Showing 273 items

matching metal working

-

Bialik College

Bialik CollegeMixed media - WIZO Medal 1982

Presented to Bialik from the Women’s International Zionist Organisation (WIZO); Israel's leading organisation for education and social services, promotes an equal society for all supported by a global network of Zionist women. Please contact [email protected] to request access to this record. An appreciation trophy to Bialik from Women’s International Zionist Organisation (WIZO). A resin puck, with a flat bottom, 9cm across and 2.5cm thick. Inside the clear resin is a medal. One side has the words WIZO, with an image signifying a mother and baby. The reverse has more text, likely Hebrew, with images of women and children working and being together, trees are a feature of these scenes.Please contact [email protected] to request access to this record. A small metal strip, glue worn off and sticky tape not adhering, has been engraved with the words: Presented to Bialik College In Appreciation March 1982 judaism, women, zionist, medal, 1980s -

Melbourne Tram Museum

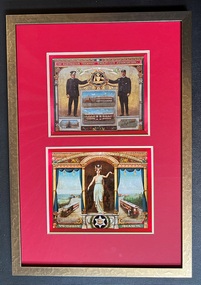

Melbourne Tram MuseumArtwork, other - Framed image of ATEA - Tramway Union Banner

The Australian Tramway Employees Association commissioned in 1915, a banner for use in marches or events. It was painted in 1916 by George Grant with its first public appearance at the Eight-Hour Day Diamond Jubilee on 10 April 1916, celebrating the 60th anniversary of the introduction of an eight-hour working day in Victoria. The reference gives a detailed history of the banner, it significance and the background to its painting. It is now held in the collection of Museums Victoria. The ATEA was the forerunner to the Australian Tramway and Motor Omnibus Employees' Association, now part of the Rail Tram and Bus Union. Image provided by Museum's Victoria to the donor - Peter Jewell. The image demonstrates the artists work and the use of symbols in the roles of a union.Framed Image - old gold coloured metal frame, Artglass, with red colour card surround with bevelled gold card inlay containing a high resolution image of the Australian Tramway Employees Association banner. Fitted with a metal hanging wire and a white surround, tape and the framers lable.tramways, unions, atea, atmoea, rtbu, banners, george grant, eight hour day -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Australian Army Issue Clasp Knife

Australian manufactured clasp knives were a standard issue to Australian Military Forces during World War 2. The most commonly encountered knife was an all metal model with a canoe shaped body. This knife was a Whittingslowe first pattern clasp knife which included a blade, a tin opener and a marline spike as well as screw driver and shackle to attach the knife to a lanyard or belt clip. These knives were given a dull Nickel plating to protect them. William Thomas Whittingslowe was born in Wales in 1888, he was educated in England and at 18 migrated to Canada and then to Australia, arriving in about 1912. After working in various states, he settled in South Australia and in the 1920s set up his own business, Whittingslowe Engineers Limited. He specialised in ironworking and knife manufacturing. His firm produced a large amount of blade ware during World War 2. He also designed and built manufacturing equipment for General Motors Holden. He died at Murray Bridge (SA) in 1956.This item is significance because it was donated by a member of the community of Wodonga which has a strong connection to Australian military history.A clasp knife made completely from metal with nickel plating. The accessories all fold into a canoe-shaped body. It included a knife, can opener and marlin spike.On knife blade: WE over a broad arrow/I\australian army equipment ww2, thomas whittingslowe, australian army -

Linton and District Historical Society Inc

Linton and District Historical Society IncPhotograph, Nell Grigg Working as a Red Cross Transport Driver, WWII, circa 1940

Nell Grigg, in uniform, was a Red Cross Transport Driver during the second World War.Original black and white photograph, in ornate metal frame, of man in wheelchair being pushed into ambulance.nell grigg, red cross, world war ii, war work -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Equipment - MODEL OF MINING CAGE

A lot of safety cages were developed in 1800s. Grippers on the cages acted to prevent the cages from "free fall" when the cables broke.Model of mining cage, metal construction, with safety cage not in working order.bendigo, gold mining, mining cage model -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Equipment - MODEL OF MINING CAGE

A lot of safety cages were developed in 1800s. Grippers on the cages acted to prevent the cages from "free fall" when the cables broke.Model of mining cage, metal construction, with safety cage in working order with ore truck. Made by Benedict Branch, won a medal at the Juvenile Tasmanian Industrial Exhibition (1883)bendigo, gold mining, mining cage model -

