Showing 18 items matching "barber's equipment"

-

Koroit & District Historical Society

Koroit & District Historical SocietyBarber's equipment

... Barber's equipment.... Barber's equipment ...Items as follows: leather strop for sharpening, shaving soap brush, strop dressing for leather, cut throat razors x 6, sharpening stone, clippers, leather razor case. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, Early 19th century

... barber’s equipment... accessory barber’s equipment barber shop razor strop razor strop ...A razor strop is flexible strip of leather or canvas used to maintain a shaving edge on a thin blade such as a straight razor. Fine powdered jeweler's rouge or other pastes can be added as an abrasive to polish the blade. The strop may be a hanging strip or a hand-held paddle. This one is a hanging strop. Strops were quite commonly found in barber shops and homes before the invention of the safety razor, They are still used for sharpening tool blades. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. KEEN EDGE MANUFACTURER In March 1906 Popular Mechanics magazine included an advertisement for Keen Edge Strop. The promise given by the advertiser, Eddy Mfg. Co. (206 Broadway, New York) was “Use the Keen Edge strop for 90 days and if not satisfied return to us and we will refund your money“. The advertisement was for a Combination Razor Strop, “the only strop made which requires no dressing.” Readers were invited to send for a booklet on Razor and the Face. In 1924 Popular Mechanics, published by Hearst Magazines, displayed an advertisement seeking a sales manager “… to sell [to] drug, hardware and cigar stores Keen Edge Strop Dressing, which sharpens straight razors and safety blades and removes old razor strops.” At that time the Keen Edge Mfg. Company was in Dallas, Texas. Razor strops are of historical significance, representing personal effects of men from the time period when men relied on strops to keep a sharp edge on their shaving blade. Strops were commonly owned and used until the acceptance of safety razors.Razor strop, leather and metal. Keen Edge brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather handle, the other end has metal, swivel hook hanger. Inscriptions pressed into leather at the ends of the straps. Impressed into leather "FINEST SELECTED HIDE", "KEEN EDGE", "FINISH" (black stained side), “A SHARPENER" (red stained side), “1 2 3”warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, keen edge razor strop -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, circa 1922

... barber’s equipment... shaving accessory barber’s equipment barber shop razor strop razor ...A razor strop such as this one was used to sharpen and polish straight-edged razors. This particular design has a swivel hook with a locking clip that allows for movement as the strop is being used. This strop is branded "Sherlite". On May 5th, 1922 the Commonwealth officially accepted and advertised the Trade Mark Application of Thomas Sherry of Victoria, for the Trade Mark of "Sherlite" to be used under the heading of "Leather, Skins unwrought and Wrought”. Thomas Sherry’s application was to use the word “Sherlite” for detachable soles made of rubberised leather. Straight razors and cut-throat razors were the major tools for shaving before the safety razor was invented in the 1880s and even today specialist shaving shops still sell straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap with a shaving brush that had boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade's edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas, or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools, and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are handheld. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish.Razor strop, leather, and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has a padded, bulbous-shaped leather grip handle, the other end has a metal, swivel hook hanger. Inscriptions painted in gold on leather at the hook end.Razor strop, leather and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather grip handle, the other end has metal, swivel hook hanger. Inscriptions printed in gold on leather at hook end.Printed gold lettering stamped “Sherlite”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, sherlite razor strop, personal effects, toiletries, thomas sherry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

... barber's equipment... strop swing razor strop barber's equipment shaving equipment ...This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Mirror

