Showing 3904 items

matching machining

-

Shepparton RSL Sub Branch

Shepparton RSL Sub BranchVickers Machine gun Oil tin, 1941

Standard ww2 .303 Vickers Machine gun oil bottleWW2 Vickers Machine gun Oil Tin, 1 Quart size dated 1941, with brass oil filling plug and Brass pouring spout and Brass chain linking both. Domed top and rectangular base.11 1941 Bedford?oil bottle -

Clunes Museum

Clunes MuseumPhotograph

STAFF OF THE CLUNES KNITTING MILL 1923. INTERKNIT SPINNING MACHINE.1 B/W PHOTOGRAPH SHOWING STAFF IN FRONT OF THE CLUNES KNITTING & MFG CO. LTD. (INCLUDES SOME CHILDEN) 1923. RECEIPT ATTACHED 1992. .2 B/W PHOTOGRAPH OF SPINNING MACHINE IN THE FACTORYclunes knitting mill staff, machinery, spinning -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Bonnet veil with Agentan lace motifs, Argentan motifs - mid 18th century. Bonnet veil mid 19th century

Fashion Item. Bonnet veils were very fashionable during the 19th century. At this time old lace was highly valued - in this case old Argentan needle lace motifs (mid 18th century) have been reclaimed and appliqued onto machine made cotton net to form this 19th century bonnet veil. Probably home-made.Mid 18th century Argentan needle lace motifs appliqued onto machine-made cotton net.lace veil, bonnet veil. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Washing Machine

Hand operated washing machine - plunger type - a central cone plunger attached to a fulcrum point (adjustable in height) on side with a long arm. Depth of plunger action also adjustable. All mounted on a three leg frame. Container is slightly coned shaped at bottom and has a drain tap at bottom for emptying water. Container can also be lifted off. Provision made for attachment of a wringer (this could be a later modification). Plunger is approx 37cm in diameter and has four 1.5cm holes for water to be forced through. Unit is galvanised steel but frame appears to have been painted with 'Silverfros'.On Side of container - 'The Zwar' VACUUM Washing Machine Patent No 2089/31domestic items, laundering -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeSewing machine

A domestic sewing machine used for dressmaking and handcrafts which was operated by hand.A hand sewing machine with a cast metal body and gold leaf decoration on the 'arm'. It stands on four 'legs/feet' with a kidney shaped base. The driving wheel is grooved for a belt. This has no handle. All cogs move.domestic, needlework, sewingmachine, stitching, dressmaking, needlecraft -

Kew Historical Society Inc

Kew Historical Society IncLeisure object - Toy Machine, TAGMA, Metal & Enamel Adding Machine, 1950s

The Kew Historical Society’s collection includes a wide range of leisure objects. Many of the items are European-made, generally of British origin, however there are a number that were made for the Australian market by Australian manufacturers. There were clearly a huge range of toys produced for the Australian and International children’s market in the Nineteenth and Twentieth centuries. The examples of toys in the collection include examples of alphabet toys, arcade toys, baby toys, construction toys, dolls, doll accessories, educational toys, soft toys, tin toys, toy animals, toy blocks, toy machines, toy typewriters, etc. Small toy adding machine. Tin with brown and white enamel painted. A small, damaged label on the front states that it was made by Toys & *** Games Australia / TAGMAtoys, toy machine, child's adding machine toy, tagma australia -

Bendigo Military Museum

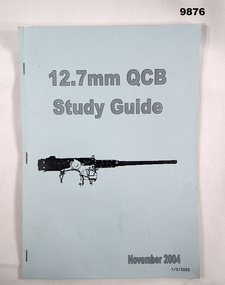

Bendigo Military MuseumManual - 12.7 MM STUDY GUIDE, Nov 2004

QCB stands for quick change barrel and relates to a heavy Browning Machine Gun. This manual set up for training course on it's use and function.Stapled assembly A4 sheets with green cover and with 42 pages of the use, description and maintenance of a Browning 12.7mm M2 Heavy Quick Change Barrel (QCB) machine gun.Date, "November 2004" then "1/2/2005".royal navy, gunnery, book, training course -

