Showing 354 items

matching processing company

-

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Creek Diversion, Cocks Power. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2 500 000 cubic yards worked, reported recovery was 17 284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1 935 900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64 397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, tin, gold mining, tin mining, creeks, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Riffle Boards on Barge, c1934. In sluicing, riffles are used to trap heavier gold particles as water washes over them. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2 500 000 cubic yards worked, reported recovery was 17 284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1 935 900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64 397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, gold mining, barge, riffles, sluicing, men, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

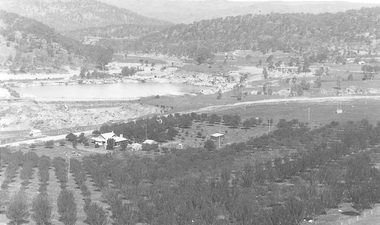

C Rankins Almond Orchard & Cocks Pioneer Pond, 1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2 500 000 cubic yards worked, reported recovery was 17 284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1 935 900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64 397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, farms, farming, almonds, sluicing, rankins, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Cocks Pioneer, East El Dorado, early 1920s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2 500 000 cubic yards worked, reported recovery was 17 284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1 935 900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64 397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, gold mining, cocks pioneer, sluicing, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Moving Cocks Pioneer Barge, c1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25,000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, tin, gold mining, tin mining, men, miners, barge, sluicing, hydraulic, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer old mine timbers. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, open cut, gold mining, tin mining, cocks pioneer, el dorado, eldorado -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Cookware, Revere Ware

... Revere Ware company engraving. Made under process patent... OHM2022_10 Revere Ware company engraving. Made under process patent ...Robin Boyd developed a close friendship with the founder of the Bauhaus in Weimar Germany, Walter Gropius, who had moved to the USA in the 1930s. Through this connection, Boyd was invited to be the Massachusetts Institute of Technology (MIT) Bemis Professor at the School in the North American academic year 1956-7. During this time, the Boyds purchased this set of Revere kitchenware, which carries the prized "Process Patent" maker's mark on the thick copper bases. Mandie Boyd recalls: "I don’t remember a lot of cooking going on in them, if any, as they were a pain to clean but looked fabulous hanging on the wall absolutely gleaming. We would all check our hair and make up in them."A set of Revere Ware Saucepans and Frying Pans. A set of four Revere Ware copper clad, stainless steel saucepans with lids and black handles and hanging rings. A set of three Revere Ware copper clad, stainless steel pans with black handles and hanging rings. The largest flat one has no lid. Saucepans: largest 175mmx140mm, smallest 120mmx180mm. Frying Pans: largest 350mmx10mm, smallest 80mmx50mm.Revere Ware company engraving. Made under process patent #2363973. 'Revere Ware 1801' 'Patent # 22726091'revere, revereware, revere ware, cookware, walsh st kitchenware, robin boyd, ohm2022, ohm2022_10 -

National Wool Museum

National Wool MuseumShuttle, estimate Mid-20th century

Example of a shuttle used for a loom in the weaving process. This shuttle was probably used as an advertising piece for Waddington's company as it is constructed differently to other examples of working shuttles in the museum collection. This shuttle is a a unique item in the collection as a shuttle made for advertising purposes instead of being made for use on a loom. Wooden loom with metal tips on either end. Loom is rectangular. One side has a green sticker. Metal pieces inside loom are not present.WADDINGTON'S/ FOR/ SHUTTLES OF QUALITY/ Phone Bradford 27668waddingston's, weaving, shuttle, loom, advertising, geelong, wool -

National Wool Museum

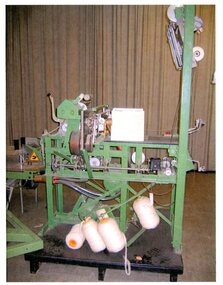

National Wool MuseumMachine - Spinning Machine Prototype, CSIRO et al, 1960s

Self-twist spinning machine prototype developed by CSIRO in the 1960's. Made by CSIRO Division of Wool Technology in conjunction with an Australian engineering company REPCO and the International Wool Secretariat. Prototype developed in 1960's and since 1970 over 3500 have been produced and sold.Self-twisting spinning machine (protoype).Label with machine: Prototype SELF-TWIST SPINNER / This prototype spinning machine was built / at Division of Wool Technology in the mid 1960's as / part of the program which developed the Self-Twist spinning / process. / Self-Twist was commercially released in / 1970 by The Division in conjunction with the Australian / engineering company Repco, and The International Wool / Secretariat. / Since 1970 more than 3500 Self-Twist / machines have been sold. / The process offers advantages in the / speed of spinning, machine size, maintenance and energy / consumption.engineering, manufacturing, wool processing, spinning, csiro, prototype, invention, wool technology, self-twist, repco, international wool secretariat -

