Showing 147 items matching "carding machine"

-

National Wool Museum

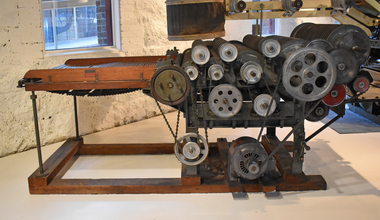

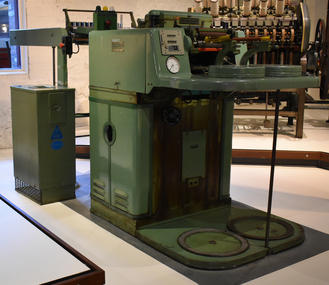

National Wool MuseumMachine - Carding Machine, CSIRO, 1960s

... Carding Machine...Carding Machine... before the next process. Carding machines constantly require... and divided into strands before the next process. Carding machines ...After scouring, the wool fibres are still tangled together. Carding untangles the fibres by brushing and straightening. The wool moves through a series of wire brush rollers that revolve at different speeds and in different directions to tease apart the wool. The fibres emerge from the machine as a continuous filmy web - called a sliver. The sliver must be thinned and divided into strands before the next process. Carding machines constantly require tuning. A highly skilled technician maintained and adjusted the speed of the rollers on the machine. This machine was developed by the CSIRO in the 1960s as a small-scale experimental machine. Industrial carding machines were four times the size of this one. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box. Also another gold plaque read: Experimental Carding Machine donated to The National Wool Museum by C.S.I.R.O Ryde has been rebuilt by Nick Sokolov of Comb Research & Development with the help of Bernard Tolan.Carder with small roller missing at coiling end. Driven by three horse power motor. Wooden slated feed table synchronised to overall gearing.carding machine, machines, wool industry, manufacturing, wool processing -

![Photograph, [Carding machine R S & S mill]](/media/collectors/510b3f7f023fd725b4cd52cc/items/540660559821f50e3cc9feba/item-media/5f585477f6fbc90cf4e4a8da/item-fit-380x285.jpg) National Wool Museum

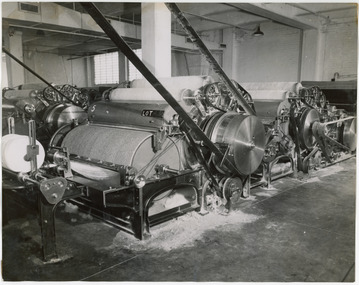

National Wool MuseumPhotograph, [Carding machine R S & S mill]

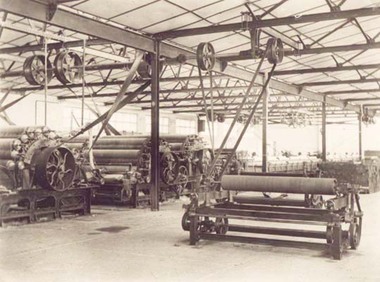

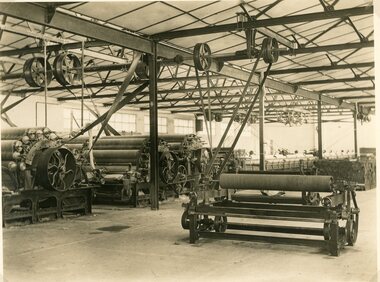

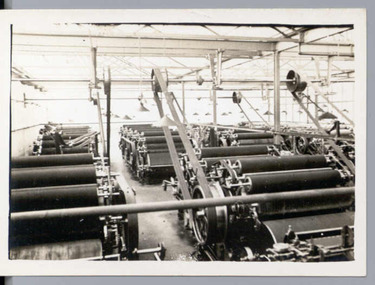

... [Carding machine R S & S mill]...Carding machine at the R S & S mill...Carding machine/ beginning of carding process/ R S & S...-and-the-bellarine-peninsula Carding machine at the R S & S mill textile ...Carding machine at the R S & S millCarding machine/ beginning of carding process/ R S & Stextile machinery textile mills - history textile mills, returned soldiers and sailors mill, carding, kidman, mr g. l., textile machinery, textile mills - history, textile mills -

National Wool Museum

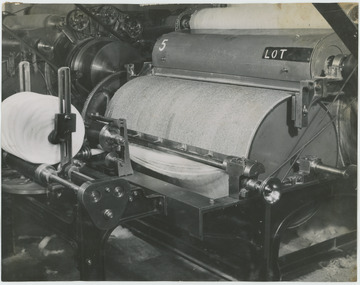

National Wool MuseumPhotograph - Carding Machine, 1960s

... Carding Machine...Black and white image showing a carding machine...., Carding Machine...., / MELBOURNE AUSTRALIA / W14 / W14, Carding Machine. Black and white ...One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a carding machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W14 / W14, Carding Machine.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

