Showing 340 items

matching recycling

-

Glen Eira Historical Society

Glen Eira Historical SocietyArticle - Glen Eira Parks and Gardens

... Recycling ...This file contains four items. 1/ An article in the Glen Eira News reporting on a new park with indigenous planting and an interpretive walk being developed to link Duncan McKinnon Reserve and Packer Park in Murrumbeena, dated September 2000. 2/ An article from the Glen Eira Leader on the converting of sports grounds from cool season to warm season grasses, as well as the installation of subsurface drip irrigation at Princes Park, Caulfield South, dated March 2012. 3/ An article from the Caulfield/Port Phillip leader reporting Caulfield RSL military historian Carl Johnson’s appeal to have a “lone pine” in Caulfield Park designated as a war memorial, dated 11/9/2012 4/ An article from the Glen Eira/Port Phillip Leader reporting on the Friends of Caulfield Park organising the first band stand concert in over twenty years with the City of Glen Eira Band, dated 6/11/2012glen eira council, hawthorn rd caulfield, glen eira rd caulfield, glen eira, caulfield, parks, reserves, leila rd caulfield, glen eira city council, landscaping, memorial park, kooyong rd caulfield north, caulfield recreation tennis club, murrumbeena rd caulfield, churchill green housing estate, north rd caulfield, boake street caulfield, exservices organisation, rsl clubs, sporting clubs, recreations, sportsgrounds, clubs, tennis clubs, associations, leisure, cultural events, cultural activities, sports establishments, recreations establishments, irrigation, water conservation, conservation of natural resources, water supply, ovals, playing fields, tennis courts, murrumbeena park, school concerts, musical activities, musical events, glen eira artists society, dimarco lisa, st. aloysius college, band rotundas, entertainment structures, musical ensembles, city of glen eira band, bands, the friends of caulfield park, gallipoli lone pine, princes park, packer park, duncan mckinnon reserve, king george reserve, caulfield park, glenhuntly park, glen huntly park, bentleigh reserve, victory park, schools, education establishments, recycling, water disposal, cultural structures, cultural establishments, caulfield rsl, johnson carl, war memorials, monuments, memorials, avenue of honour, “lone pine”, glen eira leader, glen eira news, caulfield/port phillip leader, glen eira leader -

Eltham District Historical Society Inc

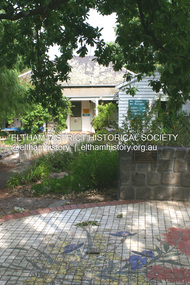

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Eltham Living and Learning Centre, 26 January 2008

In 1857, tanner John Pearson purchased three and a half acres of land in Little Eltham, at the western end of Pitt Street, with a 70-foot frontage to Maria Street (Main Road) and stretching down to the Diamond Creek for £100. He contracted Benjamin Oliver Wallis to build house for him. Wallis, a mason by trade who originated from the Cornish village of Newlyn, migrated to Melbourne in 1853 and was shortly engaged by Richard Warren to build the Eltham Hotel, which opened in 1854. When Warren fell into financial difficulty in 1858, Wallis purchased the hotel. That same year, Pearson constructed a tannery below the house with access to the water in the Diamond Creek. When Pearson became bankrupt in 1867, Wallis similarly acquired the house from Pearson’s creditors in 1868 and lived there until his death in 1896. For some of this time the house was in the name of Wallis’s son Richard but following his death in 1888, ownership reverted to his father. It was purchased by retired teacher Richard Gilsenen in 1899. Gilsenen was made acting head teacher at the Eltham State School in 1906 following the sudden death of head teacher John Brown. In the 1950s the house was bought by retired engineer Dr Alfred Fitzpatrick and his wife Claire who made various modifications to house goats and poultry as well as structural modifications to the house. In the early 1970s, Eltham Shire Councillors Frank Maas and Don Maling proposed an extended communities’ activities program be set up and the Commonwealth Grants Commission was approached for financial assistance. In 1974 a $50,000 Commonwealth Grant was received by the Shire Council to acquire the Fitzpatrick property as part of the planning to establish an extended communities’ activities program. The Fitzpatricks moved next door and Claire taught at the new Living and Learning Centre, which began in 1975, one of the first community education centres in Victoria. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p59 It’s a centre for sharing knowledge and friendship and it stands on the former hub of Eltham’s original township near Pitt Street. The Eltham Living and Learning Centre, with around 2000 participants a year, began in 1975 as one of the first Community Education Centres in Victoria. Classes ranging from macramé to wine making to environmental living have enriched the lives of thousands of people through the generosity of tutors sharing their skills free of charge. The centre’s heart is the brick cottage, built in 1858 by tanner John Pearson. He bought the three and a half acre (1.4ha) allotment fronting Maria Street (now Main Road) and stretching down to the Diamond Creek. The allotment formed part of a 316 acre (127.8ha) subdivision, owned by Josiah Holloway, called Little Eltham, north of the original Eltham Reserve.1 The allotment then passed through the hands of several speculators before it was sold to Pearson for £100 in 1857. Mr Pearson’s children attended the Eltham Primary School from 1864 to 1867. But creditors took possession of the property when his tannery folded in 1867. It was then sold to publican Benjamin Wallis, who owned the Eltham Hotel at the corner of Pitt Street and Main Road. In 1899 the property was bought by Richard Gilsenan, who became acting head teacher of the Eltham Primary State School in 1906. In the 1950s, retired engineer Dr Alfred Fitzpatrick and his wife Claire bought the property, and made structural changes. Claire, a journalist and community campaigner, modified and built pens for goats and poultry, a stable, a garage and planted fruit trees and a vegetable garden. In the early 1970s a young woman called Carina Hack approached Gwen Wesson at the Diamond Valley Learning Centre (Victoria’s first Community Education Centre) about starting a community centre. Following Wesson’s suggestion, Hack spoke to Shire President Alistair Knox ‘one bleak rainy afternoon, sipping hot drinks and discussing life’.2 Eltham Shire Councillors Frank Maas and Don Maling proposed a community activities program and the council received a $50,000 Commonwealth Government Grant for this venture.3 The Fitzpatricks sold their property to the council and moved next door and Claire taught at the new centre, which Hack named. Eltham obviously wanted such a centre as Hack recalls. ‘During the next two months we had about 50 volunteers working day, night and weekends, scrubbing down, plastering and painting walls, replacing floors, repairing fences, recycling furniture, sewing curtains and cushions, donating furniture, toys, equipment, clean-ing and gardening…’4 The first enrolment day saw a queue stretching up the driveway nearly to the gate and the first sessions attracted 270 people a week. Soon the outbuildings were converted into pottery studios and a large workshop. From 1979 the Eltham Art and Craft Market was held in the centre’s grounds and the Friends of the Centre ran it from 1980. A former program coordinator, Margaret Johnson, remembers enrolment day in the late 1970s and 1980s, when hundreds of people would queue – and some even camped overnight! Overnighters were greeted in the morning with fresh tea and toast. Another tradition was The Enrolment Day Cake with Recipe, given to volunteers. ‘One happy Enrolment Day fell on February 14 and let’s just say that St Valentine found some willing participants, paying $2 for a kiss.’5 Meanwhile the participants’ children could play at the Council Eltham Lower Park house in Hohnes Road, later in Susan Street. But the centre has had difficulties too. In 1990 a fire destroyed the stable and the police suspected arson. However the pavilion was built in its place.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, benjamin oliver wallis, claire fitzpatrick, don maling, dr alfred fitzpatrick, eltham living and learning centre, frank maas, john pearson, richard gilsenen, tannery -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Edendale Farm Homestead, 29 January 2008

