Showing 500 items matching "bureau"

-

Bendigo Historical Society Inc.

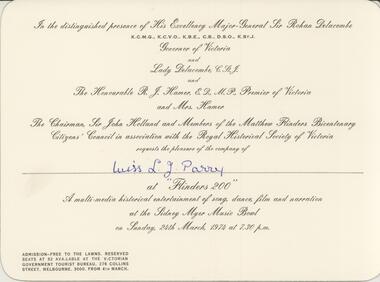

Bendigo Historical Society Inc.Document - INVITATION, 1974

Official invitation to Miss L J Parry from The Matthew Flinders Bicentenary Citizens Council and the Royal Historical Society of Victoria. A large cream coloured card printed with the following words in black script: In the distinguished presence of His Excellency Major-General Sir Rohan Delacombe Governor of Victoria and Lady Delacombe and The Honourable R J Hamer Premier of Victoria and Mrs Hamer, The Chairman Sir John Holland and Members of the Matthew Flinders Bicentenary Citizens Council in association with the Royal Historical Society of Victoria requests the pleasure of the company of Miss L J Parry at "Flinders 200"A multi-media historical entertainment of song, dance, film and narration at the Sidney Myer Music Bowl on Sunday 24th March 1974 at 7:30pm. In the lower left hand corner is printed Admission Free to the lawns. Reserved seats at $2 available at the Victorian Government Tourist Bureau 276 Collins St Melbourne 3000 From 4th March.event, entertainment, anniversary -

Waverley RSL Sub Branch

Waverley RSL Sub BranchPlaque Royal Hong Kong Police, Royal Hong Kong Police

The Hong Kong Police Force (香港警務處, HKPF; HKP), also known as the Hong Kong Police, is the largest disciplined service under the Security Bureau of Hong Kong. It is the world's second, and Asia's first, police agency to operate with a modern policing system. It was formed on 1 May 1844, with a strength of 32 officers. Queen Elizabeth II granted the Royal Charter to the Hong Kong Police Force in 1969 for their handling of the Hong Kong 1967 riots—renaming them: the Royal Hong Kong Police Force. Following the transfer of sovereignty, the Force is once again named the Hong Kong Police Force.[1] The current Commissioner of Police is Andy Tsang Wai-hung.[2] Including the Hong Kong Auxiliary Police Force and civil servants, the force consists of about 40,000 personnel; which gives Hong Kong the second largest citizen–police officer ratio in the world. In addition, the Marine Region with about 3,000 officers and a fleet of 143 vessels, is the largest of any civil police force.Wooden Plaque 15cm x x13cmRoyal Hong Kong Police -

Bendigo Historical Society Inc.

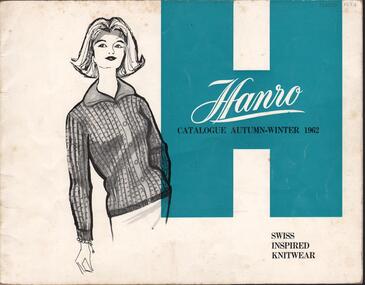

Bendigo Historical Society Inc.Magazine - HANRO COLLECTION: HANRO AUTUMN WINTER CATALOGUE 1962, 1962

The Hanro company was established in Switzerland in 1884. In 1926 a site in Hargreaves Street Bendigo, behind the School of Mines, was purchased to establish the Bendigo Knitting Mills, a subsidiary of Hanro. The managing director was Charles Handerchin who came from Switzerland. The company was delisted from the Australian Stock Exchange in 1963 when it was taken over by John Brown Industries.Hanro Autumn-Winter Catalogue 1962: The cover is of card with a white background with a large H in blue to the right. Sketched in black pen is a lady with a cardigan buttoned up with six buttons, long sleeves and a collar. To the right in white is *Hanro* under that in black print is *Catalogue Autumn-Winter 1962 Swiss Inspired Knitwear* Inside the cover is advertising. Attached with cello tape is a green sheet of paper with a sketch of a lady wearing a sweater with long sleeves and collar and bow. To the right is a medal, circular in shape with *Fashion Award Australian wool bureau* under that is Hanro, Gold Medal Winner 1962 Wool Fashion Awards*, a description of the garment, size and colour. Look better in a Hanro Sweater!* The catalogue is on gloss paper with sketched so ladies modelling Pullovers, cardigans, twin sets and jackets. Each item has its garment number description, sizes and colour. The back page is white with a large H to the left with *Hanro* in white and (Aust) Knitting Mills Limited* to the right is a box with a black border with the Sales offices addresses and phone numbers. At the bottom is *The Quality Is A Proud Tradition*.book, magazine, catalogue, hanro. catalogue. -

Returned Nurses RSL Sub-branch

Returned Nurses RSL Sub-branchNewspaper - Newspaper clipping, Community work is recognised, [1978]

After more than forty years of helping the sick, the needy and the aged, Judy Cockburn has been rewarded with an Order of Australia Medal. Judy says she is not one for the limelight and her greatest satisfaction comes from helping the aged. She said that while it can be very emotionally exhausting, she has formed some close relationships over the years. Judy moved to Essendon thirty-five years ago from Sydney after working as a welfare matron at the Austral Bronze foundry. She was in the first group of Australian Army nurses sent overseas in 1939. She served in a Palastine base hospital for four years. After the war Judy did home visits, being on call day and night; was on the Essendon Hospital Committee; worked in the hospital's opportunity shop; was a founding member of the Citizens Advice Bureau; was involved in the opening of Corandirk Hostel and continues to volunteer there; is a relief worker at the Essendon Community Centre; is on the committee of the proposed Marivale Nursing Home; visit patients at the Day Hospital; is a Life Member of the Essendon Hospital, the Austin Hospital and the Maribrnong Park Bowls Club; was involved in the establishment of the Boomerang Club and is a grandmother of six.A newspaper clipping featuring a blue title, two columns of text and a small black and white photo of a woman in bowls uniformww2, wwii, oam, ascot vale -

