Showing 407 items

matching hammer

-

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Digital Image - Cable tram grip in workshop, c1900

Digital Image of a cable tram dummy or grip car in a workshop being repaired. The seats have been removed and car partly dismantled. The grip is handing from the roof of the car. The original apron mesh is fitted along with a different coupling fitting to that of later grip cars. There are three workmen in the photo, one holding a large engineer's hammer. The car is lettered for the North Carlton to Brighton Road route with lettered glass in the the roof section, including one for "HBRy Station" - Hobsons Bay Railway Station.Yields information about the repair of cable trams at car houses or depots or the principal Nicholson St Car Repair shop.Digital image of a photograph.cable trams, workshops, depots, grip car, dummies, repairs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Badges, Warrnambool Technical School

This is a Warrnambool Technical School badge of the 1920s and 30s. Warrnambool Technical School was established in Timor Street in 1913. The senior section was later called Warrnambool Technical College and then Warrnambool Institute of Advanced Education. The latter institute moved to Sherwood Park, Warrnambool and became the present-day Warrnambool campus of Deakin University. Warrnambool Technical School moved to Caramut Road, Warrnambool and is today known as Brauer College. The badge was donated by Mirth Marfell, the daughter of Henry and Helena Marfell. She was born in Warrnambool in 1919. Her grandfather, John Marfell, a Warrnambool hay and corn dealer and miller connected to the Warrnambool Co-operative Milling Company, was prominent in community and civic affairs in the town. Mirth Marfell completed her nursing training at the Warrnambool Base Hospital and served in the Australian Army Nursing Service in World War Two for five years. She then became the first Australian nursing organizer for the Victorian Royal College of Nursing. This badge is of interest, firstly as a memento of Warrnambool Technical School from the 1920s and 30s and secondly because it came from Mirth Marfell, a Warrnambool person who had a distinguished nursing career..1 Shield shaped metal and enamel badge with green border including text enclosing a silver area featuring raised images of a torch, scales, compass, hammer, nails, artist's palette, brushes , a bar and the numbers 192. A pin clip is on the reverse .2 Circular metal and enamel badge with a golden edged green border surrounding a bronze coloured centre with a stylised golden edged scarlet torch and three horizontal bars of varied length. A pin clip is on the reverse..1 WARRNAMBOOL TECn SCHOOL LABOR TO EFFICIENCY .2 WARRNAMBOOL TECHNICAL SCHOOLwarrnambool institute of advanced education, warrnambool technical school, brauer college, warrnambool co-operative milling company, victorian royal college of nursing, history of warrnambool -

Bendigo Historical Society Inc.

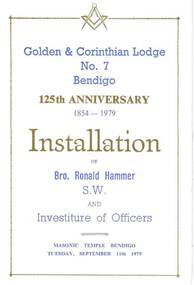

Bendigo Historical Society Inc.Document - INSTALLATION OF BRO. RONALD HAMMER GOLDEN AND CORINTHIAN LODGE NO 7

Small white booklet with blue printing inside and gold and blue printing with gold border and the Masonic emblem at the top. 125th Anniversary of the Golden & Corinthian Lodge No. 7 Bendigo 1854 - 1979. Installation of Bro. Ronald Hammer S. W. and Investure of Officers. Masonic Temple Bendigo Tuesday, September 11th 1979. Inside the booklet is a Short History of The Golden and Corinthian Lodge No. 7 of Bendigo; Ceremonial; List of Officers 1979 - 80; List of Members; toasts and Harmony and a space for autographs.organisation, masonic lodge, investure of officers, installation of bro ronald hammer, golden & corinthian lodge no 7 bendigo, criterian hotel, freemasons hotel, view point hotel, pembroke house, black swan hotel, golden lodge of bendigo, corinthian lodge of sandhurst, vahland, getzschmann, zenith lodge, 'a history of freemasonry in the bendigo district diring the firt 50 years of its existence', a h stone, k r grabasch, r hammer, m j luxford, t c k secombe, a g mcarthur, c c maskell, f a turpie, c m phillips, t k griffiths, b marett, g f turpie, r j m berry, f j palmer, l s shepherd, g e adams, w h shay, w s clemens, s n gillam, g a fraser, s b webster, j g penberthy, a k rollinson, k j beale -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Sculpture - JOHN BOMFORD PSYCHIATRIC CENTRE, COPPER BAS RELIEF EAGLE, 1970s

Bomford Bas Relief Eagle. Created from Sheet Copper. Carved and hammered Bas relief of a large Eagle.. The Carving was created by an artist in residence at the Bendigo Psychiatric Centre ( Golden City Support Services) prior to closure. It is approximately 2.00 metres high and 1.20metre wide. Mounted on a Large green wooden board. See 7311 also. Items represent the constellations Capricorn and Aquila. Once completed, they were used to identify the Squila and Capricorn patient areas at the Psychiatric Centre.artwork, sculpture -

Orbost & District Historical Society

Orbost & District Historical Societyboots

Hobnailed boots are boots with hobnails (nails inserted into the soles of the boots), usually installed in a regular pattern, over the sole. They also usually have an iron horseshoe-shaped insert, called a heel iron, to strengthen the heel, and an iron toe-piece. The hobnails project below the sole and provide traction on soft or rocky ground and snow, but they tend to slide on smooth hard surfaces. They may also have steel toecaps. When Army boots were made 100% of leather, to get some grip on the soles hob-nails were hammered into them. These boots are an example of the foot wear worn by the eA dark brown leather pair of very heavy hob-nailed boots. They have nails inserted into the soles of the boots in a regular pattern, over the sole. The toes and the heels have been strengthened with metal. The boots are made to lace up at the front.boots-hobnailed footwear -

Melbourne Legacy

Melbourne LegacyCeremonial object - Trench Art, Bell, Comradeship Bell, 1929

Bell was presented to the Melbourne Legacy Club by the departing president E.R.F. Serman in 1929. It was used during Comradeship Committee meetings.E.R.F. Serman was the Melbourne Legacy Club president in 1928-1929. Comradeship Committee meetings were very important to the Legatees.18 Pounder Shell casing that has been polished and had a small brass hook welded to the base. The casing has been split and bears the signs of being hit with a hammer. There is an inscription engraved on the front. The shell is hung from a brass arch which has been mounted to a wooden base. Two small brass hooks on the base act as a mount for the mallet. The brass arch and hooks are attached to the wooden base via flat head screws from the underside. The mallet is constructed of a brass rod with a felt head.Presented to the Melbourne Legacy Club by E.F. SERMAN PRES.1928-9comradeship, committee, legatee event -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Sculpture - JOHN BOMFORD PSYCHIATRIC CENTRE, COPPER BAS RELIEF MYTHOLOGICAL GOAT

Bomford Bas Relief Mythological Goat. Created from Sheet Copper. Carved and hammered Bas relief of a mythological creature resembling a goat with long straight horns. The Carving was created by an artist in residence at the Bendigo Psychiatric Centre ( Golden City Support Services) prior to closure. It is approximately 1.5metres high and 1.00metre wide. Mounted on a Large green wooden board. See 7312 also. Items represent the constellations Capricorn and Aquila. Once completed, they were used to identify the Squila and Capricorn patient areas at the Psychiatric Centre.artwork, sculpture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Bendigo Military Museum

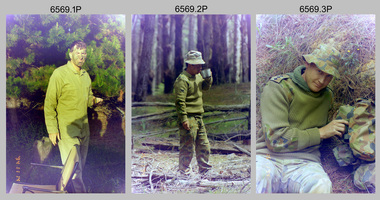

Bendigo Military MuseumPhotograph - 4th Field Survey Squadron Regimental Training - Exercise ‘Fuggy Hollow’ in SA, 1994

This is a set of 30 photographs of 4th Field Survey Squadron personnel undergoing regimental training in 1994, at Second Valley Conservation Park in South Australia. The aim of Exercise ‘Fuggy Hollow’ was typically to provide personnel a practical knowledge of infantry and minor tactics (IMT) at the section level, navigation and map reading, RATEL and survival in the Field.This is a set of 30 photographs of 4th Field Survey Squadron personnel undergoing regimental training in 1994, at Second Valley Conservation Park in South Australia. The colour photographs are on 35mm negative film and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 96 dpi. .1) - Photo, colour, 1994. Unidentified soldier. .2) - Photo, colour, 1994. CPL Phuc ‘Charlie’ Tran. .3 to .5) - Photo, colour, 1994. CAPT Chris Topovsek. .6) & .7) - Photo, colour, 1994. Unidentified soldiers. .8) - Photo, colour, 1994. L to R: SPR Fran Calvert, unidentified (x2), SPR Mark Linford, unidentified. .9) to .17) - Photo, colour, 1994. Unidentified soldiers. .18) & .19) - Photo, colour, 1994. L to R: LT Andrew Caudle, SSGT Brian Collings, OC Maj Peter Demaine. .20) - Photo, colour, 1994. WO2 Peter Hammer. .21) - Photo, colour, 1994. L to R: CAPT Chris Topovsek, SSGT Brian Collings, WO2 Peter Hammer .22) - Photo, colour, 1994. SSGT Brian Collings. .23) - Photo, colour, 1994. L to R: unidentified, SPR Fran Calvert. .24) - Photo, colour, 1994. L to R: SPR Mark Sinderberry, SGT Steve McGuiness, unidentified. .25) - Photo, colour, 1994. SPR Mark Linford. .26) - Photo, colour, 1994. L to R: unidentified (x2), SPR Fran Calvert, unidentified. .27 & .28) - Photo, colour, 1994. L to R: SSGT Brian Collings, WO2 Peter Hammer. .29) - Photo, colour, 1994. WO2 Simon ‘Andy’ Capp. .30) - Photo, colour, 1994. SGT H. Evertz..1P to .30P – There are no personnel identified. ‘1994 EX FUGGY HOLLOW (IMTs) Second Valley Conservation Park’ annotated on negatives sleeve.royal australian survey corps, rasvy, 4 fd svy sqn -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2/6/2008. Genuine Aboriginal axe head up to 2000 years old. Possibly came through trading from western district. Stone tools were used for a variety of purposes, in ways similar to those of the steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This stone is able to withstand repeated impact, and and wqas generall used for stone axes. The stone was dug or found and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Victoria.Small grey oval-shaped axe head.axehead stone-artifact aboriginal tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt. This is able to withstand repeated impact making it suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of a stone tool used by the early Indigenous people of Eastern australia.A handmade stone Aboriginal axe head.axe-head aboriginal tool stone-artefact -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationAnvil

As quoted from Wikipedia, ‘An anvil is a block with a hard surface on which another object is, struck. The block is as massive as it is practical, because the higher the inertia of the anvil, the more efficiently it causes the energy of the striking tool to be transferred to the work piece’. The lightstation’s anvil is a red-painted iron block with a conical beak or horn at one end that was used for hammering curved pieces of metal. It would have stood on a heavy free-standing pedestal, such as a large tree stump, to allow complete access to the item being hammered. Some anvils display the manufacturer’s name in the metal on the side, but this is not the case here, and its age, although unknown appears to be quite old, perhaps c.1900. It appears to have had a lot of use, and although no record of this survives, it is presumed that a forge operated on site for hammering, cutting, shaping and repairing tools such as bolts, nails, hooks, chain segments, pulley blocks, hinges, crow bars, picks, chisels, horseshoes and harness hardware. A hames hook (which forms part of the collar worn by a draught horse) survives at the lightstation as do many other heavy metal tools and pieces of equipment. The anvil is an example of the necessary resourcefulness and self sufficiency practiced by lightkeepers working and living in a remotely located workplace and home, and many of the iron items in the collection may have been repaired or even made on its working surface. As a lightstation manager Chris Richter used the anvil to manufacture pulley blocks for sash windows, repair brass door hinges & sharpen cold chisels, crowbars and picks and other lightkeepers have used this anvil for many fabricating jobs such as manufacturing ducting for the generator room ventilation system."The lightship only came in every three months with supplies and there would have been repairs to do between visits from a blacksmith - who would have had to travel on the ship. Also, the ship was only anchored in the bay long enough to unload supplies and collect and deliver lightkeeping staff – probably not enough time to get much smithy work done – especially if the weather packed it in and the ship had to depart. Lightkeepers in our time had to be self sufficient, resourceful and innovative and I imagine that would have been the case in the past." It has second level contributory significance.Red painted blacksmith's anvil. -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008 Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and so is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of an early axe head used by the Indigenous people of East Gippsland.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Rusty tin jug with small pouring lip and handle. Very plain and possibly made from a jam tin and handle soldered on side.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Rutherglen Historical Society

Rutherglen Historical SocietyCoxed Pair race boat, Richmond Boat Sheds, The Queen of Hearts, 1936

First used Boxing day 1936 at Nagambie, Launched by Mrs S.G. Williams wife of the Shire President. The champaign bottle failed to break and a hammer was required. The first race was rowed by H. Gayer (bow) W. Bourke (stroke), Ted Forbes (cox) winning maiden pairs and the same crew won lightweight pairs at Lake Moodemere 1st Jan 1937. The boat was then purchased with funds raised in a queen competition held in Rutherglen and contested by 3 queens, Elise Frances, Emma Howard and Peggy Bourke (the winner and she went on to marry the bow H. Gayer). The Queen of Hearts went to the Air Force at Tocumwal during the WWIIClinker build racing row boaton stern VRA No. 176rowing, regatta, boats -

Bendigo Historical Society Inc.

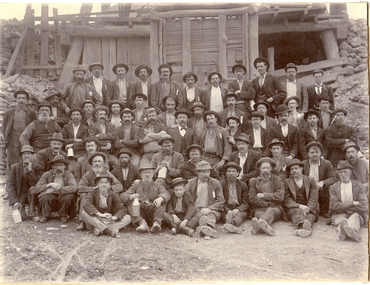

Bendigo Historical Society Inc.Photograph - GROUP OF WORKMEN IN FRONT OF C.I. BUILDING

Black and white photograph glued to cream board. Group of workmen standing and sitting in rows outside C.I. Building with wooden steps up to doorway. Three men in front row holding foot containers. One man sitting on ground at front holding engineer's hammer. Thirty men. In total. Inscriptions: on back- handwritten in pencil ' given by Cyril Jacobs. Probably Great Extended Hustlers. L Hocking, second from left in back row. W Bullen sitting in front facing left, night shift'. 'Historical Society of Vic, Bendigo Branch: hand-written in ink.person, mining, miners, bendigo, workers, workmen, mines and mining, miners, hustlers, group, great extended hustlers, mines, mining -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Cocoa Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin base and external tin lid, with round internal lid .Colour printed. Used for cocoa. Caption of a woman drinking cocoa, red Australian flag and British flag on other faces. Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," (Display side) "Manufactured by Hoadley's Chocolates Ltd, Australia.Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," "Manufactured by Hoadley's Chocolates Ltd, Australia.warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tea Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin container painted yellow with printed crosses and circles,. The lid is labelled "Robur Cross Stitch Company" and "R" imprinted in the centre although the lid is badly corroded. ‘Cross – Stitch’ (printed green in small crosses and circles) followed by ‘Nett Weight ¾ lb. (printed beige in crosses and circles). Pure Blended Tea. Robur Tea Co Ltd’ flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, robur tea co ltd, tea, tea caddy, tin, tin plating, food containers -

Queen's College

Queen's CollegeInkwell and stand, 1928

Glass inkwell and timber stand. The wooden inkstand has 2 small brass plaques attached to it.Plaque 1: "Presented to Mr A Cecil Osborne by the Trustees of Wesley's Chapel, City Road London on the occasion of the 150th anniversary November 1st 1928. Made from old oak given to John Wesley for his chapel from the government shipyards at Deptford 1777" Plaque 2: Presented by Mrs Osborne of Hammers Lane, Mill Hill, London, To the Mont Albert Methodist Church In appreciation of gifts received from the Mont Albert Congregation, November 1947.john wesley, inkwell, deptford shipyards, mont albert -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - REPORTS TO DIRECTORS OF SNOWBALL GULLY GOLD MINING CO RE MINING DETAILS AND WINDING UP (SALE)

Reports to Directors of Snowball Gully Gold Mining Co re Mining Details and Winding Up (sale); 1. 10 pages of details of mining progress (shaft sinking, drives etc) in the period 1905 - 1907 submitted by D Gummell, Manager; 2. Two pages listing the tools and implements on the mine when closed with attached letter to Directors (31/10/1907) submitted by D Gummell, Manager. Note: comment by Ralph Birrell on this second document (19/3/2013) - he observes that the sale of ''68 drills'' on the submitted list indicates that at this mine in 1905/07 they were still using drills and hammers.document, gold, snowball gully gold mining company, snowball gully gold mining company. d. gummell. ralph birrell. -

Orbost & District Historical Society

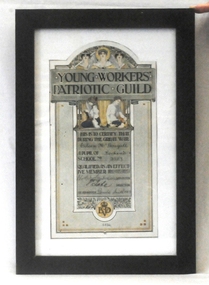

Orbost & District Historical Societyframed certificate, 1917

The Young Workers' Patriotic Guild was formed in Victorian schools in 1916. Each child who raised one pound 'by personal productive effort' received a certificate. The money was used for the war effort. This certificate was presented to Eileen McDougall, a pupil of Lochend School, in 1917 in recognition of becoming a member of the Young Workers' Patriotic Guild.This item reflects the war efforts of Victorian children during WW1.A coloured certificate framed in dark plain wooden frame. The certificate is from the Young Workers' Patriotic Guild, and includes mythical representations of 'Justice' and 'Peace' at the top, together with a female face wearing a laurel wreath. Below the banner headline are two young girls, one shown knitting a black and red sock, and the second holding what appears to be a hammer and a block of wood. The certificate commemorates the work done by a pupil at a Victorian school as a member of the Guild. It is dated 1917, and signed by the Minister of Education, the Director of Education, and the Headmaster of Kennington school. The name of the designer appears at the bottom of the certificate; it appears to be Harold Herbert. Laurel leaves and berries, and the initials 'EVD' [Education Department Victoria] appear at the base of the certificate. (from Museum Victoria)mcdougall-eileen ww1 certificate-young-workers'-patriotic-guild education fundraising -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: MEMORANDUM

Memorandum from the Office of D.R.S. Sup't Bendigo 1st July, 1938. FPM/S. Issues of Tools Comprising Enginemen's Kits on Engines. The sup't of loco Supplies has drawn attention to the enormous increase in the number of tools issued for Enginemen's kits, and below is set out the issues for 6 months under the old system and the issues for the 6 months under the new system. The percentage increase in hand hammers, hand lamps and feeders is particularly large. The above state of affairs is giving much concern and unless an improvement results it is probable that the whole system may be abandoned and the old method reverted to. Enginemen are requested to give this matter close attention in order to ensure the success of the present system. F.P. Martin District R.S. Superintendentorganisation, union, a.f.u.l.e -

Federation University Historical Collection

Federation University Historical CollectionBlack and white studio photograph, Richards & Co, Ballarat Junior Technical School Scholarship Winners and Prefects, 1923

Scholarships and Studentships played a very important role in schools of the day. Many families had to make sacrifices to enable their sons to remain at school. The addition of a third year to the junior technical course added to the burden. The main difficulty was the fee of one pound per term for students over the age of 14. There were 4 terms per year making it an expensive undertaking. Many working class boys, and they were in the majority at technical schools, had to seek employment as soon as they reached the age of 14, the statuary leaving age. Because of these financial obstacles, scholarships played an important role in the schools of the day. Older boys were selected on merit to become Prefects to assist staff. Three names are know in this photograph - Standing 3rd from left, George S Dimsey; standing top right hand end, James Hammer who achieved in B.H.P.; seated in middle front row, Lindsay F Hillman. Ballarat Junior Technical School Scholarship winners and Prefects 1923 posing for a studio photograph.Back of photograph: "Richard & Co Ballarat Photographers" stamped with additional stamp "Proofs not returned charged for" Inpencil; "Jr Tech. School"scholarship, studentship, ballarat junior technical school, leaving age, prefects, financial obstacles, working class -

Whitehorse Historical Society Inc.

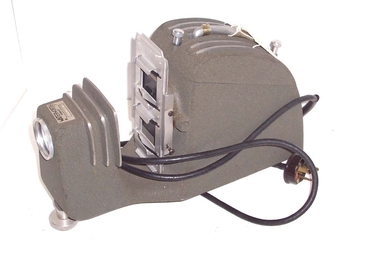

Whitehorse Historical Society Inc.Functional object - Slide/Film Strip Projector, c1960

The donor received the projector from a relative. He used it in the City of Whitehorse and surrounding areasWaterworth Slide Film Strip Projector, Model A - 300 watt, without a fan but with ventilating slots on top and an open bottom for air to flow. It has a carrying handle and a power lead with 3 pin plug which is wired in permanently. The projector lamp is at rear under the carrying handle. Image is projected through three stage lens via via the image on the 35mm strip or slide. The front lens is adjustable for focus. A knurled nut enables a height adjustment at front. Slides are inserted through the holder - whilst one slide is shown the other can be loaded ready to be slid in front of the light. The film strip holder is missing. The unit is finished in a grey hammer finish paint used in 1960 t0 1980s. The operating instructions are filed in the supplementary envelope. The projector is stored in a hand made three ply hinged box.Waterworth Hobart 5553Aphotography, projectors -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Point Bar, State Electricity Commission of Victoria (SECV), 1960's

Length of 5/8ths of inch or approx. 15.5mm diameter steel bar, which has been heated and formed at one end to give an eye approx. 32mm internal diameter and hammered and ground to form a point edge at the opposite end forming a point bar. Used by Ballarat Tram crews to change tram track points. Standard equipment to all tramcars (two each). This particular point bar was reportedly located at the Lydiard St. and Sturt St. intersection for use by inspectors and other tram crew to change the points at this intersection without obtaining a point bar from the tramcar itself. Taken by a Brisbane Tramway Museum Society member at the time of closure. The point bar was repainted by the BTMS in the green colour scheme prior to presentation to the BTPS/BTM during the 1992 COTMA Perth Conference to Carolyn Dean. Handed to the Archives for collection on 18/6/2003.trams, tramways, track equipment, tram equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wrench, Late 19th Century

Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Dusseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Bleckmanns a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to the First World War.Drop hand forged steel wrench with unusual locking mechanism to size jaw opening made by J E Bleckmann, Solingen Germany.Machine stamped on handle of wrench LOTUS L R GEBRAUCHS under has MUNSTER, J E BLECKMANN, SOLINGEN Germany. [ Translated: LR Gebrauchs= use,usage, or custom application] [Lotos] Translated: Lotus ie flower] [Solingen =town in Rhine valley]manufactures, tools, engineering, blacksmith, workshop tool, dropforged, handmade, wrench, adjustable wrench, phoenix steel, j e bleckmann, solingen, murzzuschlag, steel mill, cutlery, steel foundery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Johann Heinrich August Bleckmann, 1870 to 1920

Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Düsseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Johann Heinrich August Bleckmann a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to and just after the First World War.Plane Smoothing type with flat base. Has wooden wedge and iron missing. Knob handle is set on top and at the front. Iron 1 3/5 inches wide. Marked "Bleckmann (symbol) Safingen" "GN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane