Showing 314 items matching "stoneware"

-

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBottle, Pottery

The bottle was proably used to store ink.Straight sided, small light brown pottery bottle with a pouring lip. No cork.Lovatt. Lovatt. Ltd.domestic, pottery, brown, bottle, ink, container, ceramic, stoneware, writing equipment -

Federation University Art Collection

Federation University Art CollectionCeramic, Press Moulded Pot by Les Castle, 1979, c1979

Len CASTLE (23 December 1924 – 29 September 2011 ) Born New Zealand 'My best work is when intuition and conscious choice come together successfully.' Len Castle trained as a secondary schoolteacher and started making pottery in 1947. Initially self-taught, he was the first potter to be awarded a fellowship from the Association of New Zealand Art Societies, travelling to St Ives to work with Bernard Leach in 1956-57. He lectured at the Auckland Teachers' College until the early 1960s, before concentrating on making stoneware at Titirangi, New Zealand. Len Castle was an artist in residence at the Gippsland Centre for Art and Design (GCAD).Two piece press moulded ceramic form with glaze wash surface.ceramics, len castle, gippsland campus, jan feder memorial ceramics collection -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Photograph - Colour, Ceramic Plate by Graham Masters of Sweenies Creek Pottery

Graham MASTERS Graham Masters is a potter based at Sweenies Creek, just outside Bendigo, Victoria. He specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo, before becoming an employee, then a partner at Maldon Pottery, Maldon, Victoria, with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1983 and has been there over 20 years. In 2000 Graham Masters started working at Bendigo pottery, and is one of five in the business, specialising in large works such as vases, platters and wine barrels, all handmade on the pottery wheel. graham masters, sweenies creek pottery, ceramics -

Federation University Art Collection

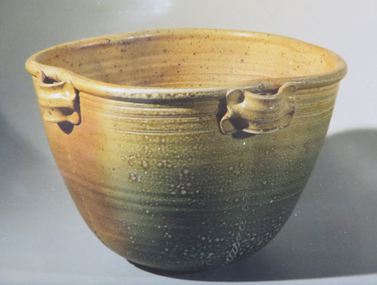

Federation University Art CollectionCeramic - Artwork - Ceramics, Len Castle, Press Moulded Bowl by Len Castle, c1979

Len CASTLE (23 December 1924 – 29 September 2011 ) Born Auckland, New Zealand 'My best work is when intuition and conscious choice come together successfully.' Len Castle trained as a secondary schoolteacher and started making pottery in 1947. Initially self-taught, he was the first potter to be awarded a fellowship from the Association of New Zealand Art Societies, travelling to St Ives to work with Bernard Leach in 1956-57. He lectured at the Auckland Teachers' College until the early 1960s, before concentrating on making stoneware at Titirangi, New Zealand. Len Castle was an artist in residence at the Gippsland Centre of Art and Design c1979.Press moulded bowl. Gift of the artist.ceramics, jan feder, jan feder memorial ceramics collection, len castle, gippsland campus -

Federation University Art Collection

Federation University Art CollectionCeramic, 'Helmet Bowl & Vessel' by Neville French, 2003

Neville FRENCH (1955- ) Born Maryborough, Victoria In 1977 Neville French graduated from Ballarat College of Advanced Education after studying a Diploma in Fine Art (Ceramics) between 1974 and 1976, and was a tutor there for six months in 1978. He holds a Master of Arts, Research (Ceramics) from RMIT Universiy, and was awarded the Vitrify Alcorso National Ceramics Award in 2012. Neville has an international reputation as a ceramics artists and educator. From 1982 to 2012 Neville French was teach and coordinator of the Ceramics department at the Ballarat School of Mines and University of Ballarat (now Federation University). From 1982 to 2012 Neville French taught Ceramics at the Ballarat School of Mines TAFE, which later merged with the University of Ballarat (now Federation University Australia). He completed a Graduate Diploma of Education at Hawthorn State College in 1980, a Certificate of Stoneware Glazes from Brisbane College of Advanced Education in 1983 and a Master of Arts Fine Art (Ceramics) at RMIT University in 2000. Between 2010 and 2012 Neville French taught post graduate honours and masters Ceramics students. During his time as a student at Ballarat Neville Bunning would collect clay from the Enfield clay pit. He described following white tyre tracks to find the location. He described the clay as silky smooth and and fired to a beautiful grey colour at stoneware tempreture. When blended with terracotta clay from Nerrina or fireclay from Bacchus Marsh a wide range of different bodies could be created. This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Two vessels made as a sculptural pair. Statement: "My work involves an exploration of elemental vessels - extending porcelain to develop taut contours and spatial dynamics. I seek to distill an essence of purity to evoke notions of quietude and transendence through the expressive use of glaze and its relationship to form, tactility, weight and light. Forms are wheel-thrown, altered and slowly scraped to develip a soft line and solidity. Coloured matt glazes are layered and fused to the porcelain body through multiple firings to give expression and luminosity to the surface,. The iodosyncratice nature of glaze stimulates the imagination. It evokes associations with the natural environement and alludes to a meditative infinity."Signed on base 'f.'art, artwork, neville french, french, ceramics, porcelain, wheelthrown, thrown and altered, alumni -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramic, Greg Daly, 'Lustred Form' by Greg Daly, 1984

