Showing 43 items matching "bootmaking"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Machine - Sewing Machine, Bootmaking, c1900

... Bootmaking ...This treadle Bootmaking machine was used by early settlers and market gardeners in Moorabbin Shire, who had to be self reliant, producing their food and making and maintaining their own equipment, clothing and utensils This Claes 'Patent Elastic' boot-making machine is an example of the skills and craftsmanship of the pioneer settlers in Moorabbin Shire c1900 A black, 'Patent Elastic' treadle, boot-maker's, sewing machine.'PATENT ELASTIC' on iron framebrighton, moorabbin, pioneers, bentleigh, market gardeners, early settlers, farm equipment, sewing machine, boot-makers, leatherwork, patent elastic manufacturing company -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBootmaker's hook, c1940

... bootmaking ...made and used by internees in Camp 3 Tatura during WW2 for making shoes and bootsHand tool used for bootmaking, hook for leatherhook, bootmakers kit, haering, manfred, camp 3, tatura, hand tool, !, trades, bootmaking -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Set of shoe lasts

... bootmaking ...Consists of 3 individual foot shaped metal casts. Largest last has a stand with a slot at the top into which the smaller lasts can be placed. Used to mould boots and shoes of different sizes in their production or repair.bootmaking -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Shoe Last

... bootmaking ...Belonged to the donor's father and uncle and are over 70 years old.A wooden last with a metal sole, almond shaped toe with 7G stamped on one side of heel and 1706 GNB on the other side.GNB 1706 7Gtrades, bootmaking -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Boot Last and Stand

... bootmaking ...Used for making Boots.No 8trades, bootmaking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBootmakers Tools, 1940

... bootmaking ...Used to polish edge of leather soles of shoes at camps1 Rectangular Wooden Tool wih cut out piece at one end.1 Rectangular Tool with cut out piece at both ends.tatura, trades, bootmaking -

Clunes Museum

Clunes MuseumBook, George Rose - The Postcard Era

THIS BOOK IS NOT JUST ABOUT POSTCAREDS AS POSTAL ITEMS THAT PEOPLE COLLECT, BUT A PICTURE BOOK THAT LEAS US INOT THE WORLD OF YESTERYEAR...Taupe coloured, soft cover book with 3 images of postcards on the front cover, an image of George Rose on front cover. 260 pagesnon-fictionTHIS BOOK IS NOT JUST ABOUT POSTCAREDS AS POSTAL ITEMS THAT PEOPLE COLLECT, BUT A PICTURE BOOK THAT LEAS US INOT THE WORLD OF YESTERYEAR... postcards, sterograph, george rose -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Footwear - LEATHER BOOTMAKING TOOLS AND COMPANY STAMP OF J.M.OKEY

Okey, J M Leather Bootmaking Tools and Company Stamp. An open Wooden box of assorted Bootmakers 'Leather working'Tools.(Some appear hand-made')Some tools seem to be chisels, cutters, crimpers etc. The box is approx. 30cm x 15cm x 15cm. These include a metal Stamp that creates an oval-shaped label. 'John M Okey., Boot & shoe-maker, Kangaroo Flat'. Also included is an 'Ivory?' Chisel. Donated by 'Mr Reed' 7.8.69. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Jim Connor, Avenue of Honour, Main Road, Eltham, 14 Jan 2017

Eltham Gateway, The old Bootmaker's Cottage adjacent to Whitecloud Cottage, 701 Main Road, Eltham The bootmaker's shop was operated by John Henry (Harry) Clark from about 1930. Clark was originally a photographer along with his brothers William (Will) Charles Clark and Clement Kent Clark. They operated as Clark Bros Photographers based at 25 Thomas Street, Windsor (Prahran) from about 1895 to 1915 at which point the premises was demolished.. Brother Clement died in 1912. By 1916 Harry was living and working as a photographer in Eltham and was recorded on the electoral rolls as a photographer up to and incliiding at least 1928. By 1931 he had changed proession to Bootmake and again continued on Main Road, Eltham South as a Bootmake at least until 1954. He died at St Vincent'e Hospital in Dec 1956. It is believed non of the brothers married. Whilst very little public record exists og Harry in the papers either as a photographer or bootmaker, one incident was reported in 1935 when he witnessed a girl on a bike come crashing down Main Road and into the pond next to his shop.Tomorrow's history documented todayeltham, jim connor collection, main road, eltham gateway, avenue of honour, dalton street, wingrove park trail, bootmakers cottage -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Jim Connor, Avenue of Honour, Main Road, Eltham, 14 Jan 2017