Edendale Farm is Nillumbik Shire Council's environment centre situated in Gastons Road, Eltham between the railway and the Diamond Creek. The homestead on the property was built in 1896 and is of historical significance, being the subject of a Heritage Overlay under the Nillumbik Planning Scheme. The Edendale property was originally part of an extensive land purchase in 1852 from the Crown by pioneer Eltham farmer Henry Stooke. He initially purchased 51 acres and later expanded his holdings by purchasing another three adjacent Crown allotments extending northerly from Josiah Holloway's Little Eltham subdivision. Despite clearing the land, Stooke did not build on this property, choosing to live on his property "Rosehill" at Lower Plenty. In 1896 Thomas Cool, Club Manager of the Victoria Coffee Palace in Melbourne purchased 7 acres of the original Stooke land and built the house now known as Edendale. Cool did not farm the land, instead using it as a gentleman’s residence, retiring to Eltham at weekends. In 1918 he purchased an additional 7 acres but in 1919 he sold the property. Later owners included J.W. Cox, the Gaston family and D. Mummery. In the 1980s the Eltham Shire Council purchased the site for use as a Council depot, but this use did not proceed. Subsequently, it was used as the Council pound. The Edendale Farm Pet Education and Retention Centre was established in the summer of 1988/1989 and was set up to replace the existing dog kennels with a high standard pet retention centre. The design style of the building was established to compliment the features of the existing house. It was equipped with 10 retention pens, a veterinary room and a pet education area where school children and other interested parties learnt about pet care procedures. It was later developed into a community farm and was run by an advisory committee and in 2000 it became an Environment Centre. In early 2006 an advisory committee was established for the development of a master plan for future development at Edendale Farm. The committee included Russell Yeoman, a former long-time shire planner and founding member of the Eltham District Historical Society. At the time of filming the Master Plan and future for Edendale was about continuing to develop Edendale as a centre of environment learning and looking at expanding displays and school program, running a lot more of life-long learning and workshops around sustainable living. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p101 A sharp turn from busy Wattletree Road by the railway line, brings a surprise. Only 1.4 km from Eltham’s centre, sheep feed, blissfully unaware of the hectic suburban activity so close by. At the entrance to the 5.6ha Edendale Farm is another surprise. A work of art that looks like huge tree trunks transformed into bowler and top-hatted men. The Fences Act 1968 by Tony Trembath with Mark Cain and John Doyle, 1996, is classified by the National Trust of Australia as having Regional Significance. The title refers to a government act on disputes between neighbors over the placement of fences and boundaries. This takes a ‘wry swipe’ at a community divided by trivial squabbles. It also celebrates making do with limited resources.1 Further along on the left, the office wall is decorated with a massive Eltham Copper Butterfly, designed by Robert Tickner and made by school children with used plastic bottles and other waste material. Nillumbik Council runs Edendale as an Environmental Education Centre, to help preserve and enhance the local environment. As early as 1988 the former Eltham Shire Council realised Edendale’s importance in meeting people’s needs, particularly of children, to enjoy farmland. The centre, with the Eltham North Reserve to the north - including remnant bushland and open parkland - makes up the major part of the public open space for this area. The council considers this area will become increasingly important to the local community for recreational use.2 Educational programs aim to encourage community involvement to ensure the long-term rehabilitation and protection of natural bushland areas. Edendale is used by people of all ages - from school children to adults - for environmental programs and workshops, as well as for recreation, to enjoy the domestic animals and to picnic. Edendale is also home to the Environmental Works staff who manage reserves and roadsides and support Nillumbik Friends environmental groups. The Friends propagate plants at the nursery, which grows indigenous plants and sells these to the public.3 The centre demonstrates the sustainable living the farm teaches, with features like solar hot water and drive lighting and for the fireplace, logs of recycled cardboard. Edendale has had a varied history as a dog pound and even as a retreat for Thomas Cool, Club Manager of the Victoria Coffee Palace in Melbourne. His single-storey weatherboard house built in 1896, which still stands, was grander than most homes in Eltham. Although such buildings were common in many other parts of Melbourne, Eltham’s poverty and remoteness did not encourage such construction. The Victorian rectangular-shaped house, with a corrugated iron roof and veranda, has elegant large rooms, leadlight windows, ceiling roses, two bay windows and ornately carved wooden fireplace surrounds. Cool bought seven acres (2.8ha) from pioneer Eltham farmer Henry Stooke’s 200 acre (81ha) farm, which he had bought from the Crown in 1852. In 1918 Cool bought an extra seven acres (2.8ha) but in 1919 sold the estate to farmer John Cox. In 1933 Cox sold Edendale to Mrs Elizabeth Gaston, after whom the road leading to the centre was named. The property was owned by several Gaston family members, who called it Edendale, then by a police constable, Douglas Mummery, until the Shire of Eltham bought it in 1970. Oddly Edendale was known as Mummery’s for almost 20 years, although Mummery owned it only for a short time.4 The shire used Edendale as a dog pound until amalgamation with other municipalities in 1996. The pound then moved to the Yan Yean Road, Plenty site, which had been used by the former Diamond Valley Shire Council. To the west and north the centre is bounded by Diamond Creek and on the east by the Melbourne-Hurstbridge railway line. Part of the Research creek forms the centre’s southern boundary.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, edendale farm -