Greg DALY (1954- ) Born Melbourne, Victoria Greg Daly is internationally known and respected as a ceramic artist specialising in rich glaze effects, and also as the author of Glazes and Glazing Techniques (1995 Simon & Schuster). His work is represented in over 24 international book publications, in over 80 national and international art galleries and museums (including the National Gallery of Australia and the Victoria & Albert Museum, London), and he has won over 36 national and international awards. He has held over 70 solo exhibitions and was President of Craft Australia from 1992-1995. He has exhibited in over 200 international and national group exhibitions. In 1999 he received an ARC grant to research the effect of firing cycles in the development of copper red glazes. Source http://www.gregdaly.com.au/bio/ This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Stoneware form decorated with lustre glaze. This ceramic form is a sculptural representation of rock forms Daly created during the 1970s and 1980s. His magnificent lustre glaze is a signature of Daly's master work with glaze production. Greg Daly is regarded as Australia's most pre-eminent ceramicist and teacher. His ceramic production is technically outstanding, his original forms float in an ethereal space far superior in conceptual design than those ceramic works which remain rooted to the table tops. This piece is a magnificent example of the work of this ceramic genius. Description by Dr Susan Patersonart, artwork, ceramics, greg daly, lustre, glaze -

Parks Victoria - Mount Buffalo Chalet

Parks Victoria - Mount Buffalo ChaletCup

Part of Victorian Railways crockery. 'When the Victorian railways took over management of the Chalet from 1 october 1924, they ran their dining room and cafe in similar fashion to the dining cars on their trains and refreshment rooms on their stations, using the same ceramic hotel-ware and electro plated nickel silverware (EPNS), all made to order items that are clearly idenitified by the distinctive 'VR' monogram. . ..The Chalet Collecton also incudes items of ceramic stoneware... and these too interpret the function and role of the dining room. The ceramic items items were generally manufactured by 'Grindley' or 'Grafton'... Ceramic ware used at the Chalet from the 1920's to the 1950's had a black VR monogram or badge and was the same crockery used in th VR dining and buffet cars. Crockery used in the VR refreshment rooms had a red monogram." (Pg 104. Historica)' Listed in Draft Inventory of Significant Collection items. Appendix A.3.Tableware. (Pg 166 Historica).Small coffee cup with Victorian Railways in scroll design with a crown motif above scroll. White china with black transfer design. Mark and inscription on base. Handle is broken, cup cracked. Cup possibly broken during removal to Bright in 2005. also two teacups of the same design and inscription. Both have handles but both are cracked.-On base,"DURALINE / SUPER /VITRIFIED / GRINDLEY / HOTEL WARE Co / ENGLAND / 3-41 " On front of cup,"VICTORIAN RAILWAYS" -

Nillumbik Shire Council

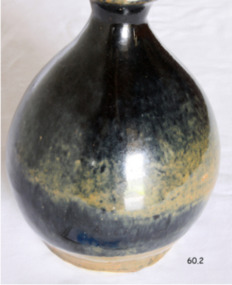

Nillumbik Shire CouncilPottery (vase): Joan Armfield, Joan Armfield, Vessel - Iron Clay, c.1975

Vessel - Iron Clay, is a wheel thrown vase that curves upwards from a narrow base to form a wide, rounded shoulder before concluding at a short, delicate rim. In contrast to the unglazed, rough texture of the exterior surface, the entrance to the vessel is smooth and shiny due to a tea leaf dust glaze. This is a low alumina tenmoku glaze, containing magnesium oxide which is responsible for the dark yellow/green striations of speckling which are formed during the slow cooling process of a reduction firing. This patterning is intermittent and dispersed with a grey/green pebbled effect. The stoneware vessel is built from clay with a high percentage of iron. -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Vic Greenaway, Porcelain Cylinder by Victor Greenaway, 1980, 1982

