Showing 3907 items

matching third

-

Bay Steamers Maritime Museum

Bay Steamers Maritime Museummodel steam engine

This model was found in the collection of Bay Steamers Maritime Museum. It is not knowt who created it but it is supposed that it was constructed to educate the many masters of the Wattle in the operation of a steam engine - a not so common mode of power these days. A Bay Steamers Maritime Museum examined the model in March 2012 and discovered that is was in poor repair. Using his existing knowledge, and with reference to some historic texts, he made some repairs and returned the model to working order. Here is his anaylsis of the situation as an excerpt from the Bay Steamers Maritime Museum newsletter Steamlines May 2012 "I was confronted with a model of a steam engine used years ago as a training aid for hopeful steam engineers. Already having a knowledge of steam operations, I considered a museum write-up for that model a ‘piece of cake’. However, on turning the model’s crankshaft, the valve timing seemed ‘out of kilter’ with the movement of the piston. Problem was that the two eccentrics on the crankshaft were not properly secured to it. Eventually I fastened the two eccentrics to the crankshaft where I felt that they should be and then realized that one of them had a chain-driven valve-timing device attached. This would be adjusted while an engine was running to achieve best performance and fuel economy whilst in operation by accurately controlling the period of time during which steam under pressure from the boiler would be admitted to the cylinder and give greater time for the steam to expand in the cylinder, move the piston and turn the crankshaft and thus, drive the attached apparatus. When the valves were correctly set up it was then possible to get the model to function properly.The model comprises a green section, which is the actual the model mounted on a brown painted board. There are two parts of the model, painted white representing the steam passages, and black representing the cast- iron portions of the cylinder-block casting, and of the main valve sliding between the cylinder a second sliding valve. Of the black portions, one slides back and forth being connected to a rod which is connected to an eccentric clamped to the crankshaft and is the nearer to the flywheel of two eccentrics. This eccentric is attached to the crankshaft at an angle of 90 degrees to the crank-pin attached to the flywheel. To operate the model simply turn the flywheel by means of the handle attached to its crank-pin. A second eccentric is also attached to the crankshaft, further away from the first eccentric, and it is adjusted to operate 90 degrees from the first eccentric (that is, 180 degrees from the crank-pin) A piston (painted silver) is located in a plastic cylinder and has a piston rod which passes through one end of the cylinder, (in actual practice a steam-proof gland seals the cylinder against loss of steam) terminating in a cross-head slide between four rails guiding it. From this cross-head, a connecting rod joins the piston-rod to the flywheel via the crank-pin attached to the flywheel which is part of the crankshaft. (In actual practice, a flywheel may not be used, particularly in a multi-cylinder engine.) The white portions of the model painted nearest to the cylinder represent the two steam ports cast into the main cylinder block, whilst one section painted in between those two represents the exhaust outlet (which may be connected to a condenser to conserve water, or to the open air). The main slide valve has three white-painted portions painted thereon. It has two white-painted marks representing the steam passages to the steam ports into the cylinder, and a third section in between the other two, being that part of the valve through which exhaust steam passes in line with the ports in the cylinder block. By rotating the flywheel, the operations of an engine will be observed as steam is admitted to the main valve via the gap between the two jaws of two moveable portions of a second sliding valve which is operated by the second eccentric attached to the crank-shaft. This eccentric is used to finely tune the valve timing of this model to obtain best running results of an engine. There are various methods used for reversing a steam engine. model compound steam engine, steam engine, model, crankshaft, valve, flywheel, wattle, engineer, eccentrics -

Bendigo Historical Society Inc.

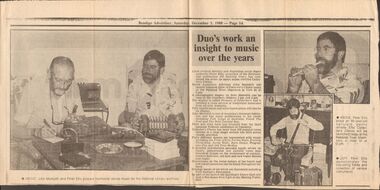

Bendigo Historical Society Inc.Newspaper - PETER ELLIS COLLECTION: BENDIGO ADVERTISER SATURDAY DECEMBER 3, 1998, 3rd December, 1998

Newspaper cutting from Bendigo Advertiser, dated Saturday, December 3, 1988 - Page 14. Photo on left is captioned: ABOVE: John Meredith and Peter Ellis prepare traditional dance music for the National Library archives. Top right picture is captioned: ABOVE: Peter Ellis plays and 80-year-old celluloid penny whistle. Ellis' 'Collector's Choice' will be launched today at the National Trust chambers in View St at 3 pm. LEFT: Peter Ellis demonstrates the one string fiddle and collection of various instruments. Article reads: Duo's work an insight to music over the years. Local musical identity and Australian social dance authority Peter Ellis, co-author of the Bicentennial publication 200 Dancing Years, has completed his series on dance music entitled 'Collector's Choice'. Noted Australian folklorist John Meredith will launch volume three of Collector's Choice today at the National Trust chambers in View St at 3 pm. A photographic display by John Meredith can be seen at the chambers between 2pm and 5pm. The display is called Pioneers of Performers and it exhibits a cross section of traditional musicians from all over Australia. Fifty superb black and white toned prints will also be on display. John Meredith is one of Australia's foremost folklorists and has many publications to his credit including Folk Songs of Australia, Frank the Poet and The Wild Colonial Boy. Peter and John have just returned from the third national folklore conference in Canberra. Collector's Choice has more than 300 popular tunes written in a clear single melody line with guitar chords provided. Forty different dances are represented with music including the Pride of Erin, Parma Waltz, Evening Three-step, Swing Waltz, Barn Dance, Progressive Jive and Old Time Medley. A detailed introduction provides handy advice on choice, presentation and suitable tunes plus historical details on the evolvement of colonial, modern ballroom, old time and new vogue dances and music. Illustrations on the social history of the bands and individual musicians can be found throughout the book. Bendigo bands of old which are illustrated including Cyril Sawyer's Swingsters. As part of the launch the Sandhurst Dance Club will host a free dance from 8pm at the Marong Public Hall.Bendigo advertiserperson, individual, peter ellis oam -

Bendigo Historical Society Inc.

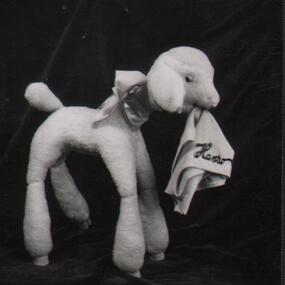

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: A COLLECTION OF PHOTOGRAPHS OF DECORATIONS FOR HANRO WINDOW DISPLAY