Ballarat Tramway Museum

Ballarat Tramway MuseumEphemera, Wal Jack, Wal Jack notebook, 1940's

Demonstrates Wal Jack's records, hand written in a recycled notebook. Note - several sheets have been cut from the book - appear to be done before use by Wal. The crossed out sheets have not been imaged - these have been transferred by Wal to Reg Item 5507 and re-ordered. Image 30 shows a sample of a crossed out page. See related documents for a pdf file of the contents. Scan No. BTM5623iX Page No. Title or Subject Notes 1 Front 2 Inside Cover Addresses for Jack McLean, John Buckland Trooper Larsen Inside front cover. 3 1 Note re NSWT steam tram motor, MMTB PCC import issues, Peter Duckett seeking info and Photo of Julien’s battery tram on test in Melbourne 4 2 MMTB No. 8, 4, photos, Tyrell’s of Sydney photos, Perth 63 dimensions and MMTB plans for Domain Road & St Kilda Rd Jtn. 5 3 Notes re NSWGR P32, VR locos at Wodonga 13/10/1941, SAR V Class V143, SAR locos – W and Wx 6 4 NSW Private locos, Woy Woy quarry and AGL at Mortlake 5 Blank 6 Blank 7 7 First cable trams – links to photos T154, 29, 154 (Adelaide) 8 8 T156, Powelltown, Ray Pearson Negs 9 9 QR B18 ¼ locos, Ray Pearson’s scrap book, PMTT Zeppelin style trams, MMTB T class locations and 178/179 rebuilding. 10 10 Hawthorn horse tramway, VR Black Rock terminus sketch 11 11 NSW Tramways, Ryde, MMTB L class, Geelong tramway notes 12 12 Locomotive “Ballarat” in WA, Brisbane and various contacts. 13 13 Notes re VR News – 1943, H class, derailments, max speeds, Koondrook tramway and Geelong level crossing. Individual typed sheets pasted onto page – loose within book. 14 to 17 14/17 List of MMTB trams to 877 and work trams Some errors noted. 18 18 Newspaper cutting – Tram Record Day revenue (Brisbane 10/1943), Steam Trams at Journey’s end – Sydney – 6/1943 list of equipment being sold by Sydney Ferries, at Parramatta, 6/1943. MMTB Tram crossings in Melbourne, list of Sydney photos sent to Wal. Cuttings and Individual typed sheets pasted onto page. 19 19 Midland locos WA, VR open wagon stencils and a siding at Mt. Evelyn. Individual typed sheets pasted onto page. 20 20 Note re Sydney four wheel tourist trams and Hawthorn Max. Traction cars locations c1945. 21 to 23 21/23 Notes on Geelong Bogie trams and carrying flags for declaration of Newtown and Chilwell as a city – 1/10/1949 (See also Reg Item 5641) 24 to 26 24/26 Notes on Wellington Corporation Tramcars 37 27 Kelburn – Karoi cable line Wellington 28 to 29 28/29 Auckland Tramway Board tramcars notes 30/31 Blank 30 32/33 Notes on Ballarat tramcars – ESCo Crossed out 34/37 Ditto – SEC Crossed out 38 Music for the people notes Crossed out 39 Notes on Ballarat trams with tail lights Crossed out 40/43 Notes on Ballarat bogie trams Crossed out 44/45 Notes on SEC tram controllers, dead man and truck lengths. Crossed out 31 45 List of Ballarat Destination roll – Dec 1949 32, 33 46/47 Notes on Bendigo Bogie Trams – 1940’s 34 48 Bendigo Destination roll on a Birney tram Easter 1950, notes on tram tail lights and fares on the Bendigo system. 49 Blank – though headed “Bendigo Birney Trams” 50 Notes trams used on special days in Ballarat Crossed out 51 Ditto and No. 24 and 23 Crossed out 52 Ditto, 15, 11, 23 and Gold tram Crossed out 53 Notes on 34 caused delays, 5/1950, and use of 23 as gold tram Crossed out 54 Notes on repair to track at Sturt and Drummond 6/1951 Crossed out - see Reg Item 7720. 55 Notes on track work in Ballarat early 1950’s Crossed out 56/57 Notes on 33, 37, pay as you enter signs and 1953 special workings Crossed out 58/60 Notes trams used on special days in Ballarat Crossed out 61/64 Blank 35 65 “Salute to the Cable Tram” – transcription of text from Truck and Bus Transportation (July 1948) 36, 37 66/67 Continued from above and list cable tram routes, opening, closing, length and route colours. 38 68 List of photos in Truck and Bus Transportation, Anniversary Issue July 1948 of cable trams. 69 Blank 39 70 Notes on Brunswick TT, Fitzroy TT colours, Adelaide Service trams and MMTB route lengths. 40 71 Notes on HTT colours, tramcars, PMTT trams and colours and NMETL colours, trams and route destination signs 41 72 Notes on MMTB routes, cable and other Melbourne tram disposals, and sale of cable trams and storage at Brunswick. 42 73 Blank - page was headed Lugarno, Switzerland and Italian border 42 Handwritten sheet – photos to get – R. Field and Peter Duckett. 43, 44 74/75 Listing of trains on all lines leaving Ballarat and days run. 45 77 Listing of negatives sent to K. Rogers in 1944 and list of MMTB Max. Traction bogie trams 117 to 138 and disposal 46 77 Listing of MMTB trams, - appears to be something to do with photos or negs held. 47 78 Listing of Ray’s (Pearson) negs /photos of Brisbane trams and other railway photos. 79 Blank 48 80 Prices of pine timber in 4/1942, list of photos “I want”, notes re VR Train length, Ironbark Gully bridge, 3817 in Harden smash 7/1948 and 1948 Ballarat destination roll. Partly crossed out. Rear Cover. Has a strong association with Wal Jack, his work to collect and record both railway and tramway information. Yields information about tramways in Ballarat, Bendigo, Geelong and other cities tramways and railways.Grey covered book with black binding containing 40 lined sheets (80 pages) with handwritten notes with the front cover partly cut out and the words "Jewellery & Engraving" book written in. Contains some newspaper clippings and pasted typed notes as listed below. The image number of each sheet is given. See individual pdf files. trams, tramways, mmtb, ballarat, bendigo, sydney, brisbane, railways, geelong, new zealand, victorian railways, sec, esco -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Great Hall, Montsalvat, 8 January 2008

