Showing 7 items matching "blacksmith tools, forge, metal, iron"

-

Numurkah & District Historical Society

Numurkah & District Historical SocietyBlacksmith Tool (unknown use)

... blacksmith tools, forge, metal, iron... high-country blacksmith tools, forge, metal, iron Round metal ...Round metal with handle. At the other end, the round metal has been flattened. On the end of the flattened piece is a rounded, thicker piece of metal (one end of this has been corroded away)blacksmith tools, forge, metal, iron -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTuyere Pipe, circa mid to late 1900's

This tuyere (word from French origin) was used by professional blacksmiths and or cattlemen before and during the Kiewa Hydro Electricity Scheme was being constructed. The need to use a furnace or forge in the shaping of metal rods, horse shoes and pipes is both a rural necessity and a construction, on site requirement. The "inventiveness" of cattlemen and construction workers to produce metal objects not available "off the shelf" is one of the inherent traits not only of rural self sufficiency but in the "pioneer" days of rural isolation one of survival.This tuyere is of great significance to the Kiewa Valley and its regions because it highlights one of the greatest strengths of the rural (especially isolated) life and its folk living there, and that is the great human factor of adaptability and survival techniques in sometimes harsh and demanding environmental circumstances. The inventiveness and the attitude, "she'll be right mate", demonstrates life on the land where specialised blacksmith activities can be found in non "professionals" because of the fact that "someone" has to do the job. This is one of the differences between country "rural" life and that found in cities and larger towns.This iron cone shaped tuyere has a small hole (diamenter 25mm) starting within an ever enlarging cone (amplification of the air pressure going through) delivering varying hot or extremely hot air into a furnace or hearth which intensifies the heat to allow the "shaping" of metal objects. The larger "flared" cone extension allows for the directed air to be spread and not concentrated.blacksmith tool, tue, bellows, fashioning metal, forge manufacturing process -

Flagstaff Hill Maritime Museum and Village

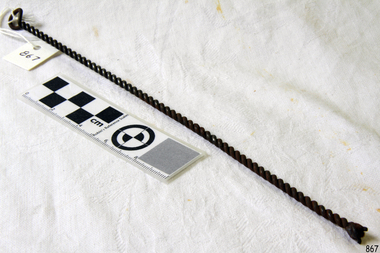

Flagstaff Hill Maritime Museum and VillageTool - Stretching Hook

Hand forged metal tool, possibly a sailmaker's hook with the hook broken. It may be a fire iron. The twisted metal is a skill learned by a blacksmith.The item is a handmade tool, an example of the work of a blacksmith. Smiths were sought after in colonial Australia. Their trade allowed them to custom make work for the different industries necessary for survival in a new land.Sailmaker's stretching tool; long thin metal rod bent in half, with centre forming a handle or loop, and long ends twisted together to form a stem. The loose ends are formed together but appear broken.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, tool, sailmaker's tool, fire iron, blacksmith, twisted rod, twisted wire, sailmaker's hook -

Numurkah & District Historical Society

Numurkah & District Historical SocietyBlacksmith hammers x 4

4 x Blacksmith hammers, metal/iron with wooden handlesblacksmith, forge, hammers, tools -

Numurkah & District Historical Society

Numurkah & District Historical SocietyBlakcsmith shaping tools x 2

... high-country Blacksmith, forge, shaping tool 2 x metal/iron ...2 x metal/iron shaping tools. Flat rectangular metal piece has corrugated pattern underneath. This metal piece has a rectangular metal handle welded onto itblacksmith, forge, shaping tool -

Numurkah & District Historical Society

Numurkah & District Historical SocietyBlacksmith Swaging tools x 4

Various shaped tools for blacksmithing, metal/iron. Three have holes in them to insert wooden handles blacksmith, forge, tools, swaging, shaping