Monash University Museum of Computing History

Monash University Museum of Computing HistoryFerranti Sirius mainframe computer, 1961

The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius computer was built in a period of rapid growth in computing technology. The first stored program computers appeared in the late 1940s and used individual designs with valve technology. By the mid-1950s valve technology was replaced by transistors and the first mass produced commercial computers became available. The Ferranti Sirius was announced in 1959 and offered a “small” academic computer. It was designed and built by the English company Ferranti Ltd and sold through a local office of the company in Melbourne. The Sirius was manufactured at the Ferranti Ltd.’s West Gorton, England factory from 1959 to 1963 and, in all, the company produced probably 22 installations although only 16 were actually recorded as sold; this included one at Ferranti’s Bureau in London and one at Ferranti’s Melbourne Bureau. Only 7 were exported and 4 of these 7 were located in Melbourne, Australia. All four were associated with computing at Monash University – the Sirius in the MMoCH collection was purchased by Monash University in 1962, a smaller Ferranti Sirius was used on the Caulfield campus (prior to amalgamation with Monash University) from 1963, the Ferranti company had its own Ferranti Sirius initially temporarily installed at Clayton campus in 1962 and then placed in their office in Queens Road, Melbourne. A fourth computer was purchased by ICIANZ (now Orica) in 1962 and was transferred to Clayton campus in 1967. Only two of these Melbourne examples have survived; one in the MMoCH collection and one at Museums Victoria. There is an example of the Ferranti Sirius in the Science Museum Group collection in the UK as well. The Ferranti Sirius in the MMoCH collection was the first computer purchased by Monash University and it was shipped to Australia to be installed by November 1962. The University had a similar model computer on loan from Ferranti Ltd during the first part of the year and it was returned to the office of the company in Queens Road, Melbourne once the University’s own machine was installed. The computer was placed on site at Clayton campus, Monash University. The computer operated from 1962 until 1972 when it was officially decommissioned. The Ferranti Sirius was sold to Mr Paul Stewart in late 1974 and removed from Monash University. Mr Stewart later donated the computer back to the University in 1988 and it was transferred to the collection of the Monash Museum of Computing History after 2001. The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius is of scientific (technological) significance as one of the early transistor digital computers that transitioned computing from first-generation valve computers to second generation commercial installations. This example of the Sirius is of historical significance in its role as a part of the Computer Centre, Clayton campus, Monash University which provided computing facilities in Melbourne in the early 1960s when there were few installations available for academic, administrative and commercial users. Staff and students were able to undertake investigative research and learn programming techniques. The Computer Centre encouraged the use of the computer across all disciplines and this provided the base to establish computer science as a subject offering and, later, a new department in the University. This growth in computer education eventually culminated in the establishment of the Faculty of Information Technology, Monash University. The Ferranti Sirius in the collection at Monash Museum of Computing History has a main unit with a CPU and memory combined with input/output equipment and one extra cabinet of memory. The Central Processing Unit is a floor-standing unit which contains the computer circuits, power supplies and has a decimal digit display panel and a normal clock. A moveable control panel is placed in front of the Unit (Currently set on a recreated desk/filing cabinet support in the display). The Sirius base unit uses acoustic delay line memory with 1000 word store. An additional 3000 word memory cabinet is set adjacent to the CPU and can be connected to increase the memory. The computer is supported by a range of input/output devices. There is a Ferranti Paper tape reader, located on desk in front of CPU. Red label on front “Ferranti tape reader. Type TR 5. Serial No. 477”. Adjacent to the CPU is a set of Simplified tape editing equipment in three pieces which includes a (1) Table unit with switches on front face. Metal tag on reverse reads “Creed & Co. Model No. S4060. Serial No. 1457. Original Customers Marking GRP7 V706”. The table has a numbered internal tag “Table Serial No. 198579. (2)Creed teletype set on table unit. Metal tag on reverse “Creed & Co. Model No. 75RPR K4M4. Serial No. 5897 Made in England”. (3)Creed paper tape reader set on table unit. This set of equipment could read paper tape and print it, or copy paper tape while allowing it to be edited, or allow a programmer or data preparation person to type and punch a new program or data. It has no electrical connection to the computer. Paper tapes were usually torn off and carried across to the computer. There is also another table unit with switches on front face and changeable setting switch on front right side which holds a Ferranti Westrex paper tape punch set. Label on reverse “Teletype Code BRPE11” This was the Computer’s only output device. BRPE-11 is a teletype model number. -

Eltham District Historical Society Inc

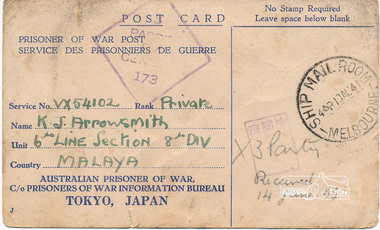

Eltham District Historical Society IncPost Card, Post Card sent to Private K.J. Arrowsmith, VX54102, 6th Line Section, 8 Div, Malaya via Prisoner of War Post, 8 August 1944 (received 14 June 1945), 8 Aug 1944