... barber’s equipment... personal grooming accessory barber’s equipment hairdresser ...A handheld mirror such as this one would be used in a 19th century family for personal grooming, or perhaps in a barber or hair dresser shop. The "ebony" wood may have been 'ebonised' wood, a process that made plain wood appear to be ebony. The handheld mirror is an example of a 19th and early 20th century personal grooming accessory. A mirror like this would often be sold with a matching hairbrush and comb. Mirror, personal handheld, oval, painted black, with a bevelled edge around the mirror glass and a wooden handle. Wood is ebony. Inscription on handle"EBONY"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mirror, reflective glass, mirror glass, handheld mirror, personal grooming, personal grooming accessory, barber’s equipment, hairdresser, hairdressing, 19th century personal effects, personal effects, toiletries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... barber's equipment... barber's equipment personal grooming "Hamon" stamped on handle ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... barber's equipment... strop barber's equipment Wooden strop, paddle strop design ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... barber's equipment... paddle strop strop shaving equipment personal effects barber's ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Kew Historical Society Inc

Kew Historical Society IncEquipment, Manual Hair Clippers, 1950s

... barber's equipment... grooming barber's equipment hairdressers hair clippers Metal ...While barber shops were the commercial premises where men and boys had their hair cut, the number of hair clippers in the Kew Historical Society's collection would indicate that frequently hair clipping was carried out in homes in the pre and post war period. Manual hair clippers were readily available for purchase. Electrical clippers were presumably used in barber shops.Metal handheld hair clipperspersonal grooming, barber's equipment, hairdressers, hair clippers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers' Equipment, hair clippers 'BURMAN", c1950

... . Chrome plated, in good condition, c1950. Barbers' Equipment, hair ...Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. Burman & Sons Ltd, of Ryland Road, Birmingham, West Midlands, manufactured Burman-Douglas steering gear. Their recirculating worm and ball design of steering gear was fitted to pre-war vehicles such as the Ford Eight and the Ford Prefect, the Bedford CA, plus heavy trucks and off-road vehicles - both pre and post-war. In its day, Burman-Douglas steering-gear was regarded as.... a "quality" feature of a car chassis specification, but the worm and ball design was eventually surpassed by the cheaper rack and pinion design that dominates today. The company also manufactured motorcycle gearboxes, horse clippers and barbers’ clippers. 1871 Company founded. 1897 Private company. 1930s Gearbox for Ariel Square-four motorcycle. (Exhibit at Birmingham Thinktank museum) 1933 Burman and Sons Limited, manufacturers of horse and barbers' clippers, sheep shearers, motor cycle gear boxes and steering gears, Ryland road, Edgebaston 1953 S. F. Burman, M.B.E., Managing Director, Burman and Sons, Ltd 1955 Acquired by Vono Industrial Products. 1961 Manufacturers of motor and motorcycle accessories. 1,500 employees. 1968 Supplied rack and pinion steering units to Ford 1978 Adwest Group acquired Burman and Sons, the steering gear part of Duport. 1986 Major reduction in staffing at Burman due to fall in demand for its products and delivery problems. A set of hand held barbers’ hair clippers with an adjustable screw, from Burman and Sons Ltd of Birmingham, England. Chrome plated, in good condition, c1950. On left arm ; BURMAN On right arm ; MADE IN ENGLANDbarbers, hairdressing, hair clippers, grooming, horse clippers, cars, motor cycles, gear boxes, rack and pinion , worm and ball, steering gears, steel manufacture, birmingham england, burman and sons ltd, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers’ Equipment, hair clippers steel, c1950

... that are alternately squeezed together and released. Barbers used them to cut ...Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. A set of hand held barbers’ hair clippers with an adjustable screw. Chrome plated, in good condition, c1950 barbers, hairdressing, hair clippers, grooming, horse clippers, steel manufacture, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

... , in fair condition, c1940 Equipment Barbers’ Equipment, hair ...1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, china shaving mug / scuttle, c1950

