Showing 3965 items matching "milkshake-machine"

-

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Orange jumper with multicoloured heathered tweed effect, white stripe accent on neck, upper arm and sleeve cuffs, two patch pockets mounted on diagonal outlined in thread matching accent colour .2 Sample tags with manufacturing information, including sizes and colours available, as well as knit swatch samples in colourways Blue Tweed/Sky/Magnolia and Cream Tweed/Magnolia/Pine.1) [tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 6 HEIGHT 120cm MADE IN AUSTRALIA .2) [blue sample label] STYLE 589/Pullover S.47. Wool Tweed. SIZES: 2 4 6 8 PRICE: $9.80 [amended to $10.75 in blue pen] $0.35 [handwritten in blue pen] $11.40 COLORS: Pink Tw/Ochre/Mag, Blue Tweed/Sky/Magnolia Cream Tweed/Mag/Pine. [Crossed out in black ink] March on Del.children's knitwear, children's clothing, clothing, knitwear, jumper, manufacturing, fashion textile production, machine knitting, heathered yarn, tweed yarn, flecked yarn, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s jumper with fair isle pattern in shades of cream and orange. Pale orange tweed yarn on chest and shoulders is flecked throughout with red, yellow, blue and green. Vent at centre front closes with three cream plastic buttons. .2 is a swing tag with manufacturer care instructions retail tags size 8 .3 is a sample tag with manufacturing information, including sizes, prices, and colours available .4 is a swatch sample for Magnolia/Navy/Blue Tweed colourway[tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 8 HEIGHT 190cm MADE IN AUSTRALIAchildren's knitwear, children's clothing, knitwear, clothing, jumper, manufacturing, fashion textile production, machine knitting, variegated yarn, variegated, colourwork, stranded colourwork, fair isle, fair isle colourwork, fair isle knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1955-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Pale Blue embroidered jumper featuring a Koala on a tree branch, with green and red foliage and a yellow butterfly embroidered on centre front chest. Jumper has long sleeves and a round collar with ribbed collar and cuffs.[Label at back neck with blue lettering woven into label] KATHRYN REGD ALL WOOL / 24 /CREATED BY ROBERT BLAKEknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, koala, australiana -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown children’s cardigan with embroidery of four baby chicks in yellow and red on green grass at bottom of front panels. Closes at centre front with three brown plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD / 20 ALL WOOL CREATED BY ROBERT BLAKEchildren's knitwear, children's clothing, clothing, knitwear, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, chickens, chicks, baby animals, cute animals -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red cardigan embroidered with decorative tuck stitches and floral motifs on front panel, crochet around collar in blue, white and green. Closes at centre front with 5 plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD ALL WOOL / 20 /CREATED BY ROBERT BLAKEchildren's knitwear, knitwear, children's clothing, clothing, cardigan, manufacturing, fashion textile production, machine knitting, embroidery, hand embroidery, floral embroidery, floral motif, tuck stitch -