Victor GREENAWAY (1947 - ) Born Sale, Victoria Victor Greenaway studied Ceramics at RMIT. He established his first workshop in Hawthorn in 1968, before moving to Ian Sprague's Mungeriba Pottery, Upper Beaconsfield in 1969. He studied under Tatsuzo Shimoaka in Mashiko, Japan under a Churchill Fellowship awarded in 1974. Upon his return he established Broomhill Pottery in Upper Beaconsfield in 1975, and in 1976 started employing trainees. He was a visiting lecturer at the Gippsland Centre for Art and Design (GCAD) c1980. Hand-decorated wheel thrown porcelaneous stoneware glazed with semi-matt, silky white and dry black glaze and magnesium carbonate. The brushwork and banding is cobalt and iron with bronzelustre on-glaze bands. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.Artist's stamp on base.gippsland campus, victor greenaway, ceramics, artists, artwork, jan feder memorial ceramics collectrion -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Ramikin Cup by Mudwood Studio, c1980s

Bill LONGLEY (03.12.1933 – 20.5.2020) Arrived Australia 1981 Bill Longley started an apprenticeship with “Kingwood Rural Industries” Surrey in 1948. In 1956 is changed name to “Greyshott Pottery" After serving in the Royal Air Force from 1954 to 1977 he undertook and later, teacher training, then bought the “Penderleath Pottery”, St Ives, Cornwall in 1977 from Anthony Richards and renamed it the “Cripplesease Pottery.” Bill made a wide range of domestic stoneware. He built up the pottery into a successful business, eventually selling in 1981 and migrating to Australia with his wife Sue. In Melbourne, Bill Longley made and sold pottery at weekend markets, as well as helping Robert Gordon (June Dyson’s son) set up his Pakenham pottery, which Gordon started in 1979. Bill Longley worked as an advisor and thrower with Robert Gorndon for some time." Bill retired in the late 1980s to Daylesford Works may be marked with an impressed 'Bill Longley, Australia'.Blue Vessel by Bill Longleyaustralian studio ceramics, bill longley, pottery, ceramics -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Blue Vessel by Bill Longley, c1980s

Bill LONGLEY (03.12.1933 – 20.5.2020) Arrived Australia 1981 Bill Longley started an apprenticeship with “Kingwood Rural Industries” Surrey in 1948. In 1956 is changed name to “Greyshott Pottery" After serving in the Royal Air Force from 1954 to 1977 he undertook and later, teacher training, then bought the “Penderleath Pottery”, St Ives, Cornwall in 1977 from Anthony Richards and renamed it the “Cripplesease Pottery.” Bill made a wide range of domestic stoneware. He built up the pottery into a successful business, eventually selling in 1981 and migrating to Australia with his wife Sue. In Melbourne, Bill Longley made and sold pottery at weekend markets, as well as helping Robert Gordon (June Dyson’s son) set up his Pakenham pottery, which Gordon started in 1979. Bill Longley worked as an advisor and thrower with Robert Gorndon for some time." Bill retired in the late 1980s to Daylesford Works may be marked with an impressed 'Bill Longley, Australia'.Blue Vessel by Bill Longleyaustralian studio ceramics, bill longley, pottery, ceramics -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps Museumbottles, unknown

all bottles found in old well on site of old Bartlett's Cordial Factory on corner of Francis Street and Service Street, Tatura opposite Lake Bartlett in 1999 by owners of the land who were clearing land to build units9 bottles, 7 glass and 2 pottery - 1)pottery, colour stone & light tan, inscription in black "drink good old ginger beer brewed by J. Bartlett & Co Tatura" and "This bottle is the sole property of J.Bartlett & Co. and must not be used by any other persons."|2)pottery, colour stone & brown, inscription in black "drink good old ginger beer made by J. Bartlett & Co Tatura" and "This bottle is the sole property of J.Bartlett & Co. Tatura" Stamped into pottery is oval stamp with words "Govancroft of Glasgow" and the number 1.|3)clear glass bottle with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co" and "Lemonade" and a small number 2. On base is "M5 29, a symbol and M".|4)clear glass bottle with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co" and "Lemonade" and a small number 2. On base is "M5 29, a symbol and M".|5)green glass bottle with marble in neck with inscription in glass "J.Bartlett & Co. JB & Co Trade Mark Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co" and "Lemonade" . On base is letter "M".|6)green glass bottle with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co" and a small number 4 . On the base is letters M750, M and ACM.|7)clear glass bottle with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co". On base is ACM.|8)clear glass bottle with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co" and small number 1. On base is M749, M and ACM.|9)clear glass bottle with fancy pattern on neck with inscription in glass "J.Bartlett & Co. J.B. Rushworth & Tatura" and "This bottle is the property of J.Bartlett & Co". On base is L567, M and ACM.tatura, bartlett, drink, bottle, glass, pottery, industry, smith, reynolds, technology, bottles, ceramics, stoneware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ceramic Bottle (Chinese Style), Minton Potteries, Late 19th century

