Showing 751 items

matching machine made

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined

... . The machine tools that made the growth of industry possible.... The machine tools that made the growth of industry possible ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale rib bone with advanced stage of calcification as indicated by brittleness. None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... . The machine tools that made the growth of industry possible.... The machine tools that made the growth of industry possible ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

... . The machine tools that made the growth of industry possible.... The machine tools that made the growth of industry possible ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined

... . The machine tools that made the growth of industry possible.... The machine tools that made the growth of industry possible ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale jaw bone one side, long & curved with advanced stage of calcification off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Orbost & District Historical Society

Orbost & District Historical Societywash tub, 1900-1910

This item was bought by George Henry Douglas Russell when he married Hilda Raymond, a parson's daughter, in 1920. This galvanised metal wash tub was manufactured for domestic use prior to household plumbing, running water or waste removal in Australian homes. On farms in the late 19th / early 20th centuries there were no built-in coppers and concrete troughs with reticulated water. Thus the washing for the family of five daughters was done with this tub. .Tubs of this type vary in size and were used for washing dishes (It was the “ kitchen sink”) or for washing smaller items of clothing “the delicates”. This tub could also have been used to bathe the children. The water was heated on a wood fired stove, then carried to the tub. This could be a lengthy and physically demanding exercise. Much more labor intensive than loading the dishwasher. After use the water may have been “recycled”by being poured onto vegetable gardens and fruit trees. Later at harvesting this tub held maize and beans to top up the three bushel bags of the threshing machines. This was before the hand sewing of the top of the bags with needle and twine.This tub is an indication that items for domestic use in the early 20th century were “made to last” and not manufactured for planned obsolescence.A large galvanized iron was tub, circular with the sides tapering slightly to the flat base. It is seamed on both sides, made from two shets of iron. The base has been soldered on. and the top rim is folded. On either side handles are rivetted on.domestic laundry was-tub galvanized-iron -

Orbost & District Historical Society

Orbost & District Historical Societyhat

A fawn-coloured wool felt hat. It has a leather band with machine punched holes sewn onto it. There is a leather band inside the hat and a label. It is pinned up on one side - stockman style.DUSTY on label - 100% wool 60cm Made in Hong Kong hat felt stockman-hat -

Orbost & District Historical Society

Orbost & District Historical Societyornament, Healey, Ada

Ada Healey was for 20 years a volunteer and organizer at the Orbost Slab Hut (Orbost Information Centre). She was known for her craft skills and was a particularly fine knitter, She did own, as a child, a handheld mini sewing machine and it is possible that the item was made using this. Ada was the only child of Tom & Queenie Warne, born in Bombala/Delegate. She married Keith Healey. The Healey family were early settlers in Marlo.This hand-sewn ornament is an example of the skill and craftmanship of women in pioneer families.A hand-sewn silk tortoise. The head is padded. Four small beads are sewn to each side. It has white/brown lining. Pink beads are sewn on either side of the head for eyes.hand-made handcraft silk ornament -

Orbost & District Historical Society

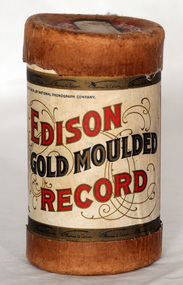

Orbost & District Historical Societyrecord container, From 1902 - 1911

Phonograph cylinders are the earliest commercial medium for recording and reproducing sound. Commonly known simply as "records" , these hollow cylindrical objects have an audio recording engraved on the outside surface, which can be reproduced when they are played on a mechanical cylinder phonograph. The "Gold-Moulded" process was developed in 1902 and involved creating a metal mould from a wax master; a brown wax blank would be placed inside and heated . as the blank expanded, the grooves would be pressed into the blank which would then be cooled. The "gold" is derived from the traces of that metal used as a conductive agent in the initial mould. "Whistler and his Dog" was performed by the Edison Military Band.Edison Records was one of the earliest record labels which pioneered sound recording and reproduction and was important in the early recording industry. Gold Moulded records used a process that Edison had developed, that allowed a mould to be made from a master cylinder which then permitted the production of several hundred cylinders to be made from the mould. Previously cylinders were recorded live or by hooking two machine together to copy from one cylinder to another, and they used softer brown wax which wore out in as few as twenty playings. Gold Moulded Records were discontinued in 1912.A cardboard cylindrical record container. It is an Edison Gold Moulded Record container. The label has red and gold print and a photo Thomas A. Edison.Hand-written on lid - Whistler & His Dogedison-gold-moulded-cylinders sound-recording records -