Mont De Lancey

Mont De LanceyFunctional object - Tea Caddy, Bushells Tea, c1920's

For generations, Bushells Coffee has been a part of everyday Australian life. It is an iconic household brand name that generations of families have grown up enjoying. These tea and coffee tins or caddies were commonly purchased from suppliers selling the well-known products of Bushels or Robur. The empty tins would have been used for storing other foods, household or farming items.A badly damaged square, Bushells Ltd 'Barley' tea canister or tea caddy with a rusted on lid and faded mountain scenes depicted around the four sides of the tin. There is indecipherable print at the bottom of each side, however, some details can be read - No. 144 (of a series) Net 1lb. Weight and other words not clearly read. The lid has a picture of the Bushells man with a long beard. This canister is from c.1920's and is very rare. There is indecipherable print at the bottom of each side, however, some details can be read - No. 144 (of a series) Net 1lb. Weight and other words not clearly read. The lid has a picture of the Bushells man with a long beard. The pictures on each side are very worn, but are of a female tea picker in traditional clothing working on a mountainside, standing near a shed with a cow and another one of her standing near an ox driven cart. metal, tea caddies, tea accessories, containers, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bellows, 1862-1875

... and 1900s in the trace of blacksmiths and other metal working smiths ...This bellows was used at the Warrnambool Racecourse by Master Farrier, Brian Chapman (1931-2017), during the 1970s but its history before then is still being investigated. The bellows have continued to be used from 1978 at Flagstaff Hill's blacksmith's workshop. Even today, in 2021, this same bellows are used by a volunteer blacksmith as he demonstrate the skills and tells of the importance of the blacksmith trade to colonial Australia. This 1860s double-action bellows is a typical form of blacksmith's or shipsmith's bellows. The end is forge-fitted with an iron nozzle or tube, called a tuyere or Tue iron, which concentrates the air to fan the fire or furnace. Tuyeres were traditionally made of cow horn. The double-action design of this bellows efficiently moves air both in and out of the chambers in the one movement of the long handle. The bellows was manufactured by John C. Onions of Birmingham, England, between 1862 and 1875. The stamp with the text, Gold Medal 1862, was also used on the business’ advertising. In 1875 the company was registered and began using the name John C. Onions Limited. JOHN C. ONIONS - John C. (Collingwood) Onions (1841-1904) was the son of a bellows maker of the same name. Onions (born 1841) and his wife Helen married in 1867 and they named one of their children John Collingwood Onions (1868-1913), as was the family tradition. He was well known as a Birmingham manufacturer of patented bellows and other forge-related equipment. He sold to the wholesale and retail markets for both local and overseas customers, including the British colonies. An 1862 advertisement points out that John C. Onions was a “Bellows manufacturer and contractor to Her Majesty’s Honourable Board of Ordinance” and His Imperial Majesty the Emperor of the French [Napoleon Bonaparte]”. The advertisement includes a sketched portrait of the Emperor Napoleon III, and an Imperial Autograph Letter dated May 23, 1854, from Napoleon, Palace of the Tulleries to Mr J C Onions of Bradford Street, Birmingham. In 1863 the company registered a patent on portable forges. In 1871 there were eight employees. John C. Onions Limited became a registered company in 1875. In 1876 an advertisements included that the company were smiths for hearths and tools in general and showed a row of six medallions including one with “Napoleon III, Emperor” and his portrait, and another “ _ _ _ 1862 MEDAL”. Their advertising motto was “For Excellence of Quality”. In 1885 the company merged with William Allday and Sons to become Allday and Onions. This mid-19th century bellows has local historical significance as it were once used by blacksmiths at the Warrnambool Racecourse in the annual racing event that continues today. This bellows is significant as a working example of equipment used in the 1800 and 1900s in the trace of blacksmiths and other metal working smiths. The bellows is technologically significant as it shows the progress from simple bellows to the double-action bellows, a time saving and efficient improvement. The manufacturer John C. Onions is historically significant as a family business that began in the 1600s and continued up until the 1980s.Bellows; large, oval, mechanical double-action smith’s bellows, manually operated, in working condition. The paddles of wood that form the top, middle sections and base of the bellows have flexible leather pieces attached firmly between them, forming airtight double lungs. Cut-outs in the panels allow the bellows to fill with air then force it out. A long handle is connected to pump the bellows and control the quantity and force of the air. The blasts of air are forced through the metal nozzle or tuyere at the end of the bellows and into the forge’s fire. Inscriptions are impressed into the wood on the upper paddle or board of the bellows. There are three circular stamps containing text. Text impressed in the wooden upper paddle of the bellows has been assumed to read “JOHN C. ONIONS, PATENTEES & MANUFACTURERS, BIRMINGHAM””?” “EXTRA” “AWARDED FOR EXCELLENCE OF QUALITY”, made from the following readable text :- “JOHN C ONIONS“ “PATENT - - - & MAN - - - - - - - - -“, “BIR - - - - HAM“, “ _ ERA - - - - “- XTRA-“, “- - - - - - - FOR EXCELL-“ “OF - - - - ITY” Text in the stamp “ - - ECE - - “, “ - - - - - / 1862 / MEDAL”, “- ITY” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john collingwood onions, john c onions, allday and onions, bellows, smith’s bellows, 19th century bellows, double-action bellows, double-acting bellows, double lung bellows, double chamber bellows, blacksmith tools, blacksmith trade, blacksmith craft, blacksmith equipment, forging equipment, john c onions patented double-action bellows, brian chapman, warrnambool racecourse, blacksmith, shipsmith, iron smith, mechanical bellows -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Colour Photograph/s, Carolyn Dean, 17/05/1992 12:00:00 AM