The subject item is believed to be a "Chinese style stoneware liquor bottle used to store "Tiger Whiskey" (rice wine). These Chinese liquor bottles are made of glazed pottery known as brown stoneware and have been made throughout the centuries by many makers until well after American Prohibition. Later varieties from the mid 20th century are commonly found in the USA with the raised lettering "Federal Law Forbids Sale Or Re-use of this bottle" a sure sign of post-1934 manufacture. This example is interesting as it has a British Minton mark of two triangles on the base indicating a date of 1879 and was likely exported to Australia by Minton. These ceramic bottles virtually always have irregularities and flaws which indicate a product has been hastily manufactured, in any event, this is a fine example of a relatively common item that may have been copied by Minton and sold as a decorative domestic item for display or mass produced for storing liquor. Giles Family: The pair of ceramic bottles were given to Vera Giles by Jim Thompson and are just many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940. A significant item of lead-glazed ceramic with the possibility it was made by the Minton potteries in England who were renowned for making quality pottery. The item style is in all probability a copy of a Chinese liquor bottle that was in common use throughout the British colonies and America up until the mid 20th Century. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established.Chinese liquor bottle one of a pair, lead glazed ceramic, dark brown and blue/black. Part of the Giles Collection.Mark of a double triangle, apex touching, on base, (Minton mark for 1879).flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, vase, pottery, ceramic ornament, domestic ware, late 19th - early 20th centuy ornament, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ceramic Bottle (Chinese Style), Minton Potteries, Late 19th century

The subject item is believed to be a "Chinese style stoneware liquor bottle used to store "Tiger Whiskey" (rice wine). These Chinese liquor jugs are made of glazed pottery known as brown stoneware and have been made throughout the centuries by many makers until well after American Prohibition. Later varieties from the mid 20th century are commonly found in the USA with the raised lettering "Federal Law Forbids Sale Or Re-use of this bottle" a sure sign of post-1934 manufacture. This example is interesting as it has a British Minton mark of two triangles on the base indicating a date of 1879 and was likely exported to Australia by Minton. These ceramic bottles virtually always have irregularities and flaws which indicate a product has been hastily manufactured, in any event, this is a fine example of a relatively common item that may have been copied by Minton and sold as a decorative domestic item for display or mass produced for storing liquor. Giles Family: The pair of ceramic bottles were given to Vera Giles by Jim Thompson and are just many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940. A significant item of lead-glazed ceramic with the possibility it was made by the Minton potteries in England who were renowned for making quality pottery. The item style is in all probability a copy of a Chinese liquor bottle that was in common use throughout the British colonies and America up until the mid 20th Century. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established.Chinese liquor bottle one of a pair, lead glazed ceramic, dark brown and blue/black. Part of the Giles Collection.Mark of a double triangle, apex touching, on base, (Minton mark for 1879).flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, vase, pottery, ceramic ornament, domestic ware, late 19th - early 20th centuy ornament, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods -

Federation University Historical Collection

Federation University Historical CollectionBooklet, N.L. Harvey Photographers, All that Glitters ... :The Growth of Ballarat Victoria, c1966

Red, blue and gold soft covered booklet. Images include the Ballarat Town Hall, The Eureka Monument, Begonia house, Ballarat Botanic Gardens,M.B. John, Sebastopol Technical School, reservoirs, Ballarat Base Hospital, Calembeen Park, Ballarat Industrial Estate, Lal Lal Falls, Buninyong Golf Course, Mayne Nickless, Firth Cleveland Plant, Bendix Mintex, Bunge, (Aust.) Pty Ltd, Martin's Stoneware, Sunshine biscuits, Timken, M.B. John and Hattersley Limited, Ballarat Gas Company, Ballarat Paper Mills, Ballarat Woollen and Worsted Mills, Eclipse Motors, E. Lucas and Co, Milk Processors Pty Ltd, Eureka Valves, Paddle Bros., George Farmer Pty Ltd, Sebastopol technical School, Burrumbeet and Windermere Co-Operative Society Ltd .greater ballarat association, develop victoria council, ballarat, begonia queens, yvonne arstall, carol penrose, wendy longmore, lal lal falls, ballarat town hall, the eureka monument, begonia house, ballarat botanic gardens, m.b. john, sebastopol technical school, reservoirs, ballarat base hospital, calembeen park, ballarat industrial estate, buninyong golf course, mayne nickless, firth cleveland plant, bendix mintex, bunge, martin's stoneware, sunshine biscuits, timken, m.b. john and hattersley limited, ballarat gas company, ballarat paper mills, ballarat woollen and worsted mills, eclipse motors, e. lucas and co, milk processors pty ltd, eureka valves, paddle bros., george farmer pty ltd, yvonne arsrtall, wendouree, shire of wendouree, guncotton factory, regina glass fibre -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Jug, Emu Jug by Albury Pottery, c1980s