See Item 11000.189A Collection of Photographs of decorations for Hanro Window Display: All black and white photo's. Photo A) A soft toy of a lamb with a bow around its neck and in the mouth is a garment with Hanro embroider on it. On the back is the number 2056 hand written in blue ink. Photo B) has two cane suitcases with handles one smaller than the other. Both have flowers woven through the cane. A petticoat with lace and two thin straps at the top is laid through the larger suitcase and a sign *Hanro* sits on the bench. On the back is 2100 hand written in blue ink and in pencil VV11. Photo C) Is of a Cane French Horn with a bunch of flowers in the horn part. A Hanro sign is attached to the middle of the Horn and a petticoat with a lace bodice and hem and two thin straps is draped through the bottom of the French Horn. Some glue on the back and 2114 in biro, 14 in pencil. Photo D) Is a mock cloths line in front of a dark background with three petticoats. The first has a lace top and hem with two straps pegged to the line, the second is hung upside down with two pegs. It has a lace top with a V neck. The third has a lace V neck top and at the hem line. The garment is pegged to the line by the straps. There are two pots with flowers hanging from the line. Photo E) A vase made of cane with flowers and a Hanro sign attached. Two petticoats either side are laid on the bench both with a lace bodice. There are two Hanro signs on the table. On the back in blue ink hand written is *Dek. Nt.2094 Photo F*. There are three cane baskets with flowers and Hanro signs at the top of each hung on a wall and two cane baskets with flowers on the table. One petticoat is hung up on the wall through the baskets. The petticoat has a lace border at the bodice, The other is laid on the table, has a V neck and lace border. A Hanro sign is in front of the petticoat. On the back printed in blue ink is *Dek. Nr. 2098* Photo G) Is three bunches of flowers to have Hanro sign attached. On the back is *Dek. 2077. Photo H) Is three groups of several crystal balls strung together with pine needles at the top and the sign Hanro at the top of each. On the back hand printed in blue ink is *Dek.2124* The photos were together in a piece of paper which has writing in green ink *Decorations for clients window display*.Reg. V. Brock Studiosphotograph, hanro. reg. v. brock. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Magazine - HANRO COLLECTION: HANRO AUTUMN-WINTER 1960 CATALOGUE, 1960

BHS CollectionHanro Autumn-Winter 1960 Catalogue: On blue card with white and black print. It has a scene of the Swiss Alps with two Swiss Chalets at the foot of the hills. In the foreground are three ladies one sitting on a chair and two leaning on a wrought iron fence. The ladies are sketched in black ink, the first with long black hair is wearing a twinset, the cardigan has long, set in sleeves and is buttoned up with nine buttons. The garments have bands on the cuffs, around the neck and on the waist. The second lady has short hair and is wearing a jumper with long set in sleeves, collar and button front insert. The jumper has bands on the sleeves and waist. The third lady with long blond hair wearing a bulky rib pullover with a large collar. At the top of the page in white print is *Autumn - Winter 1960 Catalogue. In the centre on a white banner printed in black is Hanro Quality Knitwear for Women. At the bottom in black print is *Styled In Switzerland* in a white banner. Inside the front page on a white back ground with black print is advertising and the Index. The catalogue pages on white back ground with black print and sketched garments consists of Hanro knitwear collection of Pullovers, Twin Set's, Cardigans, Jackets, Sweater Shirt and Stole, including item name, style number, description, colour and size. On the back of the catalogue is the price list, instruction on advertising and at the bottom is *This year, go along with Hanro - for Handsome Profits in Knitwear! Inside the back page of the cover is an advertising example which says *Here Now! The very latest continental wool knits Styled in Switzerland* with a scene of the Swiss Alps and village with three ladies on a balcony modelling Hanro Knitwear. In the right hand corner is the Hanro factory in Switzerland. The back cover is blue and white with black print. 5cm down from the left top is a white rectangular shape with Hanro (Aust) Knitting Mills Limited printed in black. A black stripe 5cm in from the left runs from top to bottom of the page. In the Centre Bendigo, Melbourne and Sydney address and contact details for Hanro. Down the page to the right is a list of the those represented in other states by: Queensland, Western Australia, South Australia and Tasmania. Bottom left is a sketch of the Hanro Swiss factory done in black ink on white back ground. Underneath that is *The Home of world-famous Hanro in Liestal, Switzerland. Box 116Abook, magazine, catalogue, hanro catalogue -

The Beechworth Burke Museum

The Beechworth Burke MuseumAudio - Oral History, Jennifer Williams, Gwen and Jack Scott, 24th February 2000

Jack Scott was born in Beechworth on the 24th January 1919 into a third generation Beechworth family who had migrated from Scotland, Cornwall and Ireland during the 1860s. Also present during the oral history recording is Jack’s wife, Gwen Scott. In 1878 Jack’s grandfather established the carrier business - R. Scott Carriers. Jack’s grandfather secured a contract with the Zwar Brothers' Beechworth Tannery to transport all goods between the tannery and train station via horse and cart. Jack’s father and uncle carried on the family business, before Jack and his brother eventually joined after the Second World War. The company expanded from a single horse and cart short route to multiple trucks operating interstate routes. Prior to joining the family carrier business, Jack on leaving school started work at the tannery and served in the air force during the Second World War. When asked about the working conditions at the tannery, Jack recalls while they did have union representatives, it was not particularly effectual. The union representatives were often placated by sharing multiple whiskies with the Zwar brothers when in their offices to discuss workers’ issues. Gwen’s father also worked for the tannery for a period of time, and she enjoyed the annual picnics the tannery provided for employee families. Both Jack and Gwen’s connections to the tannery reinforces the tannery’s role as a major employer and presence in the Beechworth community. Prior to marrying Jack, Gwen worked in a range of roles including at the Ovens and Murray Hospital for the Aged, managing the family home when her parents both worked during the Second World War, and apprenticed with her sister as a hairdresser. Jack and Gwen provide some insight into maternal health issues in brief discussions of hospital birthing trends and awareness of contraception and family planning. Both Jack and Gwen recalled attending the open-air cinema at ‘The Rock’ in their childhoods. Gwen remembers that the ‘elites’ would sit on chairs at the front, and Gwen’s family sat on a rug at the back, while Jack would jump the fence and get in for nothing. Jack and Gwen discuss attitudes towards both Chinese Australians and Italian migrants in Beechworth. They did not notice any racism and from their perspective felt they were accepted in the town. Jack did note that Italian employees lost their jobs at the tannery during the Second World War, but believed they all stayed within the area and found stonemason and concrete work in the interim. Jack socialised with members of the Italian community and joyfully recalled attending their homes for music nights with lots of drinking and instruments being played. This oral history recording was part of a project conducted by Jennifer Williams in the year 2000 to capture the everyday life and struggles in Beechworth during the twentieth century. This project involved recording seventy oral histories on cassette tapes of local Beechworth residents which were then published in a book titled: Listen to what they say: voices of twentieth century Beechworth. These cassette tapes were digitised in July 2021 with funds made available by the Friends of the Burke. Gwen and Jack Scott’s account of their lives in Beechworth is historically and socially significant to the cultural heritage of the region. Gwen and Jack in reflecting on their everyday experiences of operating a family business, availability of work, leisure opportunities, interaction with migrants, and access to maternal health care provide essential economic, social, and healthcare insights. Gwen and Jack Scott’s oral history recording is part of a larger collection of oral histories recorded by Jennifer Williams in 2000, collectively they provide invaluable insights into Beechworth during the 20th century, much of the information in these oral histories would be lost if not documented and missed in the interpretation of tangible objects. This is a digital copy of a recording that was originally captured on a cassette tape. The cassette tape is black with a horizontal white strip and is currently stored in a clear flat plastic rectangular container. It holds up 40 minutes of recordings on each side.Mrs Gwen and Mr Jack Scott jack scott, gwen scott, r. scott carriers, scott brothers, zwar brother's beechworth tannery, zwar tannery, beechworth tannery, ovens and murray hospital for the aged, benevolent asylum, open-air cinema, the rock cinema, italians beechworth, hospital births 1920s, wang tech, wangaratta tech, nell scott, jennifer williams, oral history, listen to what they say: voices of twentieth century beechworth, tannery union -