Colour photograph of the Ballarat Horse Tram No.1 with most of the painting of the metal work completed. Handrail installation has commenced. Warren Doubleday working on the west end steps. Photographed outside the rear of the depot by Carolyn Dean on 17/5/1992. On Fujichrome paper.In top left hand corner of print on rear "167.4 17.5.92 / Carolyn Dean / Photo"horse trams, reconstruction, depot, btps, tram 1 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionClothing - Apron - Blacksmith, 1900s

A leather apron would have been worn as a protective garment by blacksmiths. It would have helped to them from sparks and other hazards whilst they were working. Early businesses in Portland included a blacksmith. This would have been vital to the town and its development. Although the provenance of the apron is unknown it is possible that this belonged to a Portland blacksmith.Brown leather apron. Leather neck strap with metal. Metal buckle to the side. Rope pieces have been added where the original leather straps have broken off. Bottom right corner has a triangular shaped rip which has been mended and sewn back together. The leather is fairly brittle with marks and stains on it.blacksmith, leather, leather working, protective clothing, portland, glenelg shire -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Folder, Skipper, Matchem

... August 1966. Matcham Skipper working on a metal artwork... August 1966. Matcham Skipper working on a metal artwork ...Matcham Skipper was born in New Zealand in 1921 to Lena and Mervyn Skipper. The family returned to Australia. After Mervyn met Justus Jorgensen; they moved to live at Montsalvat. Matcham married Myra Gould; he became a sculptor and jewellery maker. Contents Newspaper photograph: "The artist at work - Matcham Skipper in his studio at Montsalvat", The Australian, 10 August 1966. Matcham Skipper working on a metal artwork. Photocopy of photograph: Matcham Skipper c1970. Magazine article: "Matcham Skipper - knockabout genius", POL vol.4 no.12 (~1972). Biography of Matcham Skipper. Magazine photograph: "Skipper and his home. He helped to lay the bricks", no source or date. Magazine photograph: "Matcham Skipper, of Eltham, works on his sculpture of Leda and the Swan, which will be presented to this year's winner of the David Jones fashion award", no source or date. Newspaper article: "Ageless quality before fashion", Diamond Valley News, 19 December 1883. Matcham Skipper included in exhibition of jewellers at Eltham Gallery. Newspaper photograph: "Mr Matchem Skipper puts the finishing touhes to the steel mandala yesterday", no source or date. Newspaper article: "Metallic influence of Renaissance sculptor", Diamond Valley News, ~1982. Biography of Matcham Skipper. Newspaper article: "A Matcham Skipper monologe", The Age Saturday Extra, 31 August 1985. Matcham Skipper's year in Italy. Newspaper article: "Office regalia", Diamond Valley News, 14 August 1990. Presentation of Eltham Shire mayoral chain made by Matcham Skipper. Newspaper article: "Old flicks on big screen", no source, 2004. Exhibition of Matcham Skipper's photographs "The Arnham Land Portraits" to accompany screening of Tim Burstall films. Newspaper article: "No match for Skipper", Diamond Valley News, 3 November 2010. Matcham Skipper's sculpture of a boy "Young man awakening" for Eltham Cemetery Trust. Newspaper article: "Final salute to Skipper", Diamond Valley Leader, 2 March 2011. Death of Matcham Skipper. Newspaper death and funeral notices: Matcham Skipper, so source or date. Newspaper article: "Remembering Matcham", Diamond Valley Leader, 9 March 2011. Funeral of Matcham Skipper at Montsalvat. Letter Eltham District Historical Society to Sigmund Jorgensen, 13 March 2011, seeking copies of eulogies given by Sigmund Jorgensen and Clio Skipper at funeral of Matcham Skipper. Letter Sigmund Jorgensen to Eltham District Historical Society, 21 March 2011, enclosing edited version of the eulogy with illustrations of work of Matcham Skipper. Newspaper obituary: "Eltham art colony's knockabout genius", The Age 31 March 2011. Obituary of Matcham Skipper. Newspaper clippings, A4 photocopies, etcmatcham skipper, myra skipper nee gould, marcus skipper, adam skipper, damion skipper, montsalvat, lena skipper, mervin skipper, justus jorgensen, karel zoubek, david jones fashion awards, eltham gallery, gerd bahmann, heidi wild, gilliam hillman, sonia skipper, pietrasanta, luigitommasi fonderia d'arte, peter graham, bob mclellan, thelma mclellan, tim burstall, the prize (film), the arnham land portraits exhibitio, eltham cemetery trust, jenardiy zabenko, craig macdonald, "young man awakening" sculpture, sigmund jorgensen, sue thomas, simon skipper, helen skipper, glen tomasetti, sandy kilpatrick, clio (sarah) tomasetti, raphael kilpatrick, alan marshall, alistair knox, clifton pugh, tony raunic, rita wooley, erasmus toscano, maurice toscano, mervyn garnham skipper -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Tip Dray, Prior to 1930s