Vision Australia

Vision AustraliaEquipment - Object, Soundscriber dictaphone, 1945-1960

The Sound Scriber Dictaphone allowed recordings to be imprinted into a soft disk that could then be replayed later. This was useful for blind stenographers who could transcribe the audio recording. The lid contains a speaker into which sounds are made, the front knob is allows for 'Talk' or 'Listen' and three other dials on the device allow for the tubes to be turned on/off, starting/stopping the turntable and the recording volume to be 'Dictation' or 'Conf". There are two measuring tapes placed near the recording head and the Listen head, which show the minutes in the recording. The large disk that is placed on this machine has been stopped at the 12 minute mark. At the rear of the device are two plugs, one of which is for electrical supply. This model of dicta phone remained popular until magnetic tapes.1 hinged leather case over a metal and wood machineSound Scriberaudio equipment, assistive devices -

Stratford and District Historical Society

Stratford and District Historical SocietySewing Machine

Used by Miss Alice Mitchell of Stratford. Purchased in 1909 by Miss Mitchell’s mother, and later used by Miss Mitchell who, for the duration of the war, made two pairs of socks, a flannel singlet / shirt and a pair of pyjamas (the last two on this machine), each week, for the entire war. Miss Mitchell lost three brothers and her fiancée in World War I, and was a member of the Red cross for the two world wars, and served the organisation for over 50 years.A Singer treadle sewing machine set in a large table with cast iron legs and stand with the words SINGER on it. There are two wooden drawers on either side. The machine is black and ornamented in gold. The head swings down into the stand, forming a table when not in use.world war 1914-1918 -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

8th/13th Victorian Mounted Rifles Regimental Collection

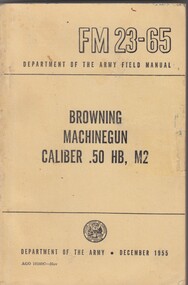

8th/13th Victorian Mounted Rifles Regimental CollectionBooklet, 1955

Us manufactured Browning machine guns were introduced to Australian Army in 1950s.The. 30 calibre replaced 7.92 mm Besa in Centurion tanks equipping 8/13 VMR in 1957. The. 50 calibre was mounted on some M113 carriers as Commanders MG. Representative of Training booklets issued to CMF units in the 1960sLightbrown covered booklet Browning Machine Gun Caliber .50HB, M2. Department of the Army Field Manual FM 23 - 65. December 1955 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

National Wool Museum

National Wool MuseumBook, Knitting, Riverhart 3 ply Pattern Book no. 3

This book was owned by the late Dr Elizabeth Kerr and was donated to the Museum by the executor of her estate, Margaret Cameron. It contains patterns for a knitting machine, using Riverhart yarns.RIVERHART / HOME KNITTING MACHINE YARNS / 3 Ply / Pattern Book / No 3 / Pattern No. / Q3-9 / Pattern No. / Q3-7 / Pattern No. / Q3-8machine knitting, riverhart yarns -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Weapon, M60 Machine Gun Flash Eliminator

This flash eliminator from a 1st Battalion, Royal Australian Regiment, M60 machine gun was hit by a Viet Cong bullet on 6 November 1965 during Operation Hump north of Bien Hoa. The bent metal on the eliminator can be clearly seen. The round fragmented on impact, wounding both the gunner, Private Anthony John McIvor from Richmond, NSW and the gun No.2 , Private Glen Brett Woodward from Brisbane, Queensland. Woodward subsequently returned to operations but McIvor was evacuated to Australia to be treated for his wounds.A muzzle device attached to the muzzle of a rifle, e.g a M60 machine gun that has a bent head.m60 machine gun, operation hump, bien hoa, pte anthony john mcivor, pte glen brett woodward, flash eliminator -

National Wool Museum

National Wool MuseumPostcard, 1910

Postcard was given to David Phillips (Donor) by a friend who was involved in the wool industry through employment at CSRIO.Postcard with black and white image on front. Image is of two men standing in front of a carding machine inside of the Warrnambool Woollen Mill. Image is printed onto postcard despite the non-straight lines suggesting the image may have been cut and pasted. Reverse of the postcard has handwritten message detailing image on the front of the postcard.Handwriting, black ink: Warrnambool Woollen Mill 1910 / First carding Machine bins / Erected b W. (Bill) + (?) / Pontefract warrnambool woollen mill, carding machine -