Orbost & District Historical Society

Orbost & District Historical Societyknitting needles

In the first half of the 20th century knitting needles were much easier and cheaper to come by than sewing machines. This is possibly why hand knitting was so popular. This pair of knitting needles are part of a time when women often made the family clothing. A pair of No. 7 pink plastic knitting needles.knitting-needles handcraft knitting leisure -

Orbost & District Historical Society

Orbost & District Historical Societyembossing machine

This was the seal for the snowy River Improvement Trust (1952-1997). The trust inaugurated the push with governments and government authorities to return the environmental flow of fresh water to the Snowy River at Jindabyne. During its existence the Trust worked hard to improve the health of the Snowy and Brodribb Rivers (revegetation, erosion prevention, fencing, drainage).This Common Seal will remind the lower Snowy district of the beneficial work of the Snowy River Improvement Trust during its existence from 1952 to June 30 1997.Common seal for the Snowy River Improvement Trust - 1952-1997. It is made of metal and has a lever to press down for the embossing stamp. The lever is spring loaded.snowy-river-improvement-trust snowy-river embossing-machine white-max -

Orbost & District Historical Society

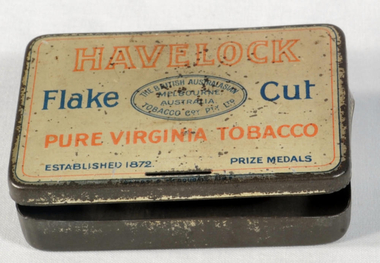

Orbost & District Historical Societytobacco tin, The British Australasian Tobacco Company Pty Ltd, mid - late 20th century

... expensive machine (tailor) made cigarettes to the roll your own ...The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palmsThe post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This item is an example from a time when smoking was readily accepted.Rectangular shaped tobacco tin with hinged lid.On lid -HAVELOCK Flake Cut Pure Virginia Tobaccotin tobacco smoking -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

Taken some time between 1914-18, the photograph depicts an aerial view of trenches in France. The image mostly shows rural landscape, although there is a house in the bottom right corner. A dotted line has been drawn across the photograph, marking the section of trenches that belonged to British forces during World War I. It is believed that the line marking on this record denotes a section of the Western Front. The Western Front was the main theatre of war during World War I. Following the outbreak of war in August 1914, the German Army opened the Western Front by invading Luxembourg and Belgium, then gaining military control of important industrial regions in France. The German advance was halted with the Battle of the Marne. Following the Race to the Sea, both the French-British and German armies dug in along a meandering line of fortified trenches, stretching from the North Sea to the Swiss frontier with France. Between 1915 and 1917 there were several offensives along the Western Front. The attacks employed massive artillery bombardments and massed infantry advances. Entrenchments, machine gun emplacements, barbed wire and artillery repeatedly inflicted severe casualties during attacks and counter-attacks and no significant advances were made. Among the most notable of these offensives were the Battle of Verdun (1916), the Battle of the Somme (1916), and the Battle of Passchendaele (1917).The record is historically significant due to its connection to World War I. This conflict is integral to Australian culture as it was the single greatest loss of life and the greatest repatriation of casualties in the country's history. Australia’s involvement in the First World War began when the Australian government established the Australian Imperial Force (AIF) in August 1914. Immediately, men were recruited to serve the British Empire in the Middle East and on the Western Front. The record has strong research potential. This is due to the ongoing public and scholarly interest in war, history, and especially the ANZAC legend, which is commemorated annually on 25 April, known as ANZAC Day.Sepia rectangular photograph printed on matte photographic paper.Obverse: A.3FE.O.146 / G2R 29 . 6 . 18 (Y p.m) / F= 10 1/4 / British Line / ------------------------------------------ / P. 250 1040 / 0. 30d. 0010 / 0. 30d. 3070 /military album, military, war, wwi, world war i, france, great britain, trenches, village, rural, western front -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