National Wool Museum

National Wool MuseumTextile - Diaper Set, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White diaper set. Short sleeved white top with two inverted box pleats along whole length, stitched at shoulder and mid chest. Embroidered in half cross stitch with two blue dogs on front. Closes in centre back with three plastic pearlescent buttons. White baby diaper shorts with ribbing at waist and leg holes .3 is a sample tag with manufacturing information, including price, size and colours available .4 is a swing tag with manufacturer care instructions.1 [label at back neck of top] Kathryn Reg’d / All Cotton / 18 .3 [sample label] [Obverse] STYLE: 314. Diaper Sat [sic] – Emb top. Combed Cotton. SIZE: 18” PRICE: 26/- COLOR: BLUE. LEMON. WHITE. [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNE .4 [retail label] [obverse] Kathryn PRE-SHRUNK KNITWEAR Style: 314 [handwritten] DESIGNED & MANUFACTURED BY Robert Blake MELBOURNE [reverse] IMPORTANT. Special care should be taken with white and pastel shades. Rinse thoroughly. Do NOT dry in sunlight. WASHING INSTRUCTIONS 1.Wash frequently to AVOID HEAVY SOILING 2.Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. 3.Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. 4.RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. 5.To dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, then safety-pin to line through shoulder tape. 6.To keep Brushed Wool garments like new brush frequently with nylon brush.children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, embroidery, embroiderer, hand embroidery, dog embroidery, animal embroidery, animal motif, dog motif, dog, animal, baby clothes, baby knitwear, baby clothing -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Three-piece brown and yellow outfit consisting of jumper, pants and hat. Jumper is long sleeved with a high crew neck and five yellow stripes above ribbing along bottom. Pants are brown with wide legs that dramatically taper into the ribbed cuff at bottom. Body of hat is brown and tapers into a long point and has a brown and yellow pompom at the tip. The hat is shaped with a tuck at the back neck near cuff..1 [Label at back neck of jumper with blue lettering woven into label] KATHRYN REGD / 24 ALL WOOL CREATED BY ROBERT BLAKEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms, wool -

National Wool Museum

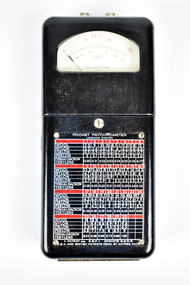

National Wool MuseumInstrument - Psychrometer, Electronova S.A, c.1965

Kathryn Knitwear Collection A Psychrometer is an instrument used to measure humidity using two thermometers, one of which is wet and one is dry. A similar example is housed at laboratoire d'histoire des sciences et des techniques (LHST). Inventory number 603.0509 Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black metal measuring instrument with clear window to view gauge for displaying humidity. Reference table listing values for different fibres is printed in red and white on a black metal plate that is screwed onto the front of the psychrometer. The instrument is housed in brown leather case with zip. It includes a printed paper instruction book with black text and greyscale figures.psychrometer, measuring instrument, humidity, textile manufacturing, fashion textile production -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFootwear - Boots, Rossiters Ltd, 1908-1920

Rossi Boots started in 1910 when Arthur Edward Rossiter resigned from his position as a supervisor at the Adelaide Boot Company and started Rossiters Ltd in a small tin shed in his backyard. A larger factory was needed so the first of three stages of a factory was built. During the Second World War Rossi Boots was a major supplier to the military making hundreds of thousands of boots that saw service in various theatres including New Guinea. The war years saw the number of employees peak at around five hundred. As methods of manufacturing footwear changed as petroleum-based products such as glues, rubbers and plastics have replaced the traditional ones of leather, nails, and threads. More modern machinery was introduced to directly mould soles to the bottom of the boot. At the end of 1987, the company moved from Unley to Hilton this move allowed production to be carried out in a more modern, fit-for-purpose factory. Since then the company has continued to change; introducing computer-controlled machines for cutting, sewing, and attaching soles. These changes occurred whilst many of Rossi's competitors moved offshore. Whilst the introduction of these machines reduced the number of local staff, it has enabled Rossi Boots to continue to manufacture in Australia. In March 2019 Rossi Boots relocated the factory, warehouse, and headquarters from Hilton to Kilburn, South Australia. This move to a new, expansive location allows Rossi Boots to continue manufacturing in South Australia housing all operations under one roof. The items are significant as they show the beginnings of an important manufacturer and innovator that is still in the original founding family's ownership and is producing boots today with exports to many countries. Boots leather lace up brownNonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo, c1960s to c1980s