The Beechworth Burke Museum

The Beechworth Burke MuseumCeremonial object - Ushabti of Taweret-Khaiti, Circa 1292 BC

Ushabti are tiny anthropoid (human-shaped) figures placed in the tombs of wealthy Egyptians. They were intended to do the work of the deceased in the afterlife. This purpose is implied through their name, which may have derived from the Egyptian word “to answer”. The Burke Museum in Beechworth is home to a particular ancient Egyptian Ushabti figure. This artefact was donated to the Museum in 1875. No details about how it left Egypt, arrived in Australia, and where it was located before this donation are known. The Nineteenth Century, when this artefact was donated, was a period when many museums acquired items of ancient Egyptian heritage. Many of these items were procured in less than desirable circumstances, having often been looted from ancient tombs and sold to tourists without documentation as to their original location and/or accompanying grave goods. These artefacts were also divested through partage (the trading of artefacts for funds); however, the latter is unlikely to have been the case for this artefact. Since the Ushabti was donated by an unknown donor, it is likely to have been in a private collection rather than an institution. Ushabti can be dated using iconographic analysis which is non-invasive and provides a comprehensive study of the artefact. The later period of the 18th Dynasty marked the beginning of an increase in both the inclusion of Ushabti as essential funerary items and the creation of Ushabti with tools. From this period, they are no longer depicted without tools. Depictions of tools including gardening hoes are frequently depicted grasped in the Ushabti’s hands whilst items like the seed-bag are depicted hanging on the back rather than in an alternative position. This Ushabti figure grasps a gardening hoe and a mattock and a small seed bag surrounded by a yoke bearing water jars are depicted on the upper back of the Ushabti. These features are essential in helping narrow this dating to the late 18th and before the early 20th Dynasty. The position of this seed bag also provides dating information. In the early 18th Dynasty this bag was consistently drawn on the front of the figurine; however, by the reign of Seti I, this feature moved to the back. Thus, since the seed bag is located on the back of this Ushabti, it cannot date to the early 18th Dynasty. By the 19th Dynasty, Ushabti’s were increasingly made from either faience or terracotta. The availability of these materials in Egypt resulted in the increase of Ushabti production with tombs containing many more figurines than previously seen. The Ushabti held by the Burke collections is made from terracotta. Terracotta was rarely used for Ushabti before and during the early 18th Dynasty with only the odd appearance until the late 18th Dynasty and becoming common through that period until the late Third Intermediate Period. Whilst the face has been damaged, there is no evidence for the Ushabti having been provided with an Osirian false beard. This omission rules out a dating of later than the 25th Dynasty when beards became prominent. The inscriptions also date the Ushabti to the New Kingdom. This is because of the use of sḥḏ (“to illuminate”) with Wsjr (“Osiris”) which only occurs in these periods. Therefore, considering all these elements, the Ushabti can be confidently be dated to between the late 18th to early 19th dynasty.Artefacts like this Ushabti are no longer exclusively representative of their origins in burial assemblages and significance in the mythology of the Egyptian afterlife but are also significant for the accumulated histories they have gained through travel. The movement of this artefact from Egypt to Australia allows insight into the collecting habits of the 19th century, and in particular, the reception of ancient Egyptian artefacts in small rural museums. The procurement of Egyptian artefacts was a social trend around the late 1800s to early 1900s. Egyptian artefacts were considered curiosities and recognised for their ability to attract public attention to museums. They were also utilised in Australian museums, like the Burke Museum, to connect the collection to one of the oldest civilisations known to man and since Australia was considered a “young” country by European settlers, this was vital and derived from an interest in Darwin’s “Origin of the Species” 1859. Furthermore, there was a culture of collecting in the 1800s amongst the affluent in English society which led to the appearance of many Egyptian artefacts in private collections. The acquisition of this Ushabti figure is not certain, but it was likely donated from a private collection rather than an institution. This particular artefact is significant as an example of a high-quality Ushabti representative of those produced during the late 18th or early 19th century. It provides insight into the individualism of an Ushabti and the mythology of ancient Egypt. It also provides an example of the types of items required in the tomb assemblages of this period and reinforces the importance of ensuring the successful afterlife of the deceased through art. This Ushabti belonged to a woman named Taweret-Khaiti, Chantress of Amun, in the late 18th Dynasty or early 19th Dynasty (c.1292 BC) of the Egyptian New Kingdom. It likely comes from an undetermined tomb in the locality of Thebes. This figure is made from Nile silt clay (a polyester terracotta; clay sourced from the banks of the Nile River) which was a popular material for Ushabti construction in the early 19th Dynasty. It is in a fair state of preservation (with the exception of a break through the centre) and originally made to a high quality. The face has been damaged but the eyes and eyebrows are clearly marked with black ink and the sclera painted white. The Ushabti is painted a light brown/yellow colour and features a vertical line of inscription down the lower front. The Ushabti wears a large wig and and a schematic collar. The arms are painted light brown and depicted crossed with bracelets around the wrists. It grasps a hoe and mattock. A yellow seed-basket is depicted on the Ushabti’s back. These features represent the likelihood that this particular Ushabti was intended to complete farm work for the deceased in the next life. There would have been additional Ushabti of similar design within the tomb who worked under the supervision of a foreman Ushabti. The foreman Ushabti would be depicted dressed in the clothing of the living. The inscriptions are painted freehand in black ink and written in a vertical column from the base of the collar to the foot pedestal on the front of the Ushabti. The owner of the Ushabti could elect to have the figures inscribed with their name, the Ushabti spell and any other details they deemed necessary. In the case of this example, the Ushabti is inscribed with the owner’s details and is an abbreviated version of the standard Ushabti formula. This formula ensured that the Ushabti would complete the desired task in the afterlife when called upon by the deceased. Ushabti which were not inscribed would represent their intended purpose through design; however, this Ushabti, like most made in the late 18th Dynasty, conveys its purpose both through both design and inscription. The inscription is as follows: sHD wsir nbt pr Smayt imn tA-wr(t)-xai(ti) mAa xrw which translates to: "The illuminated one, the Osiris (the deceased), the mistress of the household, Chantress of Amun, Taweret-Khaiti, true of voice (justified)"ancient egypt -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Book, Albert Steane, Freemasonic Records Ballarat and District 1854 - 1957, 16/10/1957 (exact)