Taken some time between 1914-18, the photograph depicts an aerial view of trenches in France. The image mostly shows rural landscape, although there is a cluster of houses in the top right corner. It is believed that this record denotes a section of the Western Front. The Western Front was the main theatre of war during World War I. Following the outbreak of war in August 1914, the German Army opened the Western Front by invading Luxembourg and Belgium, then gaining military control of important industrial regions in France. The German advance was halted with the Battle of the Marne. Following the Race to the Sea, both the French-British and German armies dug in along a meandering line of fortified trenches, stretching from the North Sea to the Swiss frontier with France. Between 1915 and 1917 there were several offensives along the Western Front. The attacks employed massive artillery bombardments and massed infantry advances. Entrenchments, machine gun emplacements, barbed wire and artillery repeatedly inflicted severe casualties during attacks and counter-attacks and no significant advances were made. Among the most notable of these offensives were the Battle of Verdun (1916), the Battle of the Somme (1916), and the Battle of Passchendaele (1917).The record is historically significant due to its connection to World War I. This conflict is integral to Australian culture as it was the single greatest loss of life and the greatest repatriation of casualties in the country's history. Australia’s involvement in the First World War began when the Australian government established the Australian Imperial Force (AIF) in August 1914. Immediately, men were recruited to serve the British Empire in the Middle East and on the Western Front. The record has strong research potential. This is due to the ongoing public and scholarly interest in war, history, and especially the ANZAC legend, which is commemorated annually on 25 April, known as ANZAC Day.Black and white rectangular photograph printed on matte photographic paper.Obverse: A.3.FE.2.291 / 62D O.20bd.P.25O.C / 16.7.18 / 12 / F 8 1/4 / Reverse: 6532military album, military, army, war, wwi, world war i, france, trenches -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

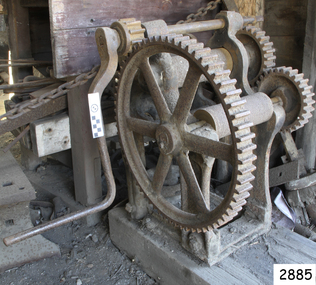

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Flagstaff Hill Maritime Museum and Village