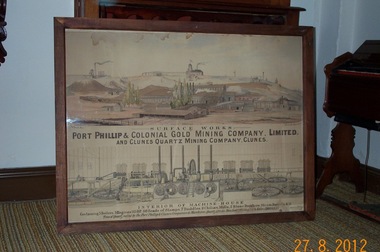

Clunes Museum

Clunes MuseumArtwork, other - FRAMED LITHOGRAPH

PORT PHILLIP & COLONIAL MINING COMPANY LIMITED AND CLUNES QUARTZ MINING COMPANY, THE MACHINE CONTAINED 5 BOILERS, 3 ENGINES 145 HP, 80 HEADS OF STAMPS, 7 BUDDLES, 2 CHILIAN MILLS & 2 STONE BREAKERS, STEAM VALVES. TONS OF QUARTZ RAISED BY THE PORT MINING & CLUNES COMPANIES TO MARCH 1880 1123365 TONS & GOLD 465,168 OUNCES, 7 DWTS, VALUE 1860, 925,54 POUNDS. EXHIBITED BY R.H. BLAND, CLUNES.LITHOGRAPH DEPICTING SURFACE WORKS OF THE PORT PHILLIP & COLONIAL MINING CO. LIMITED AND INTERIOR OF MACHINE HOUSE.local history, illustrations, lithograph, mining. -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

![Photograph, [Worsted Twisting Machines]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f619821f50e3cc9f50e/item-media/54065f619821f50e3cc9f50f/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Worsted Twisting Machines]

Acquired when "Classweave Industries" closed down11 Worsted Twisting Machines/ - machine still here 1960'stextile mills - staff woollen mills, classweave industries pty ltd federal woollen mills ltd, weaving machinery, textile mills - staff, woollen mills -

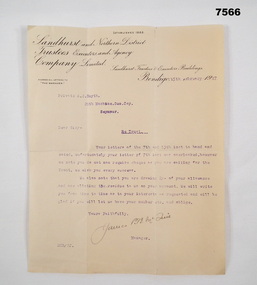

Bendigo Military Museum

Bendigo Military MuseumLetter - LETTER, SANDHURST TRUSTEES, 15th February 1917

The letter describes various financial arrangements, the letter has him in 20th MGC. Alexander Cross Smyth, No 559, enlisted 19.10.16, age 27 years 2 months in 8th Reinforcements 10th Machine Gun Company. Embarked for England 14.2.1917, embark for France 5.6.1917, detached to “A” Burial unit 9.4.1919, detached to Australian Graves Services 20.8.1919, RTA 22.10.1921, discharged from the AIF 2.2.1922. letter describes various financial arrangements. Letter refers to 20th MGC.Business correspondence. Brown with letterhead. Purple type, addressed to Private A.C. Smyth, signed by manager.Hand-written signature, addressed to Private A.C. Smyth, 20th Machine Gun Company, Seymourletter, ww1, 20th -

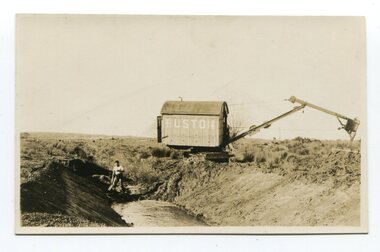

Orbost & District Historical Society

Orbost & District Historical Societyblack and white photograph, first half 20th century

Ruston & Hornsby, later known as Ruston, was an industrial equipment manufacturer in Lincoln, England, the company's history going back to 1840. The company is best known as a manufacturer of narrow and standard gauge diesel locomotives and steam shovels. This machine is probably a drag line excavator.This photograph records early an early type of excavator used to construct drainage channels in rural Victoria.A black / white photograph / postcard of a man digging in a very large trench, probably a drainage channel, with an earth mover in the background. The machine has the name "RUSTON" on it.drainage-channel earth-moving-machinery -

