of the improved Nelson's inhaler is demonstrated by the ongoing use of the item since 1865. This simple inhaler is suitable for use in homes and hospitals. This white china inhaler has an air inlet spout and an opening at the top to add hot fluids, it holds 1 litre, and drugs to the inhaler. Once added, a cork with a glass mouth piece is placed in the neck of the inhaler. For this item plastic tubing has been used as the mouth piece.On front of body inscribed, 'Dr Nelson's improved inhaler': Directions for use. Remove mouth piece, half fill inhaler with boiling water. Replace mouth piece and apply lips to it, breathe freely in and out as in ordinary full respiration.steam inhaler, dr nelson's inhaler, medical apparatus -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Home Phonograph

Thomas Edison was one of the world’s most prolific inventors, holding over 2,000 different patents. One of his earliest inventions was the phonograph. The Edison Phonograph Company was formed on October 8, 1887, to market Edison's machine. The original machine went through many modifications. The Patent information on this machine indicates that it was manufactured after May 1906. Sound was recorded on wax cylinders. Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph Beginning in 1889, pre-recorded wax cylinders were marketed. They featured professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production of the new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of early home entertainment in the late 19th and early 20th century.An Edison Home Phonograph in a wooden case. No trumpet included.On outer case' Edison On metal plate: Thomas A Edison TRADE MARK On large metal plate: Detailed inscription of Patent informationphonograph, thomas edison -

Warrnambool and District Historical Society Inc.

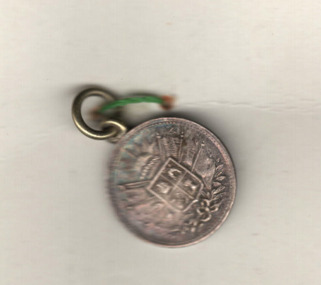

Warrnambool and District Historical Society Inc.Medals, Stokes Melbourne, Industrial & Art Exhibition 1886-7, 1896

These are souvenir medals of the Warrnambool Industrial and Art Exhibition of 1896-7. This exhibition organised by a local committee under the chairmanship of the Mayor, Walter Hickford was one of the most important events in Warrnambool's history. It ran for three months and was said to have attracted 70000 visitors. It was held in Liebig Street and utilised both the civic centre buildings and temporary buildings erected for the event. It had several exhibition courts featuring art worksand business exhibition stands, competitions,entertainments and visiting experts in various fields. These medals were made at the exhibition at the stand of Stokes and Son. Visitors to the exhibition were able to get a gold silver or bronze medal made while they watched and the medal was then perforated ready to put on a watch chain or pendant. Thomas Stokes came to Australia in the 1850's and established a successful business in Melbourne manufacturing buttons, medals and tokens. The business was called Stokes and Son following a fire in 1893.These medals are of great significance as a memento of an important event in Warrnambool -The Warrnambool Industrial and Art Exhibition of 1896-7. Medals such as these would have been in the homes of many residents of Warrnambool and district and beyond after 1896..1 This silver circular medal has text around the outer rim and an image of Queen Victoria on the reverse. On the obverse is text and an image of the Warrnambool Exhibition building erected for the occasion. The medal is secured by a red thread , button and clear tape to a piece of card. On the card is a hand drawn sketch the Warrnambool Exhibition building and a hand drawn sketch of a profile of Queen Victoria . .2This silver circular medal has text around the rim and an image Warrnambool Exhibition building on the reverse and on the obverse a stylised coat of arms topped by the rising sun . Inside the field is a sailing ship, a pick and shovel , a sheep and sheaf of wheat .1 on the Reverse : around the rim, Struck at the Exhibition mint. On the obverse : Industrial exhibition 1896 Warrnambool. .2 On the obverse : Industrial exhibition 1896 Warrnambool.warrnambool, great exhibition of warrnambool, 1896 exhibition warrnambool, warrnambool exhibition medal -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale jaw bone one side, long & curved with advanced stage of calcification off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Meat Safe known as a "Coolgardie Safe", Early 1900s