This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. The Wild A9 Stereocomparator and Wild B9 stereo plotter were introduced in 1962. The Wild B8 stereo plotter was introduced in 1966. Technicians used the Wild A9 Stereocomparator to accurately measure between pass, tie, and survey control points on aerial photographs. The Wild B9 and B8s were used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B9s used a four and a half square, and the B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting with B8 and B9 stereo plotters was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In the early days topographic detail and contours were plotted with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. Black and white and colour photos are on photographic paper and scanned at 300 dpi. .1) - Photo, black & white, c1965. Unidentified technician operating a Wild A9 Stereocomparator. .2) - Photo, black & white, c1965. Unidentified technician operating a Wild B9 stereo plotter. .3) - Photo, black & white, c1967. L to R: Unidentified technician, SPR Ken Jeffery operating a Wild B9 stereo plotter. .4) - Photo, colour, c1974. Unidentified technician, operating a Wild B8 stereo plotter. .5) - Photo, black & white, c1974. Unidentified technician operating a Wild B8 stereo plotter. .6) to .7) - Photo, black & white, c1979. Unidentified technicians operating a Wild B8 stereo plotter. .8) - Photo, black & white, c1985. Unidentified technician in AUTOMAP 2 operating a Wild B8 stereo plotter..1P, .2P, .4P, .5P, .7P – no annotations. .3P – annotated ‘Standing - , Seated SPR Ken Jefferies (sic). .6P – annotated with date ‘1979’ .8P – annotated ‘AUTOMAP 2’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, air survey, photogrammetry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, men's swim costume wool, 'Jantzen', 1930

In 1910, Portland Knitting Company began in downtown Portland, Oregon, with a few hand-knitting machines above a tiny retail store. Little did founders Carl Jantzen, Roy and John Zehntbauer know that they would achieve both fame and controversy as swimwear pioneers. Producing a wool suit for a rowing team they began offering "bathing suits" in their catalog. Knit on sweater cuff machines, the suits became popular with swimmers. The demand increased for those "Jantzens" and the company name was changed in 1918 to Jantzen Knitting Mills. The suits were made of 100% pure virgin wool. Matching stockings and stocking cap completed the costume of the day. Early advertisements guaranteed the famous rib-stitch "gives that wonderful fit". c1930 Jantzen catalogs featured upcoming movie stars, including Loretta Young, Joan Blondell, Ginger Rogers, and Dick Powell. National magazines such as Esquire, the Saturday Evening Post, Life, and Colliers published advertisements illustrated by George Petty. 2010 Jantzen has achieved new levels of success this decade through social media, attracting thousands of fans around the world who share their own memories about their favorite Jantzen suits throughout the decades Early settlers and market gardeners established their families in Moorabbin Shire c1900 and after World War 1 soldiers were assisted to purchase land near the railway line. By 1930 the population had grown with new families who had other occupations - office workers in Melbourne, tradesmen, teachers, etc - and they raised their families in Bentleigh, McKinnon, Ormond, Moorabbin and Cheltenham.Early settlers and market gardeners established their families in Moorabbin Shire c1900 and after World War 1 soldiers were assisted to purchase land near the railway line. By 1930 the population had grown with new families who had other occupations - office workers in Melbourne, tradesmen, teachers, etc - and they raised their families in Bentleigh, McKinnon, Ormond, Moorabbin and Cheltenham. Clothing, men's swim costume wool, 'Jantzen' c1930 clothing, brighton, moorabbin, pioneers, market gardeners, early settlers, moorabbin shire, bentleigh, mckinnon, dairy farms, fruit orchards, swimwear -

Bendigo Military Museum

Bendigo Military MuseumUniform - JACKET, WORK DRESS - ARMY, Australian Defence Industries, 2008

DCPU (Disruptive Pattern Camouflage Uniform) Work dress jacket - Colours light to dark green through to light to dark brown. Gore-Tex fabric for wet weather. Hood with peak and elastic drawstring with plastic lock clip. Plastic/metal two ended zipper and metal press studs - front fastening. Two front pockets with loop and hook (Velcro) fasteners. Two interior nylon mesh pocket with zipper. Sleeves at wrist - loop and hook adjustable strap. White colour polyester fabric manufacturers label on front zipper. Manufacturers information on label - black ink print. Label 1 "GSSM/www.gssm.com.au/MAR 2008/O/N 248007/ N/S/N 8415 - 66 - 145- 7093/ SIZE:L/ CHEST: 100-110CM /NAME/SERVICE" "CARE INSTRUCTIONS/ MACHINE WASHABLE: 40c/ DO NOT BLEACH/ DO NOT SPIN DRY/ DO NOT WRING/HAND TO DRY/ LIGHT/ COOL IRON/ FABRIC CONTENT/ FACE/LINER: 100% POLYESTER/ LAMINATE: PTFE" Label 2. "BATCH NO./5301011". uniform, army, work dress, dpcu -