"Dear Kevin, Everybody home here is well, hope you and Bobby are well. Sid, Laurie home, hear regular from Eddie. Lots love Polly DAD" Post Card sent to Private K.J. Arrowsmith, VX54102, 6th Line Section, 8 Div, Malaya via Prisoner of War Post, Australian Prisoners of War, C/o Prisoners of War Information Bureau Tokyo, Japan from his sister Polly (Mercia Castledine). “After the cholera had been evidence for a few days, the Nips decided that the works on the railway had to be carried on and so isolated all the cases (a number more had developed since we were first quarantined) and sent all other men back to work. By this time, the number of men unfit for work had increased tremendously and the medical officer and medical orderlies were hopelessly overworked. Volunteers were called for to assist in this cholera ward; a disease highly contagious and with a terrific death rate. This meant isolation, but did not deter many men from offering their services, Bob and Kevin Arrowsmith being selected.” - Through the Burma-Thailand Railway, pp234-5, author unknown This post card is significant for its rarity as very few ever made it through and were saved. In these instances the information provided by Polly was cryptic informing Kevin and Bob Arrowsmith that brother Eddie and brothers-in-law, Laurie Mears and Sid Castledine were all still alive.Digital image of original held in private collection of Joan Castledine, daughter of Sid and Polly (nee Arrowsmith) Castledine.bob arrowsmith, burma-thailand railway, eddie arrowsmith, joan castlemaine, kevin j. arrowsmith, laurie mears, lucy mears (nee arrowsmith), mercia (polly) castledine (nee arrowsmith), postcards, prisoner of war post, sid castledine -

Eltham District Historical Society Inc

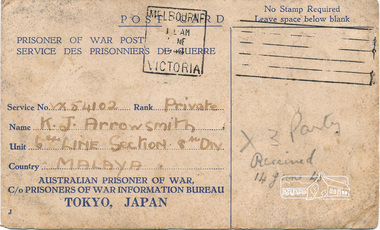

Eltham District Historical Society IncPost Card, Post Card sent to Private K.J. Arrowsmith, VX54102, 6th Line Section, 8 Div, Malaya via Prisoner of War Post, 16 June 1944 (received 14 June 1945), 16 Jun 1944

"Dear Kevin, Hope you are both well, everybody well home here, constantly thinking of you, hear regular, Eddie, Laurie, Sid. Lots love Polly Dad" Post Card sent to Private K.J. Arrowsmith, VX54102, 6th Line Section, 8 Div, Malaya via Prisoner of War Post, Australian Prisoners of War, C/o Prisoners of War Information Bureau Tokyo, Japan from his sister Polly (Mercia Castledine). “After the cholera had been evidence for a few days, the Nips decided that the works on the railway had to be carried on and so isolated all the cases (a number more had developed since we were first quarantined) and sent all other men back to work. By this time, the number of men unfit for work had increased tremendously and the medical officer and medical orderlies were hopelessly overworked. Volunteers were called for to assist in this cholera ward; a disease highly contagious and with a terrific death rate. This meant isolation, but did not deter many men from offering their services, Bob and Kevin Arrowsmith being selected.” - Through the Burma-Thailand Railway, pp234-5, author unknown This post card is significant for its rarity as very few ever made it through and were saved. In these instances the information provided by Polly was cryptic informing Kevin and Bob Arrowsmith that brother Eddie and brothers-in-law, Laurie Mears and Sid Castledine were all still alive.Digital image of original held in private collection of Joan Castledine, daughter of Sid and Polly (nee Arrowsmith) Castledine.bob arrowsmith, burma-thailand railway, eddie arrowsmith, joan castlemaine, kevin j. arrowsmith, laurie mears, lucy mears (nee arrowsmith), mercia (polly) castledine (nee arrowsmith), postcards, prisoner of war post, sid castledine -

Australian Commando Association - Victoria

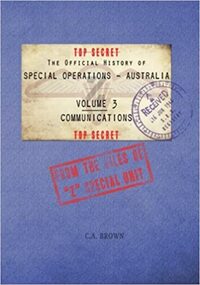

Australian Commando Association - VictoriaBook, The Official History of Special Operations Australia Vol. 3- Communications

Popularly known today as Z Special Unit, or by the wartime cover names of Inter-Allied Services Department (ISD) and Services Reconnaissance Department (SRD), Special Operations Australia (SOA) was the Special Operations component of the US-led Allied Intelligence Bureau in the Pacific Theatre during the Second World War. From the secret files of Z Special Unit, and the third in a set of five volumes, Volume 3 - Communications describes the communications links and equipment which were the lifeline for "Z" Operatives in the field. From "Z's" early days relying on Dutch military communications stations in Melbourne and Darwin to the establishment of dedicated "Z" communications stations in Darwin, Morotai and Labuan, Vol 3 provides the only comprehensive history of these sites ever committed to paper. Radio and Special Forces enthusiasts will be agog at the appendices in this volume, which not only include copies of the actual operating instructions and technical manuals for much of the specialist SOE communications hardware used by "Z" during the war, but also the once-top secret SOE ciphers and codes used by Z parties in the field. The Official History of Special Operations Australia, Volume 3 - Communications is a unique record of one of the most important aspects of Second World War Special Operations.australian special operations, special forces, world war ii -

Federation University Historical Collection

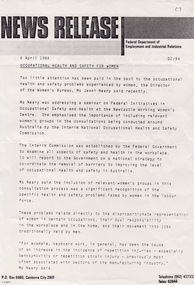

Federation University Historical CollectionDocument - Document - News Release, VIOSH: Federal Department of Employment and Industrial Relations; Occupational Health and Safety for Women, 6 April 1984