Great Hall at Montsalvat built 1938-52, designed by Justus Jorgensen Covered under National Estate, National Trust of Australia (Victoria) State Significance, Victorian Heritage and Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p129 At first glance, Montsalvat, the artists’ community at Hillcrest Avenue, Eltham, could belong to another time and place. The French provincial Gothic-style buildings blend picturesquely with the introduced and native trees and farm animals on the five hectare property. But Montsalvat belongs very much to today’s Eltham, having inspired much of its creative activity and style. The use of mud-brick and recycled building materials, for which Eltham is so well-known, was largely popularised by Montsalvat. Montsalvat – unique in Victoria and probably in Australia – is registered by the National Trust and National Estate.1 Montsalvat, named after the castle of the Knights of the Holy Grail, has attracted artists and intellectuals since it was founded in 1934. For years at weekends, artists, lawyers, philosophers, politicians and others, who shared a love for what Montsalvat stood for, gathered for a meal and stimulating discussion. The focus for this gathering of talent was Justus Jörgensen, an eccentric man with vision and charisma. It was Jörgensen’s foresight that saw the creation of Montsalvat, which in 1975 was formed into a trust to benefit the Victorian people. The property was then valued at about three million dollars. It is now visited by thousands of people annually. Born in 1894 and brought up a Catholic, Jörgensen had trained as an architect. He later studied painting at the National Gallery School under artist, Frederick McCubbin, then joined the studio of artist Max Meldrum. In 1924, Jörgensen married medical student Lillian Smith, and with artist friends they travelled to Europe to study the great masters. In London Jörgensen exhibited in several major galleries. One of his still life paintings was included in the book The Art of Still Life by Herbert Furst, which featured 100 of the greatest ever still life paintings.2 In 1929, Jörgensen returned to Melbourne where Lil, now qualified, worked as an anaesthetist at St Vincent’s Hospital. They bought a small house in Brighton and Jörgensen rented a large building in Queen Street for his studio until the Royal Automobile Club of Victoria bought it in 1955. While designing and overseeing the building of a studio for his friend the famous cartoonist Percy Leason, in Lavender Park Road, Jörgensen decided to buy land for a country retreat in Eltham. So the building of Montsalvat began. Jörgensen gathered around a dozen of his friends and students from his Queen Street studio. They set to work, first at weekends then some decided to live permanently on the site. Jörgensen had seen mud-brick buildings in Spain and recognised that Eltham’s clay soil was ideal for mud-bricks and although labour intensive, it was a very cheap way of building. Jörgensen’s students and friends worked under his direction with the help of local tradesmen, including carpenter, Len Jarrold and later stone mason, Horrie Judd. In return Jörgensen would give the students a painting lesson or two. It was the Great Depression when many were out of work. Jörgensen also inspired people to give generously of money and materials. With their help Jörgensen found second-hand materials for building. Friends donated slate for roofing, discarded firebricks were used for flooring and windows and doors and a cast-iron circular staircase came from a wrecker. The students’ day started at 7am with building and domestic chores, shared equally between the sexes. The first building was used by his friends at weekends and then became a home for his wife Lil. It consisted of three rooms and an attic under a high-pitched roof. Jörgensen then built a similar structure with the same high-pitched roof as a more permanent home for his students. The two buildings were joined together with a tower and a studio for Jörgensen. While excavating for the studio a reef of yellow mud-stone was found and then used in construction. The next building was the Great Hall, to be used for dining, exhibitions and meetings and completed in 1958, after a halt during the war. Whelan the Wrecker donated the stone-framed windows from the building that housed the Victorian Insurance Co. in Collins Street, which had been demolished in the 1930s. The swimming pool was donated and cubicles were built for the students with their initials marked in tiles on each doorstep.1 One of Jörgensen’s great abilities was to recognise how to use material which harmonised. He would comb through wreckers’ yards for what he needed. Regarding his buildings as sculptural pieces, his first consideration was for the aesthetic quality of a building and only then for its functionality.2 At Montsalvat, Jörgensen found he was able to put his ideas into practice without compromise and those who worked with him had to conform to his ideas. With the Jörgensens, the colony’s original nucleus consisted of the Skipper family – Mervyn and wife Lena, daughters Helen and Sonia and son Matcham,who was to become an eminent jeweller and sculptor represented in National Gallery collections throughout Australia and in European museums.3 Other members were Arthur Munday, Lesley Sinclair, Helen Lempriere, Ian Robertson, John Smith, George Chalmers, John Busst and Sue Van der Kellan; also Jörgensen’s three sons – Max, Sebastian and Sigmund – and Saskia, Sonia Skipper and Arthur Munday’s daughter. Montsalvat went through some hard times when local gossips spread rumours of sexual shenanigans at Montsalvat. However Montsalvat also had many local supporters – especially amongst the local tradespeople. The colony was certainly unconventional – with Jörgensen’s wife Lil (and son Max) and life-time partner Helen Skipper, (mother of Sebastian and Sigmund) living at Montsalvat. Sonia Skipper says in her biography that the group were ‘very conscious of their responsibilities to each other and a desire to make their relationships work’.4 By World War Two many buildings around the Great Hall were completed. Jörgensen was a pacifist, as were most of his students. Some of the Montsalvat community enlisted while others engaged in essential services like dairy farming and market gardening for the war effort. It was then that Jörgensen constructed farm buildings. After the war many well-known personalities such as Clifton Pugh, landscape gardener Gordon Ford, and builder Alistair Knox, were drawn to Montsalvat. They learnt that building was not a ‘sacred cow’ only for professionals, but that anyone who was willing to get their hands dirty could do it. The post-war shortage of materials also encouraged builders to follow Montsalvat’s lead in reusing materials. When Jörgensen died in 1975, his influence did not – thanks largely to the vigilance of his son, Sigmund, who became its administrator. The weekend dinners have gone, but in 2008 about 14 artists still work at Montsalvat – some living there – including a couple who have been there since its early days. Under Sigmund’s direction Montsalvat further expanded its activities which included festivals, art exhibitions, concerts and weddings. Sigmund completed the Chapel, then the Long Gallery next to the pool, After the barn burnt down, he replaced it in 1999 (the builder was Hamish Knox, Alistair’s son) with a new gallery and entrance and added a restaurant. Sigmund has been careful that any new building blends in with the character of Montsalvat. In 2006 Montsalvat was restructured for its continued financial viability and with the help of Arts Victoria a new executive officer was appointed. A representative board from the wider community was established, which includes members from the former Montsalvat Trust including Sigmund Jörgensen – who is now the heritage and arts adviser to the new company Montsalvat Ltd.5 Today, visiting Montsalvat one still sees artists, students and visitors enjoying the unique and beautiful surroundings.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, great hall, montsalvat -

Flagstaff Hill Maritime Museum and Village

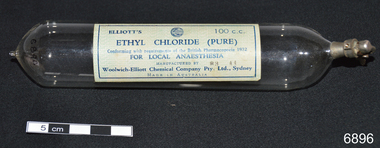

Flagstaff Hill Maritime Museum and VillageContainer - Medication Ampoule, Woolwich-Elliot Chemical Company Pty Ltd, Sydney, 1930s

This anesthetic ampoule, once containing pure Ethyl Chloride, was used from the 1930s to sedate patients before an operation. It was made and distributed by Sydney company Woolwich-Elliott Chemical Company Pty Ltd. The company had a recycling program, as indicated by the lable offering "6d [6 pence] will be allowed on return to us in good order and condition". This ampoule was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’s own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The anesthetic ampoule, once containing pure Ethyl Chloride, is an example of the medication used in surgery in the early to mid 1900's. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Medication ampoule once containing Ethyl Chloride, a pure local anesthetic. Glass cylinder with metal closure, once used in the 1930s, VERY FRAGILE. Part of the W.R. Angus Collection. Contained 100cc; made in Australia by Woolwich-Elliott Chemical Company Pty Ltd, of Sydney. Printed text on label includes "ELLIOTT'S ETHYL CHLORIDE (PURE) 100cc / FOR LOCAL ANAESTHESIA / Manufactured by Woolwich-Elliott Chemical Company Pty Ltd, Sydney / Made in Australia" and "Conforming with requirements of the British Pharmacopeia 1932". Another label is printed "6d will be allowed on return to us in good order and condition"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, surgical preparation, surgical medication, medicaiton ampoule, anesthetic ampoule, pure ethyl chloride, woolwich-elliott chemical company pty ltd, -