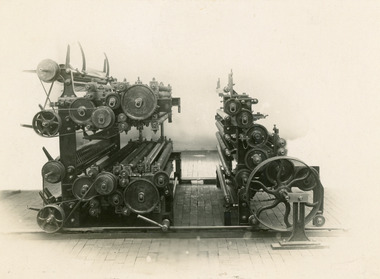

National Wool MuseumPhotograph, Carding Machine, Unknown

... Carding Machine...Black and white photograph of a carding machine.... photograph of a carding machine. Carding Machine Photograph ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Black and white photograph of a carding machine.Rear handwritten top edge - Chadwickstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph - Carding Machine, 1960s

... Carding Machine...Black and white image showing a carding machine.... Carding Black and white image showing a carding machine ...One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a carding machine.W38 / Woollen Cardingwool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumPhotograph - Carding Machine, 1960s

... Carding Machine...Black and white image showing detail view of a carding... and white image showing detail view of a carding machine. Photograph ...One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing detail view of a carding machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W13 / W13. Close-up of Carding.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

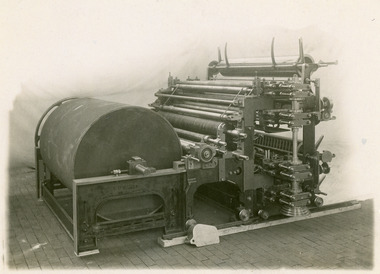

National Wool MuseumPhotograph, Carding Machine, Unknown

... Carding Machine...Two black and white photographs of a carding machine... photographs of a carding machine. The first photo is of the rear ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Two black and white photographs of a carding machine. The first photo is of the rear of the machine, the second the front.8054.1 - rear handwritten top edge - Chadwicks left edge - unknown 8054.2 - a calculation of numberstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

... Carding Machine.... Location of photo looks to be in a textile mill. Carding Machine ...Photographs were most likely used for promotional purposes. The photographed machine was made by Tomlinsons (Roshdale) Limited, was British machine manufacture company based in Rochdale.Black and white photo of a Rag Puller Machine in landscape format. Location of photo looks to be in a textile mill.On machine - Tomlinsons (Roshdale) Limited.textile machinery, wool manufacture, wool, timlinsons, rag pulling -

National Wool Museum

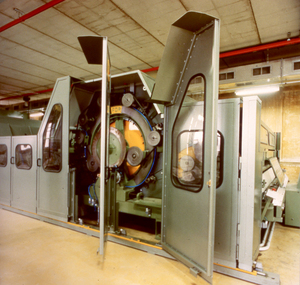

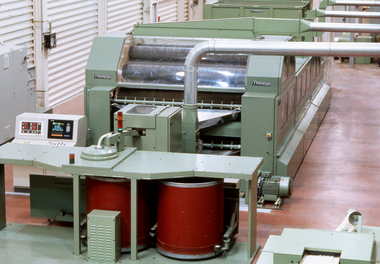

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Machine, Thibeau Schlumberger, 1990s

... Carding Machine, Thibeau Schlumberger... machinery. Carding Machine, Thibeau Schlumberger Photograph Slide ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing exterior of carding machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Machine, Thibeau Schlumberger, 1990s

... Carding Machine, Thibeau Schlumberger... machinery. Carding Machine, Thibeau Schlumberger Photograph Slide ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing exterior of carding machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Machine, Thibeau Schlumberger, 1990s

... Carding Machine, Thibeau Schlumberger... machinery. Carding Machine, Thibeau Schlumberger Photograph Slide ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing exterior of carding machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Machine, Thibeau Schlumberger, 1990s

... Carding Machine, Thibeau Schlumberger... machinery. Carding Machine, Thibeau Schlumberger Photograph Slide ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing exterior of carding machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPostcard, 1910

... Carding Machine... is of two men standing in front of a carding machine inside... / First carding Machine bins / Erected b W. (Bill... at CSRIO. Warrnambool Woollen Mill Carding Machine Handwriting ...Postcard was given to David Phillips (Donor) by a friend who was involved in the wool industry through employment at CSRIO.Postcard with black and white image on front. Image is of two men standing in front of a carding machine inside of the Warrnambool Woollen Mill. Image is printed onto postcard despite the non-straight lines suggesting the image may have been cut and pasted. Reverse of the postcard has handwritten message detailing image on the front of the postcard.Handwriting, black ink: Warrnambool Woollen Mill 1910 / First carding Machine bins / Erected b W. (Bill) + (?) / Pontefract warrnambool woollen mill, carding machine -