Shaving soap scuttles are distinguished from shaving mugs by having a separate area for hot water. The hot water is for dipping a shaving brush into to make a lather with the soap which is then applied to the skin before using the razor. Vintage scuttles are often elaborately decorated. Between 1880 and 1920 is the original time period for the occupational shaving mug. Most men owned a shaving mug, either at home or at a barber shop. Mugs purchased for home use typically were purchased through local stores, had more variety in style but usually went without a name. Barber shops sold mugs with the owners’ names on them partly because they thought that shaving rash came from sharing the same soap. In reality, the rash was not a result of soap but of unsterilized razors. Transfer ; The Duryea Motor Wagon was among the first standardized automobiles and among the first powered by gasoline. Fifteen examples were built by the Duryea Motor Wagon Company of Chicopee, Massachusetts, between 1893 and 1896. Their enterprise followed the first commercially available automobile which was patented by Karl Benz on January 29, 1886, and put into production in 1888. The Duryea Motor Wagon remained in production until 1917. The Duryea brothers entered their horseless carriage in many shows and races. A china shaving mug / scuttle with a car transfer. The mug has a wide spout to hold / insert the shaving brush , a perforated tray opening at the top to hold the soap and a bulbous base for the hot water. car transfershaving equipment, safety razors, cheltenham, early settlers, moorabbin, shaving soap sticks, shaving brushes, shaving scuttles, shaving rash, infectious diseases, barber shops, -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Accessory - MAGGIE BARBER COLLECTION: 24CT GOLD PLATE MIRROR, 1890's

Object. Rectangular in shape, 15 cms x 10.5 cms mirror frame, with a 17 cms handle. The mirror has a bevelled edge, and is backed with a deep cream linen fabric embroidered in a fine silk floral-spray petit pomt embroidery. The frame is marked 24 ct. GPL (24ct gold plate). The handle adjoins the mirror with three graduated circles, and three more circles, graduated in diameter, form a small ''knob''at the lower edge.24ct Gold Platedomestic equipment, gold, 24ct gold plate hand mirror -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - MAGGIE BARBER COLLECTION: SILVER CANDLE-SNUFFER, Mid 1880-1900's

Object. pointed at one end, with a 1.7 cm ''foot'' under the point. The Ushaped snuffer to one side below the point, This has a medallion shaped decorative medallion on the side. The interior scissors action snuffer-- which moves in a sideways action is hallmarked: WH &S followed by an indistinguishable mark. Two oval shaped loops form the handles, and each has a 1.7 cm ''foot''.domestic equipment, table setting, silver candle-snuffer -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Vest

Khaki mesh and cloth pilot's vest five pockets on front fastened with domes - various sizes, Two pockets on front fastened with zips. Vest is fasted with zipper down front, three pockets astened with domes on side of back, one large pocket on back with velcro fastenerVest - Survival mesh net. Size medium - Rest of label too faint to read. "Barber" written in black textavest, clothing -

Wodonga & District Historical Society Inc

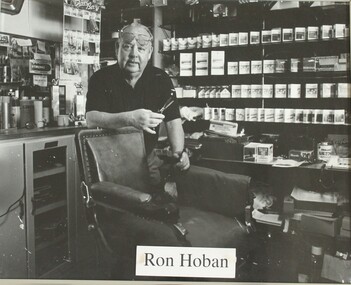

Wodonga & District Historical Society IncPhotograph - Ron Hoban - Barber of Corryong, Rob Elliott, 1993

This image is one from a series of portraits taken by Rob Elliott to record the character of the Border District through the faces if its identities. Ronald Joseph Hoban was born in 1930. In 1951, Mr Hoban, or "Hobie" as he became known, opened his hairdresser and tobacconist business in Corryong. This was at the height of the construction of the Snowy Mountains Scheme and business was thriving. As the tobacco industry slowed down, Mr. Hoban branched out to selling sporting equipment with a focus on fishing tackle and even selling guns and ammunition when it was legal to do so. He was an active and much-loved member of the Corryong community until his death in November 2014. This portrait is significant as it depicts a person who made a significant contribution to community of Corryong and district. The business he established still operates as Hobie’s Sports Store.A black and white photo of a man standing behind a barber's chair, scissors in hand. He has glasses pushed up on his forehead. Tobacco products are stored on the shelves in the background.ron hoban, corryong barber, people of the border -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Telegraph section, Chadburn & Sons, 1875-1898