The Coolgardie safe was invented in the late 1890s on the Western Australian goldfields. Its invention was credited to a local contractor named Arthur Patrick McCormick. It was a practical system to preserve food prior to modern refrigeration. The wire grid kept the food safe from vermin and allowed breeze to blow through. It was often covered with wet hessian so that as the breeze circulated the water evaporated, creating the same concept as coolant in modern refrigerators and ice boxes. In most respects it was a variation of the bushman’s hessian bag hanging in a tree. In larger towns and cities during this time period large "ice works" could deliver block ice to areas that required a form of refrigeration. These ice blocks where held in early refrigerators to keep perishables cool. In isolated or rural households, the Coolgardie or meat safe was the next best, practical solution for food preservation. This safe was used in the home of the Conway family in Wodonga.This item is very significant to the Wodonga region as it represents the initiative and problem solving skills of the early settlers. It also reflects the primitive conditions in which they lived before the arrival of more modern services such as electricity.Meat safe or Coolgardie safe manufactured in Australia. This safe is made from metal and has been painted in green paint. 2 sides of the safe have a pattern of 6 squares of holes to allow for ventilation and air flow. The holes would also guard against insects and other vermin. There is one shelf inside, dividing it into 2 sections. The safe has a hook attached so that it can be suspended, often from a tree or on a verandah to increase air flow. The safe would often be covered by wet hessian to promote further cooling and preservation of foods such as milk, butter and meat.coolgardie safe, food preservation, pioneers innovation -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Small Butter Churn, E. Cherry & Sons, c1880 - 1920

North east Victoria was a major dairy producing region in the late nineteenth century. The Wodonga Butter Factory Ltd was established in 1892. Many families living in the town or on farms also owned their own cow for family needs and produced their milk and butter. This churn is representative of the equipment they used to process their own dairy products at home. This churn was made by E. Cherry & Sons which was established in Gisborne, Victoria in 1858. Edward Cherry (1830-1910) arrived in Australia from Hertfordshire, England, in 1855. The business manufactured churns and in 1875 opened a larger factory. On his death, the business was taken over by his son and continued to operate until the 1970s.This item has strong links to the history of Wodonga and north east Victoria. It has interpretative potential in the areas of local agricultural history, and the social history of food and farming.A wooden butter churn with metal turning handle and removable lid. The wooden paddle inside is attached to the turning handle which rotates to churn the butter. The model number is T1. It was probably made by E Cherry & Sons of Gisborne although the brand is blurred.On one side in black: "T 1"butter churns, dairying industry, domestic appliances, e. cherry churns -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Radiator