Eltham District Historical Society Inc

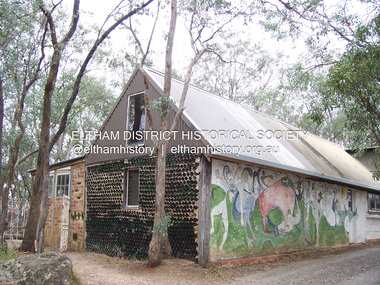

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Art Gallery at Clifton Pugh's Artists' Colony, Dunmoochin, Barreenong Road, Cottles Bridge, 5 February 2008

Art Gallery with mural painted by Clifton Pugh (1924-1990) at his Artists' Colony, Dunmoochin, Barreenong Road, Cottles Bridge. Following military service in the second world war, Clifton Pugh studied under artist Sir William Dargie at the National Gallery School in Melbourne as well as Justus Jorgensen, founder of Montsalvat. For a while he lived on the dole but also worked packing eggs for the Belot family saving sufficient to purchase six acres (2.4 ha) of land at Barreenong Road, Cottles Bridge. He accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in a property of approximately 200 acres, stablishing it as one of the first artistic communes in Australia alongside Montsalvat in Eltham. It was around 1951 that Pugh felt he had '"done moochin' around" and so the name of the property evolved. He bought timber from Alistair Knox to build his house on the crest of a hill. Inspired by local goldminer's huts, it was a one room wattle-and-daub structure with dirt floor. Over the years it expanded with thick adobe walls made from local clay, high ceilings and stone floors. All materials other than the local earth were sourced from second hand materials, most found at wreckers' yards. Artists from across the nation were drawn to Dunmoochin, with several setting up houses and shacks on the property, maintaining their independence but sharing their artistic zeal. Artists who worked or resided at Dunmoochin included Mirka Mora, John Perceval, Albert Tucker, Fred Williams, Charles Blackman, Arthur Boyd and John Olsen. In 2002, Pugh's house along with its treasure trove of art and a library of some 20,000 books was destroyed by fire. Traces of Pugh's home remain with the presence of the Victorian doorframe archway with leadlight of intricate design, procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. In place of Pugh's house rose two double-storey mud-brick artists' studios topped with corrugated iron rooves curved like the wings of a bird with accommodation for seven. The original studios, gallery and other buildings survived the fire. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p153 It’s not surprising that artist Clifton Pugh was drawn to Cottles Bridge to establish his artists’ colony Dunmoochin. Undisturbed by the clamour of modern life at Barreenong Road, Pugh was surrounded by the Australian bush he loved, and where his ashes were later scattered. The 200 acres (81ha) of bushland, broken by glimpses of rolling hills, has more than 50 species of orchids and Pugh shared his property with native animals including kangaroos, emus, phascogales, wombats, and diverse bird life. Pugh encouraged these creatures to join him in the bush by creating, with Monash University, a holding station where the animals were raised. Dunmoochin inspired Pugh for such paintings as in a book on orchids and the Death of a Wombat series.1 But his love for the bush was accompanied by the fear that Europeans were destroying it and much of his painting illustrated this fear and his plea for its conservation.2 However it was his house rather than the surrounding bush that was to be destroyed. Tragically in 2002 Pugh’s house, with its treasure of art and library of 20,000 art books, was destroyed by fire. Traces of the beauty of Pugh’s home still remain, however, in the magnificent Victorian doorframe archway with leadlight of intricate design procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. Now in place of Pugh’s house, are two double-storey mud-brick artists’ studios topped with corrugated roofs curved like birds’ wings, with accommodation for seven. The original studios, gallery and other buildings remain.3 Pugh grew up on his parents’ hobby farm at Briar Hill and attended the Briar Hill Primary School, then Eltham High School and later Ivanhoe Grammar. At 15 he became a copy boy for the Radio Times newspaper, then worked as a junior in a drafting office. Pugh was to have three wives and two sons. After serving in World War Two in New Guinea and Japan, Pugh studied under artist Sir William Dargie, at the National Gallery School in Melbourne.4 Another of his teachers was Justus Jörgensen, founder of Montsalvat the Eltham Artists’ Colony. Pugh lived on the dole for a while and paid for his first six acres (2.4ha) at Barreenong Road by working as an egg packer for the Belot family. Pugh accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in the 200 acre property. They, too, purchased their land from the Belot family by working with their chickens. Around 1951 Pugh felt he had ‘Done moochin’ around’ and so the name of his property was born. Pugh bought some used timber from architect Alistair Knox to build his house on the crest of a hill. Inspired by local goldminers’ huts it was a one-room wattle-and-daub structure with a dirt floor. It was so small that the only room he could find for his telephone was on the fork of a tree nearby.5 Over the years the mud-brick house grew to 120 squares in the style now synonymous with Eltham. It had thick adobe walls (sun-dried bricks) made from local clay, high ceilings and stone floors with the entire structure made of second-hand materials – most found at wreckers’ yards. Pugh’s first major show in Melbourne in 1957, established him as a distinctive new painter, breaking away from the European tradition ‘yet not closely allied to any particular school of Australian painting’.6 Pugh became internationally known and was awarded the Order of Australia. He won the Archibald Prize for portraiture three times, although he preferred painting the bush and native animals. In 1990 not long before he died, Pugh was named the Australian War Memorial’s official artist at the 75th anniversary of the landing at Gallipoli. Today one of Pugh’s legacies is the Dunmoochin Foundation, which gives seven individual artists or couples and environmental researchers the chance to work in beautiful and peaceful surroundings, usually for a year. By November 2007, more than 80 people had taken part, and the first disabled artist had been chosen to reside in a new studio with disabled access.1 In 1989, not long before Pugh died in 1990 of a heart attack at age 65, he established the Foundation with La Trobe University and the Victorian Conservation Trust now the Trust for Nature. Pugh’s gift to the Australian people – of around 14 hectares of bushland and buildings and about 550 art works – is run by a voluntary board of directors, headed by one of his sons, Shane Pugh. La Trobe University in Victoria stores and curates the art collection and organises its exhibition around Australia.2 The Foundation aims to protect and foster the natural environment and to provide residences, studios and community art facilities at a minimal cost for artists and environmental researchers. They reside at the non-profit organisation for a year at minimal cost. The buildings, some decorated with murals painted by Pugh and including a gallery, were constructed by Pugh, family and friends, with recycled as well as new materials and mud-bricks. The Foundation is inspired by the tradition begun by the Dunmoochin Artists’ Cooperative which formed in the late 1950s as one of the first artistic communes in Australia. Members bought the land collaboratively and built the seven dwellings so that none could overlook another. But, in the late 1960s, the land was split into private land holdings, which ended the cooperative. Dunmoochin attracted visits from the famous artists of the day including guitarists John Williams and Segovia; singer and comedian Rolf Harris; comedian Barry Humphries; and artists Charles Blackman, Arthur Boyd and Mirka Mora. A potters’ community, started by Peter and Helen Laycock with Alma Shanahan, held monthly exhibitions in the 1960s, attracting local, interstate and international visitors – with up to 500 attending at a time.3 Most artists sold their properties and moved away. But two of the original artists remained into the new millennium as did relative newcomer Heja Chong who built on Pugh’s property (now owned by the Dunmoochin Foundation). In 1984 Chong brought the 1000-year-old Japanese Bizan pottery method to Dunmoochin. She helped build (with potters from all over Australia) the distinctive Bizan-style kiln, which fires pottery from eight to 14 days in pine timber, to produce the Bizan unglazed and simple subdued style. The kiln, which is rare in Australia, is very large with adjoining interconnected ovens of different sizes, providing different temperatures and firing conditions. Frank Werther, who befriended Pugh as a fellow student at the National Gallery Art School in Melbourne, built his house off Barreenong Road in 1954. Werther is a painter of the abstract and colourist style and taught art for about 30 years. Like so many in the post-war years in Eltham Shire, as it was called then, Werther built his home in stages using mud-brick and second-hand materials. The L-shaped house is single-storey but two-storey in parts with a corrugated-iron pitched roof. The waterhole used by the Werthers for their water supply is thought to be a former goldmining shaft.4 Alma Shanahan at Barreenong Road was the first to join Pugh around 1953. They also met at the National Gallery Art School and Shanahan at first visited each weekend to work, mainly making mud-bricks. She shared Pugh’s love for the bush, but when their love affair ended, she designed and built her own house a few hundred yards (metres) away. The mud-brick and timber residence, made in stages with local materials, is rectangular, single-storey with a corrugated-iron roof. As a potter, Shanahan did not originally qualify as an official Cooperative member.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, art gallery, clifton pugh, dunmoochin, cottlesbridge, cottles bridge, barreenong road -