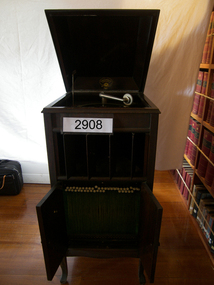

Flagstaff Hill Maritime Museum and VillageGramophone, 1911

Until late 1925, all record players reproduced sound by purely mechanical means and relied on a so-called "amplifying" horn to efficiently couple the vibrations of the stylus and diaphragm to the space occupied by the listeners. In 1906, the Victor Talking Machine Company, Columbia's arch competitor, introduced a line of models in which the horn and other hardware were concealed within a cabinet, made to look like fine furniture rather than a mechanical device. They named the new style a "Victrola". It quickly proved to be very popular and successful. Other makers, adopting the distinctive suffix, introduced their own "-ola" internal horn machines, such as Edison's Amberolas and Columbia's Grafonolas. They were soon outselling the external horn models. At first, like nearly all other early record players, all Grafonolas were driven by a spring motor that the user had to wind up with a crank before playing a record. In 1915, Columbia began to introduce electric-motor-driven models, as a majority of urban areas had been wired to electrical grids. The electrified Grafonolas supported both alternating and direct currents from 110 to 220 volts. Electrified Grafonolas never gained the popularity enjoyed by the spring motor-driven versions due to substantially higher prices and a lack of electrical service in rural areas. Grafonolas were manufactured under the 1886 United States Letters Patent No. 341,214 which Columbia Graphophone company acquired through its predecessor American Graphophone Company. Two models were available; a portable table model and bigger stationary floor model, offering limited mobility through the application of casters. The most notable table models included Grafonola Favorite introduced in 1911 and Grafonola Savoy introduced in 1915. The most notable floor models included Grafonola Symphony Grand introduced in 1907, Grafonola Regent introduced in 1909, Columbia Mignon introduced in 1910, Grafonola Princess introduced in 1911, Columbia Colonial introduced in 1913. Various period Grafonolas were introduced in 1917 to cater to an increasingly prosperous clientele. Columbia Phonograph Company began to manufacture a series of ornate, limited edition period machines. These were highly priced (some as high as US$2,100 ) special orders that provided consumers with options to choose styles which matched their interior décor. Although the Gramophone does not have a large monetary value, it is of social significance as it demonstrates the progress made in audio reproduction from the first Edison cylinder machines to improvements that allowed ordinary people to be able to buy music discs and enjoy music in their own homes. Gramophone with internal horn, floor model, mechanically operated by a crank handle. Colombian Grafonola Princess (Type F2) brand. Gramophone is in a wooden display cabinet with room for record storage underneath and is complete with handle. Manufactured in 1911 by Columbia, USA."Columbia Grafonola Type 2 Made in USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, record player, gramophone, mechanical gramophone, floor model gramophone, gramophone record, columbia graphophone company, american graphophone company, columbia, grafonola, grafonola princess, music, playing music, audio reproduction, sound equipment, domestic entertainment, 1911 gramophone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

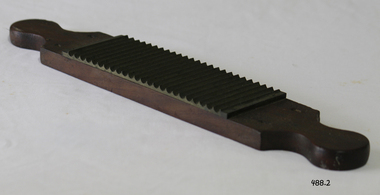

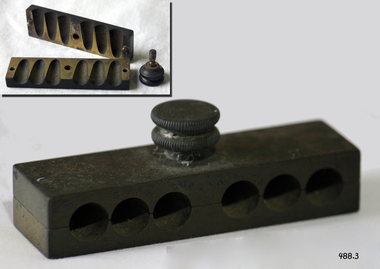

Flagstaff Hill Maritime Museum and VillageEquipment - Pill Maker Board

Before factory production became commonplace in medicine, dispensing was considered an art and pill machines such as these were a vital component of any chemist’s collection. This machine dates back to the days when your local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Pill machines such as these first appeared in the mid-1700s and quickly became a staple of the Victorian chemist’s shop. A ‘pill mass’ of medicinal powders mixed with a binding agent would be hand-rolled into a pipe on the tile at the back of the machine. This would then be placed across the grooved brass plate and cut into equal-sized pills using the corresponding side of the roller. Once all the necessary ingredients for the pills had been measured and ground with a pestle and mortar a final ingredient was poured in, syrup – this acted as a binding-agent. You could then roll it into a sausage shape. The largest part of the machine is the board. This is set at an angle and is comprised of the rolling surface, the cutting grooves, and the collection-tray. The large flat surface is for rolling out the pill-paste into the sausage shape. This is then rolled towards the brass cutting-grooves. The paddle (the second piece) is flipped over so that the grooves there line up with the grooves on the board. Rollers on the ends of the paddle roll against the brass edges of the board, and they guide the paddle straight across the grooves, taking the pill-mass with it. The grooves on the paddle and the board slice up the pill-mass and, after rolling the thing back and forth a couple of times like a rolling-pin, the circular pills roll off the grooves and into the tray at the bottom. https://galwaycitymuseum.ie/blog/collections-spotlight-victorian-pill-making-machine/?locale=en The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Pill making device including a grooved base board and grooved sliding board with two pill moulds.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pills, pill maker, medicine, health -