Bendigo Military Museum

Bendigo Military MuseumUniform - TROUSERS - COMBAT DRESS, ARMY, Australian Defence Industries, 2019

AMCU (Australian Multi Camouflage Uniform) Combat Dress colours - light to dark green through to mid to dark brown. Cotton/polyester fabric. Green colour plastic button. Nylon and metal zipper. Trousers - waist band with belt loops, two front pockets, two large side pockets with zipper closure, two small lower pockets with hook and pile flap closure, zipper fly. green cotton fabric pocket lining. At ankle - elastic drawstring with plastic lock clip. White colour polyester fabric manufacturers label on right pocket lining. Light khaki colour plastic knee pads insitu. Manufacturers information on label - black ink print. "ADA/ MADE IN AUSTRALIA/ FED 2019/ PO: CC3623/ NSN: 84155 66 161 6287/ SIZE 32R ( 79-84 cm/ ^/ NAME:/ PM KEYS:/ MAIN: /75% COTTON/ 25% POLYESTER/ STRETCH:/ 91% NYLON 9% ELSATANE/ KNEE PAD MUST BE/ REMOVED BEFORE/ CLEANING HOT MACHINE/ WASH, NO BLEACH/ NO FABRIC SOFTENERS/ MAY BE TUMBLE DRIED HOT/ DO NOT IRON OVER STRETCH PANELS/ OR HOOK AND PILE".uniform, army, combat dress, amcu -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchTrousers, Australian Defence Apparel, 2015

These trousers are part of a General Purpose Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was developed in 2014 and replaced camouflage as the uniform worn during general base duties and in non-warlike environments. Although a camouflage pattern, this design is not intended for use as camouflage. This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of current Airforce General Purpose Uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating GPU uniform design from the Army alongside the colours and motifs of the Australian Airforce. General Purpose Uniform (GPU) trousers in Airforce colours of blue and grey in camouflage pattern. Long pants with elasticised drawstring fastener at ankle and velcro adjustment fasteners at the waist. Pants take a straight leg style and bears several pockets: two thigh level pockets with zippered horizontal opening, two open hip pockets on the front, one open pocket on the reverse right hand side with blue plastic button fastener. Five large belt loops encircle the waist and there is a zippered fly, secured at the top with a blue plastic button.Label on interior front right of trousers reads: “A193/ADA/MADE IN AUSTRALIA/JUL 2015/ PO: CC2X91/NSN: 8415 66 161 4017/SIZE: 95 R/(broad arrow)/NAME:............/PM KEYS NO:............./75% COTTON 25% POLYESTER/WARM MACHINE WASH 40*C/RINSE WELL, WARM IRON/DO NOT IRON OVER HOOK AND PILE/DO NOT BLEACH/DO NOT STARCH/MAY BE TUMBLE DRY 40*C/DRYCLEANABLE (P)”camouflage, general purpose uniform, airforce, uniform, australian defence force -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMILLIONAIRE (#2) 10 keys

Plaque: ‘Hans W Egli/Ingenieur / Fabrikation von flechenmashinen [sic; ?] / Pat. O, Steiger / Zurich II / No 2566. Sole Agents for Australia / Peacock Bros./ Business Systems Company / 558 , 560, 562 Collins St., Melbourne / and at / Sydney, Adelaide, Perth’ Plaque: ‘Presented to . / Department of Information Science / Melbourne University / by the / Gas & Fuel Corporation of Victoria / This calculating machine was used by Engineers of the Metropolitan Gas Co and Gas & Fuel Corporation / from 1917 to 1970’ -