Eltham Gateway, The old Bootmaker's Cottage adjacent to Whitecloud Cottage, 701 Main Road, Eltham The bootmaker's shop was operated by John Henry (Harry) Clark from about 1930. Clark was originally a photographer along with his brothers William (Will) Charles Clark and Clement Kent Clark. They operated as Clark Bros Photographers based at 25 Thomas Street, Windsor (Prahran) from about 1895 to 1915 at which point the premises was demolished.. Brother Clement died in 1912. By 1916 Harry was living and working as a photographer in Eltham and was recorded on the electoral rolls as a photographer up to and incliiding at least 1928. By 1931 he had changed proession to Bootmake and again continued on Main Road, Eltham South as a Bootmake at least until 1954. He died at St Vincent'e Hospital in Dec 1956. It is believed non of the brothers married. Whilst very little public record exists og Harry in the papers either as a photographer or bootmaker, one incident was reported in 1935 when he witnessed a girl on a bike come crashing down Main Road and into the pond next to his shop.Tomorrow's history documented todayeltham, jim connor collection, main road, eltham gateway, avenue of honour, dalton street, wingrove park trail, bootmakers cottage -

Mont De Lancey

Mont De LanceyBall and Ring Bunion Stretcher

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron ball and ring bunion stretcher.boot stretchers -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP, Unknown

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, and nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together and neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A pair of handmade, adult brown leather work boots, with brown leather laces, decorative stitching, metal eyelets and are stitched with waxed thread. The soles are covered with hob nails in a decorative pattern. They have metal caps on the heels. bootlaces, boots, footwear, clothing -

NMIT (Northern Melbourne Institute of TAFE)

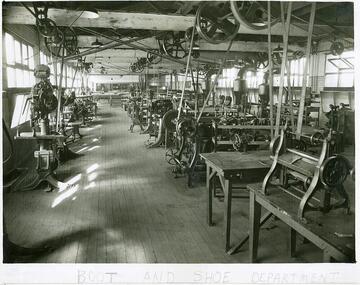

NMIT (Northern Melbourne Institute of TAFE)Photographs: CTS 1943-1946 Boot and Shoe - Footwear Building, Photographs: : CTS 1943-1946 Boot and Shoe - Footwear Building

A number of black and white photographs recording the history of Collingwood Technical School's Boot and Shoe building. This building was burnt down in 1943. Machinery valued at £14,000 was lost. Total damage was estimated at £25,000. It was the only bootmaking school in Melbourne. (Scott p.48). It was replaced by the Footwear Trades building which was constructed between 1945 and 1947. The foundation stone for the new building was laid on 21st February 1945 by the Hon. T. T. Hollway, MLA, Minister of Education. The photographs include: The original Boot and Shoe classroom [1929]-1943; The Burnt out building 1943; Six photographs of the Laying of the Foundation Stone event on 21st February 1945 by the Hon. T. T. Hollway, MLA, Minister of Education (note the band on the roof in most of these six photos); Two photographs of the progressive construction of the new building. See Scott's history p.49.collingwood technical school, buildings, boot and shoe building, footwear building, fires, nmit -

Federation University Historical Collection

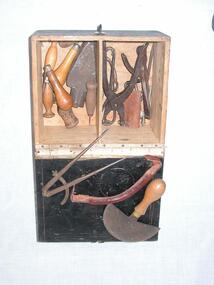

Federation University Historical CollectionTool - Leatherwork Toolkit, Leatherwork Toolkit in Timber Box, c1920

... bootmaking ...Thought to have been used in shoemaking classes held for repatriated soldiers at Ballarat School of Mines. At the Ballarat Technical Art School, during the early twentieth century, leather art was popular but had little industrial value and was usually a minor study. The Victorian Education Department set examinations in art leather work. Copies of many Technical School Examination Papers are kept within the University's historical collection.Black wooden box with metal latch and handle. Contains assortment of tools, some with timber handles, some metal. Two halves inside box. Lid is attatched by canvas nailed to bottom. leather, tools, box, world war one, ballarat school of mines, shoemaking, bootmaking, bootmaker, leatherwork, repatriation -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

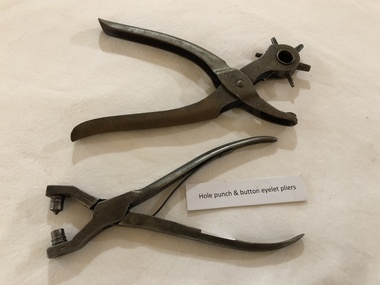

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

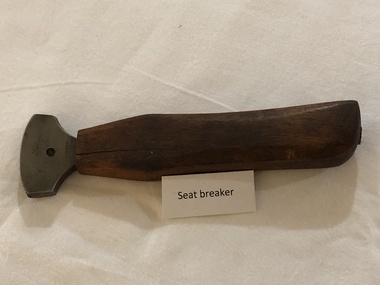

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails