Showing 334 items

matching textile machines

-

National Wool Museum

National Wool MuseumTextile - Beanie, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Teal knitted ribbed beanie with gathered crown.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green skirt shaped with darts and has an elastic waistband. Has a brown silky lining. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Jumper, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green long sleeved crew neck jumper with black horizontal stripes on lower half. Button at the back of neck. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Cardigan, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green cardigan with black edged scallop detailing on collar, button band and faux pockets.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Campfire Gathering, Meeting Place Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). The circle and diamond pattern are ancient symbols used by Wadawurrung people dating pre-colonisation on possum skin and kangaroo skin cloaks, other artefacts like spear heads (carved), wooden shields, stone tools and caves were painted with blood, ochre and bound with grass tree sap, black wattle tree sap and kangaroo fats. The diamond pattern was a strong design used by men on shields and women on baskets and adornments. Shields were taken from the tree in the colder months when the tree was cold as the wood came off cleaner. Ochre colours of red, white, yellow and charcoal were often used to colour in and decorate the skin side of possum skin cloaks, wooden shields, spear heads, baskets and some coolamon bowls.The design for this cloak has been simplified from the original artefact design.Cloak with black and white diamond and circle design on outer cloak and coral and white line pattern within lining. Trimming is solid black. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung, first nations, cloak -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Gum Blossom and Bottle Brush in Dilly Bag Cloak (Women Basket Making and Sharing Knowledge), 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). The colours of this cloak refer to natural pink ochre and indigenous flowering plants on Wadawurrung Dja. The pink ochre is sourced by Deanne Gilson at Black Hill in Ballarat, Victoria. Men also made woven dilly bags to hold their possessions in. The basket making was an ongoing aspect of daily life for Wadawurrung people and often done in cooler months when the weather was too bad to go outside. Many women and family groups had their own style and techniques that were traded amongst other groups. Wadawurrung women had a particular stitch they used and incorporated elaborate symbols into the basket designs. Tammy Gilson’s weaving represents this stitch. This cloak pays homage to them and the changing seasons as they created, particularly the cooler months leading into the warmer season when several gum blossom flower. This cloak was worn once by artist Deanne Gilson at a formal opening at the Art Gallery of Ballarat in 2022. A Welcome to Country ceremony was performed while wearing it.Pink native flower in baskets motif on a pink background on outer cloak, pink and white diamond and circle design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Kunawarrar Ngaramili (Black Swan Dancer) Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). The black swan cloak refers to the black swan of Geelong and Ballarat were the swan has had its own fight to survive during the early colonial years where white swans were introduced by colonisers and the black swan fought back as they do not naturally get along. The wave pattern is taken from a traditional shield pattern held in the Melbourne Museum, South Eastern archive collection of shields. The wave refers to the water and travelling across water to fish, hunt and survive. This cloak is about survival, water, and the swan living on the water. It also refers to a contemporary dance of Kunuwarra the black swan, which was performed by a group Wadawurrung women (including artist Deanne Gilson) for Tanderrum (Melbourne – Naarm) in 2016. The dance is available to watch on youtube.Black swan, heart motif with water design on outer cloak, female figure and red native flower design on lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, first nations art, wadawurrung dja -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Banksia Tree Cloak (water and fire business), 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future).The sacred banksia