Eltham District Historical Society Inc

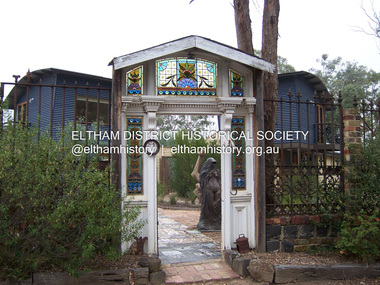

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Doorway of Clifton Pugh's former house at Dunmoochin, Barreenong Road, Cottles Bridge, 5 February 2008

Following military service in the second world war, Clifton Pugh studied under artist Sir William Dargie at the National Gallery School in Melbourne as well as Justus Jorgensen, founder of Montsalvat. For a while he lived on the dole but also worked packing eggs for the Belot family saving sufficient to purchase six acres (2.4 ha) of land at Barreenong Road, Cottles Bridge. He accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in a property of approximately 200 acres, stablishing it as one of the first artistic communes in Australia alongside Montsalvat in Eltham. It was around 1951 that Pugh felt he had '"done moochin' around" and so the name of the property evolved. He bought timber from Alistair Knox to build his house on the crest of a hill. Inspired by local goldminer's huts, it was a one room wattle-and-daub structure with dirt floor. Over the years it expanded with thick adobe walls made from local clay, high ceilings and stone floors. All materials other than the local earth were sourced from second hand materials, most found at wreckers' yards. Artists from across the nation were drawn to Dunmoochin, with several setting up houses and shacks on the property, maintaining their independence but sharing their artistic zeal. Artists who worked or resided at Dunmoochin included Mirka Mora, John Perceval, Albert Tucker, Fred Williams, Charles Blackman, Arthur Boyd and John Olsen. In 2002, Pugh's house along with its treasure trove of art and a library of some 20,000 books was destroyed by fire. Traces of Pugh's home remain with the presence of the Victorian doorframe archway with leadlight of intricate design, procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. In place of Pugh's house rose two double-storey mud-brick artists' studios topped with corrugated iron rooves curved like the wings of a bird with accommodation for seven. The original studios, gallery and other buildings survived the fire. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p155 It’s not surprising that artist Clifton Pugh was drawn to Cottles Bridge to establish his artists’ colony Dunmoochin. Undisturbed by the clamour of modern life at Barreenong Road, Pugh was surrounded by the Australian bush he loved, and where his ashes were later scattered. The 200 acres (81ha) of bushland, broken by glimpses of rolling hills, has more than 50 species of orchids and Pugh shared his property with native animals including kangaroos, emus, phascogales, wombats, and diverse bird life. Pugh encouraged these creatures to join him in the bush by creating, with Monash University, a holding station where the animals were raised. Dunmoochin inspired Pugh for such paintings as in a book on orchids and the Death of a Wombat series.1 But his love for the bush was accompanied by the fear that Europeans were destroying it and much of his painting illustrated this fear and his plea for its conservation.2 However it was his house rather than the surrounding bush that was to be destroyed. Tragically in 2002 Pugh’s house, with its treasure of art and library of 20,000 art books, was destroyed by fire. Traces of the beauty of Pugh’s home still remain, however, in the magnificent Victorian doorframe archway with leadlight of intricate design procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. Now in place of Pugh’s house, are two double-storey mud-brick artists’ studios topped with corrugated roofs curved like birds’ wings, with accommodation for seven. The original studios, gallery and other buildings remain.3 Pugh grew up on his parents’ hobby farm at Briar Hill and attended the Briar Hill Primary School, then Eltham High School and later Ivanhoe Grammar. At 15 he became a copy boy for the Radio Times newspaper, then worked as a junior in a drafting office. Pugh was to have three wives and two sons. After serving in World War Two in New Guinea and Japan, Pugh studied under artist Sir William Dargie, at the National Gallery School in Melbourne.4 Another of his teachers was Justus Jörgensen, founder of Montsalvat the Eltham Artists’ Colony. Pugh lived on the dole for a while and paid for his first six acres (2.4ha) at Barreenong Road by working as an egg packer for the Belot family. Pugh accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in the 200 acre property. They, too, purchased their land from the Belot family by working with their chickens. Around 1951 Pugh felt he had ‘Done moochin’ around’ and so the name of his property was born. Pugh bought some used timber from architect Alistair Knox to build his house on the crest of a hill. Inspired by local goldminers’ huts it was a one-room wattle-and-daub structure with a dirt floor. It was so small that the only room he could find for his telephone was on the fork of a tree nearby.5 Over the years the mud-brick house grew to 120 squares in the style now synonymous with Eltham. It had thick adobe walls (sun-dried bricks) made from local clay, high ceilings and stone floors with the entire structure made of second-hand materials – most found at wreckers’ yards. Pugh’s first major show in Melbourne in 1957, established him as a distinctive new painter, breaking away from the European tradition ‘yet not closely allied to any particular school of Australian painting’.6 Pugh became internationally known and was awarded the Order of Australia. He won the Archibald Prize for portraiture three times, although he preferred painting the bush and native animals. In 1990 not long before he died, Pugh was named the Australian War Memorial’s official artist at the 75th anniversary of the landing at Gallipoli. Today one of Pugh’s legacies is the Dunmoochin Foundation, which gives seven individual artists or couples and environmental researchers the chance to work in beautiful and peaceful surroundings, usually for a year. By November 2007, more than 80 people had taken part, and the first disabled artist had been chosen to reside in a new studio with disabled access.1 In 1989, not long before Pugh died in 1990 of a heart attack at age 65, he established the Foundation with La Trobe University and the Victorian Conservation Trust now the Trust for Nature. Pugh’s gift to the Australian people – of around 14 hectares of bushland and buildings and about 550 art works – is run by a voluntary board of directors, headed by one of his sons, Shane Pugh. La Trobe University in Victoria stores and curates the art collection and organises its exhibition around Australia.2 The Foundation aims to protect and foster the natural environment and to provide residences, studios and community art facilities at a minimal cost for artists and environmental researchers. They reside at the non-profit organisation for a year at minimal cost. The buildings, some decorated with murals painted by Pugh and including a gallery, were constructed by Pugh, family and friends, with recycled as well as new materials and mud-bricks. The Foundation is inspired by the tradition begun by the Dunmoochin Artists’ Cooperative which formed in the late 1950s as one of the first artistic communes in Australia. Members bought the land collaboratively and built the seven dwellings so that none could overlook another. But, in the late 1960s, the land was split into private land holdings, which ended the cooperative. Dunmoochin attracted visits from the famous artists of the day including guitarists John Williams and Segovia; singer and comedian Rolf Harris; comedian Barry Humphries; and artists Charles Blackman, Arthur Boyd and Mirka Mora. A potters’ community, started by Peter and Helen Laycock with Alma Shanahan, held monthly exhibitions in the 1960s, attracting local, interstate and international visitors – with up to 500 attending at a time.3 Most artists sold their properties and moved away. But two of the original artists remained into the new millennium as did relative newcomer Heja Chong who built on Pugh’s property (now owned by the Dunmoochin Foundation). In 1984 Chong brought the 1000-year-old Japanese Bizan pottery method to Dunmoochin. She helped build (with potters from all over Australia) the distinctive Bizan-style kiln, which fires pottery from eight to 14 days in pine timber, to produce the Bizan unglazed and simple subdued style. The kiln, which is rare in Australia, is very large with adjoining interconnected ovens of different sizes, providing different temperatures and firing conditions. Frank Werther, who befriended Pugh as a fellow student at the National Gallery Art School in Melbourne, built his house off Barreenong Road in 1954. Werther is a painter of the abstract and colourist style and taught art for about 30 years. Like so many in the post-war years in Eltham Shire, as it was called then, Werther built his home in stages using mud-brick and second-hand materials. The L-shaped house is single-storey but two-storey in parts with a corrugated-iron pitched roof. The waterhole used by the Werthers for their water supply is thought to be a former goldmining shaft.4 Alma Shanahan at Barreenong Road was the first to join Pugh around 1953. They also met at the National Gallery Art School and Shanahan at first visited each weekend to work, mainly making mud-bricks. She shared Pugh’s love for the bush, but when their love affair ended, she designed and built her own house a few hundred yards (metres) away. The mud-brick and timber residence, made in stages with local materials, is rectangular, single-storey with a corrugated-iron roof. As a potter, Shanahan did not originally qualify as an official Cooperative member.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, art gallery, clifton pugh, dunmoochin, cottlesbridge, cottles bridge, barreenong road -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Tess Justine (Nillumbik Shire Council), Murray's Bridge over the Diamond Creek, Eltham North, 19 Feb 2022