Stawell Historical Society Inc

Stawell Historical Society IncArchive, Sands & McDougall, Sands & McDougall's Melbourne and Suburban Directory for 1890, 1890

Hard Cover with missing spine Fron cover: Ads for Melbourne Permanent Builing Society Top Half. Austral + Otis + Elevator and Engineering Company Limited. Botttom Worthington Steam Pumping Machinery Printed across the Pages on top of book: The Sweet Hapsburg Pianos & Organs at Wertheim;'s DEpot 59 Swanston Street. Across The Sides of the Pages: Melbourne Suburbs Green Pages Alphabetical Red Pages: Trade & Professional Yellow Miscellaneous Bottom; The Wonderful Wertheim Sewings Machines, Mangels and Washers 59 Swanston Street -

Flagstaff Hill Maritime Museum and Village

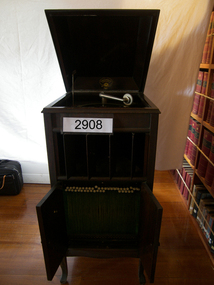

Flagstaff Hill Maritime Museum and VillageGramophone, 1911

Until late 1925, all record players reproduced sound by purely mechanical means and relied on a so-called "amplifying" horn to efficiently couple the vibrations of the stylus and diaphragm to the space occupied by the listeners. In 1906, the Victor Talking Machine Company, Columbia's arch competitor, introduced a line of models in which the horn and other hardware were concealed within a cabinet, made to look like fine furniture rather than a mechanical device. They named the new style a "Victrola". It quickly proved to be very popular and successful. Other makers, adopting the distinctive suffix, introduced their own "-ola" internal horn machines, such as Edison's Amberolas and Columbia's Grafonolas. They were soon outselling the external horn models. At first, like nearly all other early record players, all Grafonolas were driven by a spring motor that the user had to wind up with a crank before playing a record. In 1915, Columbia began to introduce electric-motor-driven models, as a majority of urban areas had been wired to electrical grids. The electrified Grafonolas supported both alternating and direct currents from 110 to 220 volts. Electrified Grafonolas never gained the popularity enjoyed by the spring motor-driven versions due to substantially higher prices and a lack of electrical service in rural areas. Grafonolas were manufactured under the 1886 United States Letters Patent No. 341,214 which Columbia Graphophone company acquired through its predecessor American Graphophone Company. Two models were available; a portable table model and bigger stationary floor model, offering limited mobility through the application of casters. The most notable table models included Grafonola Favorite introduced in 1911 and Grafonola Savoy introduced in 1915. The most notable floor models included Grafonola Symphony Grand introduced in 1907, Grafonola Regent introduced in 1909, Columbia Mignon introduced in 1910, Grafonola Princess introduced in 1911, Columbia Colonial introduced in 1913. Various period Grafonolas were introduced in 1917 to cater to an increasingly prosperous clientele. Columbia Phonograph Company began to manufacture a series of ornate, limited edition period machines. These were highly priced (some as high as US$2,100 ) special orders that provided consumers with options to choose styles which matched their interior décor. Although the Gramophone does not have a large monetary value, it is of social significance as it demonstrates the progress made in audio reproduction from the first Edison cylinder machines to improvements that allowed ordinary people to be able to buy music discs and enjoy music in their own homes. Gramophone with internal horn, floor model, mechanically operated by a crank handle. Colombian Grafonola Princess (Type F2) brand. Gramophone is in a wooden display cabinet with room for record storage underneath and is complete with handle. Manufactured in 1911 by Columbia, USA."Columbia Grafonola Type 2 Made in USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, record player, gramophone, mechanical gramophone, floor model gramophone, gramophone record, columbia graphophone company, american graphophone company, columbia, grafonola, grafonola princess, music, playing music, audio reproduction, sound equipment, domestic entertainment, 1911 gramophone -