tree was a favourite for Wadawurrung people. Flowering before deep Winter, the banksia was used for spear making and other wooden tools. The sap was drunk as a sweet drink and the seed pods used for water straining and fire sticks. The banksia tree flowers at the time when fire sticks farming is practiced marking the days before the coldest days and nights and the hotter days.White, orange, and yellow banksia design on outer cloak, yellow and white circle and diamond design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Nan’s Spirit Watching over me (Rita Dalton) Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future. The white ochre was used to create the feather pattern. White ochre is deeply connected to spirit or ‘murrup’ as we call it in language. The ochre is used on our bodies in ceremonies to paint our body up and is also placed on graves when someone passes. The white ochre is our most sacred connection to our ancestors and is used to celebrate both life and death. I source the white ochre from the You Yangs and only take what I need for ceremony and my painting.White and black feather motif with yellow eye design on outer clock, brown feather motif in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Bundjil the Eagle Creator Spirit Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). Bunjil the eagle used to be a man called Karringalabil. As a man he created the first man and woman out of bark from the sacred manna gum tree and clay from the river bed. He created the plants, animals, mountains, waterways, sky and under Country. After which he turned himself into an eagle. He has two wives, Kunuwarra the black swan sisters. After he completed all of creation he flew up into the sky at Lal Lal Falls and he now watched over us as a star in the night sky and as an eagle by day.Brown, red and white tone feather motif with yellow eye design on outer clock, red and black diamond and circle design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Waa the Crow Totem Cloak (Waa represents our ancestors watching over us), 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). Waa the Crow Totem Cloak (Waa represents our ancestors watching over us). Waa and all the birds get their names by the sounds the bird makes.Blue feather motif with blue star background on outer clock, blue and black feather design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Murnong Daisy Cloak (Women Gathering Food) Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future. The murnong was one of the main food sources for First Peoples before colonisation as it grew right across Wadawurrung Dja. The introduction of the sheep and cattle saw the murnong eaten roots and all and it quickly became less plentiful. The tubers were eaten raw or roasted on a fire. Water could be added to make a paste for small children to eat. The woman’s wooden digging stick that was used to gather and harvest plants was often buried with the woman for her afterlife and is considered sacred women’s knowledge. All parts of the plants and trees were and still are honoured as sacred medicine, healing plants and bush food knowledge.Yellow flower and female figure motif on black background on outer cloak, black and white diamond, and circle design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak, murnong -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Traditional Diamond Design, Pick and Gold Cloak (protection and survival of our men and women), 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). This cloak represents a traditional shield and stands for strength, resilience and standing proud. It protects us as we move forward. The gold represents the gold fields of Ballarat and Golden Plains shire. It also represents fool’s gold (pyrite) as First People had no use of gold, instead the people are the gold.Black, white, and red stripe design with flower and stem motif on outer cloak. Lining is a red and white stripe motif. Trimming is solid black. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak, murnong -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Nan’s Purple Orchid Cloak (Indigenous orchid season), 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future). Deanne states that this is her favourite season and she loves painting the small orchids as they flower after the cold season begins to clear.Black cloak with pink and purple toned flower motif on outer cloak, purple and black diamond, and circle design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak, murnong -

