Showing 489 items matching " early modern"

-

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, 316 Canterbury Road, corner of Essex Road

... early modern style...A black and white photograph of an early modern style house... photograph of an early modern style house built on a corner block ...Mr Walter Sessford Cornhill was born in c1886 in Orsett, Essex; died 2 September 1940 and buried in Box Hill Cemetery (B-069-0028). He was a carpenter. He married Rhoda Fraser (1882-1947). A son John Edmund was a plumber. Daughter Lillian married Charles Frederick Barrow. Walter Cornhill moved from 3 Essex Road to 316 Canterbury Road some tome after 1937. The house passed to Charles Frederick Barrow and wife Lillian and subsequently to Leonard Clement Gangell and his wife Pamela Gangell, nee Barrow.A black and white photograph of an early modern style house built on a corner block. It is built of brick. The upper portion of the house is rendered with occasional brickwork patterning. A low brick fence borders both street frontages.canterbury road, essex road, 1940, early modern style, mr walter sessford cornhill, mrs rhoda cornhill, miss rhoda fraser, mr john edmund cornhill, miss lillian cornhill, mr charles frederick barrow, mrs lillian barrow -

The Celtic Club

The Celtic ClubBook, P. L. Henry, Danta ban : poems of Irish women early and modern, 1991

... Danta ban : poems of Irish women early and modern... An anthology of poems both early and modern authored by Irish women ...An anthology of poems both early and modern authored by Irish women, selected and translated by P.L. Henry, Galway University.Bib, notes, p.217.non-fictionAn anthology of poems both early and modern authored by Irish women, selected and translated by P.L. Henry, Galway University.irish spirituality, irish poetry -

Robin Boyd Foundation

Robin Boyd FoundationDocument - Manuscript, Robin Boyd, (Early masters of modern architecture…)

... (Early masters of modern architecture…)... melbourne Discusses the styles and aspirations of modern ...Discusses the styles and aspirations of modern architecture post World War 2 in contrast to pre-war architecture (incomplete manuscript).Handwritten, quarto, 1 pagele corbusier, eero saarinen, modernism, world war 2, robin boyd, manuscript -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - WHAT HOUSE IS THAT? A GUIDE TO VICTORIA'S HOUSING STYLES, c2004

... Early Modern... Bungalow Early Modern Modern What House is That? A Guide ...What House is That? A Guide to Victoria's Housing Styles. Housing styles, colours, architecture. Photographs & illustrations. 27 pages. Green sft coverhouses, housing styles, colours, architecture. early victorian, mid victorian, late victorian boom style, queen anne, edwardian, californian bungalow, early modern, modern -

Ringwood and District Historical Society

Ringwood and District Historical SocietyBook, Eltham District Historical Society Inc, Tower of Remembrance and War Memorial Park on Garden Hill at Kangaroo Ground, Victoria, 2010

... with photocopied images of early and modern features of the memorial... with photocopied images of early and modern features of the memorial ...Soft cover plastic bound 105-page A4 size book with photocopied images of early and modern features of the memorial and surrounding area. -

Robin Boyd Foundation

Robin Boyd FoundationDocument - Manuscript, Robin Boyd, The Sad End of New Brutalism, 1967

... spirit of early modern architecture, in the context of Reyner... of the rebellious spirit of early modern architecture, in the context ...Discusses the new brutalism, as a revival of the rebellious spirit of early modern architecture, in the context of Reyner Banham's book "The New Brutalism", with the subtitle ethic and aesthetic. Boyd discusses the arguments of Banham and the new brutalism in the context of the subtitle. It concludes with a code to characterise the modern movement.Original manuscript of an article published in Architectural Review Vol 142, No 845, July 1967. pp. 9–11 and reprinted as ‘El triste fin del Nuevo Brutalismo’ in 'Cuadernos Summa Nueva Vision' (Buenos Aires), No’s 24/25, May 1969, pp. 51-53.Two copies. One typewritten (c/copy) pencil edits Second typewritten (p/copy). Both quarto, 14 pagesle corbusier, reyner banham, smithson, peter and alison smithson, modernism, brutalism, robin boyd, manuscript -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter AVO, circa 1930 to 1951