Early form of home heating and because of the copper dish was considered one of the better models|Manufacturing History Museum Victoria|Commentary: Australian manufacturing history Philip Wollen|Many years ago, when I was an ambition young man, I took over a company called Hecla.|This business was formed in 1872, long before Federation was even contemplated. The company established a rich tradition in the Australian manufacturing industry. The prodigious product range included kettles, mixers, toasters, hairdryers, urns, pie warmers, bain maries, and electric blankets for the domestic and commercial market. During the war it even manufactured parts for aircraft. It was one of Melbourne's largest employers.|Hecla was one of the pioneers in TV advertising, led by icons like Bert Newton, Bobby Limb, Evie Hayes and Graham Kennedy who ad Jibbed his way through irreverent and unscripted naughtiness about Hecla electric blankets and foot warmers. The slogan was 'By Hecla, its good.'. One can imagine the fun Bert and Graham had with their double entendres.|In the 60's Hecla entered into a partnership with General Electric and expanded rapidly. The massive factory, on the corner of Alexandra Parade and Chapel Street overlooking the Yarra River was a Melbourne landmark.|The business was formed by one of the scions of Melbourne industry. Mr Marriott was a metal worker of some repute, building the lights in front of Melbourne's Parliament House, the first steam car, the sideboard at the RACY Club, and the first factory to run on electricity.|By the time I acquired the company it was a shadow of its former self, incapable of competing with cheap Chinese imports. Wandering around the warehouse late one night I discovered a large, boarded up storeroom which appeared not to have been opened in decades.|Over several months I combed through the room, unearthing a treasure trove of products from a bygone era. Dusty files, engineering drawings, wooden prototypes, patent records, and correspondence from distributors on every continent.|I decided to track down an old man, Ray, long retired after 50 years with Hecla. He was not well off financially and welcomed the paid work. It turned out that he had done his apprenticeship with the company and there wasn't much he didn't know about it. He had been personally involved in the manufacture of almost every type of product on the Hecla smorgasbord's of products.|So for over 2 years he methodically assembled a mini museum of Hecla products, painstakingly polishing them and ensuring they were in working order. He attached the original brochure of each product and their respective warranty cards. For him it was ,a labour of love. For me it was a fascinating, if vicarious journey, into Australia's manufacturing past.|My colleagues complained that I was wasting money on his salary, our time and factory space on stuff that should have been dumped years ago. I tried to explain that I was merely a steward of the Hecla tradition, not merely an owner. Besides, the look on Ray's face convinced me that there was another dynamic at work. One I could see, but didn't really understand.|After he Passed away I faced a dilemma. What to do with this 'museum' of Hecla history. Nobody was interested.|So I kept the 'stuff' in private storage, hoping that same day someone would be interested in it. And the years passed.|Finally, I had a brainwave. Perhaps the Melbourne Museum would be interested. It was a long shot but I made the call. I had a nagging suspicion that they would think I was simply trying to get them to relieve me of paying for this huge collection to be taken to the tip.|To my surprise they said they would be willing to take a look, I secretly hoped that they would take the whole collection and not leave me with an incomplete jumble of appliances that I would indeed have to take to the tip.|On the appointed day, four serious looking young people showed up. Armed with digital cameras, note books and poker faces they spent four hours analysing the goods and the supporting materials. I asked them if they had any interest and their response was decidedly non-committal. It depends on the acquisitions committee, I was told. I was disheartened and packed up the exhibits to go back into storage.|Imagine my surprise when months later they telephoned to say that they had researched the history of the company, and yes, they would like to take the whole collection. And a truck with 'handlers' would arrive the following day to pick it up. Two years ago all Hecla's archives left me forever and went to the Museum's warehouse.|Well, to my delight I received a call yesterday inviting me to a private viewing of the exhibition at the Melbourne Museum. These young historians had meticulously assembled an impressive display of Melbourne's industry and technology going back to the 1800's. They thanked me like a significant benefactor when it is I who should have thanked them.|I saw the excitement in the eyes of these young people who had somehow managed to dig out and assemble memories from Australia's past. If this is the standard of care that the curators of the Melbourne Museum show all their exhibits, our history is in safe hands.|Their meticulous work took me back to those years long ago when I saw an old man lovingly assembling and cataloging a lifetime of his work.|It took me back to the day when Australians actually made things. Long before we became a nation of quarrymen. Before we became animal-factory 'farmers'. Of a time when products didn't break down, or dumped and replaced before the warranty expired. When men like Mr Marriott cared deeply about what their hands produced.|It reminded me of the call I received from an elderly lady in Tasmania asking for the electrical element for a Hecla K7 kettle. I searched the archives and called her back. The K7 was produced decades earlier and we no longer carried that spare part. She was quite disheartened and told me her kettle had finally 'given up the ghost' and she couldn't bear to part with it. It was a present from her husband on their wedding day 45 years ago. Her final words were 'they don't make them like that, do they? By Hecla they were good.'|I'm glad I followed my instinct and put Ray back on the payroll all those years ago..|I like to think Mr Marriott would have been pleased.Pedestal radiator. Base is cast iron with three feet with rose design on each. Pedestal supports a copper spherical reflector plate which has an electrical connection box at its base. The connection box is joined to the pedestal by a screw and nut to enable the reflector to be tilted. The element is cone shaped and is in the centre of the plate. The element is protected by a wire guard.Hecla Firedomestic items, heating -

Arapiles Historical Society

Arapiles Historical SocietyTool - Roy SCHMIDT Collection - Handmade Garden Forks (2)

These hand tools are examples of early to mid-20th century garden cultivators, designed for home gardening, small-scale agriculture, or kitchen gardens. Their full-metal construction suggests they were built for durability and could be used in tough soils where wooden-handled tools might break. The minimalist yet practical design would have made them ideal for weeding, soil aeration, or root work in garden beds. Such tools were commonly found in household sheds and were often homemade or locally manufactured by blacksmiths or rural toolmakers. – Roy SCHMIDT resided with his siblings Mabel and Jack at ‘Parklands’ 85 Lake Avenue Natimuk home of Heinrich Friederick ‘Heiny’ & Minna Christina SUDHOLZ nee LANGE and their children Louis, Sophie, Alma, Lena (Roy's Mother), Florence 'Florrie' and Edward ‘Ted’.The image shows two vintage hand garden forks or cultivators, each constructed entirely from metal, including coiled wire handles. The implements are similar in size and style, but differ in tine configuration: [1] Handmade Garden Fork Straight Prongs: Has five straight, flatter tines, more like a rake, and is better suited for fine cultivation, weeding, or breaking up soil clods. [2] Handmade Garden Fork Claw Prongs: Features three thick, curved tines arranged in a spiral and claw-like fashion. These tines are more widely spaced and likely used for loosening tough or compacted soil, or for aerating.gardening -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Foot Warmer, Hecla Electrics Pty Ltd, c. 1920