National Wool Museum

National Wool MuseumTextile - DIY Deluge Design No. 5, Alison Withers, 2023

Artist Alison Withers work DIY Deluge Design No. 5 was awarded Expressions: The Wool Quilt Acquisitive Award in 2023. Works were received from across Australasia and internationally from some of quilting’s most highly regarded and awarded artists. Finalists work was displayed at Art Quilt Australia 2023 presented by Ozquilt Network and the National Wool Museum from 12 August to 12 November 2023. Artist Statement: It's clear we need to adapt the anatomy of our human spaces to become more resilient to the increasingly unavoidable impacts of climate change. Made by piecing, applique and free machine stitching, using industrial felt, hand dyed merino felt, woollen suiting, cotton fabric, wool theatre curtain backing and cotton and polyester thread.Rectangular portrait orientated art quilt depicting an environmental scene including boats, lights, elevated buildings, plants and birds on a background of shades of cream, blue and grey. A baton is sewn into the back at the bottom.Back: DIY Deluge Design No.5 / Alison Withersquilt, ozquilt network, prize, wool, art, felt, piecing, applique -

National Wool Museum

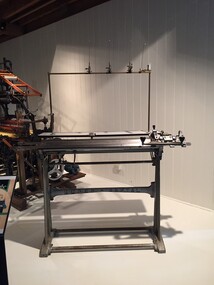

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

National Wool Museum

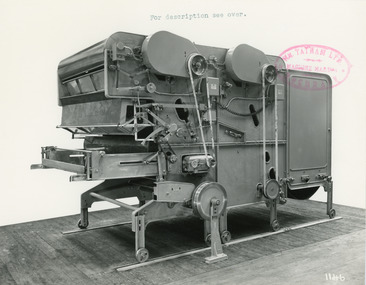

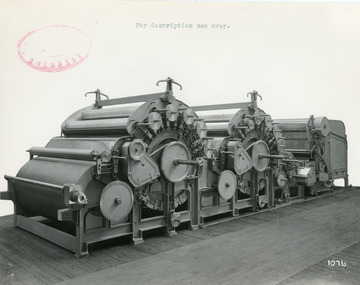

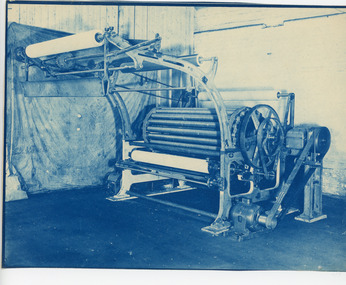

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

... . The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

National Wool Museum

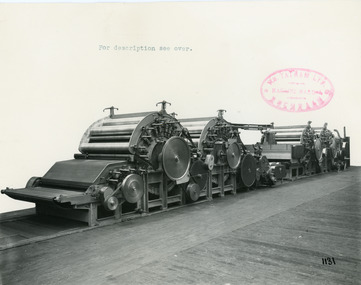

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

... countries around the world. textile machinery tatham carding machine ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

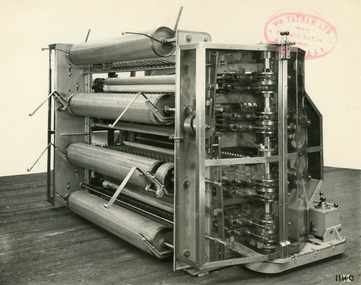

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

National Wool Museum

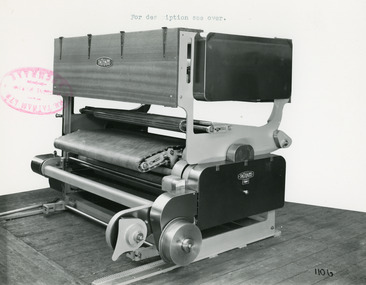

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

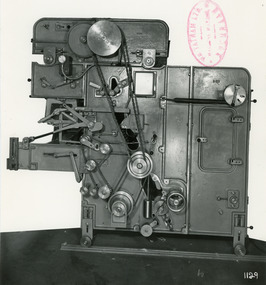

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

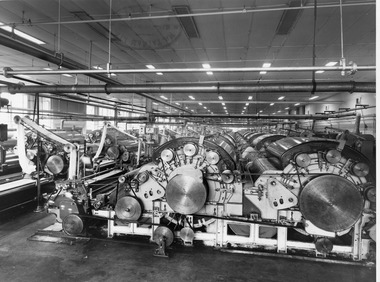

National Wool MuseumPhotograph - Carding Machines

Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

National Wool MuseumPhotograph, Q-VEE Machine, 29/06/1937

Photographs were most likely used for promotional purposes. The Q-VEE machine is a scouring machine. When fabric is removed from the loom it is often stiff, rough or uneven. Scouring removes the oils and dirt picked up from manufacture, leaving the fabric soft and fluffy. The photographed machine was made by J. Stone & Co, a British marine and railway engineering company based in Deptford in south east London.Four black and white, blue tinged photos of a Scouring Machine from different angles. Black writing on the rear, typed with a typewriter and stamped with the company stamp.8051.1 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 849 8051.2 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 856 8051.3 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 851 8051.4 - front on machine - FIY Chain Gear J.Stone & Co Ltd London rear - P.I.V. Dial Control Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 853textile machinery, wool manufacture, wool, scouring -