Murray's Bridge over the Diamond Creek on the Diamond Creek Trail just prior to demolition and replacement with a new steel bridge. Heritage advice obtained by Nillumbik Shire Council, following a suggestion by the Eltham District Historical Society (EDHS), is that the original bridge appears to have been a simplified version of the Country Roads Board’s (CRB) standard timber bridge design of the early-to-mid 1920s. In c1990 Murray’s bridge was renovated with three recycled steel girders as part of a bike/pedestrian path in the reserve. During these alterations many parts of the bridge were removed, and some were replaced. Heritage advice indicates the condition of Murray’s bridge is poor. The remaining original parts are all in poor condition, with severe weathering, splitting and rot, especially to the stringers retained on the bridge. Heritage advice is that Murray’s Bridge does not have sufficient significance in the cultural history of the Nillumbik area to warrant inclusion in the Nillumbik Shire Heritage Overlay and also does not have sufficient significance as a rare survivor to warrant inclusion in the Nillumbik Shire Heritage Overlay. There are no indications in the historical record that this site was individually important to the cultural history of this area. EDHS is comfortable with the heritage advice provided to Council and has worked closely on this project with Council. EDHS has suggested some of the removed timbers be used in the vicinity of the bridge for landscaping and possibly seating, so as to retain these remnants close to the site of the original bridge, which is the last old timber bridge along the lower reaches of the Diamond Creek. Mary (Sweeney) Murray and John Wright Murray selected 80 acres, Lot C Section 16 and Lot 5 Section 17 Parish of Nillumbik, under an occupation license in 1866. John died in 1867 and freehold was granted to his son John in 1873. The farm was known as ‘Laurel Hill’. John Junior was an Eltham Shire councillor and sometime president from 1887 up until 1897. He added Lot A Section 16 to the farm in ca1888. John and his younger brother James arranged to rent/purchase Lot B Section 17, across Diamond Creek to the west, in ca1900. It appears that John and James farmed separately for a few years, with a new homestead built for James ad family on the high point of Lot B Section 17 in ca1910. John sold off Lot 5 Section 17 in 1912. When John died in 1912 James took over the land on both sides of the Diamond Creek. The old homestead on the west side of the Creek disappeared. A farm bridge over Diamond Creek from this period may have been located close to the northern boundary of the farm. John Langlands, owner of the farm known as ‘Ihurst’ on the west side of Diamond Creek to the south of the Murray’s land, died in 1907. In 1909 his land was then subdivided into 100 lots to become the ‘Glen Park Estate’. Other similar subdivisions of nineteenth century farms around Eltham in this period included the ‘Franktonia (or Beard’s) Estate’ to the northeast and ‘Bonsack’s Estate’ between Eltham and Greensborough. Soon after the opening of the railway extension line from Eltham to Hurstbridge in 1912, Glen Park and nearby residents including James Murray agitated for a railway station or siding to be located half-way between Eltham and Hurstbridge, so that the Glen Park residents who used the railway daily did not have to walk into the Eltham or Hurstbridge stations. Some believed Coleman’s Corner (opposite Edendale Farm) was an appropriate spot for the platform. James Murray was among those who thought the railway should be located on his land, closer to half-way between Eltham and Hurstbridge stations. The Railways Commissioners warned that the locals would have to fund these works themselves. The Glen Park Estate residents initially had difficulty accessing Eltham by road, with only an old low-level bridge over Diamond Creek at the south end of their estate. A new timber trestle bridge across the creek, now on Wattletree Road, was opened in 1915. Road access to the north was gained in 1927 when the new Murray’s Road, which crossed the Murray’s land, was built. Residents continued to agitate for a Glen Park station. By 1926 the Railways Commissioners’ preferred site was on the Murray’s land. They arranged an estimate of cost of a full-length platform. The estimate was too much for the locals, who in 1928 argued unsuccessfully for a shorter and hence cheaper platform. By 1929 Murray had agreed to donate the land, but the locals would still have to fund the works. Murray decided, unilaterally it would appear, to commence work on a timber trestle road bridge over Diamond Creek to link the new Murray Road to the proposed station. Late in 1929 he stopped work on the bridge, for reasons unknown, but started work again and completed the bridge in 1931. There is no further newspaper evidence of the campaign for the Glen Park station until 1939, when Murray and another local, Mr Maxwell, met the Railways Commissioner. The Glen Park locale now included 45 homes on the west side of the creek and 20 on the Eltham side. Most of the residents used the train every day. The Commissioner remained adamant that only a full-length platform could be built for safety reasons. It appears the campaign dissolved at this point. The increasing move to cars may have had an impact. There is no evidence of Murray’s bridge ever being connected to Murray’s Road, or of it having wide