Bendigo Military Museum

Bendigo Military MuseumWeapon - TRIGGER PARTS

Various parts of weapon trigger system and trigger guards, Items in the collection of Sgt P.L.James, refer Cat No 7446 for his service details.1. Container - brown rusted metal box with sliding lid. Items 2 - 6 all contained within box. 2. Trigger mechanism - hard curled metal part with curved trigger at one end and swinging lever attached by small screw at other end. 3. Lever tripping - silver metal part of the trigger mechanism of the weapon, highly machined and gear attached to one side. 4. Post spring gear - extended black metal pipe (hollow) with gear mechanism attached to end. 5. Container - various parts of threads, screws, springs etc. 6. Bag and small parts - various screws, bolts and other metal parts.trigger mechanism, ww2 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - COACH BUILDING WORKS

Black and white photograph of a coach building business. Note the number of workers involved in the manufacture of the different styles required by customers. To the right of photo there are a number of workers using machines to manufacture the different body parts that are required. One cart to left of photo appears to be the finished product. Centre top there is a cantilever structure with bodywork stacked on top and a number of wheels, large and small, hanging from the side. There are also a number of wheels hanging from posts of the building framework. Note the differing clothing styles of the workers from shirt, trousers and apron, to hats shirts, waistcoats, trousers. Differing stages of construction have bodies on tables, wooden frameworks, boxes and wooden horses.industries -

Bendigo Historical Society Inc.

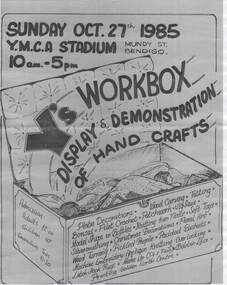

Bendigo Historical Society Inc.Document - Y.M.C.A., Y'S WORKBOX, DISPLAY & DEMONSTRATION OF HAND CRAFTS, 27 October 1985

Event, Bendigo Y.M.C.A., Y's Workbox, Display & Demonstration of Hand Crafts, at The Y.M.C.A. Stadium, Mundy Street, Bendigo, Sunday October 27, 1985, 10am - 5pm. Admission: Adults $2.00 , Children 50c, Devonshire Teas $1.20. Crafts include: Plate Decorations, Wood Carving, Tatting, Bonsai, Filet Crochet, Patchwork, Jigsaws, Model Ships in Bottles, Knitting from Fleece, Soft Toys, Silversmithing, Christmas Decorations, Floral Art, Wood Turning, Pickled People, Padded Baskets, Machine Embroidery, Applique, Knitting, Overlocking, Latchhook Rugs, Make-Up (TV & Films), Bobbin Lace, Printing, Golden North Centre.event, exhibition, bendigo y.m.c.a. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - LONG GULLY HISTORY GROUP COLLECTION: SHOWCASING OUR PAST

Weekender article from the Bendigo Advertiser 20/2/1999 mentioning the push for a museum for Bendigo by John Gascoigne. People including Kathryn Mackenzie, , Heidi Teague, Joan Bolton, David Bolton, Joan O'Shea, Cliff Binks, Frank Cusack, Ted Barkmeyer, Andrew Paul and Peter Tangey were interviewed. There is a colour photo of Joan Bolton with an old printing machine and a black and white photo looking up Mitchell Street. On the back of this page there is another item relating to preserving Bendigo's Past, (from Weekender 17). A black and white photo at the top of the page shows Bendigo in the 1860s looking up Mitchell Street, (Photo courtesy of Frank Cusack).bendigo, history, long gully history group, the long gully history group - showcasing our past, bendigo advertiser 20/2/1999, john gascoigne, golden dragon museum, bendigo pottery, rsl memorial hall, central deborah gold mine, greater city's heritage and historical societies, kathryn mackenzie, bendigo tourism inc, heidi teague, german heritage society, eureka museum, joan bolton, david bolton, bolton bros, joan o'shea, lister house, northern district school of nursing graduates association, department of human services, public records office, bendigo hospital, cliff binks, school of mines, bendigo regional institute of tafe, frank cusack, bendigo junior technical school, national trust chambers, information centre, commonwealth bank, city of greater bendigo, museum victoria, andrew paul, sir john quick, jenny whitelaw, peter tangey, fortuna, george lansell, army's topographical mapping unit, a steele -

Bendigo Historical Society Inc.