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. The Director of the Women's Bureau, Ms Jenni Neary spoke on Federal Initiatives in Occupational Safety and Health at the Newcastle Working Women's Centre. She emphasised the importance of including women's groups in the consultations being held around Australia. This was a significant recognition of the specific health and safety problems faced by women in the labour force.A4 page printed both sidesBarbara Fergusson viosh, victorian institute of occupational safety and health, federal department of employment and industrial relations, director of the women's bureau, newcastle working women's centre, jenni neary, information officer, barbara fergusson, consultations -

Federation University Historical Collection

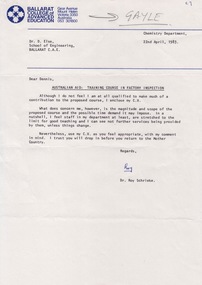

Federation University Historical CollectionDocument - Document - Correspondence, VIOSH: Ballarat College of Advanced Education; Training Course in Factory Inspection, 1983

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Letters from Dennis Else, Eric Wigglesworth, Richard Gillis and Derek Woolley organizing the course and timetable for the Training Course in Factory Inspectors that would come under Australian International Development Assistance Bureau (AIDAB) funding. See photographs 26735 See also documents 26686 and 26687 See Booklet re Training Course written by BCAE - 26850Four A4 pages, typedLetterheads for Ballarat College of Advanced Education, The Menzies Foundation and Altona Petrochemical Company Ltd.viosh, victorian institute of occupational safety and health, ballarat college of advanced education, dennis else, eric wigglesworth, richard gillis, derek woolley, gayle richards, the menzies foundation, altona petrochemical company ltd, letterheads, factory onspection, environmental health advisor -

Parks Victoria - Wilsons Promontory Lightstation

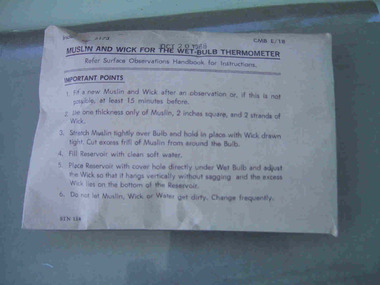

Parks Victoria - Wilsons Promontory LightstationMuslin & Wick

This item, which dates to 1988, is contained in the original supply packet and survives in good condition. It was commonly used by lightkeepers for both wet and dry bulb thermometers, with the muslin going into the bottom of the dry bulb where it was held in place by the wick and ‘end of the wick was then placed in a jar of deep water to keep the bulb cool’. The difference in temperatures between the dry and wet bulb thermometers could then be worked out to establish the dew point in the air.They were common in lightstations, but this intact item remains in the original packaging and is a fine representative example of its kind. It was acquired from the Bureau of Meteorology. Recording and communicating weather readings was an important facet of lightstation work and a number of different but related items of meteorological equipment survive at the six lightstations managed by parks Victoria. The Cape Nelson collection includes a pair of Australian-made thermometers in their original box, both in Fahrenheit, with one recording the minimum, the other the maximum temperature and a barometer table with instructions for correcting readings. Cape Otway has a Beaufort Scale, a table of wind forces which lists 12 types on a scale of 1 to 12, and provides associated speed in knots and travel time per minute or hour. Gabo Island has an anemometer, wind speed indicator and a wind speed recorder.Muslin and wick for a wet bulb thermomenter in unopened white paper packaging with directions for use printed on the package on the front.On front of package,"MUSLIN AND WICK FOR WET BULB THERMOMETER......." -

Department of Energy, Environment and Climate Action

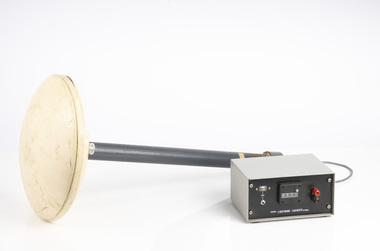

Department of Energy, Environment and Climate ActionLightning Detector

Lightning is one of the major causes of bushfires, particularly in the remote mountains. This lightning detector system was developed by Dr. Peter Kourtz at Canada’s forest fire research institute. By 1977, some 300 were in use across the country. The small mushroom antenna could detect short-range (20-mile) changes in electrostatic field associated with lightning strikes. It needed to be placed out in the open on a hilltop and away from nearby trees. It simply counted the number of "strikes". The detector doesn't seem to have a direction finding capability or be able to distinguish between cloud-to-cloud or cloud-to-ground lightning. It's not sure how this particular unit found its way to Victoria. The Bureau of Meteorology's (BOM) current lightning detector network uses radio waves emitted by lightning to pinpoint the location of lightning strikes. The network is operated by a private company that sends data to the BOM in real time. Lightning detection systems use sensors like antennas, GPS receivers, and processing systems to detect radio waves, also known as sferics. The systems calculate the lightning's location and speed by measuring how long it takes for the radio signal to reach the different antenna stations. The BOM also has a Thunderstorm Tracker that uses weather radar data to identify areas of potential thunderstorm activity. The tracker updates every six minutes and shows the direction thunderstorms are moving, as well as their expected position in 10, 20, and 30 minutesLightning detector 1970sQ-Techforests commission victoria (fcv), weather, bushfire, bushfire aviation -