National Wool Museum

National Wool MuseumBook, Wool and the nation 3rd ed

"Wool and the nation 3rd ed, 1960" , gives an overview of all facets of the "Wool" industry.shearing sheep breeding - history merino sheep - history wool - history wool sales wool processing textile industry - history, goldsbrough, mort and company limited, shearing, sheep breeding - history, merino sheep - history, wool - history, wool sales, wool processing, textile industry - history -

National Wool Museum

National Wool MuseumBook, Wool and the Nation- a sketch of the Wool Industry in Australia

"Wool and the Nation: a sketch of the Wool Industry in Australia" - Goldsborough Mort and Company Limited, 1946."Wool and the Nation: a sketch of the Wool Industry in Australia" - Goldsborough Mort and Company Limited, 1946.wool - history wool growing wool brokering wool industry wool processing wool sales, goldsbrough, mort and company limited, wool - history, wool growing, wool brokering, wool industry, wool processing, wool sales -

National Wool Museum

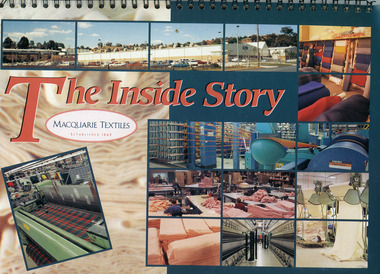

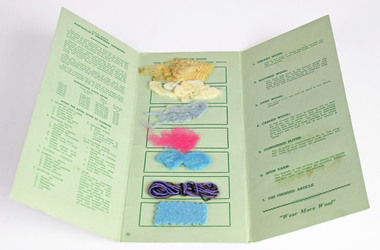

National Wool MuseumBooklet - Binder, The Inside Story, 1995

Binder begins by discussing the history of Macquarie Textiles before expanding into explaining the operations of the company and how they produce their different finished worsted and woollen textiles. The information is dated to 1995 and makes for interesting reading into the past, especially the information in regards to computers and how they were begin to be introduced into the work place.A4 sized binder with 8 individual pages containing information on both front and back. Coloured ink with attached samples make up the contents of these pages. All pages have the same image of wool in the backgroundmacquarie textile, wool processing -

National Wool Museum

National Wool MuseumAlbum - Photo Album, Grazcos, c.1999

Photo album detailing the process involved in the Jumbo Wool Auction Service. This process was developed by Grazcos, a company who advanced innovations for shearers and wool farmers before amalgamating with Dalgety in the early 1990s. Grazcos was a well-known name to source a competent shearing team, or as a destination for wool in need of bulk classing. The Jumbo Wool Auction service was designed to process wool more efficiently through volume. 63 traditionally dumped farm bales of wool would fill a typical shipping container. The Jumbo Wool Auction Service enabled 108 farm bales to fit into the same container. This brought reductions in the costs of handling, selling, storing, and shipping of wool. This photo album details this process; from classing to shipping. This photo album was a draft copy produced for review before the production of mass-produced advertising flyers. 12-page hard cover photo album. Internally colour images and printed text have been stuck behind a protective plastic onto paper. The backing paper has many distinctive orange and grey horizontal lines. Printed text is in black ink. Colour images are 2 x 3 inches with rounded corners. Images and text are numbered 1 to 16 detailing the process of the Jumbo Wool Auction Service developed by Grazcos.wool auction, wool processing, grazcos -

National Wool Museum

National Wool MuseumArchive - Wool sample card, Onkaparinga Woollen Mill Company, 1950s

Note from collector- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from." Salesman's Wool sample card containing samples of wool at different stages of processingJohn Taylor/With Compliments from Onkaparinga/Woollen Co.Ltd/Adelaide, Sth Aust. Mills Lobethal and Thebarton, S.A/Always insist on Onkaparinga Rugs.Blankets.Worsteds.Melanges.Woollens and Flannelswool, blanket fever, advertisement, onkaparinga, sample -

National Wool Museum

National Wool MuseumBooklet, Wool and the Nation

"Wool and the Nation: a sketch of the wool industry in Australia" - Goldsbrough, Mort & Co. Ltd, 3rd ed., 1960.shearing wool brokering woolclassing wool processing wool - history, goldsbrough, mort and company limited, shearing, wool brokering, woolclassing, wool processing, wool - history -

National Wool Museum

National Wool MuseumEnvelope

Envelope produced by the Stamina Clothing Company, manufacturers of work clothes, who used Crusader brand cloth produced by the Australian Woollen Mills complex at Marrickville, NSW. It was made to house a set of 16 information cards on the manufacturing processes in a woollen mill. They were issued as give aways and could be found in the pockets of Stamina brand clothing.Envelope for 16 information cards (4350-4365) which were promotional give aways from Crusader Mills, c.1945-1955.Crusader / With the good wishes of the / makers of Crusader Clothaustralian woollen mills pty ltd stamina clothing company -