Born at the Victorian town of Sandhurst (now Bendigo, Albert Steane attended the Gravel Hill State School until the fourth class, then transferred to the Central School 1976 where he gained the Merit Certificate. The monitor system of teacher training had been introduced and he passed as a fourth, third, second and first class pupil teacher. At about 16 years of age Steane was appointed a teacher monitor at £12 per annum. Albert Steane was awarded the Teachers' Certificate of Competency in 1897. He was the first headmaster of the Ballarat Technical School, and opened the Sloyd (woodwork) Centre in 1902 at the Ballarat East Art School (later known as the Ballarat East Free Library). According to the Ballarat Courier of 23 March 1957 Steane established the Ballarat Junior Technical School in February 1913, a part of the School of Mines and Industries Ballarat. The beginning classes with 86 pupils were held at a temporary site at the Dana Street School. Classrooms were so scattered that Steane recalled without his motorbike he would never have covered the ground! By 9 September 1921 the Junior Technical School Building was officially opened on the site of the old Ballarat Gaol. In a confidential report of 1916 Steane was described as one of the best organizers in schools at that time, and he was noted for his strong but fair discipline. In the 1926 school report the Chief Inspector wrote that 'no boy is neglected'. Steane held the position of headmaster at the Ballarat Junior Technical School for 29 years retiring on 16 April 1942. Steane is known for the teaching of Sloyd or woodwork, which was an important point in his career, and for his love of gymnastics. He was made a life member of the Ballarat Y.M.C.A. in 1968 aged 91 years. The teaching of woodwork in Victoria began in 1901 and Steane was chosen, among 18 others for the inaugural training course at Queensberry State School in Melbourne. Because of his lifelong love of gymnastics Steane organized a gymnastic display for the Education Department in 1902 at Bendigo's Golden Jubilee Exhibition. He was one of those instrumental in establishing the Ballarat Y.M.C.A. and directed its physical culture evening classes in 1906. In 1908 Steane toured the world visiting the Swedish Naas Institute and the Gymnastic Festival in Germany. Steane in his reminiscences recalls: "In 1908 I obtained leave of absence and undertook a world trip to further my knowledge of both manual art training and physical training. On this trip I visited U.S.A., Canada, Scotland, England and Europe. Notable events were the attendance at the great 11th Deutche Turnfest at Frankfurt, inspection of the Naas Training School for Sloyd at Naas, Sweden inorgorated [sic] by Otto Solomon, and attendance at Physical Education Demonstrations at London given by the Swedish institution. These P.E. demonstrations were given to assist the organization and introduction of P.E. training in London schools.On returning to Ballarat I resumed my position at the Ballarat East Sloyd Centre and continued my studies at the Ballarat Art School gaining the Drawing Teachers' Certificate." Steane died, aged 93 years, on 13 July 1970, at Sydney, leaving his widow Grace Elliott Steane and children Eric and Violet. Steane is listed on the University of Ballarat Honour Roll at https://www.ballarat.edu.au/curator/honour-roll/honourroll_steane.shtml Printed green book with soft cover. The book lists all masonic bodies, including lodges and chapters, that have worked within 30 miles of Ballarat during the first 100 years of Freemasonry in the district. Includes a Loose, one page addenda et Corrigenda.The image of Albert Steane in the front of the book is inscribed "Yours faithfully A.W. Steane."ballarat, freemason, freemasonic, lodge, albert steane, a a w steane, a j dean, mark lodges, royal ark mariners, royal arch chapters, masonic orders -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Clare Gervasoni, Nimon's Bridge, 1999, 04/10/1999

Nimons Bridge was built in 1890, as part of the then Ballarat-Linton railway. The bridge is 17 spans with tall timber piers of four driven piles each, with triple sets of diagonal cross-bracing and walers and a single row of longitudinal horizontal bracing between piers. The spans are of a uniform twenty feet (6.1 metres), originally supported by four 21-inch x 9-inch (535 mm x 230 mm) Kauri timber beams per span, following the standard V.R. design of the period. When the superstructure was rebuilt after the 1953 fire, the timber beams were replaced with two 24-inch (610mm) deep rolled-steel-joists on each span. These are marked 'Lancashire Steel Co., Scotland' and are believed to have been second-hand. The deck of transverse-timber planks is 103.6 metres in length. Overall the bridge has an impressive appearance with its exceptionally tall triple-cross-braced piers creating a 'three-tiered' effect, with the deck 19.2 metres above the Woady Yaloak River. The Ballarat-Skipton line closed in 1985. Nimons Bridge has been recently restored, as part of the Ballarat-Skipton Rail Trail. How is it significant? Nimons Bridge is significant for technical, historic and aesthetic reasons at a State level. Why is it significant? Nimons Bridge is technically significant as Victoria's fourth-tallest timber trestle bridge when built, and as the third-tallest surviving example. It is also the second-largest composite bridge combining traditional timber piers with RSJ spans and a timber deck and falls within a select group of fewer than ten timber railway bridges with horizontal longitudinal bracing between the piers and three sets of double cross-bracing on its tallest piers, creating a visually striking 'three tiered' effect that enhances its viaduct form. Nimons Bridge is historically significant as having served initially the mining community at Linton, then the Western District agricultural area and in later years a kaolin quarry at Pittong. Nimons Bridge is historically significant as a representative of the 'light' branch line methodology that stimulated the explosion of railway construction in Victoria during the 1880s, and provides an interesting contrast with the more solid and vastly more expensive railway viaducts built in similar terrain on Victorian main lines, at Moorabool and Taradale, in the late 1850s. Approached by a deep cutting and high embankment at either end, the bridge represents a very cost-effective late 19th century engineering solution to the characteristic physiography of western Victoria with flat basalt plains intersected by deep wide valleys occasionally subject to severe flooding. Nimons Bridge is aesthetically significant for its visually impressive viaduct form, crossing a deep and steep-sided valley that is part of a rich cultural landscape. Within close proximity of the bridge are mullock dumps, tailings, shaft sites and other relics of the deep-lead alluvial mining era. The bridge is the most visually spectacular timber-trestle rail bridge in Western Victoria and is among the most spectacular timber-trestle rail bridges surviving anywhere in Victoria. It is part of the Ballarat-Skipton Rail Trail. Classified by the National Trust :02/10/2000 (http://vhd.heritagecouncil.vic.gov.au/places/67986)Colour photograph of a log bridge known as Nimon's Bridge.ballarat-linton, nimons bridge, nimon's bridge, log bridge, viaduct, timber-trestle rail bridge -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, George Leslie Rayment of Surrey Hills, AIF serviceman in WW1