... meters used earlier. Modern meters (2000 onwards) have become.... This meter took the place of three or four meters used earlier ...When this AVOMETER was being utilised in the early 1950's it was at the "leading" edge of electrical measuring instrumentation.The first meter was produced by Automatic Coil Winder and Electrical Equipment Co. in 1923. This model was produced in the time from 1933 to 1951 when it was superseded by the most popular model, Model 8 (1951 to 2008).This AVO meter brought the measuring of three electrical power indicators i.e., amps, volts and ohms into one measuring unit. By using a "one fits all" unit, the carrying of separate measuring devices was reduced considerably. The need for a mountainous and a large area of operational requirements, such as the SEC Vic Kiewa Hydro Electricity Scheme, to minimise the weight of equipment carried by electricians and technicians was of the utmost relevance. The significance of this meter to the Kiewa Valley region relates to the impact of modern technology (at that time) upon a mainly rural environment. This equipment shows how the boost of "modern" equipment into the area because of the "Hydro Scheme" was facilitated a lot faster than would have taken under "normal" evolutionary time. The speed of information on all "new technology" had a relatively slow assimilation rate to those living in rural communities. This AVOMETER is a Model 7 MKII, production pre 1951. This meter measures electrical Amps, Volts and Ohms and has two internal batteries for its power. The main casing is made from aluminium with a bake-lite front. The front has a "window" detailing, with a needle pointer, the amount of electrical power being tested. There are two big dial switches, detailing Direct Current(DC) and Alternating Current(AC) when reading measurements of Ampere, Voltage and Ohms for power. This meter took the place of three or four meters used earlier. Modern meters (2000 onwards) have become digilised and are considerably lighter in weight and smaller. There are two electrical connection leads (one black and one red) each has a removable clasp and is 125cm long.Molded on the front centre panel " UNIVERSAL AVOMETER". Below this and above the left hand dial "D.C. SWITCH" .Above the right hand switch the right "A.C. SWITCH". On the left of each switch is an arrow pointing to it.The left switch is marked with a "+" and the right one with a "-". There is a "divisional 2" mark. Between and below the dials is "CUT OUT" plunger.electrical meters, electrical equipment, sec vic., state electricity commission of victoria, mt beauty, bogong village -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBook, Cream of the Country, 1989

... History of dairy industry in Victoria from early settlers... early settlers to modern technology. Includes Tatura Butter ...History of dairy industry in Victoria from early settlers to modern technology. Includes Tatura Butter Factory and Shepparton and story of Joe FordGreen hard cover, green dustcover, cream writing, square picture on front of 2 men and cattledairy industry, tatura butter factory, joe ford -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Magdala-Cum-Moonlight Mine Looking North West & with 2 miners using a modern rock drill 1902

... . Some of the miners on the Magdala mine had early versions... of the miners on the Magdala mine had early versions of the modern rock ...Mining Scene of Drilling in Underground Magdala-Cum-Moonlight Mine 1902. A stope in rich stone looking North West. Some of the miners on the Magdala mine had early versions of the modern rock drill. Two of the miners are pictured here drilling in the rock face.Two miners underground working a rock drill stawell mining -

Federation University Historical Collection

Federation University Historical CollectionBook, Edward Lhuyd, Archaeologia Britannica, 1707, 1707