National Wool Museum

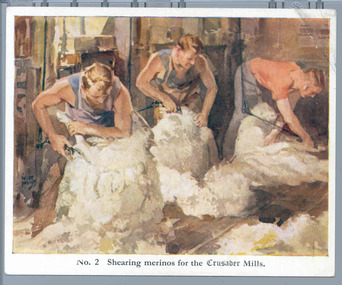

National Wool MuseumCard

This card is the second in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of sheep shearing.Card no. 2 from the Crusader Mills information card set, c.1945-55. Verso of card no. 2 from the Crusader Mills information card set, c.1945-55.No. 2 Shearing merinos for the Crusader Mills.shearing, australian woollen mills pty ltd stamina clothing company -

National Wool Museum

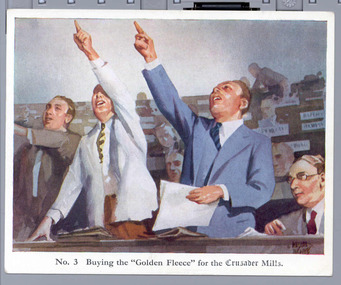

National Wool MuseumCard

This card is the third in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool buying and wool sales.Card no. 3 from the Crusader Mills information card set, c.1945-55. Verso of card no. 3 from the Crusader Mills information card set, c.1945-55.No. 3 Buying the 'Golden Fleece' for the Crusader Mills.wool brokering wool sales, australian woollen mills pty ltd stamina clothing company, wool brokering, wool sales -

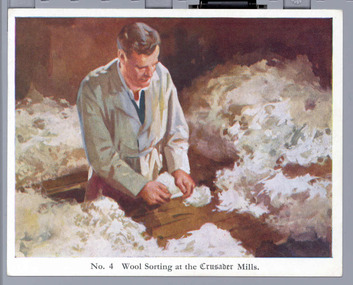

National Wool Museum

National Wool MuseumCard

This card is the fourth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool sorting and classing.Card no. 4 from the Crusader Mills information card set, c.1945-55. Verso of card no. 4 from the Crusader Mills information card set, c.1945-55.No. 4 Wool Sorting at the Crusader Mills.woolclassing, australian woollen mills pty ltd stamina clothing company -

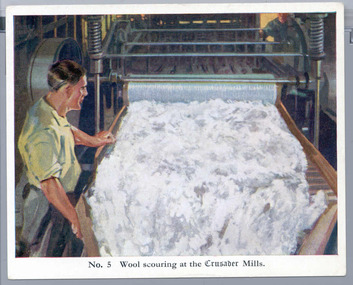

National Wool Museum

National Wool MuseumCard

This card is the fifth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool scouring.Card no. 5 from the Crusader Mills information card set, c.1945-55. Verso of card no. 5 from the Crusader Mills information card set, c.1945-55.No. 5 Wool scouring at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, scouring -

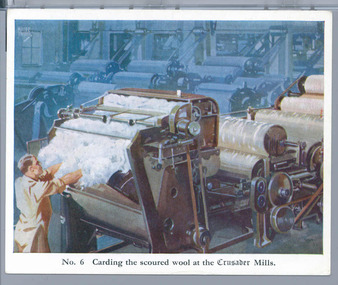

National Wool Museum

National Wool MuseumCard

This card is the sixth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool carding.Card no. 6 from the Crusader Mills information card set, c.1945-55. Verso of card no. 6 from the Crusader Mills information card set, c.1945-55.No. 6 Carding the scoured wool at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, carding -

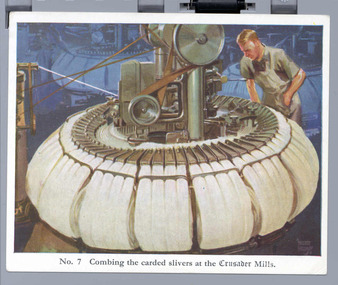

National Wool Museum

National Wool MuseumCard

This card is the seventh in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool combing and shows a Noble comb.Card no. 7 from the Crusader Mills information card set, c.1945-55. Verso of card no. 7 from the Crusader Mills information card set, c.1945-55.No. 7 Combing the carded slivers at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, combing, noble comb -

National Wool Museum

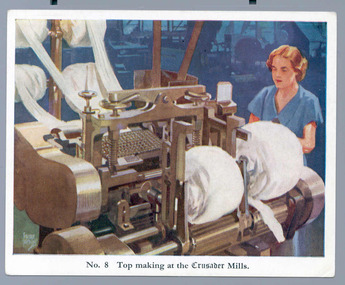

National Wool MuseumCard

This card is the eighth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of top making at a gilling machine.Card no. 8 from the Crusader Mills information card set, c.1945-55. Verso of card no. 8 from the Crusader Mills information card set, c.1945-55.No. 8 Top making at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, gilling, top making -