George's grandfather was James Rayment Snr (1817-1890). He was born in Essex, England. He arrived in Melbourne aboard the “Bengal” in 1840. He married Jane McKnight on 12 March 1861. She died in 1871. James lived in South Melbourne until he married Elizabeth Brown in 1873. He moved to “Spenceycroft” at 654 Canterbury Road in 1880 - the property had a dairy. He moved to 85 Croydon Road, Surrey Hills (the house still stands) in 1886 but still ran the dairy. He moved back to South Melbourne and died there in 1890. His son James Rayment Jnr (1862-1916) was born in Emerald Hill. He married Harriet Ratten in 1882 and lived at 85-87 Croydon Rd Surrey Hills until 1914. He also owned properties at 70,72,81 and 83 Croydon Road. Harriet died in 1897. He married Victoria Benbow in 1898. In 1912 his occupation was fishmonger. In 1914 he moved to “The Wattles” at 95 Middlesex Road, Surrey Hills. In 1919 his wife Victoria owned lots 45,47,49,51,53,55 Durham Road. Surrey Hills. He died 1916 and Victoria died in 1939. James, the third, lived in Middlesex Road, Surrey Hills where he and his wife had a flower and vegetable farm. His brother was George Leslie Rayment (1894-1976), known as Les, the subject of this photo. He was born in Boroondarra. He lived at 85 Croydon Road, Surrey Hills. In 1914 he enlisted and served in the HQ staff 3rd Light Horse Brigade and was promoted to Staff Sergeant. In 1916 he was discharged for family reasons, those being that his father had died and there was no-one at home to support the family in Middlesex Road. In 1918 he married Grace Lewis at the Highfield Methodist Church. In 1919 they moved into “Clovelly”, 94 Durham Road, Surrey Hills. In 1927 his wife Grace died and in 1933 he married Celia Lewis. In 1936, with the help of his brother James, they built their new house at 14 Benwerrin Road, Surrey Hills. Celia died in 1967 and Les in 1976. Les had 2 children Dr Dulcie Grace Rayment and Norma Lesley Rayment. (Information courtesy of Mel Constable; Mel's wife is a Rayment descendant). Les' brother, James Arthur Rayment, was born in Balwyn in 1889. His A.I.F. record states - he joined on the 14 July 1915 to the 5th Field Company Engineers. His father was living in Middlesex Road, Surrey Hills at the time of his enlistment. He returned to Australia and was discharged on 22/7/1919. His occupation was carpenter; his religion, Methodist. He was 26 years and 2 months at enlistment and left Australia on 23/11/1915. James Arthur Rayment married Lilian Sarah Smith in 1920 (Ref: Victoria 1920/6780). REF: Mrs Dorothy Legg - James Rayment and his wife Elizabeth lived and farmed in Russell Street in the 1860s. The land was a dairy property and may have included some of the land later owned by the Presbyterian Church. Their sons James and Alex walked to the Balwyn State School. James married and lived at 'The Wattles' in Middlesex Road.Black and white photo of George Leslie Rayment in AIF uniform, standing with his hands behind his back. armed forces, world war, 1914 - 1918, clothing and dress, (mr) george leslie rayment, les rayment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ship's Wheel, 1871 or earlier

The ship building company E. & A. Sewall, from Bath, Maine, USA, built many ships that had wheels with the same decorative, starburst pattern on them as this particular wheel segment, including the Eric the Red. The wheel was manufactured by their local Bath foundry, Geo. Moulton & Co. and sold to the Sewall yard for $100, according to the construction accounts of the vessel. Eric the Red was a wooden, three masted clipper ship. She had 1,580 tons register and was the largest full-rigged ship built at Bath, Maine, USA in 1871. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, and was the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows that Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric the Red, who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) - about a quarter to a third of America’s total exhibits - from America for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Z. Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were 2 saloon passengers also. On 4th September 1880 the ship had been sailing for an uneventful 85 days and the voyage was almost at its end. Eric the Red approached Cape Otway in a moderate north-west wind and hazy and overcast atmosphere. Around 1:30am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, south west of the Cape Otway light station. Captain Allen ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. A heavy sea knocked the man away from the wheel, broke the wheel ropes and carried away the rudder. The sea swamped the lifeboats, the mizzenmast fell, with all of its rigging, then the mainmast fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually the Captain made it to the deckhouse and the men pulled him up. At about 4:30am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer Dawn was returning to Warrnambool from Melbourne, its sailing time different to its usual schedule. Cries were heard coming from out of the darkness. Captain Jones sent out two life boats, and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Z. Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and the able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia, passed away in the Warrnambool district; an obituary was displayed in the local paper. The captain and crew of the Dawn were recognised by the United States Government in July 1881 for their humane efforts and bravery, being thanked and presented with substantial monetary rewards, medals and gifts. Neither the ship, nor its cargo, was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steam ship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally those on board the Pharos had the name of the wrecked vessel. During this operation Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated on to Point Franklin. Some of the vessels yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of floating wreckage about 10 miles off land, south east of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and fly catchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod, samples of wood and a medal for bravery. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and tea pots, half a dozen silver serviette rings and two sewing machines. The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and sheds around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7 foot long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at ship building in Apollo bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn". “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) Segment of a ship's wheel, or helm, from the wreck of the sailing ship Eric the Red. The wheel part is an arc shape from the outer rim of the wheel and is made up of three layers of timber. The centre layer is a dark, dense timber and is wider than the two outer layers, which are less dense and lighter in colour. The wheel segment has a vertically symmetrical, decorative copper plate inlaid on the front. The plate has a starburst pattern; six stars decorate it, each at a point where there is a metal fitting going through the three layers of timber to the rear side of the wheel. On the rear each of the six fittings has an individual copper star around it. The edges of the helm are rounded and bevelled, polished to a shine in a dark stain. Around each of the stars, front and back, the wood is a lighter colour, as though the metal in that area being polished frequently. The length of the segment suggests that it has probably come from a wheel or helm that had ten spokes. (Ref: F.H.M.M. 16th March 1994, 239.6.610.3.7. Artefact Reg No ER/1.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship's-wheel, eric-the-red, helm, shei's wheel, ship's steering wheel -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaFurniture - Volum Medicine chest

This chest is the typical mid-18th century model. Thought to have belonged to captain James Volum.A medicine chest was a necessity for all sea journeys. Sometimes surgeons were onboard ships if there were passengers but on merchant ships, the captain had to be able able to look after his crew. A medium size mahogany cabinet with four protruding feet, small free hinged handles on left and right sides which are positioned approximately 5/8ths up from the bottom of the item, these handles can hinge 100 degrees upwards. The front and back 6/8ths of the cabinet can hinge open, as can the top of. Both front and back doors can be locked closed with their own respective hook latch which is on both sides of the cabinet. The top lid can be locked by interacting with a metallic keyhole which is present on the front of the cabinet close to the top. Revealed by opening the top lit is storage location with two rows of three storage spaces and one row of four. Revealed by opening the front door, is a single shelf with six divided locations for an equal number of glass containers, though only five remain in complete form. Below this self are three rows of drawers of differing dimensions, each with a small white knob. There are two drawers of equal width in the first row. Each drawer has four equally divided sliding pieces on its top face. When removed, these lids reveal a respective small space. Present on small paper labels on each of these lids are identifiers of the material which was stored. There are three equally sized drawers in the second row, which are less wide than the previous row. Only two of the drawers in this row have lids, of which each only have a single lid which covers a single compartment, each of these have a single label on them. The middle drawer contains a small glass mortar and pestle which are restrained by small wooden fixtures within the drawer. There are two drawers of equal width and greater height than any of the previous drawers in the third row. The first drawer has a single compartment containing multiple vials of varying dimensions, some of which feature a paper label with a respective inscription. Some of these vials are broken. In the second drawer has no lid which covers its four equally sized glasses. These are restricted by a wooded piece with four circular cut-outs. Revealed by opening the back door are two equally sized and spaced shelves which both have four divided locations which are filled by eight respective glass containers. These glass containers are of similar design to those in the front compartment but are larger. Some of these glass jars have paper labels like those found on previous glass containers.Label on top lid:volum collection, medecine chest, portable furniture, geelong, peterhead, scotland, captain, seafaring, whaling, london, bishopsgate, old gravel lane, london docks, tobacco dock, james burrows -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Document - Helen Gibson obituary