Australian Commando Association - Victoria

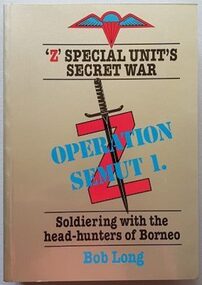

Australian Commando Association - VictoriaBook, Z Special Units' Secret War- Operations SEMUT 1, 1989

An account of the operations of The Allied Intelligence Bureau (AIB) better known as ‘Z’ Special Unit. Now a scarce and highly sought after title. The author’s personal experiences with Australian Special Forces (Services Reconnaissance Department) which involved guerrilla soldiering with the head-hunters of Japanese held Borneo during World War 2. Z Special Unit an administrative support unit of (also known as Special Operations Australia (SOA) or the Services Reconnaissance Department (SRD)) was a joint Allied special forces unit formed during the Second World War to operate behind Japanese lines in South East Asia. Predominantly Australian, SRD was a specialist reconnaissance and sabotage unit that included British, Dutch, New Zealand, Timorese and Indonesian members, predominantly operating on Borneo and the islands of the former Netherlands East Indies. The unit carried out a total of 81 covert operations in the South West Pacific theatre, with parties inserted by parachute or submarine to provide intelligence and conduct guerrilla warfare. The best known of these missions were Operation Jaywick and Operation RIMAU, both of which involved raids on Japanese shipping in Singapore Harbour; the latter of which resulted in the deaths of twenty-three commandos either in action or by execution after capture. Although the unit was disbanded after the war, many of the training techniques and operational procedures employed were later used during the formation of other Australian Army special forces units and they remain a model for guerrilla operations to this day.Hard Cover with Dust Jacket – 608 pagesInscribed by author-Bob Long AK223 SEMUT 1 Borneo 1945 -

National Wool Museum

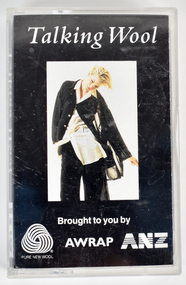

National Wool MuseumAudio - Talking Wool, August 1994

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.Cassette tape featuring image of a woman in black and white clothing.front: Talking Wool / Brought to you by / PURE NEW WOOL / AWRAP / ANZ spine: Talking Wool / August / 1994 / 5 back: Contents / SIDE ONE / AWRAP and IWS Intergrate Activities / by Mac Drysdale, Chairman, AWRAP, / Chairman, IWS / Changes to Quality Arrangements / by John O'Connor, General Manager, / International Market Development, AWARP / Pitti Filati Yarn Fair, Florence / by Terry Hennessey, General Manager, / National Marketing, AWRAP / Menswear in the US / by Judith Pinder, Associate Product Manager, / Menswear, IWS - Americas / SIDE TWO / Review of R & D Functions / by Mac Drysdale, Chairman, AWRAP / China Wool Product / by Bill Jones, Co-ordinator AWRAP/AIDAB / (Australian International Development Assistance / Bureau) China Wool Project / AWRAP in India / by Stuart Ascough, International Market Executive / (Early Stage Processing) / Produced by SG Communications Pty Limited. / ACN 063 021 796 © Copyrightstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, training, technical advice, mills, cassette tape, audio -

Puffing Billy Railway

Puffing Billy RailwayNumber 14 - Shay Locomotive (Builder’s Number 2549), 22 June 1912

geared steam locomotive Built by the Lima Locomotive Works, USA in 1912 (Builder’s Number 2549). “Class a” 13 Ton (13.3 tonne) . This locomotive hauled freight on the Ali-Shan Forest Railway in Taiwan and is capable of pulling 90 Tons (91.8 tone) loads over steep gradients at low speeds. . This A-type Shay locomotive was built by Lima Locomotive Works, Ohio (builder's number 2549 of 1912) for the Alishan Forest Railway, Taiwan. The Alishan Forest Railway featured a large fleet of Shay locomotives and many still survive, together with a portion of the railway which is now a tourist operation. Alishan Shay No.14 was gifted to the Puffing Billy railway in 1971 by the Alishan Forest Railway - Taiwan Government forest Bureau and arrived on the 12th October 1971 at the Puffing Billy Museum at Menzies Creek. Loco: Shay No.14 ( Shop Number 2549 ) Class: A 18-2 ( 2-cylinders / 2-trucks Class A ) Built for: Alishan Forest Railway Bulit by Lima Locomotive Corporation In service 22 June 1912 Samuels, Samuels & Co., Ltd. (D), Taipei, Formosa (Japan); For: Alishan Forest RY #14, Kirun (Keelung), Formosa, (Japan) (1945) Alishan Forest RY #14, Keelung (Chilung), Taiwan (12 Oct 1971) Puffing Billy RY #14, Belgrave, Victoria, Australia Gauge 30" Status Preserved - In Storage at Museum There is only one original LIMA mark left on any of the Alishan RY Shays and it has no number. All of their Shays have been re-built, changing much of the original Lima product. Most were renumbered for various reasons without regard to Lima Shop Numbers over the years. "Girder Type Frame" details from http://www.shaylocomotives.com/data/lima3354/sn-2549.htm Historic - Industrial Narrow Gauge Railway - Geared Steam Locomotive which worked on the Alishan Forest Railway, Taiwan.geared steam locomotive - Class: A 18-2 ( 2-cylinders / 2-trucks Class A ) - made of wood and iron and wrought iron, Glass14puffing billy, shay, geared locomotive, steam locomotive, industrial narrow gauge railway, 2'6", ali shan forest railway -

Department of Energy, Environment and Climate Action

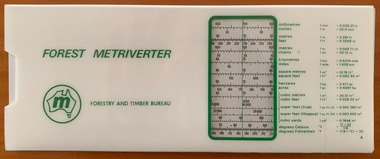

Department of Energy, Environment and Climate ActionForest Metriverter, Side Rule

Decimal currency was spectacularly introduced in an overnight overthrow on 14 February 1966, but it took another 8 years before metrication finally arrived in the forest and timber industry. Eventually, the measurement of logs and sawn timber changed from imperial, and excruciating, measures such as super feet of sawn timber, billets and cunits (100 cubic feet) of stacked pulpwood and hoppus log volumes to simpler cubic metres. Measuring firewood was a particular nightmare. For example, there were standard chords, stove cords, kitchen cords, running cords, face cords, thrown chords, fencing cords, country cords, long cords, raummeter or steres (1m x 1m x 1m). A standard cord of firewood had a volume of 128 cubic feet, measured as a pile 8 feet long, 4 feet high and 4 feet wide (3.624 m3). And how about this for confusing…. in Victoria, an imperial or long ton (by measure) of green firewood was a stack 5 feet long billets (2 axelengths at 2′ 6″ each), one axelength high (2′ 6″) and two axelengths long (5 feet) equalling 62.5 cubic feet. For added befuddlement, there were three different sorts of tons: Imperial tons or long tons, American short tons and metric tonnes (spelled with two n’s). Not forgetting that a cubic imperial ton of firewood (40 cubic feet) which equalled 1.133 cubic metre. The metrication process began in 1974 and was completed by 1976 but the transition was not without its challenges along the supply chain for foresters, overseers, logging contractors, sawmillers, hardware stores and builders alike. Timber lengths changed from feet to metres but were still sold in multiples of one foot or 0.3 m (1.8, 2.1, 2.4, 2.7 etc) whereas a menacing lump of 4-Bee-2 transformed into a rather less colourful 100mm by 50mm. Measurement and calculations of area also became so much easier in hectares rather than complicated acres, roods and perches. The Forest Metriverter slide-rule was issued by the Forestry and Timber Bureau to make metric conversions easier.Forest MetriverterRoss Pennyforest measurement, surveying, forests commission victoria (fcv) -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Memorandum, Melbourne & Metropolitan Tramways Board (MMTB), Eucharist Congress and Procession, 1934

Memorandums and table card for tram scheduling for Eucharist Congress and Procession: 1 - Newspaper clipping: "Papal Legate on Cathay - Due in Melbourne November 26, Papal Legate, Cardinal MacRory will visit for the National Catholic Congress in Melbourne December 2 to 9. 230H x 55W, poor condition 2 - Letter from WV McCall, Town Clerk, to Rev NA Clack, Eucharistic Congress Bureau, advising of receipt of letter advising of changes to Eucharist Congress Procession. Handwritten note to "Mr Davidson, for your information, 19/11/34". 335H x 210W, poor condition, torn edges and folds 3 - Set of 3 table cards for Eucharistic Congress Show Grounds "Men's Night". Thursday 6/12/34 "Down Loading at City Rd. Camberwell Glen Iris, South Melb Toorak, Elsternwick St Kilda Beach, 223H x 76W 4 - Set of 4 memos from DJ Davidson to depots regarding tram scheduling for Eucharistic Congress Show Grounds "Men's Night". Note pinned to front, handwritten in red pencil, Eucharistic Congress Mens Night - Thurs 6/12/34. 127H x 204W, 265H x 208W, good condition 5 - Set of 13 pages of memos relating to the the Eucharistic Congress and Procession, Sunday 9 December, 1934. 6 - Arrival and departure times of country trains on Sunday 9 December, 1934, replacing previous timetable. 7 - Memo from Assistant Manager to Dist Traffic Supts NS & SS. Other similar memos relating the the event. 8 - Letter from WV McCall, to Secretary, MMTB, advising of Eucharistic Procession, Sunday 9 December, 1934. Handwritten note to "Mr Davidson, for your information, 7/12/34". 263H x 206W, poor condition, torn edges and foldstrams, tramways, instructions, events, eucharistic congress, showgrounds -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionAltona Collection Photography and Cataloguing - November 2024

In November 2024, a small group of cheerful volunteers from the Forests Commission Retired Personnel Association (FCRPA) toiled over nine days to dust-off, photograph and record nearly 300 artifacts in DEECA's Altona Museum. It followed a similar project at the FCRPA's Beechworth Museum in February 2024. The Altona project was generously supported by DEECA / FFMVic to engage professional photographer Mark Jesser from Wodonga whose boundless energy and good humour helped to create these amazing images. Special thanks go to the FFMVic Chief Fire Officer, Chris Hardman, as well as Andrew Stanios and Kat Jensen for making it happen. FFMVic crews and the ever-patient staff from Altona took a strong interest and also helped to shift some of the heavy items like pumps and the Bedford tanker which was very welcome. The Forests Commission and its successors continuously encouraged bushfire research and innovation. In 1946 a large parcel of industrial land was purchased at North Altona as a fire cache and workshop. The Altona workshop became a hotbed of new technological thingumajigs… a marvellous blend of Aladdin’s Cave of Wonders coupled with Wallace and Gromit’s madcap contraptions… an exhilarating place where lots of gizmos were invented and tested… mostly with astounding results... but nearly always with some head-scratching frustrations… and thankfully not too much explosive mayhem. In fact, a lot of Australia’s pioneering equipment development was led by staff from Altona, often in collaboration with other State forestry and fire authorities. The CSIRO also contributed significantly. The US Forest Service, the US Bureau of Land Management and US State agencies such as the California Department of Forestry and Fire (CalFire) as well as the Canadian Forest Service faced similar challenges and proved strong and willing partners in sharing knowledge, ideas, equipment and expertise over many decades. The collection at Altona started in the 1970s by fire equipment wizard Barry (Rocky) Marsden. As obsolete equipment was returned to the Fire Protection Workshop for auction, Rocky began the process of selecting some which would be interesting to retain and display. The items at Altona represent just a small sample of the amazing story of Victoria's forestry and bushfire heritage. The largest item was undoubtedly the Bedford tanker which took two days and nearly 1000 photos which were later stitched together with photoshop. The oldest item is probably the Ericsson wall telephone from 1904. There are also many unique items, but the CSIRO incendiary machine and ping-pong incendiary machine developed at Altona probably had the most significant impact on fire management in Australia. There are plenty of gaps in the collection, but some items are in regional DEECA offices. It’s hoped to merge the FCRPA's Beechworth collection to Altona one day and rename the site to honour Rocky Marsden. There may be some additions to the Altona museum over time, but space is limited. The museum is available to visit by appointment. Peter McHugh - January 2025 forests commission victoria (fcv) -

Waverley RSL Sub Branch

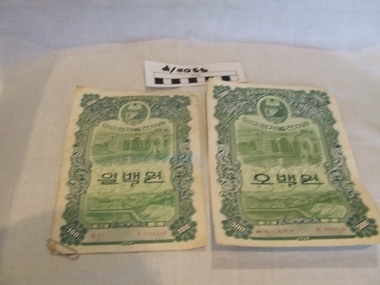

Waverley RSL Sub BranchKorean Currency and N.A.T.O. Forces Notes

Used during Korean War Won (1947-) Main article: North Korean won After the division of Korea, North Korea continued using the Korean yen for 2 years until the Central Bank of the Democratic People's Republic of Korea was established on December 6, 1947 and a new currency was issued. It was at the time pegged at par to the Soviet ruble. It was revalued at a rate of one hundred to one in February 1959 and new won were issued. In the following years the won faced some devaluation, caused by the subsequent devaluation and redenomination of the Soviet ruble. From 1978 to 2001, the North Korean government maintained an iconic rate of 2.16 won to the US dollar; since then banks in the country exchange at rates closer to the black market rate. However, rampant inflation has been eroding the North Korean wŏn's value to such an extent that currently it is believed to be worth about the same as the South Korean wŏn. In any case, the U.S. dollar and other currencies are still worth more in North Korean wŏn on the black market than officially. South Korean currencies[edit] Won (1945-1953)[edit] Main article: South Korean won (1945) Following the end of the division of Korea, the won was introduced to replace the Korean yen. The won was subdivided in 100 jeon. The first banknotes were issued by the Bank of Joseon in denominations ranging from 5 jeon to 100 won. In 1950 the currency management switched to the Bank of Korea and new notes were then issued, mostly with higher denominations. The first note put in circulation by the Bank of Korea in 1950 was printed in Japan by the National Printing Bureau (国立印刷局). The next year the Korea Minting and Security Printing Corporation was created and took over as printer of South Korean currency. At the time of the introduction in 1945 the won was pegged to the Japanese yen at a rate of 1 won = 1 yen. In October of the same year the anchor currency got change to the US dollar at a rate of 15 won = 1 dollar. Toward the end of the Korean War the won was devaluated at 6000 won = 1 dollar. Following that the hwan was introduced as the new currency at a rate of 1 hwan = 100 won. Hwan (1953-1962)[edit] Main article: South Korean hwan Due to devaluation of the won the hwan was introduced on February 15, 1953 at the rate of 1 hwan = 100 won. It was subdivided in 100 jeon, but they were never used. New banknotes in denominations between 10 and 1000 hwan were issued. Starting in 1959, 10 and 50 hwan coins were also issued to replace the lower denomination notes. Those were the first circulating coins in South Korea. Due to the short notice of the change in currency, the first series of the new notes was commissioned from the United States Government Printing Office. The notes were released in five denominations, all with an identical design. Some replacement notes with a more suited Korean theme were later issued, starting with the 100 hwan just a month later. The hwan suffered from inflation as well. At its introduction, it was pegged to the United States dollar at 1 dollar = 60 hwan, but toward the end of its life it was devaluated at 1 dollar = 1250 hwan. In 1962, the won was reintroduced at the rate of 1 won = 10 hwan. The 10 and 50 hwan coins were kept in circulation until March 22, 1975.5 Currency notes issued by Korean Government and R.A.A.F. denominations of 100, 100 Won and 1 shilling国立印刷局, currency korea, money korea, money korean war -