Federation University Historical Collection

Federation University Historical CollectionScientific Instrument, Weighing Machine, c1970

In 2000 6 Staffmembers were asked if they had knowledge of this item. Barry Shearer remembered it well. Rob Greig, John Murray, Neville Gower, Stafford McKnight and Gael Ramsay had no knowledge of it. The weighing machine was used in the Ballarat Institute of Advanced Education Chemistry Laboratory until it was replaced by more modern weighing machines. A bench-top single pan weighing machine with built in ballance masses, applied by external colour-coded hand wheels. Fine adjustment used electric indication method. Sheet metal enclosure is painted green hammertone. Base is cast scientific instruments, stanton instruments, balance, weighting machine, barry shearer, chemistry -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryPhotograph

The Lidwill machine was designed by Mark Lidwill in 1913, for the purpose of mechanical or insufflation anaesthesia. It was manufactured by Elliott Bros. of Sydney.Colour photograph of a Lidwill anaesthetic machine sitting on carpet. A circular metal ether vaporiser sits on a brown wooden base, with brown tubes connecting to a trap bottle and metal valves, and a brown tube connected to the valve is coiled on the floor.anaesthetic equipment, lidwill anaesthetic machine, mark lidwill, ether vaporiser, elliott bros sydney -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing, Baby's white nylon dress size 1 c1960, c1960

Nylon was a new synthetic material that became very popular c 1960 because it was easy care, had machine embossed decoration and required no ironing. Women in City of Moorabbin made clothes for their families while settling in the new estates opened in Ormond, Bentleigh and Moorabbin post World War 11.Nylon was a new synthetic material that became very popular c 1960 because it was easy care, had machine embossed decoration and required no ironing. A Baby's white nylon dress size 1 with machine embossed flowers, short sleeves, lace trim, plastic buttons and appliqued nylon flowers. Size 1clothing, baby clothes, nylon, dressmaking, layette, knitting,craftwork, wool, early settlers, city of moorabbin, bentleigh, ormond, moorabbin, post war settlers, world war 11 1939-40 sharp valma, -

Rutherglen Historical Society

Rutherglen Historical SocietyPhotograph - Image, 1970s

This is a photo of one of the first upright machine grape harvesters operating in the Rutherglen area. It was operating in the B Seppelt & sons Distillery Road vineyards on the edge of the Murray River in Wahgunyah. Riding on the top of the machine are from left to right Mandy Jones (partly obscured), Rolly Guscot (vineyard manager), machine driver, Doug Jones (manager) and Leanne Schoen (nee Jones). Mandy Jones and Leanne Schoen being the daughters of Doug JonesBlack and white photograph of several people riding on top of a machine operating in a vineyard. On left hand side is Leanne Jones , her father Doug Jones ( Manager of Seppelts) The photograph was taken in the flats vineyard ( now Pfeiffer vineyard) It was reputably the first mechanical grape harvester in the areaOn back of photo: "170% [upper case D in small circle] Seppelt's"wineries, north east victoria, wine industry, mechanical harvester, grape harvest, seppelts winery, rutherglen, doug jones -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, c1880

Machine used by Francesca Schwerkolt, August Schwerkolt daughter -in - law. She was the grandmother of the donor.Hand and foot operated transverse shuttle sewing machine with ornate foot treadle. Wooden top with mechanism in centre. Base of mechanism has mother of pearl inlay. Ornate iron supports. Two drawers on either side with ornate handles. Centre drawerOn Sewing Mechanism - ' Syst 182/Manufactured in Germany/Specially for/Hugo Wertheim'|On Base - 'Griffin' in ironwork|'Wertheim' in ornate ironwork on sides|S No. 6778165domestic items, sewing, textile machinery -

Orbost & District Historical Society

Orbost & District Historical Societyadding machine, 1964

Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manuaIly and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.On front -P3981115 mathematics accounting burroughs adding-machine business calculator -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Accessories