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - HANRO COLLECTION: HANRO JOURNAL

BHS CollectionHanro Journal: The front has a solid front and back cover and is of a green material with a marble type pattern trimmed at the top and bottom right hand corners with light brown suede triangles. The curved spine of the book is also light brown suede and the binding extends to 4cm on to the cover. 5.5cm down from the top of the spine is a 4.9 x 3.3cm red sticker with gold trim top and bottom of three strips and flowers under and on top of the third strips. The sticker has a tear and dog ears at the bottom. In gold in the centre is the word JOURNAL. The back of the journal is the same as the front but has more wear noticeable at top left and a tear at the bottom. Inside the cover is a paper lining of blue and cream mottled background with red uneven swirl a cream cloth spine with cotton thread for attaching. When the Journal is closed the pages form a colourful pattern of red, yellow, blue and green. Inside the book is light blue paper, on the left top hand written in pencil is 11/-, underneath that is 20/-. Numbers 24100, 27236, 25951, 25844 and some dacomb shorthand further down the page. On the right hand side centre of the page is the heading, hand written in black ink which has been underlined in red is *Hanro (Aust) Bendigo Knitting Mills Pty Ltd May 13th 1926* Page 1 of the Journal :- The Journal is all hand written in black ink and ruled up in red pen. At the top headed *Journal*, underlined in red. The page is ruled up into ten columns of various sizes. First column is the date May 1926. The page lists the distribution of Ordinary and Deferred Shared and their amounts. Next is Expenditure, for the land and buildings and setting up of the business, plant and equipment and various assets acquired from Bendigo Knitting Mills Pty Ltd. At the back of the book is a Debit Note From *Hands chin & Ornis S.A. Liestal (Suisse) to *Hanro* (Aust.) Bendigo Knitting Mills Pty. Ltd. Dated 10th September 1932. Debit Note No. 319. *Our payment to Messrs. Jacky, Maeder & C0, Basle as per your letter of August 10th 1932. SFr. 37.70 pounds * Then hand written in pencil is *Charged ? 168*` Also at the back is a group of letters with a hand written note in pencil, on the front dated 20/01/33 attached with a metal clip and pin reads *Bad Debts to be written off* under that it lists the names, where they are from and the amount owning and the total. Box 116Bbendigo, industry, hanro journal., hanro. journal -

Red Cliffs Military Museum

Red Cliffs Military MuseumDocument, Life history of Sgt. William Carroll, (estimated); early -mid 1990

This short history is in a display of photos and a copy of a letter written home by Sgt Carroll to his Aunt.A brief written life history from birth to death of William Carroll service Number 815. As written by a member of Red Cliffs R.S.L. in consultation with the family.Born in Wangaratta in 1891, was a drover and boundary rider in Queensland when enlisted.Sgt. Carroll was one of the original members of the 21st Battalion, 6th Brigade, 1st AIF, which was formed at Broadmeadows early 1915. The battalion embarked from Melbourne on the Uylsses on the 8th May 1915 enroute to the Middle East. Saw action Middle East> Gallipoli>Middle East to reform and reorganise > Western Front> Somme> Bullecourt> Ypres> Somme> Mont St. Quentin> Villiers Bretonneux> Hamel Mutiny./ Sgt. Carroll was twice wounded in action (at Fluers and Broondseinde)and was recommended for the Distinguished Conduct Medal, with a Sgt Cozens (No 825 also original member, on the 15th September 1916, for exceptional zeal in the performance of their duties and coolness in action, which had a great affect on the moral of their mem. He was discharged medically unfit with gun wounds to his left knee and back. Of the full Battalion strength of the original Officers and men, there were 16 Officers and 24 Or's left. 21st Battalion left buried on foreign soil 47 Officers and 827 Or's. It was the highest decorated Battalion of the 6th Brigade. Listed are some of the Battles and Misfortunes that Sgt. Carrol survived to return to Australia. Torpedoed on the troop ship Southland enroute to Gallipoli 1915;/ First Australian troops to Garrison Cairo; First Australian Infantry Unit into line in France; Last out of the line; Staging a successful mutiny; 21st Battalion was disbanded in 1918. Sgt. Carroll was given block 276 Red Cliffs, he sold his block in 1982. He was interested in Community affairs and was involved in ADFA, RSL, Mildura Club, and Mildura Show Society and was the third last Red Cliffs Soldier Settler to die. He was in his 100th year.medal, distinguished, battalion, aif, 21st, 6th, brigade, 1st, mutiny, gallipoli, wangaratta, 1891, boundary, rider, ulysses, middle, east, western, front, conduct -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionAward - Set of Twenty Two Security Loan Honour Pennants, Commonwealth of Australia, c 1946 - 1963