The ship’s telegraph section was once part of the navigational equipment of the famous paddle steamer, PS Hygeia, and was later installed on Flagstaff Hill’s exhibit, the steamer Rowitta. This is the Bridge Section of a ship’s telegraph, a Duplex Gong model, made by Chadburn & Son of Liverpool. The gong sounded two signals whenever the navigational commands to change the speed or direction were given by the ship’s pilot. Communication between the ship’s pilot and the engine room in the late 19th to the mid-20th centuries was made with a system called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The equipment has two parts, the Bridge Section and the Engine Room Section. The Bridge Section was usually mounted onto a pedestal, and the Engine Room Section was attached to a vertical surface. The standard marine commands were printed or stamped around the face of the dial and indicated by a pointer or arrow that was usually moved by a rotating brass section or handle. The ship’s pilot stationed on the Bridge of a vessel sends his Orders for speed and direction to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell or bells to signal the change at the same time. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. CHADBURN & SON, Liverpool- Chadburn Brothers, William and C.H., were joint inventors and well-established makers of optical and scientific instruments and marine gauges. The firm was granted the Prince Albert Royal Warrant in the late 19th century. In 1870, William Chadburn applied for a patent for his navigational communication device for use on ships. By 1875, Chadburn & Son was producing the brass Engine Order Telegraph in its plant at 71 Lord Street, Liverpool. In 1911, the ship, RMS Titanic, was launched, fitted with Chadburn & Sons E.O.T. The Chadburn Ship Telegraph Company Limited was registered in 1898 to take over Chadburn & Sons. In 1903, a large factory at Bootle, near Liverpool, and its products were being sold overseas. In 1920, electric-powered telegraphs were developed. In 1944, the name changed to Chadburn’s (Liverpool) Limited. In 1968, the company became Chadburn Bloctube Ltd. In 2000, the company, now Bloctube Marine Limited, was still manufacturing ship telegraphs. The P.S. HYGEIA 1890-1932: - This ship’s telegraph was installed on the new paddle steamer, PS Hygeia, one of three iconic pleasure steamers famous for providing regular services in Port Phillip Bay, Victoria, to thousands of passengers between the ports of Queenscliff, Sorrento, Portsea, Dromana, Rosebud, Rye, and Mornington. It joined the Ozone and the Weeroona, all three described as being glamorous, powerful and fast. Its ticket office was on the pier itself. The P.S. Hygeia was built in Yorker, Scotland, in 1890, by Napier, Sharks & Bell. It was registered in Melbourne, Australia, by Hubbart, Parker & Co. in 1891. The steel ship was 92 metres long, able to travel at 22 knots, and licensed to carry over 1600 passengers in luxury, with even a barber shop on board. The regular service between the ports in Port Phillip Bay, Victoria, continued for over 40 years. With the decline in passenger demand, the service wound down. The Hygeia was sold to H.M. Morris in 1931 for demolition and breaking up. Equipment, fittings, and even lifebuoys were sold, with many items purchased by people who had some connection to the Hygeia. On August 25th, 1931, what was left of the vessel departed Port Melbourne and eventually, in June 1932, it was laid to rest at the ships’ graveyard outside Port Phillip Heads. The SS ROWITTA 1909-2015: - The ship’s telegraph was originally installed on the PS Hygeia. It was purchased when the Hygeia was broken up in 1931 and later installed, in 1975, on Flagstaff Hill’s SS Rowitta, an exhibit greatly enjoyed by the public until it was demolished in 2015. The ferry “SS Rowitta” was built in 1909 in Hobart, Tasmania. The timber steam ferry was built using planks of Huon and Karri wood. It was a favourite with sightseeing passengers