From Museum Victoria: Made in about 1927 by Hecla Electrics Pty Ltd and sold under the model name 'Foot Warma'. The foot warmer was made from the late 1920s until the 1950s and did not change substantially in design during this time. The Hecla brand name and logo was registered in 1918 by Clarence Marriott. It was inspired by the recent eruption of Iceland's volcano Mt Heckla. Clarence and his father James were metal workers who had made Australia's first carbon filament electric radiators in 1899, and also built an early steam car. As electricity use exploded in the 1920s and 1930s, 'Hecla' became a household name in Melbourne. They made a wide range of appliances for the home, and supplied commercial appliances to cafés, hospitals and offices. In 1927, the company shifted from small premises in the city to a bigger, electric-powered factory in South Yarra. Hecla had no retail stores of its own - instead it sold products through wholesalers and retailers, including the State Electricity Commission (SEC). The company promoted its goods through advertisements in home magazines and displays in shop windows, home shows and the 1935 All-Electricity Exhibition. A popular advertising slogan in the 1930s was 'Hecla household helps make happy healthy housewives!'. Hecla ceased manufacturing in Melbourne in the 1980s.Documentation of how people lived and is an example of early domestic electrical appliances. From Museum Victoria: Hecla Electrics Pty Ltd were a significant Melbourne manufacturing company, who became a household name in the 1920s making small electric appliances such as heaters and kettles. They also made a variety of other electrical appliances for domestic, commercial and military use. The company manufactured electric appliances in Melbourne from about 1922 until the 1980s, although Clarence Marriott, who formed the company, had begun making radiators with his father James in 1899. The company had a reputation for quality products. The company also played an important role within the Australian domestic and commercial appliance industry, both as a leading innovator and through its role in training skilled staff, many of whom went on to work for competitors such as Kambrook, Electrolux and Sunbeam. This electric coffee percolator represents the typical small domestic appliance that the Hecla company was famous for. Along with other items in the Hecla Collection, it highlights the diversity of electric appliances that the company made. This object also highlights the legacy of high quality design and metal construction work that Clarence and James established for the company, stemming from their early work as talented art metal workers. It also represents the first major period of the take-up of electricity use in the home. This take-up began in the 1920s and 1930s with the use of small appliances, and by the 1950s electricity had become commonplace in the home, and large appliances such as refrigerators and stoves became standard.Square metal object. The top surface is heavy cast iron and patterned with floral motifs. In the centre is a circle with the words ' Hecla Foot Warma' inside. Under the top is a black metal base with two feet at either end which extend the length of the base. The back foot is higher than the front foot. There is a circular disk from which extends the electrical cord. The cord is brown and white checks. At the end of the cord is a plug on which is printed 250V AMP S.2 EARTH 5. The plug is brown and made from Bakelite. On the base is a rectangular label which has words printed - HECLA Australia.Top: HECLA/-FOOT-/WARMA Base: Volts / 230/250 / WATTS / 80 / HECLA / Australia / CAT. NO. F26domestic, city of portland, glenelg shire council, electrical, foot warmer, heating, hecla, manufacture -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Hematite (iron oxide)

Hematite is an iron ore significant for its high iron content (70%) and as being one of the two main iron oxide minerals, the other being magnetite. Hematite has a rating of 5-6 on the Moh's hardness scale and is often found as an accessory mineral in many igneous rocks. (an accessory mineral being "any mineral in an igneous rock not essential to the naming of the rock" - Britannica) Hematite has historically been the mainstay of South Australia’s iron ore production. (Magnetite: South Australia’s potential) Making up the eastern section of the Gawler Rangers, the Middleback Range is a mountain range on the eastern side of Eyre Peninsula in South Australia that has been a source of iron ore (its main commodity in minerals) for over a century. (see https://www.mindat.org/loc-22576.html). "Large reserves of high-grade iron ore were identified in 1890 in the Middleback Range, west of Whyalla. From 1915 these ores were shipped to Newcastle and later to Port Kembla, both in New South Wales. Local production of pig iron began when the first blast furnace was opened at Whyalla in 1941, and construction of an integrated iron and steel plant began there in 1958." (Britannica, South Australia: Resources and power). This area is home to 24 mines/mineral deposits (according to mindat.org, thought the Sarig Map provided by SA gov on their Energy and Mining website indicates significantly more mining leases).This mineral specimen was collected from the Middleback Ranges before the area was identified as holding large reserves of iron ore and being commercially mined and is representative of South Australia's significant and ongoing history of iron ore mining, and its contribution to Australia's steel manufacturing industry of the early 20th century (this specimen being collected in the prelude to these events).A small ferric oxide mineral composition a mid-blue-grey in colour with specks of rust-brown throughout.HEMATITE / (iron oxide) / Locality: Middleback Ranges, S. Aust.middleback ranges, iron ore mining, mining, south australia -