A Dray is a type of dead axle wagon that was used to transport heavy loads or objects. They had a flat level floor and while some had no sides, others had box bodies and sides. Tip Drays (also known as Tip Carts, Muck Cart, Scotch Cart, Tumbrel or Putt in different parts of England) were smaller than other drays as their loads were heavy and usually only pulled by one horse. Their basic design included two wheels, a tipping body and shafts. The Tip Dray has a unique mechanism that allows the top to tip backwards to tip the load out of the back of the dray. The tipper was activated by a handle at the front allowing the driver to operate it while still having control over the horse. A Tip Dray was an indispensable piece of equipment in the days before tractors and mechanical trucks. They were used by farmers and carters to transport hay, rocks, bricks, gravel and rubbish etc. and because they were useful for dumping loads, they were favoured for use in road and railway construction. A photo in the collection of the Lorne Historical Society shows a tipping dray being used during the construction of the Great Ocean Road. They were part of the daily street traffic in towns and cities around Australia from the early days of settlement. In Australia in the early 1900's, carters began to join unions to protect their jobs and pay. N.S.W. had a "Trolley, Draymen and Carters Union", Queensland had a "Tip Dray Men's Association" and in W. A. the "Top Dray Driver's Union" had a "cessation of work" in 1911 when they were fighting for an increase in their day's wages. In 1910 a meeting of Tip Carters was held in Geelong at the Trades Hall to discuss the formation of a union (The Geelong Tip Dray Carters) which was a success and a schedule of rates for all carting, whether by contract or day labor, was fixed. By 1912 they had "labelled" more than 50 drays and had representatives on the "Trades Hall and Eight Hours Committee". By the mid 1930's and early 1940's, tip drays were being superseded by mechanical trucks and utes. However tip drays continued to be used in some circumstances. They were a practical solution to the problem of petrol rationing during W. W. 2. It was noted in a letter to the editor in the "Sunshine Advocate" in 1938 that a positive argument for continued use of Tip Drays for rubbish collection related to the idea that a horse drawn vehicle involved with lots of stops and starts at different houses (very like a milkman's delivery route) often involved the horse "driving itself" while the driver picked up the rubbish - something a motor truck was unable to do! Another article written in August 1935 and published in the Age in a parliamentary report into the rubber industry noted "tip drays had almost disappeared and in their place, metal was carted in 5 ton motor trucks" but the report went on to say that as a part of the Government relief work (during the Great Depression) the Government had "to some extent reintroduced the tip drays so that a greater number of men would be employed". This particular tip dray was owned by Mr. Oswald (Jack) Bourke. He used it to deliver dry goods from Sunbury to the Queen Victoria Market in Melbourne several times a week in the 1930's and then (between 1945 and 1962) Mr. Bourke used it on the garbage round in Springvale Victoria for the Springvale Council. The Council owned three drays and the "No. 3" painted on this dray is in recognition of its original number. After the death of Mr. Bourke in 1990, one of Mr. Bourke's sons (Andy) found the dray in a shed and restored it. The sign writing on the back and side panels were added during the restoration. This Tipping Dray is a significant example of a horse drawn vehicle that was used by workers from the early days of white settlement through to the 1940's and even into the early 1960's. It was used in a range of "working class" occupations - road construction, railway construction, carting goods, rubbish collection etc. and would have been found in cities, country towns and on farms.A wooden and metal tipping dray with a box body and four sides. It has two iron and wooden wheels (with 14 spokes), two wooden shafts and a metal tipping mechanism. The back panel folds down to allow loads to be dumped out. It is painted in green and cream with sign writing on one of the sides and on the front and back panels. It features decorative painted lines and designs in burgundy, cream and light blue on most of the wooden parts. The tipping mechanism is on the front of the dray's left side and consists of a metal pin secured with a metal ring, and a lever.Front of dray - "No. 3" Side of dray - "A. & M. BOURKE / Contractors / LONGWARRY" Back of dray - "G.T. ANDREWS / QUEEN VICTORIA MARKET - Stand C23 / Phone DANDENONG 225"flagstaff hill maritime museum and village, warrnambool, shipwreck coast, tipping dray, dray, tip dray, tip cart, vehicles, horse drawn vehicle, springvale council, jack bourke, muck cart, scotch cart, tumbrel, putt, box body, oswald bourke, sunbury, queen victoria market, melbourne, no. 3 -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Colour print, Kodak, Students Picking Fruit, 1960