National Wool Museum

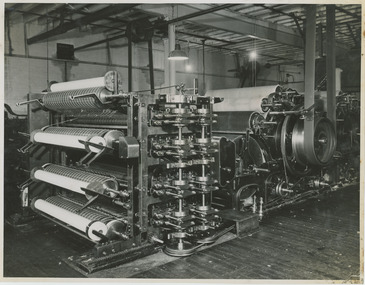

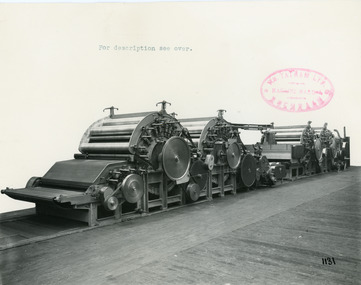

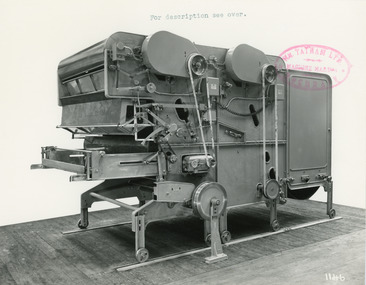

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

... carding machine.... A carding machine disentangles and cleans wool fibres... taken place. A carding machine disentangles and cleans wool ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

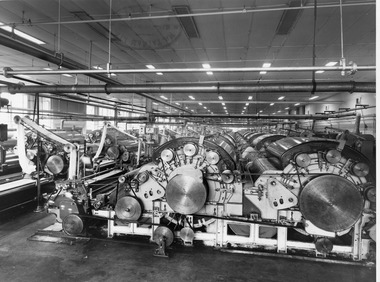

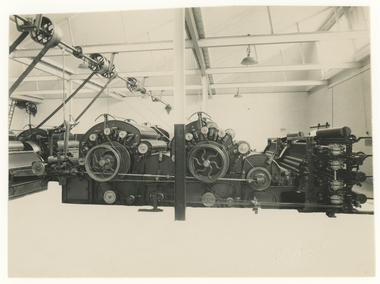

National Wool MuseumPhotograph - Carding Machines

... , to showcase new Carding Machines in a newly developed textile factory... Carding Machines in a portrait format. A man is working at the end.... of Rochdale, to showcase new Carding Machines in a newly developed ...Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

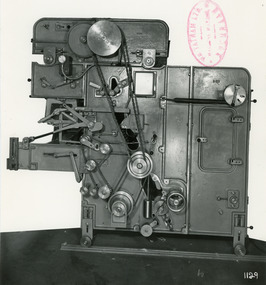

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

... uncarded wool to carding machines, The photographed machine... and sequentially supplies uncarded wool to carding machines ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

National Wool MuseumMachine, Hand Carding

... Machine, Hand Carding... made Machine, Hand Carding ...The Kacoonda Carder subjected to patent action Australian madehart-davis(deceased), ms mary - kacoonda enterprises -

National Wool Museum

National Wool MuseumPhotograph, Carding R S & S

... Carding machine at the R S & S mill...-and-the-bellarine-peninsula Carding machine at the R S & S mill textile ...Carding machine at the R S & S millCarding / R S & Stextile machinery textile mills - history textile mills, returned soldiers and sailors mill, carding, kidman, mr g. l., textile machinery, textile mills - history, textile mills -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, North Western Woollen Mills -- Carding Machines

... North Western Woollen Mills - Carding Machines... grampians North Western Woollen Mills - Carding Machines Stawell ...North Western Woollen Mills - Carding Machinesstawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, North Western Woollen Mills -- Carding Machines

... North Western Woollen Mills - Framed - Carding Machines... grampians North Western Woollen Mills - Framed - Carding Machines ...North Western Woollen Mills - Framed - Carding Machinesstawell industry -

National Wool Museum

National Wool MuseumCatalogue, Textile Machinery Specialities

... for grinding machines and card making machines..... Catalogue for grinding machines and card making machines. Textile ..."Textile Machinery Specialities" - Dronsfield Bros Ltd, Atlas Works, Oldham, England, 13th ed. 1924. Catalogue for grinding machines and card making machines.textile machinery, dronsfield bros ltd -

National Wool Museum

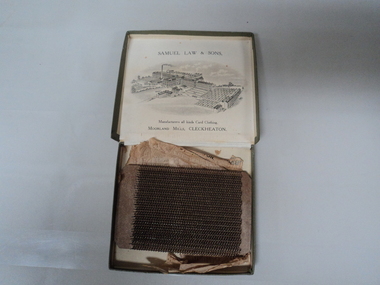

National Wool MuseumSample, Card Clothing

... on the fibres.' This fits into a carding machine ("The Textile... operated on the fibres.' This fits into a carding machine ...Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