Albury Pottery was established in the late 1970s to supply pottery for the party plan company Cooperware, a spin-off from Faberware. Located in Hudson Crescent, Lavington, the pottery was managed by Rudolph Dybka until 1983, then by Ron Petch, who had previously worked as sales manager for Cooper Pottery, one of Cooperware's UK suppliers. By the mid-1980s, the pottery had four throwers and a further 5-6 employees, and was specialising in stoneware with distinctive ribbed forms and light blond glazes. In 1985, the pottery was sold to the NSW Government as a workers' cooperative, and Petch moved to Old Ballarat Pottery as production manager. In 1987, the Petch's bought back into the business with partners Pat and Ken Snape, moving to slip casting, doubling the operating area, opening a terracotta plant in a separate location and establishing a tourism presence in the Old Cheese factory between Albury and Wodonga. As the business grew it took on more partners and this proved problematic in a declining market for production pottery. The Petch's pulled out in 1991 and the pottery closed shortly afterwards. (CC BY NC SA Judith Pearce, accessed https://www.flickr.com/groups/1281707@N21/discuss/72157629392131982/, 15 October 2024.)A ceramic jug with a brown top, and an emu on a white ground.albury pottery, emu -

Federation University Art Collection

Federation University Art CollectionCeramic, 'Salt Glazed Bowl' by John Edye, c1983

John EDYE (1944- ) John Edye trained in London at Harrow School of Art in the 1970s, and worked with Peter Dick in Yorkshire and Colin Pearson in Aylesford, Kent before returning to Australia to head the Sturt Pottery at Mittagong from 1974 to early 1978. At Sturt, his trainees included Piers Laverty, Wim Boot, Will Castle, Ruth Elder, Colin McNeill, Penelope Carr, Patrick Forman and Malcolm Campbell. Edye introduced them to salt-glazing, a technique at that time not widely used by studio potters. After leaving Sturt, he established the Little Forest Pottery at Yerrinbool in the Southern Highlands of NSW with Penelope Carr, who moved to Hazelbrook to set up her own pottery in 1983. Edye ran his pottery on a production scale for many years, making reduced and salt glazed stoneware and tutoring part time at East Sydney Technical College. Recently he has been working in Egypt as a technical advisor to an aid project, and he was a speaker at the Australian Ceramics Triennale 09. His works are marked with an impressed 'JE' and/or with the three-lobed tree emblem of Little Forest Pottery. John Edye was a visiting lecturer to the Gippsland Centre of Arts and Design (GCAD).Salt Glazed BowlTwo Stamps on basejohn edye, ceramics, jan feder memorial ceramics collection, gippsland -

City of Greater Bendigo - Civic Collection

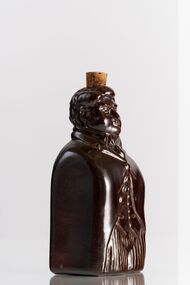

City of Greater Bendigo - Civic CollectionCeramic - Bendigo Pottery :: Australian Prime Minister Flask, Bendigo Pottery, Alfred Deakin, c 1975

Established by George Guthrie in 1857 (about 5km north of its current site) and then again seven years later in 1864 after it initially closed, Bendigo Pottery remains one of the most influential and longest running Pottery’s in Australia. Over the years the Pottery has contributed to the growth and development of the district through both its products including building products, table ware and decorative and commemorative war as well as artistically, being responsible for training and supporting many potters locally. The City of Greater Bendigo has had a long history of partnering with Bendigo Pottery and the Civic Collection holds a number of important items within its collection. This Alfred Deakin 'reform' flask was one of a limited edition character bottles produced by the Pottery to commemorate important figures in Australian politics. The original reform flasks were English salt-glazed stoneware flasks produced in the early 19th century shaped into the form of figures connected with the Reform Bill of 1832. Much was made of puns like ‘the spirit of reform’ at the time. Artist John Frith has taken the reform flask form as inspiration for a series of political ceramics of some Australian Prime Ministers. The series includes Edmund Barton, Alfred Deakin and Chris Watson.Glazed ceramic flask in the shape Alfred Deakin. Square shaped with most of the detail on the front facing side other than head which is more detailed. Cork still in place in top of head.On reverse of flask; Alfred Deakin / Prime Minister / of Australia / 1903 - 1904 / 1905 - 1908 / 1909 - 1910 Bendigo Pottery / LMTED / Edition Series / 101/200 /Australia Signed lower left; 'Frith'australian politics, bendigo pottery -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionCeramic - Bendigo Pottery :: Australian Prime Minister Flask, Bendigo Pottery, Sir Edmund Barton, c 1975