National Wool Museum

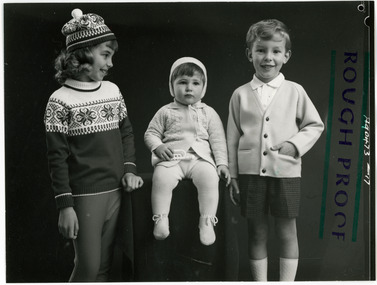

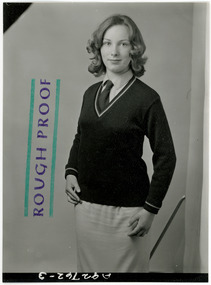

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1964-1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White short-sleeved jumper with all-over pattern of aqua blue diamonds. Blue floated threads slightly show through white on main body, leading to an overall pale blue effect on body, with white collar and cuffs. Closes with three pearlescent plastic buttons at back neck. .2 is a retail tag marked with the style code, and includes generic information on care for garments of different material composition..1) [label stitched into back neck of garment] KATHRYN REGD CREATED BY ROBERT BLAKE .2) [retail tag, intended to be folded in three, printed on both sides] [OBVERSE] KATHRYN Children’s Knitwear STYLE: [blue pen] S/35B SIZE: PRICE: / KATHRYN Garments are… • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY / NOW .. KATHRYN GOES TO . . SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYN [REVERSE] WASHING INSTRUCTIONS WOOL Wash frequently to AVOID HEAVY SOILING Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. TO dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, DRY IN SHADE… AVOID SUNLIGHT. When dry, place brown paper or pressing cloth over garment and press with iron at correct heat. ORLON Wash as wool Lay flat to dry but DO NOT IRON. To keep brushed suits like new, brush frequently with nylon brush supplied. COTTON Wash by hand for preference in Velvet Soap suds. Rinse thoroughly in cold water and remove all excess water before drying on line. Please do not use any harsh detergent or bleach. Designed and manufactured by ROBERT BLAKE Pty. Ltd., MELB. (handwritten in pencil) S35 (untintelligible)/5 / NOW KATHRYN GOES TO SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYNknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, colourwork -

National Wool Museum

National Wool MuseumTool - The Austral Unit Calculator, Industrial Consultants, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Measuring instrument with five circular white layers and one long transparent plastic ruler on top. Transparent layer is now yellowed, was likely originally clear. All of the layers connected with a metal rivet at the centre, allowing the discs and line indicator to move in relation to each other. Discs are labelled (inside – outside) Cost per Thousand Overall Unit Hour U/S [units] produced in 1000s No. of persons Bonus Percentage 9017.2 Black leather case with white block letter printing [9017.3 - 9017.5] Inside case are three notes (one printed, two handwritten) that provide instructions for using the calculator[label on obverse of case] THE AUSTRAL UNIT CALCULATOR ISSUED BY INDUSTRIAL CONSULTANTS, MELB MADE BY MELB >W&G< AUST.business, business history, manufacturing history, calculator, textile fibres textile history -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for the boys line of Robert Blake/Kathryn knitwear in the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesBOYS WOOL WINTER 1980 COLOR SWATCH RED BURGUNDY BROWN RYE PEBBLE OYSTER NAVY BLUE SHADOW DENIM GRANITE GREYfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for Kathryn knitwear for the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesKATHRYN WOOL WINTER 1980 COLOUR SWATCH RED BROWN RUST DEEP RED GREEN NAVY BLUE SHADOW SKY BLUE MAGNOLIAfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the 14 wool colour options for the ladies' line of Kathryn knitwear for the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesLADIES WOOL COLOR SWATCH WINTER 1980 RED BLACK MAGNOLIA OYSTER SILVER BLUE SHADOW NAVY TEAL GREEN BRACKEN RYE BROWN BURGUNDY DEEP REDfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

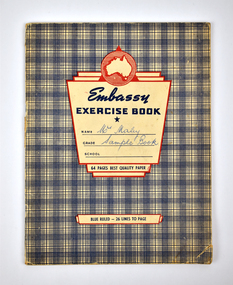

National Wool MuseumArchive - Notebook, Kathryn Knitwear, 1947-1953

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history. The ‘Embassy’ brand was a house brand of Coles stores from 1929-1994, and manufactured a wide variety of household goods. The manufacture of this specific style of notebook can be dated to between 1947 and 1953.Notebook with handwritten instructions, formulas and sketches detailing patterns for samples. ‘Embassy’ exercise book cover is printed with a blue checked pattern on a background that was originally likely white, but appears cream due to discolouration. The centre of the front cover has a trapezoidal label that provides space for handwritten labels, and features a map of Australia inside a red circle, as well as the manufacturers branding. The 64 internal pages are printed with blue lines as a writing guide.[Obverse] Embassy EXERCISE BOOK NAME [handwritten] Mrs Maley GRADE [handwritten] Sample Book SCHOOL 64 PAGES BEST QUALITY PAPER BLUE RULED – 26 LINES TO PAGE [sample of internal pages] [left page] Notes: 34” = 3 garments out of 40” Length 32” = 3 “ “ “ 38 “ “ 30” = 28” = Cut together (26” = 4 garments “ “ 33” “ (24 = 4 garments “ “ 33” length Blue 36” Red 36 ½“ Green 36” Royal 35 ½” [right page] Design Esquire (Width 35 ½ - 36) Size 34” Width Yardage Size 32” Width Yardage Sample cotton 90 ribs for 28” Size 28” (sample size) Width cut to 20 ½ (double) Yardage 34 ½“ for 2 garm. Size 26” Width Yardage Size 24” Width Yardagebusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, embassy brand, coles -

National Wool Museum

National Wool MuseumTool - Garment Brush, c.1953-1962

Sample of Kathryn Knitwear Collection. This brush was included with a brushed wool leginette suit (NWM-08916), in order to maintain the fluffy finish of the garment after wear and washing. Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Transleucent nylon brush with rows of thin bristles mounted in an offset pattern[Printed on plastic packaging] CARE OF BRUSHED FABRICS To obtain original condition brush garment frequently between wearing and after washing. Follow laundering instructions on swing ticket.brush, garment brush, brushed wool, laundry, garment care, nylon brush, accessory -

National Wool Museum

National Wool MuseumLetter, P Rowe International, 6/10/1969