Historical information

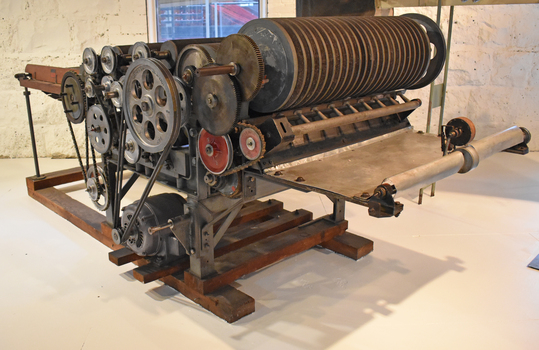

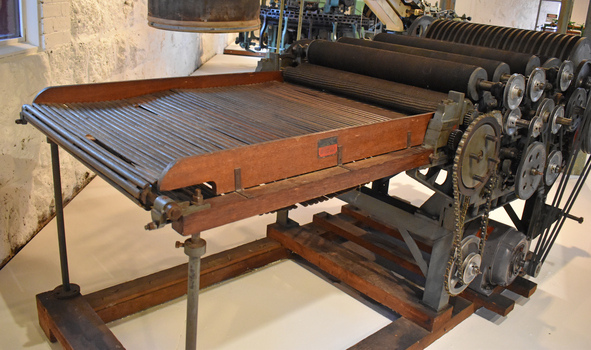

After scouring, the wool fibres are still tangled together. Carding untangles the fibres by brushing and straightening. The wool moves through a series of wire brush rollers that revolve at different speeds and in different directions to tease apart the wool.

The fibres emerge from the machine as a continuous filmy web - called a sliver. The sliver must be thinned and divided into strands before the next process.

Carding machines constantly require tuning. A highly skilled technician maintained and adjusted the speed of the rollers on the machine.

This machine was developed by the CSIRO in the 1960s as a small-scale experimental machine. Industrial carding machines were four times the size of this one.

Gold plaque on display with machine until 2018 read:

G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.

Also another gold plaque read:

Experimental Carding Machine donated to The National Wool Museum by C.S.I.R.O Ryde has been rebuilt by Nick Sokolov of Comb Research & Development with the help of Bernard Tolan.

Physical description

Carder with small roller missing at coiling end. Driven by three horse power motor. Wooden slated feed table synchronised to overall gearing.