Federation University Historical Collection

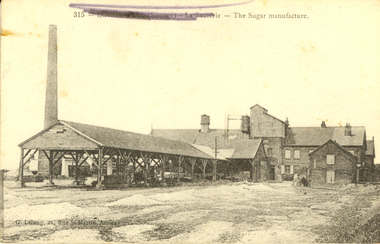

Federation University Historical CollectionPostcard, G. Lelong, The Sugar Manufacture, Somme, France, c1917, c1917

This postcard was sent from France during World War One WW1 to Violet Holmes [mother and aunty of other WW1 soldiers], by the son of a neighbouring Ascot Tourello District Family, the Wrigley Family. Violet inherited "Sauchieburn" an Ascot property on the death of her husband William Holmes in 1914. On her death this property was to be left to their 4 children and administered by a relative till the youngest child turned 27. As young boys, Violet's husband William, and his brother Henry, lived with their Aunt Catherine Coghill and Uncle William Coghill at ‘Sauchieburn’ Ascot. The Coghills had no children of their own. He and his brother Edward started a stock and station business at Clunes. Henry and Violet Holmes subsequently inherited "Sauchieburn" from Catherine (nee Holmes) and William Coghill, direct descendants of the Coghills Creek, Ascot, Tourello pioneer settler Captain William Coghill [Jane Dyer, May 2024] Catherine and her brother Edward Carter Holmes drowned at sea.This is an extract from the Korumburra Times, Wednesday June 6, 1956: The fated travellers wrecked off N.S.W. ‘On May 29th, 1886 in bright moonlight the Ly-e-Moon, the pride of the Australian coastal fleet, broke her back on the treacherous rocks of Green Cape, off the NSW coast. Eighty souls perished within range of the beacon rays of the lighthouse, including representatives of the earliest families ever to settle in Poowong. The passengers. On the main deck, Mr Edward Holmes, a Poowong grazier and former owner of ‘Wombalano’. He had sold this property with the object of going to Queensland and settling there. The proceeds of sale amounting to 1,200 pounds in gold sovereigns were under lock and key in the Purser's Office. Mr Holmes, although advanced in years, had unformed plans to invest his money in some Queensland enterprise. In the meantime he would visit his married daughter and [his] two sons, who had previously settled in Queensland. With him on board was his widowed sister Mrs Coghill who had also accepted an invitation to go north. News of the shipwreck, means of communication being slow, did not reach Korumburra for nearly a week. By then all hope had been abandoned for the missing. Relations and friends thronged the Melbourne shipping office, but the answer was always the same - All passengers unaccounted for were presumed drowned. Black and white postcard of a sugar refinery in The Somme, France. The name of the town has been scrubbed out in purple pencil by a censor during World War One. The back of the card is written on in pencil,Written on back of card: Dear Violet, received photos and letters and thank you for forwarding same. Are we having lovely spell of weather. This morning is quite warm and pleasant. The photo of you all standing in front of your house is a good one and you all look to be getting enough to eat. Mother looks as if she it getting stronger after her severe illness. Your concert party will be broken up through the Vale girls leaving but you should have no difficulty in finding volunteers to fill the ranks. By all of your letters you are all looking forward to the day we return 9as we are). I wouldn't like to bet too much that we would be home by this time next year [ ? ] by the way fritz is fighting lately he would very much like to get [peace?] I think we will give him all he wants this summer. J. Waller was here last night is looking well. With best wished to you all. I am sincerely. [W.Wrigbee? Wrigley]somme, la suererie, chatham family collection, amiens, france, world war 1, postcard, ly-ee-moon, william coghill junior, ascot victoria, pioneers of ascot, shipwreck -

Mont De Lancey

Mont De LanceyDomestic object - Glass Preserving Jars, Fowler's, c 1915+

Fowler's Vacola preserving jars have a rich history, beginning in 1915 with Joseph Fowler in Melbourne, Australia. Inspired by his uncle's fruit-preserving business in England, Fowler developed a method for home bottling and preserving food, which became particularly popular during the Depression era. The system relies on heating contents to a specific temperature (92°C) for a set time (one hour) to achieve a sterile and sealed product. Fowler's Vacola is still a popular method for preserving food today, and the company continues to manufacture preserving kits and accessories. Five mixed Fowler's clear glass preserving or storage jars with no lids. They have embossed Fowler's branding on them. 1 tall 'No 40' jar with a long neck. 2 'No 28' jars. 1 'Fowler's Patent Vacola No 45 Home Preserving Jar'. 1 'Fowler's Patent Vacola No 15 Home Preserving Jar'.'No 40' 'No 28' 'Fowler's Patent Vacola No 45 Home Preserving Jar' 'Fowler's Patent Vacola No 15 Home Preserving Jar'.food preserving jars, food storage containers, containers