Colour photograph of 4 Students picking fruit in the Orchard standing on wooden and metal ladders.'Kodak Colour Print made by Kodak (Australia) Pty. Ltd. June, 1960.'fruit picking, students working outside, orchard, ladders -

Mont De Lancey

Mont De LanceyDomestic object - Mantel Clock

The mantel clock has a rich history that dates back to the 18th century. These smaller clocks were designed during an age when people wanted elegant timepieces that fit on mantels or shelves. Their compact size and decorative designs made them a popular choice for homes of the time. They graced the mantelpieces or tables in homes, serving as both functional timepieces and sophisticated decorations. These clocks often feature ornate wooden carvings and intricate designs, with their gentle ticking and chimes adding a cozy ambiance to living spaces. It was used by Harold and Jean Parker.An antique wooden mantel clock made in USA with an Australian made Duff brand oak case with a plain angled top with round shaped pillar styled sides. It has a white ceramic dial face with black digits and black metal hands. The dial is covered by a glass and gold trimmed covering that may be opened on the right side. Inside the case is a Waterbury Clock Co of USA key and the internal workings are visible. It is not in working order.'Duff' brand brass plaque on back of cover. The key has 'Waterbury Clock Co USA' stamped on it.clocks, timepieces, clock components, clock keys, mantel clocks -

Mont De Lancey

Mont De LanceyDomestic object - Mantel Clock, 1880's - 1920's

The mantel clock has a rich history that dates back to the 18th century. These smaller clocks were designed during an age when people wanted elegant timepieces that fit on mantels or shelves. Their compact size and decorative designs made them a popular choice for homes of the time. They graced the mantelpieces or tables in homes, serving as both functional timepieces and sophisticated decorations. These clocks often feature ornate wooden carvings and intricate designs, with their gentle ticking and chimes adding a cozy ambiance to living spaces.A small vintage decoratively carved dark timber steeple mantel pendulum clock with a white cardboard face, black roman numerals and black metal hands. There is a brass trim around the face. The turned wooden frame at the front has has It is in working order. The very ornately white painted pattern on the glass door has a leaf and floral pattern. The door opens with a small decorative brass catch to reveal the inner workings. It has an ornate hanging brass pendulum and the internal workings are visible.There are two spirit plumb levels inside, one is aluminium metal and is attached to the wall. There is a brass key which does not wind the mechanism. clock keys, clock components, timepieces, clocks, mantel clocks -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Nell Gwynne Mine Site, 1934