Established by George Guthrie in 1857 (about 5km north of its current site) and then again seven years later in 1864 after it initially closed, Bendigo Pottery remains one of the most influential and longest running Pottery’s in Australia. Over the years the Pottery has contributed to the growth and development of the district through both its products including building products, table ware and decorative and commemorative war as well as artistically, being responsible for training and supporting many potters locally. The City of Greater Bendigo has had a long history of partnering with Bendigo Pottery and the Civic Collection holds a number of important items within its collection. This Sir Edmund Barton 'reform' flask was one of a limited edition character bottles produced by the Pottery to commemorate his contribution to Australian politics. Edmund Barton became Australia’s first Prime Minister on New Year’s Day 1901, at a huge public ceremony in Centennial Park in Sydney. Reform flasks were English salt-glazed stoneware flasks produced in the early 19th century shaped into the form of figures connected with the Reform Bill of 1832. Much was made of puns like ‘the spirit of reform’ at the time. Artist John Frith has taken the reform flask form as inspiration for a series of political ceramics of some Australian Prime Ministers. The series includes Edmund Barton, Alfred Deakin and Chris Watson. Glazed ceramic flask in the shape of Sir Edmund Barton. Square shaped with most of the detail on the front facing side other than head which is more detailed. Cork still in place in top of head.On reverse of flask; Sir Edmund / Barton / Prime Minister / of Australia / 1901 to 1908 Bendigo Pottery / LMTED / Edition Series / 110/1200 /Australia Signed lower centre; 'Frith'australian politics, bendigo pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Hot water bottle, late 19th - early 20th century

This hot water bottle was designed to lay flat in a bed between the sheets. Its purpose was to warm the bed before use. The bottle was filled with hot water then a stopper was placed in the top to seal it, preventing the water from running out. The inscription on the attached label of this hot water bottle gives both the donor's details and the location of the bottle when it was first displayed at Flagstaff Hill Maritime Village. the "P.M.O." are the initials for the Port Medical Office. The donor's details are also written in pencil on the base of the bottle. In the 16th-century people warmed their beds with the 'bed warmer', which was a long-handled, metal pan filled with hot coals and embers and covered with a lid. The pan was placed between the bedsheets to warm the bed before the person retired to sleep for the night. In the early 19th-century earthenware bed warmers came began to be used for the same purpose. They would be filled with hot water and sealed then often wrapped in fabric. The ceramic material would hold the heat for quite some time, without being too hot for the person in bed to also warm their feet as they went off to sleep. Hot water bottles were later made from glass, copper, brass or tin. Some manufacturers made them into decorative pieces that still had practical use. In 1903 a patent was taken out for the first rubber hot water bottle, invented by Slavoljub Eduard Penkala, a Croatian engineer. This bottle is of historic significance, as an example of personal heating equipment used in the late 19th and early 20th centuries.Hot water bottle, earthenware, pale colour with brown glaze on top over the shoulder and mouth section and clear glaze on the remainder of the sides. The cylindrical bottle tapers to a slightly narrower base. One side of the bottle, about a sixth of the circumference, is flat. The base of the bottle has a handwritten inscription. An inscription was on the paper label originally attached to the bottle. Inscription hand written on base of bottle "Mrs K. Rob _ / Browns Rd / Offic / 3 _ _ 9" Inscription on paper label " "Mrs K Robinson Browns Rd Officer 3809 - Hot water bottle P.M.O." flagstaff hill, warrnambool, shipwrecked-coast, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic item, hot water bottle, heating equipment, ceramic bottle, stoneware bottle, potter, earthenware, personal item, bed warmer, foot warmer, flat-sided hot water bottle, household item, stoneware, clay, ceramic -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionCeramic - Bendigo Pottery :: Australian Prime Minister Flask, Bendigo Pottery, John C Watson, c 1975

Established by George Guthrie in 1857 (about 5km north of its current site) and then again seven years later in 1864 after it initially closed, Bendigo Pottery remains one of the most influential and longest running Pottery’s in Australia. Over the years the Pottery has contributed to the growth and development of the district through both its products including building products, table ware and decorative and commemorative war as well as artistically, being responsible for training and supporting many potters locally. The City of Greater Bendigo has had a long history of partnering with Bendigo Pottery and the Civic Collection holds a number of important items within its collection. This John C Watson (Chris Watson) 'reform' flask was one of a limited edition character bottles produced by the Pottery to commemorate important figures in Australian politics. He was the first Labour Prime Minister elected forming a minority government in April 1904, aged 37, after the ALP withdrew its support from Deakin. He was one of the first socialists to head a government in a parliamentary system, attracting international attention, and remains Australia's youngest prime minister. After less than four months in office, the Watson government lost a confidence motion and Watson was succeeded as prime minister by anti-socialist George Reid. The original reform flasks were English salt-glazed stoneware flasks produced in the early 19th century shaped into the form of figures connected with the Reform Bill of 1832. Much was made of puns like ‘the spirit of reform’ at the time. Artist John Frith has taken the reform flask form as inspiration for a series of political ceramics of some Australian Prime Ministers. The series included Edmund Barton, Alfred Deakin and Watson.Glazed ceramic flask in the shape John Watson. Square shaped with most of the detail on the front facing side other than head which is more detailed. Cork still in place in top of head.On reverse of flask; John C Watson / Prime Minister / of Australia / 27.4.1904 / To / 18 .08. 1904 Bendigo Pottery / LMTED / Edition Series / 55/1200 /Australia Signed lower centre; 'Frith'australian politics, bendigo pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Teapot, Josiah Wedgwood & Sons Ltd, 1890

Josiah Wedgwood (1730–95), came from an established family of potters and trained with his elder brother. He was in partnership with the leading potter Thomas Whieldon from 1754 until 1759 when a new green ceramic glaze he had developed encouraged him to start a new business on his own. Relatives leased him the Ivy House in Burslem, Stoke-on-Trent, and his marriage to Sarah Wedgwood, a distant cousin with a sizeable dowry, helped him launch his new venture. After an extensive and systematic program of experiment Wedgwood in 1765 created a new variety of creamware, a fine glazed earthenware, which was the main body used for his table wares thereafter. After he supplied Queen Charlotte with a tea set for twelve the same year, she gave official permission to call it "Queen's Ware" (from 1767). This new form, perfected as white pearlware (from 1780), sold extremely well across Europe, and to America. It had the additional advantage of being relatively light, saving on transport costs and import tariffs in foreign markets. Wedgwood developed several further industrial innovations for his company, notably a way of measuring kiln temperatures accurately, and several new ceramic bodies including the "dry-body" Stoneware, "black basalt" (by 1769), cane ware, and jasperware (the 1770s), all designed to be sold unglazed, like "biscuit porcelain". In the later 19th century the company returned to being a leader in the design and technical innovation, as well as continuing to make many of the older styles. Despite increasing local competition in its export markets, the business continued to flourish in the 19th and early 20th centuries, remaining in the hands of the Wedgwood family, but after World War II it began to contract, along with the rest of the English pottery industry. After buying several other Staffordshire ceramics companies, in 1987 Wedgwood merged with Waterford Crystal to create Waterford Wedgwood plc, an Ireland-based luxury brands group. After a 2009 purchase by KPS Capital Partners, a New York-based private equity firm. Wedgwood has always been associated with fine china, porcelain, and luxury accessories, the entrepreneur Josiah Wedgwood rapidly became successful and was soon one of the largest manufacturers of Staffordshire pottery. Wedgwood is a significant pottery manufacturer as the company is especially associated with the "dry-bodied" (unglazed) stoneware Jasperware in contrasting colours, and in particular that in "Wedgwood blue" and white that has become a trademark. Teapot and lid, Wedgwood blue Jasperware with white patternImpressed name Wedgewood and date letter "S" = 1890flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, teapot, wedgewood blue, wedgewood teapot, tea pot, kitchen ware, josiah wedgwood, staffordshire potteries -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionDecorative object - Ceramic platter, Bendigo Pottery, Strathfieldsaye Shire 1866 - 1991, 1991

Graham Masters is a potter based at Sweenies Creek, just outside Bendigo, Victoria who specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo, before becoming an employee, then a partner at Maldon Pottery, Victoria with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1984. (1.) (Judith Pearce). Built in 1869, the (former) Strathfieldsaye Shire Hall is one of The City of Bendigo's earliest surviving public buildings. Designed by George Steane and built by George Pallett in 1869 the Strathfieldsaye Shire Hall has aesthetic significance as a purpose built Shire Hall designed in the Free Classical manner. It is also of importance as an early example of the novel system of cavity wall construction. The building is largely intact and unaltered. Other important elements include the arched portico of the main entrance with brick arched features on either side; the brick quoining and dressings to the round arch windows; the three gabled roof; and the matching chimneys that reinforce the symmetrical design. The Hall has social significance as a temporary schooling facility in the 1870s and as a flood refuge in 1889. The Strathfieldsaye Shire Hall is a brick building designed in the Free Classical manner. This style was favoured by the Public Works Department for a number of public buildings including Shire Halls and courthouses. The form includes a central taller volume flanked by matching smaller gables. In the case of the Shire Hall these would be occupied by the Shire Secretary and Shire Engineer whilst the larger volume was the council chamber. The portico at the front is designed with a flat arch in the centre and matching smaller arches each side. The face red brick is unadorned apart from a plain string course at the roof springing point, brick quoining and dressings to the round arch windows. There are matching chimneys that are located to reinforce the symmetrical design and the original roof is believed to have been slate but is now corrugated iron. Large wheel thrown ceramic platter with a shallow well, broad flaring ledge and raised on a high foot rim. Rim decorated with slab rolled gum trees protruding on centre left and right sides of plater. which reflect the low relief image of trees and the Strathfieldsaye Shire Hall on the surface of the plate. Glazed with golden brown and cream. Front centre top; 'Shire of Strathfieldsaye'. Front lower centre '1866 - 1991 - 125 Years'. Signed 'G Master / 1991' on rim centre right. Reverse; signed 'G Master' / 1991. Bendigo Pottery stamp.shire of strathfieldsaye, bendigo pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Earthenware jar, Bailey & Co, circa 1878