Australia, like many countries involved in both the First and Second World Wars realised that they would need more funds to resource their campaigns, so war loan programs were developed. These programs encouraged the population to purchase government war bonds which would be repaid with interest at a later time while immediately assisting the war effort. Post WW2 the government continued to encourage citizens to save money in an attempt to curb inflation. Security loans formed part of this countries economic program from the 1940's onwards. Districts were allocated a quota for which they encouraged citizens to subscribe and pennants were awarded for the highest per capita payment amongst the town population. In 1946 Bendigo was the first country city in Australia to record a quota success for the Second Security Loan, raising £260,480 from 1953 subscribers. Triangle felt screen printed pennants, various colours with two ties along left side. Pennants range in date from 1942 until 1963. 253.1 Blue felt triangle pennant with two ties on long side. Gold printed Commonwealth of Australia Coat of Arms, cream printed text and one star top left of crest. Dimensions: 1010mm W x 355 H x 3mm 253.2 Blue felt triangle pennant with two ties on long side. Gold printed Commonwealth of Australia Coat of Arms, printed cream, red and blue coloured text . One cream coloured printed star top left of crest. Dimensions: 985 W x 367 H x 3mm 253.3 Blue felt triangle pennant with two ties on long side. Gold printed Commonwealth of Australia Coat of Arms, printed cream, red and blue coloured text . One cream coloured printed star top left of crest. Dimensions: 955W x 355 H x 3mm 253.4 Green felt triangle pennant with two ties on long side. Gold printed Commonwealth of Australia Coat of Arms, printed cream, red and green coloured text . One cream coloured printed star top left of crest. Dimensions: 970 W x 367 H x 3mm 253.5 Green felt triangle pennant with two ties on long side. Gold printed Commonwealth of Australia Coat of Arms, printed yellow, pink and green coloured text . Two cream coloured printed stars top left of crest. Dimensions: 975 W x 370 H x 3mm 253.6 Red felt triangle pennant with two ties on long side and remnants of bronze ribbon stapled to long side. Yellow printed Commonwealth of Australia Coat of Arms, printed white, yellow, cream and light blue text . Two cream coloured printed stars top left of crest. One light blue star centre right. Dimensions: 1055 W x 355 H x 3mm 253.7 Light blue felt triangle pennant with two ties on long side and bronze ribbon stapled to long side. Yellow printed Commonwealth of Australia Coat of Arms, printed red, white and dark blue text . One cream coloured printed star top left of crest. Dimensions: 966 W x 355 H x 3mm 253.8 Green felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms, printed pink, white and yellow text . One cream coloured printed star top left of crest. Dimensions: 970 W x 350 H x 3mm 253.9 Red felt triangle pennant with two ties on long side and remnants of bronze ribbon stapled to long side. Yellow, blue, red and cream printed Commonwealth of Australia Coat of Arms with printed black, white and light blue text. Additional text on long side of pennant adjacent to ties. Three cream coloured printed stars top left of crest. Dimensions: 965 W x 350 H x 3mm 253.10 Blue felt triangle pennant with two ties on long side and remnants of bronze ribbon attached to ties. Yellow printed Commonwealth of Australia Coat of Arms with printed dark blue, cream and red text. Two cream coloured printed stars top left of crest. Dimensions: 930 W x 365 H x 3mm 253.11 Red felt triangle pennant with two ties on long side. Yellow, blue, red and cream printed Commonwealth of Australia Coat of Arms with light blue and cream text. Three cream coloured printed stars top left of crest. Dimensions: 1025 W x 355H x 2mm 253.12 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with light blue text. Additional text on long side of pennant adjacent to ties. One cream coloured printed star top left of crest. Dimensions: 920 W x 338 H x 3mm 253.13 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with maroon text. One cream coloured printed star top left of crest. Dimensions: 930 W x 360 H x 3mm 253.14 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with yellow text. Two cream coloured printed stars top left of crest. Dimensions 910 W x 345 H x 3mm 253.15 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with light blue text. one cream coloured printed star top left of crest. Dimensions: 905 W x 345 H x 3mm. 253.16 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with brown text. One cream coloured printed star top left of crest. Dimensions: 930 W x 360 H x 3mm 253.17 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with blue text. One cream coloured printed star top left of crest. Dimensions: 915 W x 350 H x 3mm 253.18 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with blue text. One cream coloured printed star top left of crest. Dimensions: 950 W x 355 H x 3mm 253.19 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with blue text. One cream coloured printed star top left of crest. Dimensions: 950 W x 355 H x 3mm 253.20 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with cream text. One cream coloured printed star top left of crest. Dimensions: 965 W x 360 H x 3mm 253.21 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with blue text. One cream coloured printed star top left of crest. Dimensions: 950 W x 365 H x 3mm 253.22 Dark blue felt triangle pennant with two ties on long side. Yellow printed Commonwealth of Australia Coat of Arms with cream text. One cream coloured printed star top left of crest. Dimensions: 940 W x 365 H x 3mm 253.1 Austerity /War Loan / Nov - Dec 1942 / Honour Pennant 253.2 Second / Security Loan / Oct - Nov 1946 / Honour Pennant 253.3 Third / Security Loan / April - May 1947 / Honour Pennant 253.4 Fourth / Security Loan / Oct - Nov 1947 / Honour Pennant 253.5 Fifth / Security Loan / April - May 1948 / Honour Pennant 253.6 Seventh/ Security Loan / March – April 1949 / Bendigo 253.7 Eighth / Security Loan / Sept – Oct 1949 / Honour Pennant 253.8 Ninth / Security Loan / March 1950 / Honour Pennant 253.9 Special Award / Tenth / Security Loan / August 1950 / City of Bendigo 253.10 Eleventh/ Security Loan / Nov-Dec 1950 / Honour Pennant 253.11 Special Award / 12th Security Loan / may- June 1951 / City of Bendigo 253.12 Sixteenth / Security Loan / Nov-Dec 1952 / Honour Pennant 253.13 Eighteenth / Security Loan / Sept – Oct 1953 / Honour Pennant 253.14 Nineteenth / Security Loan / March 1954 / Honour Pennant 253.15 Commonwealth / Security Loan / August 1954 / Honour Pennant 253.16 Commonwealth / Security Loan / august 1954 / Honour Pennant 253.17 Commonwealth / Security Loan / August 1956 / Honour Pennant 253.18 Commonwealth / Security Loan / August 1957 / Honour Pennant 253.19 Commonwealth / Security Loan / May 1960/ Honour Pennant 253.20 Commonwealth / Security Loan / September 1960/ Honour Pennant 253.21 Commonwealth / Security Loan / February March 1961/ Honour Pennant 253.22 Commonwealth / Security Loan / February 1963 / Honour Pennant commonwealth loan scheme, city of greater bendigo awards -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Melba & Co, 7th Australian Infantry Training Battalion WW1

George Alfred Yung, known as Alf, pictured in the second row, 10th from the left, enlisted on 25/02/1916; embarked on 19/02/1917; was killed during the battle of Menin Gate at Yrpres, Belgium on 20/09/1917. https://www.awm.gov.au/collection/U51447 The 7th Battalion was among the first infantry units raised for the AIF during the First World War. Like the 5th, 6th and 8th Battalions, it was recruited from Victoria and, together with these battalions, formed the 2nd Brigade. The battalion was raised by Lieutenant Colonel H. E. "Pompey" Elliott within a fortnight of the declaration of war in August 1914 and embarked just two months later. After a brief stop in Albany, Western Australia, the battalion proceeded to Egypt, arriving on 2 December. It later took part in the ANZAC landing on 25 April 1915, as part of the second wave. Ten days after the landing, the 2nd Brigade was transferred from ANZAC to Cape Helles to help in the attack on the village of Krithia. The attack captured little ground but cost the brigade almost a third of its strength. The Victorian battalions returned to ANZAC to help defend the beachhead, and in August the 2nd Brigade fought at the battle of Lone Pine. While holding positions captured by the 1st Brigade, four members of the 7th Battalion, Corporal A. S. Burton, Acting Corporal W. Dunstan, Lieutenant W. Symons and Captain F. H. Tubb, earned the Victoria Cross - Burton posthumously. The battalion served at ANZAC until the evacuation in December. After the withdrawal from Gallipoli in December 1915, the battalion returned to Egypt. In March 1916, it sailed for France and the Western Front and entered the front line trenches for the first time on 3 May. The battalion's first major action in France was at Pozieres in the Somme valley where it fought between 23-27 July and 15-21 August. After Pozieres the battalion manned trenches in the Ypres salient in Belgium, before returning to the Somme valley. It saw out the horrendous winter of 1916-1917 rotating between training, working parties and duty in the trenches. In early 1917, the Germans withdrew to the Hindenburg Line and the 7th Battalion participated in the brief advance that followed and then came to a grinding halt before Bullecourt. The battalion was withdrawn from the front line for training on 9 May 1917 and did not return to action until the Ypres offensive of September and October. It fought major battles at Menin Road on 20 September and Broodseinde on 4 October, and then spent much of ensuing winter in the Ypres mud. In March and April 1918 the 7th helped stop the German spring offensive in northern France and later participated in the Allies' own great offensive of 1918, that began with the battle of Amiens on 8 August. The advance by British and empire troops on 8 August was the greatest success in a single day on the Western Front, one that German General Erich Ludendorff described as, "the black day of the German Army in this war". The battalion continued operations until late September 1918. At 11 am on 11 November 1918, the guns fell silent. The November armistice was followed by the peace treaty of Versailles signed on 28 June 1919. In November 1918 members of the AIF began to return to Australia for demobilisation and discharge. In March, the battalion was so reduced that it and the 6th Battalion were amalgamated to form a composite battalion. In turn, this battalion was merged with another, formed from the 5th and 8th Battalions, to form the 2nd Brigade Battalion. https://www.awm.gov.au/collection/U51447army, soldier, alf yung, 7th australian infantry battalion -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaArticle, Kerrie O'Brien, Want to peek inside Melbourne’s finest mansions and buildings? This is your chance, 30 June 2022