National Wool Museum

National Wool MuseumCard

This card is the ninth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of the drawing out of the top.Card no. 9 from the Crusader Mills information card set, c.1945-55. Verso of card no. 9 from the Crusader Mills information card set, c.1945-55.No. 9 Drawing out the Top prior to spinning at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, drawing -

National Wool Museum

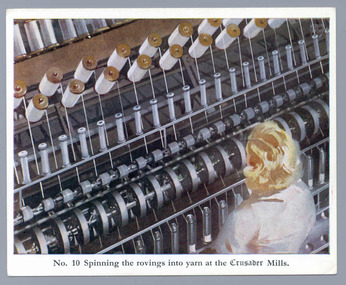

National Wool MuseumCard

This card is the tenth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of spinning.Card no. 10 from the Crusader Mills information card set, c.1945-55. Verso of card no. 10 from the Crusader Mills information card set, c.1945-55.No. 10 Spinning the rovings into yarn at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, spinning -

National Wool Museum

National Wool MuseumCard

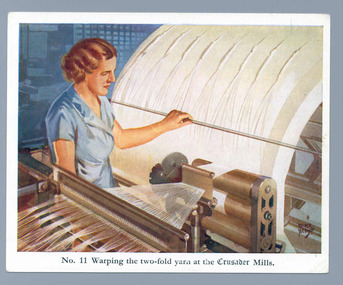

This card is the eleventh in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of warping.Card no. 11 from the Crusader Mills information card set, c.1945-55. Verso of card no. 11 from the Crusader Mills information card set, c.1945-55.No. 11 Warping the two-fold yarn at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, warping -

National Wool Museum

National Wool MuseumCard

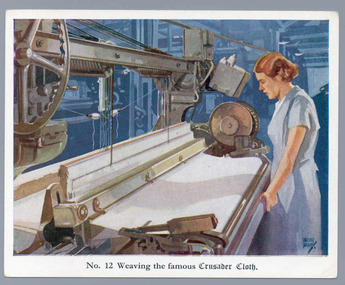

This card is the twelfth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of weaving.Card no. 12 from the Crusader Mills information card set, c.1945-55. Verso of card no. 12 from the Crusader Mills information card set, c.1945-55.No. 12 Weaving the famous Crusader Cloth.australian woollen mills pty ltd stamina clothing company, weaving looms -

National Wool Museum

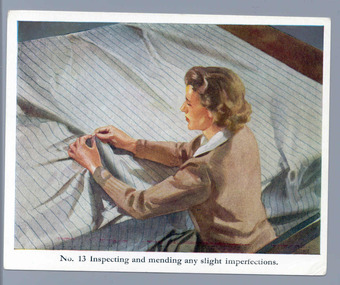

National Wool MuseumCard

This card is the thirteenth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of mending the newly woven cloth.Card no. 13 from the Crusader Mills information card set, c.1945-55. Verso of card no. 13 from the Crusader Mills information card set, c.1945-55.No. 13 Inspecting and mending any slight imperfections.australian woollen mills pty ltd stamina clothing company, mending -

National Wool Museum

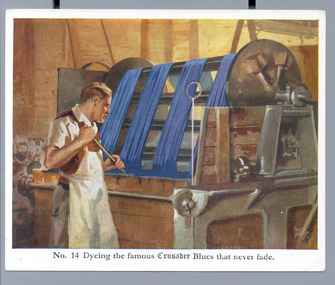

National Wool MuseumCard

This card is the fourteenth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of dyeing.Card no. 14 from the Crusader Mills information card set, c.1945-55. Verso of card no. 14 from the Crusader Mills information card set, c.1945-55.No. 14 Dyeing the famous Crusader Blues that never fade.australian woollen mills pty ltd stamina clothing company, dyeing -

National Wool Museum

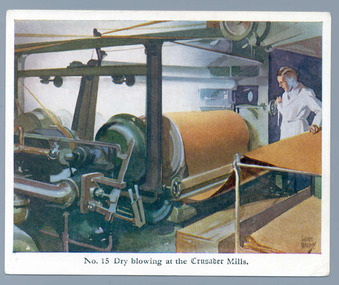

National Wool MuseumCard

This card is the fifteenth in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of dry blowing the cloth, which fixes the width and imparts lustre.Card no. 15 from the Crusader Mills information card set, c.1945-55. Verso of card no. 15 from the Crusader Mills information card set, c.1945-55.No. 15 Dry blowing at the Crusader Mills.textile finishing, australian woollen mills pty ltd stamina clothing company