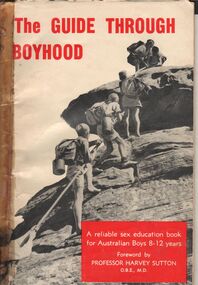

Bendigo Historical Society Inc.Book - AILEEN AND JOHN ELLISON COLLECTION: BOOKLET - THE GUIDE THROUGH BOYHOOD

Small booklet (32 pages) "The guide through boyhood" A reliable sex education book for Australian boys 8-12 years. Foreword by Professor Harvey Sutton O.B.E., M.D. Booklet published by Father and son welfare movement of Australia. Fifth edition April, 1958. Contents - Part 1: The miracle of being born; chapter 1: boys will be boys. Chapter 2: we grow from an egg. Chapter 3: father's help too. Chapter 4: how we start to grow. Chapter 5: growing and being born. Chapter 6: into the world. Part 2: Your body a wonderful machine. Part 3: A lad's friend.books, school, sex education -

Bendigo Historical Society Inc.

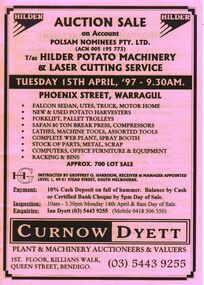

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - POLSAM NOMINEES PTY LTD

Pink paper catalogue with black printing for a sale on account of Polsam Nominees Pty. Ltd. T/as Hilder Potato Machinery & Laser Cutting Service on 15th April '97 at Warragul. For sale were vehicles, potato harvesters, forklift, pallet trolleys,80 ton press, compressors, lathes, machine tools, assorted tools, complete web plant, spray booth, parts, metal, scrap, computers, office furniture & equipment, racking and bins. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - polsam nominees pty ltd, hilder potato machinery & laser cutting service, geoffrey o harrison, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - PETER ELLIS COLLECTION: LETTER

Photocopies of some pages mentioning the Museum. Part of a letter by P H MacGillivray, President, Report on the Botany Class, Report on the Chemistry and Metallurgy Classes, The Museum, including what exhibits, attendance of visitors and opening times. A number of pages of Donations to the Museum from 1/7 1891 to 30/6/1892, including the names and address of the donors. There is a list of the Classification of Specimens (received during the year). Also mentioned is Botany - Lecturer - J B Lillie Mackay and Zoology - Lecturer - J B Lillie Mackay. There is also a part of the printing about Architectural and Geometrical Drawing, Machine and Building Construction - Teacher - W H E Nicolai.museums, peter ellis collection, bendigo school of mines, dr macgillivray, rev j garlick, dr colquhoun, mr g alec thomson, mr j eardsley edwards, dr quick, j m harcourt, j robshaw, r bloomfield rees, j d crofts, w h carwardine, dr dendy, professor marshall hall, professor baldwin spencer, department of education, sir frederick mccoy, baron von mueller, j w faul, john robshaw, henry jackson, j b lillie mackay, melbourne university, mr a south, department of forestry, mr perrin, the pharmacy board of victoria, education department -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - T C WATTS & SON COLLECTION: 62 CARPENTER STREET, BENDIGO, 1930

Black and white photographs (s) mounted on rectangular brown board. House, two storey, brick, roughcast above dado height, upper storey has shingles under windows shingles below front gable. Brick verandah piers with wooden freized upperparts. Two stepped masonry approaches, two event verandahs. Roughcast to lower walls below floor level, lower window with six lights [5 leadlighted] On back of photo ' Phillips, Carpenter Street. £2500 sewered with all furnishing including wireless set but not including sewing machine, piano or organ and £3000 with all furniture'. 2012 photo of house attached to record.bendigo, business, t c watts & son -

Ballarat Tramway Museum

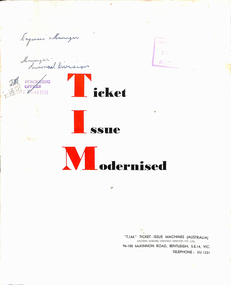

Ballarat Tramway MuseumManual, TIM - Ticket Issue Machines (Australia) and Bentleigh, "Ticket Issue Modernised", c1950

Twelve page book printed on off white paper, side stapled and titled "Ticket Issue Modernised". Details the TIM system, benefits, uses, sample tickets, components, examples of use, TIM "Major" for long distance routes, use for admission tickets, packing slips, cash receipts etc along with sample tickets, costs, cancellation punch and servicing. On the rear has a list of British Transport undertakings using the system and other users. Printed in Australia, c1950; appears to be an Australian version of the English document. See page four for a photo of "The first Australian fleet to be fitted with "TIM" machines" - thought to be Eastern Suburbs Omnibus Services Pty Ltd, Melbourne.On front cover as shown in the photo, receipt stamped of 28 March 1951 and distribution lists.trams, tramways, tickets, ticket machines, buses -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - FAVALORO COLLECTION: PIECE OF SILK FABRIC WITH LACE AND EMBROIDERED INSERT, 1920-30's

Textiles. This is a beautiful remnant of fine cream silk fabric, with a 3.5 cm deep band of cotton lace, woven with a floral design, stitched around the lower edge. A triangular shape above the lower edge, is formed by the insertion of a piece of 2 cm wide cotton lace, also with a floral design, folded and machine stitched as an insertion. The same lace is also inserted in a 9.5 cm high "frame" over an embroidered panel 7.5 cm x 6 cm wide and featuring a delicate circular embroidered and cut-work floral design. (Perhaps this remnant of beautiful fabric was cut from the lower edge of a camisole, or a baby's gown).textiles, domestic, piece of silk fabric with lace -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

Orbost & District Historical Society

Orbost & District Historical Societygramophone record, Ave Maria / Ora Pro Nobis, 1930's-1940's

Zonophone was a record label founded in 1899 in Camden, New Jersey, by Frank Seaman. The Zonophone name was not that of the company, but was applied to the records and machines sold by Seaman from 1899–1900 to 1903. In the United Kingdom and the Commonwealth, the Gramophone Company continued to use the Zonophone label until 1931. 'Zonophone' indicates the British label rather than Zon - O- Phone, the earlier American label. Madame Deering was Eleanor Jones-Hudson. Eleanor Jones-Hudson (1874-1946) was a Welsh soprano and wife of the flautist Eli Hudson. She recorded extensively for the Gramophone Company, in excerpts from opera, operetta, oratorio, ballads and songs. She was sometimes credited as Alvena Yarrow and as Madame Deering. The phonograph disc record was the primary medium used for music reproduction until late in the 20th century, replacing the phonograph cylinder record—with which it had co-existed from the late 1880's through to the 1920's. Records retained the largest market share even when new formats such as compact cassette were mass-marketed.. (ref Wikipedia) This item is an example of an item once commonly found in homes. By the late 1980s until 1991, digital media, in the form of the compact disc, gradually replaced the vinyl record.A black gramophone record with a blue and gold label - Zonophone. One side is Ave Maria sung in English by Madame Deering, a soprano, with orchestra and chorus. On the other side is Ora Pro Nobis (Pray For Us). It has the serial no. 472.Pressed onto the Ave Maris side is 7793-e.zonophone gramophone-record madame-deering-eleanor-jones-hudson ave-maria