The handmade earthenware jar was one of a group of artefacts in the McCulloch Collection that were recovered from the shipwreck Loch Ard. The jar could have been from the ship's cargo or personal effects. There are other jars in our collection that were recovered from the Loch Ard. The object is now one of the shipwreck artefacts in Flagstaff Hill’s Mc Culloch Collection, which includes items recovered from the wrecks of the Victoria Tower (wrecked in 1869) and Loch Ard (wrecked in 1878). They were salvaged by a diver in the early 1970s from the southwest coast of Victoria. Advanced marine technology had enabled divers to explore the depths of the ocean and gather its treasures before protective legislation was introduced by the Government. The artefacts were donated to Queensland’s Department of Environment and Heritage Protection (EHP) by a passionate shipwreck lover and their locations were verified by Bruce McCulloch. In 2017 the Department repatriated them to Flagstaff Hill where they joined our vast collection of artefacts from Victoria’s Shipwreck Coast. The Loch Ard: - The three-masted, square-rigged iron ship Loch Ard belonged to the famous Loch Line which sailed many ships from England to Australia. The ship was built in Glasgow in 1873. The Loch Ard made three trips to Australia and one trip to Calcutta before its final voyage. The Loch Ard left England on March 2, 1878, under the command of Captain Gibbs, bound for Melbourne with a crew of 37, plus 17 passengers and a load of cargo. The general cargo included straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were items included that were intended for display in the 1880 Melbourne International Exhibition, including the famous Loch Ard Peacock. On June 1, 1878, Captain Gibbs was expecting to see land but visibility was reduced by fog. As it lifted, the sheer cliffs of Victoria's west coast came much closer than expected. The captain was unable to steer away and the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. The top deck was loosened from the hull, the masts and rigging came down and knocked passengers and crew overboard, and even the lifeboat crashed into the side of the ship and capsized. Of the 54 people on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael. The well-packed Minton porcelain peacock also survived, safe inside its crate. Much of the cargo was washed up, smashed and broken, and some was salvaged. Other cargo is still with the wreck at the base of Mutton Bird Island, now protected by Government law. The artefact is an example of cargo or personal items on board a ship in 1878. It provides a reference point for classifying and dating similar items. This artefact is significant for its association with the sailing ship Loch Ard, one of the best-known, and one of the worst, shipwrecks in Victoria’s history. Flagstaff Hill’s collection of artefacts from Loch Ard is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. It is historically significant for representing aspects of Victoria’s shipping history. Container, round brown earthenware jar with a wide mouth, thick lip, a wide neck that tapers slightly inwards towards the shoulder, and a body that tapers slightly inward towards the base. The glazed surface is rough. The variegated colours of the clay also has small dark speckles. There are several chips and dents on the jar. The inscription is stamped into the lower edge. Made by Bailey & Co., England. Recovered from the wreck of the Loch Ard.Inscription “Bailey [&] Co / ENGLAND” flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, white star line, victorian heritage register, sailing ship loch ard, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, migrant ship 1878, cargo ship 1878, stoneware jar, domestic container, kitchenware, kitchen storage, bailey & co england, shipwreck artefact, wreck dive, mcculloch collection, bruce mcculloch, 1878, sailing ship, earthenware, stoneware, domestic jar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf ink bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Ink bottle or ink well; cylindrical shaped, salt-glazed, mid-brown ceramic bottle. It has a small round mouth, rounded lip that extend past the short neck, wide shoulders, straight sides, flat bottom. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history. Ink bottle, glazed, prange-brown ceramic cylinder, ring of clay on top for lip, narrow mouth, very short neck on wide shoulder that reaches out to edge of of straight-sided body, flat base. On the shoulder, close to the neck, are concentric lines in the clay. There are dark areas around the lip and mouth opening. The clay appears to have a fold line on its body. The material has flecks of darker material in it. Sediment around shoulder. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century