use for any purpose by locals. James Murray died in 1947 and the farm was taken over by his son James (Jim). Jim started to sell off parts of the farm in the 1980s, retaining a few acres around the ca1910 homestead and building a new house there. Recreation reserves were established along the creek. In ca1990 Murray’s bridge was renovated with steel girders as part of a bike/pedestrian path in the reserve. The old farmhouse was demolished in ca2014. * * * A theory posted on local community Facebook groups was that the bridge was built in the 1860s and was built to be more robust than was necessary for the movement of cows from one side of the creek to the other. It was suggested the robustness was necessary to support the weight of gold ore being transferred from a mine on Murray’s land to a railway siding near Murrays Bridge (presumably for transfer and processing at Diamond Creek). Perhaps this may have been one of the motivators for Murray, who really knows? Knowing when mining operations ceased on his land and how that fits the overall timeline would be useful but at the time the bridge was built, local gold production was minimal at best. The known facts are: • The railway line came to Eltham in 1902. • The extension of the railway from Eltham to Hurstbridge was constructed in 1912 so no railway line even existed through Murray's property until 1912 and the Victorian Railways maps at the time show no such siding on Murray’s property. • In 1923 a new company was formed in anticipation of the old Diamond Creek Gold Mine being re-opened. The mine had been previously closed and flooded. It was noted in the press at the time that the mine was within a mile of the railway. Nothing really came of this. • Construction of Murrays Bridge was commenced by James Murray in early 1929 in anticipation of a proposed flag station being nominated on his land, but work ceased shortly afterwards. The proposed flag station was commonly referred to as Glen Park as the residents of the Glen Park Estate wanted Option 1, located near them with the platform adjacent to Colemans corner. This was probably never going to fly as it was virtually in eyesight of Eltham station. Allandale Road was the third option, but the Commissioners' preferred option was No. 2 - on Murray's property. • The Railway Commissioners were not going to finance any such station and the works had to be funded by private landowners and residents, hence Murray investing in this himself. • Murray recommenced work two years later and finished his bridge in 1931 but unfortunately for him, the proposed flag station never eventuated. The bluestone siding you reference may well have been built by Murray as part of the proposed station platform. • Up until then, apart from the Main Road bridge, which was washed away in 1924, virtually all local crossings over the Diamond Creek were low lying bridges – Kaylocks Bridge at Brougham Street, Diamond Street bridge, Glen Park Road bridge. It is expected that Murray also had a low-lying bridge to connect his land either side of the creek. These were all washed away or severely damaged multiple times in the 1920s. Lessons were learnt, and Murrays Bridge appears to have been built in accordance with Country Road Board standards of the time. Flood damage was ongoing, and even more recently constructed raised bridges kept getting washed away, e.g., the new Wattle Tree Road bridge in 1958 just months after completion. Murray’s bridge was reinforced with steel some 30 years ago presumably to provide additional floodwater resistance, given the history of bridges disappearing in floodwaters. • In March 1932 it was reported in the Advertiser that there were still some prospectors operating around Eltham North who apart from further scarring the face of the earth over the previous two years had gained significant experience but little gold - hardly a driving factor for constructing a dedicated railway siding and bridge to transfer gold ore. It is far more probable that James Murray was hoping to have the railway station located on his property and invested his money by building the bridge to lead to it as well as a station platform. Had the station eventuated, it may well have driven up the value of his land for subdivision and new housing estates like the Glen Park Estate. That did not eventuate. Whilst the bridge was indeed old (90 years), the core structure being completed in 1931, it had been modified substantially from original and hence had no significant historic value – i.e., it was not a representative example of its type, construction, and age. Given that the bridge was not worthy of saving, the Eltham District Historical Society with Council’s support, and the Eltham Woodworkers group endeavoured to see what suitable sized timbers were salvageable to fabricate a commemorative seat. Unfortunately, the experts at the Woodworkers group were unable to salvage any suitable length/width timbers to fabricate the seat due to the presence of rot. Last remaining wooden trestle bridge on the Diamond Creek Trail just prior to demolition and replacementBorn digital image (27)diamond creek (creek), diamond creek trail, murrays bridge, ‘laurel hill’, john wright murray, mary (sweeney) murra, john murray jnr, james murray, john langlands, ‘ihurst’, ‘glen park estate’, beard's estate, franktonia, bonsack's estate, glen park estate, glen park railway station -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century