Significant to mining history of Bendigo.Black and white photograph of Nell Gwynne mine site. Bottom level of metal headframe on left hand side of image, three men working on wooden construction immediately in front of headframe.Written in pencil on back of photograph in pencil:' Erecting Nell Gwynne Sinking Winch 16/2/35'nell gwynne gold mine, shaft, gold mining, sinking winch, headframe -

Bendigo Military Museum

Bendigo Military MuseumEquipment - WATER BOTTLE, C.WW1 onwards

.1) Khaki felt cover in leather strap harness, metal top cork attached with cord. .2) Adjustable leather shoulder strap attached through rings on harness.military equipment - kit, containers - drink consumption, trades - leather working, passchendaele barracks trust -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTrophy - Tawonga South Tennis, 1950

The Tawonga South Tennis Club commenced in 1946 and was situated on the last property on the riverside before the Tawonga South bridge where there was also a kiosk. Tennis was very popular in the Kiewa Valley with the influx of players available from the Kiewa Hydro Electric Scheme. In the Bogong-Tawonga Tennis Association there were three Bogong teams - Cope, McKay and Beauty with the other teams from Tawonga called Wanderers, Rovers, Pines and South Tawonga. Reported in the SEC magazine, Oct--Nov. 1946 Page 45:- "The membership now totals eighty, and both Bogong courts are in continuous use during week-ends and in the evenings and early mornings." There were clubs & teams in Bogong, Mt Beauty and Tawonga. This trophy indicates that there was a tennis association at Tawonga South in 1950. In 1945 the Tawonga South school was set up to serve the children of the State Electricity Commission of Victoria employees. The school was extended from one room to two in 1955 to avoid congestion. This would indicate that the population would have been sufficient for a tennis club as well. In the SEC Magazine 1946 Page 45:- "South Tawonga Tennis Club has arranged social functions to raise funds, and working bees are busy on the erection of a tennis court. The president is Mr. N. Piera, the secretary Mr. H. Wilson and the treasurer Mrs. W. Griffiths.Tarnished metal trophy with cup and two, extending above the cup, handles either side. The cup is raised by a decorated stem which is attached to a brown plastic hexagonal base. Tawonga South Tennis / Association 1950 / Donated by G.T.Kennedytennis. tawonga south. g.t. kennedy. kiewa valley. sport. club -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDomestic object - Tin Match Box

By the close of the 19th century, colonial children in Australia (especially poorer ones) were expected to work by age 10 or 11. Boys could become apprentices or assistants to trades such as butchers, printers, carpenters, bakers, smiths or services such as delivering newspapers. Girls could work as domestic servants, seamstresses, or in large clothing factories or weaving mills. Girls as young as 6 could work in cities selling stationary or matches to passers-by. In the 1880s workers in matchstick factories, predominantly women and young girls (4-16 years old) from working-class families could work up to 14 hours a day and were exposed to deadly phosphorous vapours on a daily basis. This led to the devastating disease known as “phossy jaw” or “phosphorous necrosis of the jaw” which caused the jawbone to rot. This small rectangular tin matchbox with raised writing on top would once have been gold and brightly coloured. It has a metal striker on the inside as this type of match contains phosphorous which is volatile and can be lit by friction. Duncan's Waterproof Wax vestas -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Tube, Endotracheal, Kuhn, Circa 1900

The evolution of endotracheal intubation for anaesthesia was a slow process. Franz Kuhn (1806-1929), a head and neck surgeon working in Kassel, Germany, between 1902 and 1911, is said to have done more than any other to obtain general recognition for endotracheal anaesthesia. Kuhn's tube, is a flexible metal one inserted on a stilette which was then withdrawn. The tube was then secured with an elastic neck strap and connected by a rubber tube to a Trendelenburg cone. The glottis was packed with oiled gauze. Metal spiral tube with elaborate handle at one end and rounded at the other. There is a metal clasp at the base of the handle which all forms part of the endotracheal tube. Inside the tube is a curved metal piece that functions as an introducer.kuhn, endotracheal, airway, intubation