Open House 2022: "Like many Melburnians, Ying-Lan Dann has long been fascinated by the Mission to Seafarers, in Docklands. When she was invited to create a work in response to a building as part of this year’s Open House Melbourne, she knew immediately which it would be. Taking a peek behind the closed doors of some of Melbourne’s finest and most interesting buildings is a core premise of the weekend event, now in its 15th year. During that time, the program has grown from half a dozen buildings to a 200-plus strong list that extends to Ballarat and Bendigo. “[It’s] much more expansive and citizen-led,” says Fleur Watson, Open House Melbourne’s executive director. “As a public festival, it has always had a spirit of generosity, this gesture of opening up and allowing visitors to come and look and experience things.” Swinging open their doors at the end of the month will be some of the city’s finest mansions, including Villa Alba in Kew and Brighton’s Billilla, the Cairo flats in Fitzroy, the newly renovated Jewish Museum designed by Kerstin Thompson, the Melbourne Quakers Centre, the Albanian Mosque in Carlton North and many more. Considering how to approach the event this year, held remotely for the past two, Watson decided to explore beyond the traditional, with associate professor and director of curatorial practice at Monash University Tara McDowell. The two have co-curated an exhibition of works to run concurrently with the Open House program, called Take Hold of the Clouds. That’s where Dann’s work, Circular Temporalities, comes in, one of seven commissions around town in which local and international artists respond to chosen buildings or sites. A lecturer in interior design at RMIT as well as an artist, she is interested in time and finding different mediums to show things in flux and, having grown up on Phillip Island, she often uses water as a theme. When she started spending time at the Mission, Dann found there was an oculus at the top of the dome, known as the Norla Dome. She thought about how that small but significant opening related to where sailors spent so many months of the year, the sky being the only thing they would see much of the time, stars guiding the way in times gone by, and of the recent stories she’d heard about sailors being trapped at sea during COVID. Built in the Arts and Craft style between 1916 and 1919 and designed by architect Walter Butler, the Mission includes a chapel, clubroom, Chaplain’s house, a small cottage and the Norla Dome, which was apparently inspired by the Pantheon. The Mission was funded by the government and the Ladies Harbour Lights Guild, who Dann was also intrigued by. “One of the things those women identified is that life at sea is very dangerous [and they] wanted to give them a space of sanctuary and support,” she says, adding that for many years, the dome was used as a gymnasium. Her work inside the dome includes a 35-minute loop film, recorded from the ferry during the crossing from Queenscliff to Sorrento. The horizon takes up about a third of the shot and moves as the waves rise and fall, mirroring the journeys made by the sailors who found refuge at the mission over the years; it will be projected onto a gauze-like fabric, allowing glimpses of the building behind. Dann also plans to activate the site over the course of the weekend and will read a poem by Justin Clemens.The articles gives an insight of the création of the artwork by Ying-Lan Dann. digital copy of an article with photographs published in the Ageopen house melbourne, 2022, ying-lan dann, take hold of the clouds, norla dome, exhibition, the age, cultural events -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBearing cap, (estimated); Before The Newfield completion in 1889

This bearing cap is thought to be from a donkey winch engine, (or steam donkey, or donkey winch), which is a small secondary steam engine with a cylindrical shaped boiler. In 19th century merchant sailing a steam donkey was often used in marine applications such as to help raise and lower larger sails, load and unload cargo or to power pumps. The bearing cap could have been used on the donkey engine to hold the rod of the winch gear wheel in place, or bolted to another bearing cap around the neck on the top of the boiler’s cylinder, connecting it to the flue. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1889 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt, the main export product of Sharpness. At about 9pm on 28th August 1892, in heavy weather, Captain Scott sighted, between heavy squalls, the Cape Otway light on the mainland of Victoria but, due to a navigational error (the ship’s chronometers were wrong), he assumed it to be the Cape Wickham light on King Island, some 40 miles south. He altered his course to the north, expecting to enter Bass Strait. The ship was now heading straight for the south west Victorian coast. At about 1:30am the Newfield ran aground on a reef about 100 yards from shore and one mile east of Curdie’s Inlet, Peterborough. The ship struck heavily three times before grounding on an inner shoal with 6 feet of water in the holds. Rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The rescue was a difficult operation. The Port Campbell Rocket Crew arrived and fired four rocket lines, none of which connected with the ship. Peter Carmody, a local man, volunteered to swim about one mile off shore to the ship with a line to guide the fourth and final lifeboat safely to shore. He was assisted by James McKenzie and Gerard Irvine. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one man style of navigation" and that the Captain had not heeded the advice of his crew. According to Jack Loney ‘… when the drama was over . . the Newfield was deserted except for the Captain’s dog and two pigs.’ Peter Carmody was awarded the Bramley-Moore medal by the Liverpool Shipwreck and Humane Society for Saving Life at Ssea, which he received by mail on January 21st 1893. The medal and a letter of congratulations were donated to Flagstaff Hill Maritime Museum by Peter Carmody’s grand-daughter Norma Bracken and her son Stuart Bracken on 25th May 2006. The Bearing Cap joins other items in the Newfield collection.Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is significant because of the relationship between the objects. The Newfield collection is archaeologically significant as the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its association with the shipwreck.Brass bearing cap from the wreck of the sailing ship “Newfield” is possibly from a donkey winch engine. The half-circle shaped cuff with a rectangular brass block attached to the outside of each end of the half-circle. Both blocks have a round hole in their centre and are approximately the same depth and width as the cuff. Midway around the half-circle cuff is another brass block that is about twice the depth of the cuff. It appears to have been a circular shape that has been modified to match the width of the collar, having had the sides of the circle cut off to leave straights edge parallel to the edges of the cuff. In the centre of this block is another hole, and there appears to be the head of a bolt inside this hole. The bearing cap is lightly encrusted.1893, flagstaff hill, flagstaff hill maritime museum, maritime museum, warrnambool, newfield, 1892, 28 august 1892, port campbell, shipwreck, nineteenth century, ship, curdie s river, victorian shipwrecks, barque, ship wreck, 29 august 1892, 19th century, bearing cap, donkey engine, donkey winch, steam donkey -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNail, circa 1810