![Photograph, [No 1 Carding Room Machines c30's]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f599821f50e3cc9f4d6/item-media/54065f599821f50e3cc9f4d7/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [No 1 Carding Room Machines c30's]

... No 1 Carding Room Machines c30's still in use until 1960's... Woollen Mills No 1 Carding Room Machines c30's still in use until ...Acquired when "Classweave Industries" closed downNo 1 Carding Room Machines c30's still in use until 1960's 15 7A 14/57 74%textile machinery woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile machinery, woollen mills -

National Wool Museum

National Wool MuseumPhotograph

... and shows the carding machine. The donor worked at the Valley Mill... and shows the carding machine. The donor worked at the Valley Mill ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the carding machine. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, carding -

National Wool Museum

National Wool MuseumFunctional object - Time Card Rack

... A time clock, sometimes known as a clock card machine... the time card hit a contact at the rear of the slot, the machine ...A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that recorded the time an employee entered and left the factory. In mechanical time clocks, this was accomplished by inserting a heavy paper card, called a time card, into a slot on the time clock. When the time card hit a contact at the rear of the slot, the machine would print day and time information (a timestamp) on the card. One or more time cards could serve as a time sheet or provide the data to fill one. This allowed a timekeeper to have an official record of the hours an employee worked to calculate the pay owed an employee.Metal time card rack.time sheet, time card, factory, employee, work life, punch clock, textile industry -

National Wool Museum

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

... necessary to restore The Carding Machine, Noble Comb & The Gill Box.... necessary to restore The Carding Machine, Noble Comb & The Gill Box ...This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

National Wool MuseumFunctional object - Time Card Rack

... A time clock, sometimes known as a clock card machine... the time card hit a contact at the rear of the slot, the machine ...A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that recorded the time an employee entered and left the factory. In mechanical time clocks, this was accomplished by inserting a heavy paper card, called a time card, into a slot on the time clock. When the time card hit a contact at the rear of the slot, the machine would print day and time information (a timestamp) on the card. One or more time cards could serve as a timesheet or provide the data to fill one. This allowed a timekeeper to have an official record of the hours an employee worked to calculate the pay owed an employee.Metal time card rack.time card, rack, employee, factory, timesheet, data, mechanical, punch clock -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

... . The Automatic Feeding Machine automatically dispenses wool to a carding... dispenses wool to a carding machine, so that an even, constant ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

National Wool Museum

National Wool MuseumTextile - Onkaparinga Blanket, Waffle Collection, Unknown

... consisted of one carding machine, one spinning mule of 30 spools... consisted of one carding machine, one spinning mule of 30 spools ...Onkaparinga started in South Australia in 1869. Migrating from Germany, two brothers, Heinrich and Edward Kramm, both weavers, purchased and brought with them some machinery and established themselves in Hahndorf in a mud hut. Their original plant consisted of one carding machine, one spinning mule of 30 spools and 2 hand looms. The spinning mule was horse driven, the others all hand operated. The wool was washed by hand and dried in the sun then teased by hand. Now 145 years later the brand name Onkaparinga, is known all over the world, the products reflect the experience, passion and ingenuity of over a century's tradition in providing luxurious home wares. Donated to the National Wool Museum by Joyce GrayLight orange waffle weave woolen blanket, with nylon trimming. Product tag included with plastic case. On product tag - The better way to sleep. Onkaparinga onkaparinga, blanket, wool, kramm -

Bendigo Military Museum

Bendigo Military MuseumCard - CARD, CHRISTMAS, MEMORABILIA

... AUSTRALIAN COMMONWEALTH MILITARY FORCES. Inside the card... MILITARY FORCES. Inside the card "10th Machine Gun Company ..."Potter Frank Hales 153, 10th Aust Machine Gun. Died of wounds 3 Nov 1917. Wimereu Communal Cemetery, Plot IV, Row L, Grave 3.Cream coloured card, red silk bow on front with the Rising Sun Emblem in gold ink. Inside has 4 paper pages. Middle pages have gold writing. Last page and inside back cover is a handwritten in black ink letter. Letter written 5 Nov 1916. Letter contents - hoping the receiver, his wife, and kiddies are well. They have not reached the front as yet. Very wet and muddy also measles & mumps are infecting a few.AUSTRALIAN COMMONWEALTH MILITARY FORCES. Inside the card "10th Machine Gun Company AUSTRALIAN IMPERIAL FORCES. To wish you a Merry Christmas and a Happy New Year from 2nd Lieut F. H. Potter.card, christmas card, ww1