Showing 232 items matching " castings"

-

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Tender Document, Melbourne & Metropolitan Tramways Board (MMTB), "Manufacture, supply and delivery of iron castings contract No. 96", 4/1920 and 6/1920

... "Manufacture, supply and delivery of iron castings contract... Castings ...Set of two tender documents, each of two foolscap sheets for the supply and delivery of castings to the Boards repair shops (Nicholson St or Holden St?), with patterns supplied by the Board. Gives details of the quality, approx. quantity, patterns, delivery, rejection, payment, cancellation and other details. .1 - "Manufacture, supply and delivery of iron castings contract No. 96" - 70 to 85 tons /half year - tenders closed 29/4/1929. .2 - "Manufacture, supply and delivery of steel castings contract No. 96" - 50 tons / year - tenders closed 10/6/1920. 2 copies of each, either pinned or clipped with a brass clip in top left hand corner.trams, tramways, tenders, contracts, mmtb, cable trams, castings, brake blocks -

Melbourne Tram Museum

Melbourne Tram Museumbook - Engineering Standards, Standards Association of Australia, "E30 - 1934 - Australian Standards Specification for Manganese Steel Castings for Tramway Trackwork", 1934

... Manganese Steel Castings for Tramway Trackwork" ...Set of two Engineering Standards stapled within in a Standards Association of Australia folder" with the numbers stamped and hand written onto the cover. Contains 6 sheets printed using the Gestetner process and one photocopy on foolscap paper. Contains the standards for "E30 - 1934 - Australian Standards Specification for Manganese Steel Castings for Tramway Trackwork"in ink "1939" and "Hardwood Paving Blocks" on right hand edge.trams, tramways, standards, track materials, track repairs, road works, points, trackwork -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumMold, Gold Ingot

This is one of three gold molds on display in the Gold Carriage.Iron Casting. Casting stamp on the handle is illegible.Top and bottom are rectangular with the bottom smaller than the top, and sides are trapezoidal. A Handle is included as part of the casting.Casting stamp on the handle is illegible.gold, mining, mold ingot -

Moorabbin Air Museum

Moorabbin Air MuseumManual (collection) - Atar engine parts photographs, Technique Photographs for Atar Austenal and Shaw Precision Castings

... Castings ...Photos of precision castings -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (item) - CAC Various booklets on Limits, Foundry Metal Castings, VTOL Airliner, Plant facilities for Manufacture, Overhaul & Repair - Aircraft & Jet Engs

... CAC Various booklets on Limits, Foundry Metal Castings ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Avon RA3 Part 1 Sand Castings In Aluminium

... CAC Collection - Avon RA3 Part 1 Sand Castings In Aluminium ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Avon RA3 Part II Sand Castings In Iron, Aluminium & Magnesium

... CAC Collection - Avon RA3 Part II Sand Castings In Iron ... -

Moorabbin Air Museum

Moorabbin Air MuseumPhotograph (Item) - CAC photographs of Steel, Bronze & Aluminium castings of components

... CAC photographs of Steel, Bronze & Aluminium castings of ... -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

Wannon Water

Wannon WaterScour valve mould

The moulds were used to make casting moulds to manufacture spare parts for the high pressure valves in the main pipeline for the Otway Water Supply System. Used in conjunction with valve stem mould, Wf mould and high pressure scour valve mould (casting) water mains. It is unknown whether these moulds are originals from the 1930's or later copies.Used in the manufacture of spare parts for the Otway Water Supply pipeline Wooden casting moulds3" SCOUR VALVEpipelines, otways -

Wannon Water

Wannon WaterValve stem mould

Used to make casting moulds for the Otway Water Supply System in the 1980s. Used in conjunction with scour valve mould, Wf mould and high pressure scour valve mould (casting) watermainsUsed in the manufacture of spare parts for the Otway Water Supply pipelinevalve stem casting mould in plywood boxwatermains in black textaotway region, water supply, pipelines -

Wannon Water

Wannon Water3" Scour valve mould, Valve mould

Used in the manufacture of spare parts for the Otway Water supply pipeline in the 1980s. Used in conjunction with scour valve mould, valve stem mould and high pressure scour valve mould (casting) watermains Used to manufacture spare parts in the 1980swooden casting mould3" Scour Valve in silver raised lettering WF Logo in silver and raise In black texta - DEMAC 4 off C.I.otway region, pipeline, water supply -

Wannon Water

Wannon WaterWf valve mould, Mould

Used in the manufacture of spare parts for the Otway Water supply pipeline in the 1980s. Used in conjunction with scour valve mould, valve stem mould and high pressure scour valve mould (casting) watermainsUsed to manufacture spare parts in the 1980sWooden casting mould in 2 piecesotway region, pipelines, water supply -

Wannon Water

Wannon WaterHigh pressure scour valve mould (casting) watermains, Mould

Used to make casting moulds for the high pressure main Otway Supply System pipeline. Was used in conjunction with scour valve mould, Wf mould and valve stem mould in the 1980sUsed to manufacture spare parts for the main Otway pipeline2 wooden boxes each contain the mould for casting valves for wtaermains pipelines. Moulds lined with green coloured sealantwatermains written in black ink on outside of boxotway region, water supply, pipelines, valves -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, Melbourne & Metropolitan Tramways Board (MMTB), "Casting production and machining at Preston Workshops", 7/1963

... Castings ...Typed report on the use of precision casting methods at Preston Workshops foundry to reduce the amount of machining post-casting. Looks at the methods of precision casting, the type of equipment needed for this, and those companies in Melbourne using shell moulding, Includes an extensive list of items and the number of units used each year that this method could be used for. Report by J Scholtz dated 12-7-1963.Yields information about the examination of costs and methods of using shell moulding processes at Preston Workshops.Document or report 7 foolscap sheets - carbon copytramways, technical information, preston workshops, costs, foundry, castings, plate shop -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon Ball, Late 18th to 19th centuries

This cannon ball could have been made as ammunition to be shot from a 24-pounder gun, perhaps a deck cannon or Carronade on a sailing ship. It is similar to those used by both British and French navies from the late 18th and 19th centuries. The iron cannon ball shows the casting mark around its circumference made by the mould during the casting process. The cannon ball is an example of ammunition used during naval conflicts in the late 18th and 19th centuries. It was made for cannon or Carronade similar to those in the collection of cannon at Flagstaff Hill Maritime Museum.Cannon ball; a heavy black iron ball with a casting seam around its circumference. The surface is shiny with many pits and has slight corrosion. There are several chips including one large deep chip and a small, crescent shaped chip. The cannon ball’s size is similar to a cast iron 24-pounder shot.flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, artillery, ammunition, cannon ball, shot, 24-pounder, 24 pdr, deck cannon, ship cannon, military, cannon, gun, iron ball, moulded ball, naval gun, deck gun, navy, carronade, war, maritime weapon, cast iron, mould -

Ballarat Tramway Museum

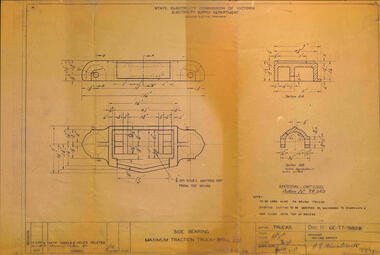

Ballarat Tramway MuseumDrawing - GE-T7-7680B, State Electricity Commission of Victoria (SECV), "GE-T7-7680B - Side bearing Brill 22E", 19/7/1948

... castings ...Drawings - "GE-T7-7680B - Maximum Traction Side bearing Brill 22E" showing the casting that holds the wearing brasses in position on the top sides of the bogie. Revision B, drawn July 1948 in the Geelong drawing office and signed by Mr H Hornabrook. Pattern TP 345.Yields information about the side bearing holder for a brill 22E truck.Drawing - dyeline print, folded - GE-T7-7680Btramways, secv, brill 22e, 22e trucks, castings -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Engineer inspecting a casting at Grimwade Castings, 1950s

B&W photo of engineer inspecting a large metal casting at Grimwade Castings, 1950sindustry - manufacturing - foundries, peter griffin, grimwade castings pty lty -

Melbourne Tram Museum

Melbourne Tram MuseumLetter, Victorian Railways, "letter to TMSV", 4/10/1965 12:00:00 AM

... Castings ...Letter from Acting Controller of Stores, Victorian Railways to the Rolling Stock Supervisor, Tramway Museum Society of Victoria, regarding patterns for castings used on railway tramcars. Letter dated 4 October 1965. Original letter and photocopy of letter.trams, tramways, rolling stock, vr trams, victorian railways, castings, tramway museums, tmsv -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Fire Box, Late 19th to early 20th century

Item used in the late Victorian to early Edwardian period as an insert into a house fireplace allowing the burning of coal or wood as fuel to heat a home.An item that is significant as it gives an insight into daily domestic life in the home regards heating.Fire box insert & tray black metal Embossed design to casting at back of box flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Orbost & District Historical Society

Orbost & District Historical Societyfossil

Inspected by George Rawlings 6.2.2013.A fossilised worm casting., as in a beach or sand worm of a large variety. The worm secretes organic substances that harden in the burrow and the ejected material is called castings.fossil worm-casting -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchWeapon - Brass Casting of Machete

Full size brass casting of machete in sheath. MA (68 or G8 -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncStrip Casting Machine, not known

ELROD strip casting machine not in working order.'MACHINE NO. F2713E ' etched on brass plate. Instruction plate on top surface.trades; printing; machinery; casting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1930s

Dawn commenced operations in the Melbourne suburb of Coburg, Victoria in 1917 under the name of Dawn Manufacturing Co. It was founded by four brothers named Blake, who were all engineers. The first products manufactured were vices. After the first world war, Dawn grew considerably and was selling its products all over Australia. They were very busy during the depression with each employee working 60-80 hours a week. During the second world war, Dawn was supplying vices and clamps to the Australian Defence Department along with munitions. In 1959, the company was taken over by the G.N. Raymond Group. The Dawn catalogue was expanded to now included a wide range of engineer's vices, woodworker's vices, plumber's vices & equipment, G-clamps, quick-action clamps and toggle clamps. In 1973, Dawn was acquired by Siddons Ramset Limited. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998, Dawn regained its 100% Australian ownership and now as a separate strategic business unit, began to improve and expand its manufacturing and marketing operations in Australia and overseas. Drill Press, Self-feeding, belt-driven. Embossed within the casting "Dawn Melb Australia Mfg".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, dawn drill press, drill press -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLINO TYPE MACHINE, prior to 1998

This item was used at "The Tarrengower Times" Maldon, Vic by Ron ADAMSLino-type casting machine with furnace for casting lead plates. Makes type used in printing. Motor made by Crompton Patison. Keyboard to select letters to be cast.MODEL 78 No 17175trades; printing; machinery; casting ; tarrengower times -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Grimwade Castings, Williamstown Road, Port Melbourne, 1960s

Colour photo of front of Grimwade Castings, Williamstown Road. 1960sindustry - manufacturing - foundries, peter griffin, grimwade castings pty ltd -

Puffing Billy Railway

Puffing Billy RailwayHydrostatic lubricator

Machined Bronze casting with sight glasses and feed control valvesDetroit Lubricator co.Detroit,u,s,a -

Wangaratta RSL Sub Branch

Wangaratta RSL Sub BranchMemorabilia - Trench Art P38 Lightning Plane

The Lockheed P-38 Lightning is an American single seated, piston-engined fighter aircraft that was used during World War II. Trench Art is the name given to objects manufactured by both soldiers and civilians from shell casings, bullets, shrapnel and miscellaneous battlefield debris, and is predominantly associated with World War I (1914 – 18)Brass shell castings in form of P38 Lockheed lightning planeNiltrench art, plane, p38, lightning plane, world war 2 -

Royal Australasian College of Surgeons Museum and Archives

Royal Australasian College of Surgeons Museum and ArchivesPainting - Plaque, Bronze relief casting of H Devine by Stanley Hammond, Stanley Hammond, H Devine

Plaque, Bronze relief casting of H Devine by Stanley Hammondh devine, stanley hammond