National Wool Museum

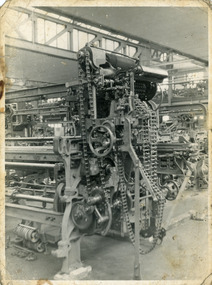

National Wool MuseumPhotograph, Loom, Unknown

Photograph of a Hutchinson, Hollingworth and Co. Limited Loom gears and mechanisms. Hutchinson, Hollingworth and Co. was an Oldham-based loom manufacturer estalished in 1860 by Messrs. John Hutchinson (c.1816-1888) of Cawthorne and James Hollingworth(c.1834-1895) of Holmfirth.Three black and white photographs in portrait format of a looms gear mechanisms.8052.1 - front on machine mid left quadrant - Hutchinson, Hollingworth and Co 8052.2 - front on machine mid left quadrant - Hutchinson, Hollingworth and Cotextile machinery, wool manufacture, wool, loom -

National Wool Museum

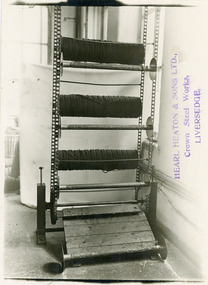

National Wool MuseumPhotograph, Yarn Spinning Machine, Unknown

Photographs most likely used for promotional purposes. The photographs are of a yarn spinning machine used to place yarn onto bobbins. The machine was made by Hearl Heaton and Sons Ltd, founded in 1809. The company played an important part in Britain’s Industrial Revolution, providing bobbins to the textile mills across the North of England.Four black and white photographs of a yarn spinning machine. The first two photos show the machine in the lower floor of the building and the last two are on the upper floor. The are connected by the two chains working the machine.8053.1 - Front right edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.2 - Rear middle - No.1 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.3 - Front top edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.4 - No. 2 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge.textile machinery, wool manufacture, wool, spinning -

Federation University Art Collection

Federation University Art CollectionTextile - Artwork - Textile, 'Through the Yellow Glass' by Helen Burgess

Helen BURGESS (c.1927 - 08.03.2018) Born Sydney, New South Wales Helen Burgess gained a Diploma of Design and Craft, and instructed Craft in the Occupational Therapy Departments of Repatriation and Rehabilitation. In 1957 she came to Victoria, gaining a Technical teachers Certificate from the Bendigo School of Mines. Soon after moving to Ballarat in 1973 she joined the newly formed Ballarat Embroiders Guidance Group (later Embroiders Guild). She lectured in Craft at the Ballarat Institute of Advanced Education from around 1974. She retired from the Ballarat College of Advanced Education in 1982. Helen Burgess was also an office bearer with the Ballarat Field Naturalists Club. Helen retired from BCAE in 1982 as Lecturer in Art and Craft, having commenced at BIAE approx. 1974. This work was possibly exhibited at the Embroiderers Guild, Victoria - Ballarat Branch. In 2015 Helen Burgess was considered one of the guild's longest members, at it was thought she was a foundation member of the Ballarat Branch.Textile landscape featuring applique, and hand and machine embroidery.Signed verso 'H. Burgess'.artwork, artist, helen burgess, textiles, embroidery, applique, landscape, ballarat field naturalists club, embroiderers guild -

Mont De Lancey

Mont De LanceyTextile - Tablecloth

Donated by Mrs. Adamson in early 1900.White linen rectangular tablecloth, heavily embroidered in white. Edge has open weave with machine crocheted lace. Has floral round embroidered centre piece. tablecloth -

Mont De Lancey

Mont De LanceyDoily

Cream-coloured, circular doily with machine lace and a floral pattern throughout. There is a single flower in the centre with a square border around it.household textiles., doilies, table linen. -

Mont De Lancey

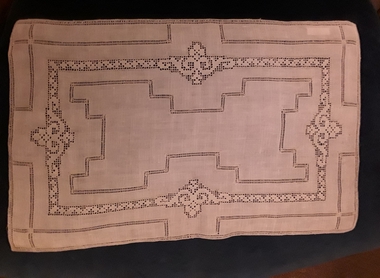

Mont De LanceyTextile - Doiley, Unknown

Used for placing food on or ornaments on furniture.A rectangular ornamental machine made doiley made of white cotton with a cut out pattern for use under cakes or ornaments placed on furniture.table linen, lace, cotton, cotton thread, table accessories, soft furnishings