This sewing machine and its accessories was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's mother used it and the accessories in 1942. Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Dark green box with red & white inscription on top. Inside are 7 metal (silver coloured) attachments for Singer Sewing Machine including one for sewing zips, ruffling foot, rolled hemming foot .singer manufacturing co.. clothes. fetes. domestic. sewing. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Laundry equipment, Mangle, c1900

The mangle was used in the laundry at Key's, Exchange Hotel. This large, iron framed, manual, machine with 3 cylinders for rolling and pressing washed clothes was a prominent and necessary piece of equipment used by early settler women in Moorabbin Shire 1800 to mid 1900sThis large Mangle was used at The Exchange Hotel, Nepean Highway, Cheltenham , built in 19thC , now known as The Tudor Inn.A large, iron framed, manual, machine with 3 cylinders, for rolling and pressing washed clothes, connected by cogs manually operated by turning a side wheel with a large crank handle.On an oval plate at base of iron frame 'W. Summerscales / & Sons / Keighley Englandclothing, brighton, moorabbin, linen, washing machine, bentleigh, market gardeners, laundry equipment, mangle, early setters pioneers -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, Wal Jack

Black & white photo of 'Red Lion Hotel', Main Road, Ballarat East, c1940's to 1950's(early). 'Mrs. A. Mong' on rear of photo. From the Mong family (Paul a member of the Museum) a relative was the proprietor of the hotel until the early 50's. On Kodak print paper, Velox. Reference: Mr. Albert Mong, Norman St. Ballarat. Reimaged 17/7/2017 both front and back.in machine stamp '6320'trams, tramways, ballarat hotels, mong family, hotels -

Puffing Billy Railway

Puffing Billy Railway1920's Station Cash Box Tin - Hobbs & Co London, 1920's

1920's Station Cash Box Tin Made by Hobbs & Co London Lever Machine Made Alfred Charles Hobbs (October 7, 1812 – November 6, 1891) was an American locksmith and inventor. Hobbs went to London as a representative of the New York company of Day & Newell, which was exhibiting at the Great Exhibition of 1851. Hobbs had brought with him his boss's (Robert Newell) Parautoptic lock, designed to compete with, and surpass, the locks available at the time in Britain. He was the first one to pick Bramah's lock and the Chubb detector lock at the Great Exhibition of 1851 and forced the lock manufacturers to improve their designs. The lock controversy continues a subject of great interest at the Crystal Palace, and, indeed, is now become of general importance. We believed before the Exhibition opened that we had the best locks in the world, and among us Bramah and Chubb were reckoned quite as impregnable as Gibraltar— more so, indeed, for the key to the Mediterranean was taken by us, but none among us could penetrate into the locks and shoot the bolts of these masters. The mechanical spirit, however, is never at rest, and if it is lulled into a false state of listlessness in one branch of industry, and in one part of the world, elsewhere it springs up suddenly to admonish and reproach us with our supineness. Our descendents on the other side of the water are every now and then administering to the mother country a wholesome filial lesson upon this very text, and recently they have been "rubbing us up" with a severity which perhaps we merited for sneering at their shortcomings in the Exhibition. In 1854 he was awarded a Telford Medal by the Institution of Civil Engineers for his paper 'On the Principles and Construction of Locks'. Sign on a strong room door. Hobbs became one of the founders of the lock making firm of Hobbs Hart & Co. Ltd. The company started in 1851 and was formally registered as Hobbs and Co. in 1852. But by 1855 it had become Hobbs, Ashley and Company. The name then changed to Hobbs, Ashley and Fortescue, with an address at 97 Cheapside in London. Then for the next ninety years the address was 76 Cheapside in London. In 1860 Hobbs returned to America and lived in Bridgeport, Connecticut, and went on to hold a dozen patents for firearm ammunition manufacturing. In 1880 he listed himself as a "Superintendent Of Cartridge Factory" Info from https://en.wikipedia.org/wiki/Alfred_Charles_HobbsHistoric - Railways - Station Cash Box Tin 1920's Station Cash Box Tin - Hobbs & Co London Metal Tin - painted Black, Gold and Red with Brass Lock and HandleHobbs & Co London Lever Machine Made1920's station cash box tin, puffing billy