steaming along Tasmania’s Tamar and Derwent rivers for 30 years. Rowitta was also known as Tarkarri and Sorrento and had worked as a coastal trading vessel between Devonport and Melbourne, and Melbourne, Queenscliff and Sorrento. The vessel had given over 100 years of service and pleasure. This Bridge section of a ship’s Engine Order Telegraph, used with an Engine Room section, represents late-19th-century change and progress in communication and navigation at sea. This type of equipment was still in use in the mid-20th century. It is significant for its association with its maker, Chadburn & Son, of Liverpool, a well-known marine instrument maker whose work was recognised by English Royalty, and whose products were selected to supply similar equipment for use on the RMS Titanic. The ship’s telegraph is also significant for its association with the paddle steamer PS Hygeia, one of three iconic steamers that transported thousands of passengers from port to port within Port Phillip Bay, Victoria, for over 40 years from the 1890s to the 1930s. Queenscliff Borough remembers the Hygeia by naming a road near the pier Hygeia Drive. The Hygeia is registered on the Victorian Heritage Database as a vessel of significance, VHR S329. In 1901, Hygeia had the privilege of carrying their Royal Highnesses, the Duke and Duchess of York, from Mornington to St Kilda Pier, Melbourne, during their Royal visit celebrating the Federation of Australia. The ship’s telegraph is also important for its connection with the Rowitta, a large exhibit on display at Flagstaff Hill Maritime Village, aiding maritime education for over 40 years. It represented the importance of coastal traders to transport, trade and communication along the coast of Victoria, and before the availability of rail and motor vehicles, serving many roles. Bridge section of a Ship’s Telegraph or Engine Order Telegraph (E.O.T.). The round, double-sided, painted glass dial is inside a brass case behind glass. It is fitted onto an outward tapering brass pedestal with a round base. The brass indicator arrows between the handles point simultaneously to both sides of the dial when moved. An oval brass maker’s plate is attached to the top of the case. The dial’s faces have inscriptions that indicate speed and direction, and the front face and plate include the maker’s details. A serial number is stamped on the collar where the dial is fitted to the pedestal. The ship’s telegraph is a Duplex Gong model, made by Chadburn & Son of Liverpool. It was originally part of the navigational fittings on the paddle steamer, PS Hygeia.Dial, maker’s details: “PATENT “DUPLEX GONG” TELEGRAPH / CHADBURN & SON / TELEGRAPH WORKS / PATENTEES & MANUFACTURERS / 11 WATERLOO ROAD / LIVERPOOL” LONDON / 105 FENCHURCH STREET” “NEWCASTLE / 85 QUAY + SIDE” “GLASGOW / 69 ANDERSON QUAY” “PATENT” Dial instructions: “FULL / HALF/ SLOW / FINISHED WITH ENGINES / STOP STAND BY / SLOW / HALF / FULL / ASTERN / AHEAD” Maker’s plate: “CHADBURN / & SON / PATENT / LIVERPOOL” Serial number: “22073”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, engine order telegraph, e.o.t., navigational instrument, communication device, ship’s telegraph, engine room section, bridge section, rms titanic, chadburn & son, chadburn brothers, william chadburn, chadburn ship telegraph company, chadburns, duplex gong, liverpool, ss rowitta, navigation, marine technology, pilot’s orders, steam power, hobart, tasmania, devonport, tasmanian-built, ferry, steam ferry, steamer, 1909, early 20th century vessel, passenger vessel, tamar trading company, launceston, george town, sorrento, tarkarri, speculant, peter mcgennan, p j mcgennan & co. port phillip ferries pty ltd, melbourne, coastal trader, timber steamer, huon, karri, freighter, supply ship, charter ferry, floating restaurant, prawn boat, lakes entrance, ps hygeia, paddle steamer, pleasure steamer, port phillip bay, queenscliff, portsea, dromana, rosebud, rye, mornington, hubbart parker & co, 1890, 1903, h.m. morris, hygeia