... to travel to Cornwall to study the language. Early Modern Cornish... the language. Early Modern Cornish was the subject of a study published ...Printed at the Theater for the author, MDCCVII . And sold by Mr . Bateman in Pater -Noster-Row, London: and Jeremiah Pepyat bookseller at Dublin. Lhuyd [Lhwyd; formerly Lloyd], Edward (1659/60?-1709), was a naturalist and philologist and the Keeper of the Ashmolean Museum. Lhuyd was a pioneering linguist. In the late 17th century, Lhuyd was contacted by a group of scholars, led by John Keigwin of Mousehole, who were trying to preserve and further the Cornish language and he accepted the invitation to travel to Cornwall to study the language. Early Modern Cornish was the subject of a study published by Lhuyd in 1702; it differs from the medieval language in having a considerably simpler structure and grammar. In 1707, having been assisted in his research by fellow Welsh scholar Moses Williams, he published the first volume of Archaeologia Britannica: an Account of the Languages, Histories and Customs of Great Britain, from Travels through Wales, Cornwall, Bas-Bretagne, Ireland and Scotland. This book is an important source for its linguistic description of Cornish, but even more so for its understanding of historical linguistics. Some of the ideas commonly attributed to linguists of the nineteenth century have their roots in this work by Lhuyd, who was "considerably more sophisticated in his methods and perceptions than [Sir William] Jones’’. Lhuyd noted the similarity between the two Celtic language families: Brythonic or P–Celtic (Breton, Cornish and Welsh); and Goidelic or Q–Celtic (Irish, Manx and Scottish Gaelic). He argued that the Brythonic languages originated in Gaul (France), and that the Goidelic languages originated in the Iberian Peninsula. Lhuyd concluded that as the languages had been of Celtic origin, the people who spoke those languages were Celts. From the 18th century, the peoples of Brittany, Cornwall, Ireland, Isle of Man, Scotland and Wales were known increasingly as Celts, and are regarded as the modern Celtic nations today. (Wikipedia)Oversize book. Includes the original languages of England and Ireland, Amoric Grammar, Amoric-English Vocabulary, Welsh words ommitted from Dr Davies' dictionary, Cornish Grammar, Ancient Scottish language, Irish-English Dictionary. Four page index which includes the errata, has the list of subscribers, mainly 3 columns per page. Includes a Cornish Grammar and dictionary of the Irish language, Archaeologia Britannica, Giving Some Account Additional to What Has Been Hitherto Published, of The Languages, Histories and Customs of the Original Inhabitants of Great Britain: From Collections and Observations in Travels Through Wales, Cornwal, Bas-Bretagne, Ireland and Scotland. Chapters on: The comparative Etymology, The comparative Vocabulary, The Armoric Grammar and Vocabulary, Dr Davies's Dictionary, Cornish Grammar, Catalogue of British Manuscripts in Welsh and Latin, Essay towards a British Etymologicon, The Introduction to the Irish, Irish Dictionary etc. language, gaelic, irish, scottish, edward lhuyd, welsh, latin, greek, etymologicon, celtic -

Federation University Historical Collection

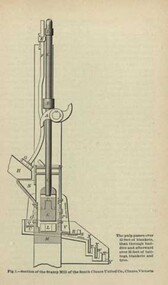

Federation University Historical CollectionBook, The Scientific Publishing Co, Stamp Milling of Gold Ores, 1897

... Mills of California; Milling in Black Hills South Dakota; Early... South Dakota; Early Australian methods, more modern Australian ...Brown, hard, cloth covered book of 260 pages, including an index and illustrations. The contents include the Philosophy of the Stamp-Milling Process; Gilpin county colarado; Typical Stamp Mills of California; Milling in Black Hills South Dakota; Early Australian methods, more modern Australian Methods; Gold Milling at Bendigo; Double discharge Mortars in Victoria; Stamp Mills of Otago New Zealand, Review of Australian Practice, Wear and Tear of a Mill; Flouring of Mercury. Illustrations include South Clunes United Company, Crushing Mill at Ballarat, Battery at Bendigo.mining, milling, colorado, ballarat, bendigo, california, clunes, america, united states of america, modern australian methods, star of the east, sebastopol, britannia united, bakery hill, north cornish mill, daylesford, new normanby, north cornish -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Lantern Slide, c1900

... This image of a man is possible an early version...This image of a man is possible an early version ...This image of a man is possible an early version of the modern photographic technique the 'selfie'. Lantern slides, sometimes called 'magic lantern' slides, are glass plates on which an image has been secured for the purpose of projection. Glass slides were etched or hand-painted for this purpose from the Eighteenth Century but the process became more popular and accessible to the public with the development of photographic-emulsion slides used with a 'Magic Lantern' device in the mid-Nineteenth Century. Photographic lantern slides comprise a double-negative emulsion layer (forming a positive image) between thin glass plates that are bound together. A number of processes existed to form and bind the emulsion layer to the base plate, including the albumen, wet plate collodion, gelatine dry plate and Woodburytype techniques. Lantern slides and magic lantern technologies are seen as foundational precursors to the development of modern photography and film-making techniques.This glass slide is significant because it provides insight into Beechworth's social amenities and religious infrastructure in the late Nineteenth Century. It is also an example of an early photographic and film-making technology in use in regional Victoria in the time period.Thin translucent sheet of glass with a square image printed on the front and framed in a black backing. It is held together by metals strips to secure the edges of the slide.burke museum, beechworth, lantern slide, slide, glass slide, plate, burke museum collection, photograph, monochrome -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel hacksaw 'Marples', 20thC

... in Sheffield since those early days. Although modern technology has... early days. Although modern technology has been used in some ...A hacksaw is a fine-toothed saw, originally and principally for cutting metal. They can also cut various other materials, such as plastic and wood; for example, plumbers and electricians often cut plastic pipe and plastic conduit with them. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vice, hacksaw blades should be set to be facing forwards. Joseph Marples & Son Pty Ltd Traditional Craftsmans Hand Tools made in Sheffield. The finest quality hand made tools, backed by over 170 years of manufacturing heritage. .In the 1840’s Joseph Marples was one of several ‘Marples’ (most of which were related) in Sheffield manufacturing joiners tools, such as brass inlaid rosewood & ebony braces, boxwood spokeshaves, beech planes, gauges and squares. The business has remained within the family to this date, and has been based in Sheffield since those early days. Although modern technology has been used in some instances, many of the traditions of manufacturing fine hand tools has remained the same using selected materials and hand finishing, indeed the same threads are used in the gauges as were used over 100 years ago. A steel hacksaw. 'Marples' with bladeMARPLEStools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond, joseph marples & son pty ltd, sheffield , england, -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1964-1970

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White short-sleeved jumper with all-over pattern of aqua blue diamonds. Blue floated threads slightly show through white on main body, leading to an overall pale blue effect on body, with white collar and cuffs. Closes with three pearlescent plastic buttons at back neck. .2 is a retail tag marked with the style code, and includes generic information on care for garments of different material composition..1) [label stitched into back neck of garment] KATHRYN REGD CREATED BY ROBERT BLAKE .2) [retail tag, intended to be folded in three, printed on both sides] [OBVERSE] KATHRYN Children’s Knitwear STYLE: [blue pen] S/35B SIZE: PRICE: / KATHRYN Garments are… • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY / NOW .. KATHRYN GOES TO . . SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYN [REVERSE] WASHING INSTRUCTIONS WOOL Wash frequently to AVOID HEAVY SOILING Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. TO dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, DRY IN SHADE… AVOID SUNLIGHT. When dry, place brown paper or pressing cloth over garment and press with iron at correct heat. ORLON Wash as wool Lay flat to dry but DO NOT IRON. To keep brushed suits like new, brush frequently with nylon brush supplied. COTTON Wash by hand for preference in Velvet Soap suds. Rinse thoroughly in cold water and remove all excess water before drying on line. Please do not use any harsh detergent or bleach. Designed and manufactured by ROBERT BLAKE Pty. Ltd., MELB. (handwritten in pencil) S35 (untintelligible)/5 / NOW KATHRYN GOES TO SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYNknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, colourwork -

National Wool Museum

National Wool MuseumTool - The Austral Unit Calculator, Industrial Consultants, c.1960

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Measuring instrument with five circular white layers and one long transparent plastic ruler on top. Transparent layer is now yellowed, was likely originally clear. All of the layers connected with a metal rivet at the centre, allowing the discs and line indicator to move in relation to each other. Discs are labelled (inside – outside) Cost per Thousand Overall Unit Hour U/S [units] produced in 1000s No. of persons Bonus Percentage 9017.2 Black leather case with white block letter printing [9017.3 - 9017.5] Inside case are three notes (one printed, two handwritten) that provide instructions for using the calculator[label on obverse of case] THE AUSTRAL UNIT CALCULATOR ISSUED BY INDUSTRIAL CONSULTANTS, MELB MADE BY MELB >W&G< AUST.business, business history, manufacturing history, calculator, textile fibres textile history -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for the boys line of Robert Blake/Kathryn knitwear in the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesBOYS WOOL WINTER 1980 COLOR SWATCH RED BURGUNDY BROWN RYE PEBBLE OYSTER NAVY BLUE SHADOW DENIM GRANITE GREYfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for Kathryn knitwear for the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesKATHRYN WOOL WINTER 1980 COLOUR SWATCH RED BROWN RUST DEEP RED GREEN NAVY BLUE SHADOW SKY BLUE MAGNOLIAfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the 14 wool colour options for the ladies' line of Kathryn knitwear for the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesLADIES WOOL COLOR SWATCH WINTER 1980 RED BLACK MAGNOLIA OYSTER SILVER BLUE SHADOW NAVY TEAL GREEN BRACKEN RYE BROWN BURGUNDY DEEP REDfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing -

National Wool Museum

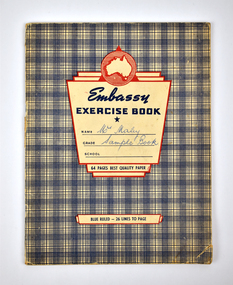

National Wool MuseumArchive - Notebook, Kathryn Knitwear, 1947-1953

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history. The ‘Embassy’ brand was a house brand of Coles stores from 1929-1994, and manufactured a wide variety of household goods. The manufacture of this specific style of notebook can be dated to between 1947 and 1953.Notebook with handwritten instructions, formulas and sketches detailing patterns for samples. ‘Embassy’ exercise book cover is printed with a blue checked pattern on a background that was originally likely white, but appears cream due to discolouration. The centre of the front cover has a trapezoidal label that provides space for handwritten labels, and features a map of Australia inside a red circle, as well as the manufacturers branding. The 64 internal pages are printed with blue lines as a writing guide.[Obverse] Embassy EXERCISE BOOK NAME [handwritten] Mrs Maley GRADE [handwritten] Sample Book SCHOOL 64 PAGES BEST QUALITY PAPER BLUE RULED – 26 LINES TO PAGE [sample of internal pages] [left page] Notes: 34” = 3 garments out of 40” Length 32” = 3 “ “ “ 38 “ “ 30” = 28” = Cut together (26” = 4 garments “ “ 33” “ (24 = 4 garments “ “ 33” length Blue 36” Red 36 ½“ Green 36” Royal 35 ½” [right page] Design Esquire (Width 35 ½ - 36) Size 34” Width Yardage Size 32” Width Yardage Sample cotton 90 ribs for 28” Size 28” (sample size) Width cut to 20 ½ (double) Yardage 34 ½“ for 2 garm. Size 26” Width Yardage Size 24” Width Yardagebusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, embassy brand, coles -

National Wool Museum

National Wool MuseumTool - Garment Brush, c.1953-1962

... for their early adoption of modern materials and techniques that had broad... for their early adoption of modern materials and techniques that had broad ...Sample of Kathryn Knitwear Collection. This brush was included with a brushed wool leginette suit (NWM-08916), in order to maintain the fluffy finish of the garment after wear and washing. Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Transleucent nylon brush with rows of thin bristles mounted in an offset pattern[Printed on plastic packaging] CARE OF BRUSHED FABRICS To obtain original condition brush garment frequently between wearing and after washing. Follow laundering instructions on swing ticket.brush, garment brush, brushed wool, laundry, garment care, nylon brush, accessory -

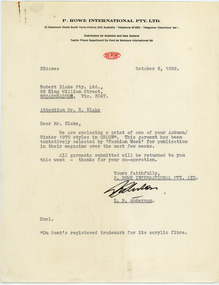

National Wool Museum

National Wool MuseumLetter, P Rowe International, 6/10/1969

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Letter from E. B. Anderson from P. Rowe International Pty. Ltd. On behalf of DuPont International to Robert Blake, owner of Kathryn Knitwear. The letter confirms the tentative selection of a Kathryn Knitwear Orlon garment to be published in ‘Fashion Week’ as advertising for both Kathryn knitwear and DuPont’s Orlon fibre. The Advertisement can be found under the accession number NWM-09065.[obverse] P. ROWE INTERNATIONAL PTY. LTD. 12 Claremont Street South Yarra, Victoria 3141 Australia – Telephone 24 6561 - Telegrams ‘Chemfibre’ Me[unintelligible] Distributors for Australia and New Zealand Textile Fibers department Du Pont de Nemours International SA EBA: mes October 6, 1969. Robert Blake Pty. Ltd., 26 King William Street, BROADMEADOWS, Vic. 3047 Attention Mr. R. Blake Dear Mr Blake, We are enclosing a print of one of your Autumn/ Winter 1970 styles in ORLON*. This garment has been tentatively selected by ‘Fashion Week’ for publication in their magazine over the next few weeks. All garments submitted will be returned to you this week – thanks for your co-operation. Yours faithfully, P. ROWE INTERNATIONAL PTY. LTD. [signature] E. B. Anderson. Encl. *Du Pont’s registered trademark for its acrylic fibre.business, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents -

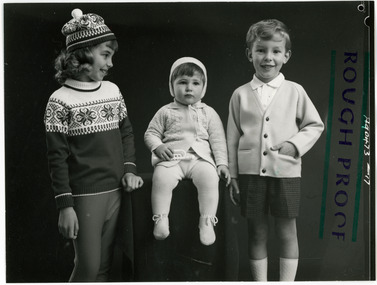

National Wool Museum

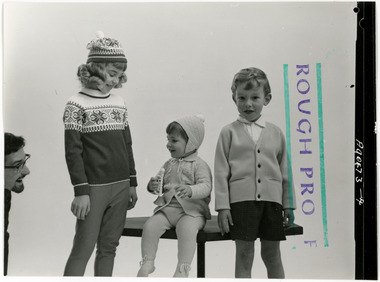

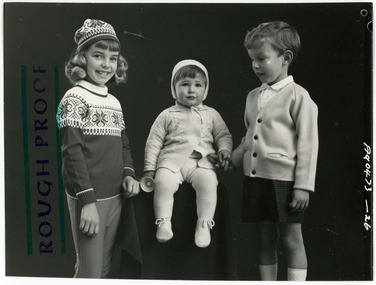

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-17 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A90473-17 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumArchive - Advertisement, 6/10/1969

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white printed advertisement showing a small child wearing a pale v neck cardigan with scalloped border at the neck and embroidered floral motif holding a white rose. Text advertises Kathryn knitwear garment made with Orlon acrylic fibre by DuPont. Communication regarding this advertisement can be found under NWM-09063[obverse] IT’S GOOD TO GROW UP IN SOFT AND GENTLE Orlon* ACRYLIC FIBRE THIS ONE CREATED BY KATHRYN REGD * DU PONT’S REGISTERED TRADEMARK FOR ITS ACRYLIC FIBRE. DU PONT MAKES FIBRES NOT THE GARMENT SHOWN HERE. SOLE REPRESENTATIVES IN AUSTRALIA AND NEW ZEALAND – P ROWE INTERNATIONAL, PTY. LIMITEDbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

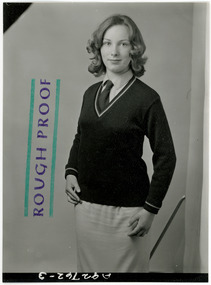

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a young woman with chin-length curly hair, wearing a dark v-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the bottom edge with white ink is an index code A92762-3 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse (stamped in blue ink with green ink lines above and below)] ROUGH PROOF (upside down) A92762-3 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

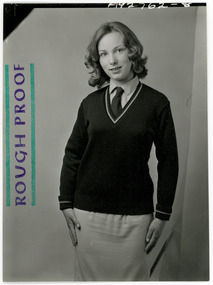

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

... ’ was well-known for their early adoption of modern materials...’ was well-known for their early adoption of modern materials ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of a young woman with chin-length curly hair, wearing a dark v-neck jumper with a pale stripe at the neck and sleeve cuffs over a collared shirt and tie. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the top edge with white ink is an index code A92762-8 From a promotional shoot for Kathryn Knitwear Collegewear[Obverse] A92762-8 (stamped in blue ink with green ink lines above and below)] ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing, teenagers, school uniforms -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972