Showing 46 items matching "clock mechanism"

-

Flagstaff Hill Maritime Museum and Village

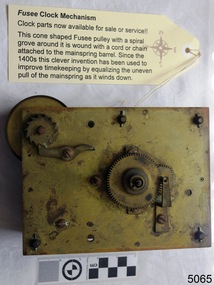

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

... Fusee Clock Mechanism...clock mechanism... mechanisms. The earliest existing clock with a fusee, also... Vinci also show fusee mechanisms. The earliest existing clock ...The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock case, Late 19th to early 20th centuries

... for the clock mechanism. The doors may have given access for winding... to be fitted with a clock mechanism.... or fitted space for the clock mechanism. The doors may have given ...This vintage-era clock case has a curved top and two doors, one at the side, and the other at the top. It could have had another frame for the front with a window or fitted space for the clock mechanism. The doors may have given access for winding the clock with a key and to set the time or perhaps an alarm or chime. It is possible that the arched shape was the bottom of the clock case and not the top, in which case, there would be more space for a pendulum to swing. The wooden case would amplify the sound of the tick of the clock.The wooden clock case is connected to domestic life in the late 19th and early 20th centuries when households could afford at least one clock for their furnishings.Wooden clock case with open front and arched top, which may be the bottom of the case. It has a hinged door on the side and another door on the top with a small brass knob. This case is ready to be fitted with a clock mechanism.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, clock case, clock case with two doors, pendulum clock case, vintage, horology, time keeping, clock maker, domestic clock, furnishing -

Marysville & District Historical Society

Marysville & District Historical SocietyPhotograph (Item) - Colour photograph, Unknown

... A colour photograph of the clock winding mechanism...A colour photograph of a man oiling the clock winding... of the clock winding mechanism in The Marysville Museum in Marysville ...A colour photograph of the clock winding mechanism in The Marysville Museum in Marysville in Victoria.A colour photograph of the clock winding mechanism in The Marysville Museum in Marysville in Victoria. Fred Sawyer was originally from London, but then later relocated to Sydney, Australia, and then to Marysville in Victoria where he established The Marysville Museum. The Marysville Museum held a collection of horse-drawn vehicles, veteran, vintage and classic vehicles, various machinery and memorabilia. Gillett & Johnston was a clockmaker and bell foundry based in Croydon, England from 1844 until 1957. Between 1844 and 1950, over 14,000 tower clocks were made at the works. The company's most successful and prominent period of activity as a bellfounder was in the 1920s and 1930s when it was responsible for supplying many important bells and carillons for sites across Britain and around the world. A successor company continues operation in Bletchingley, Surrey, under the Gillett & Johnston name, engaged in clock-making and clock and carillon repair. the marysville museum, marysville, victoria, photograph, fred sawyer, 1865 gillet bland and co turret clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

... There are no markings on the clock or mechanism ... There are no markings on the clock or mechanism Naval brass ships bulkhead clock ...Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

... No markings or inscriptions on clock case or mechanism ... industries No markings or inscriptions on clock case or mechanism ...In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationWeights

... for lens clock-work mechanism attached to a bent metal rod... used for lens clock-work mechanism attached to a bent metal rod ...A small number of heavy cast iron weights and two rods remain at the Point Hicks. The weights and rods were part of the original clockwork mechanism that was fitted beneath the lens to keep the kerosene-fuelled light turning. They were attached to a cable or chains and moved vertically in similar fashion to the way weights move on grandfather clocks. As the weight fell, the optic clock was driven and the lens was turned. To keep the clock turning, the weight needed to be wound back up to the top of its travel. The cables and weights in this lighthouse were visible as they moved through the length of the tower up to the lantern room. It was usual for systems to move inside a tube extending up to the top, but in this case the tower’s cast iron spiral staircase, which is supported on cantilever cast iron brackets set into the concrete wall, spiralled around the space in which they moved. Lighthouse keepers had the arduous job of having to constantly wind the clock to keep the light active, and at least two keepers needed to observe a strict roster of hours. When electric motors were invented, all of this became redundant and the motors were able to turn the optic for as long as there was power to drive them. In December 1964, the original 1890 Chance Bros kerosene-fuelled light and clockwork mechanism were replaced by small electric motor, and the number of keepers reduced to two. The six circular weights and rods originate from the obsolete system and may have been part of a larger set. Wilsons Promontory retains seven of its original set of ten weights, all of which are detached from the tower’s weight tube. Cape Schanck has a set of fourteen weights remaining in situ as well as another four detached weights, which have inscriptions . One weight is displayed in the lantern room at Cape Otway. The Point Hicks weights have first level contributory significance for the insights they provide into the superseded technology and operations of a late nineteenth century lighthouse. They are well provenanced and are significant for their historic value as part of the lightstation’s Chance Brothers optical system installed in 1890.PHLS0005.1 Round cast iron weight with flat base used for lens clock-work mechanism attached to a bent metal rod. PHLS0005.2 Removable round cast iron weight with flat base used for lens clock-work mechanism stored above the other weight. -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionFunctional object - Clock, Post Master General, c 1890

... Wall clock with ceramic face consisting of twelve Roman... of spades with a "P" in the centre. Clock mechanism stamped verso..." in the centre. Clock mechanism stamped verso; 146 / PMG / PMG Wall clock ...When the Commonwealth Post and Telegraph Act was passed in June 1902, and a national Postmaster General's Department (the PMG) was established the responsibility for the nation's mail and telephone services fell on local Post Offices. The Bendigo Post Office, built in 1887 and is situated on Pall Mall, it was the central distribution centre for receiving and delivering communication and postal services until 1997 and is now the Bendigo Visitor Centre. Clocks such as these were issued by the Post Master General's Department which was a department of the Australian federal government, established at Federation in 1901, whose responsibilities included the provision of postal and telegraphic services throughout Australia. It was abolished in December 1975 and replaced by the Postal and Telecommunications Department.Wall clock with ceramic face consisting of twelve Roman numerals with hand and minute hand. Clock has a wooden body with glass viewing panel in centre and brass internal mechanism and pendulum. The clock is fitted into a wooden display case and held in place by wooden pegs. The lower case has a small drawer which opens and holds the winding key. PMG on ceramic face centre upper. '146' and 'PMG' stamped into wooden clock frame below the number six. Key is stamped front; '8' verso; 'Made in England / Popular / Progress' and an ace of spades with a "P" in the centre. Clock mechanism stamped verso; 146 / PMG / PMGcity of greater bendigo post office -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Punch Clock, manual, circa 1880

... panel is a door that accesses the clock mechanism.... the clock mechanism. Functional object Punch Clock, manual Howard ...The large, early, manual, ‘Punch-Clock’, (also known as a Time Clock), used by the Shire of Moorabbin employees to “clock-on and off” each working day circa late 1800s early 1900s.This 'Punch-Clock' was used by employees of the Shire of Moorabbin circa 1880 - 1900 and was donated to the City of Moorabbin Historical Society by the now defunct Moorabbin City Council in 1984.The large manual, ‘Punch-Clock’, (also known as a Time Clock), used by the Shire of Moorabbin employees to “clock-on and off” each working day circa late 1800s early 1900s. The clock face is exposed and the internal mechanism is encased in a wooden cupboard with two glass framed side panels. Right side panel is a door that accesses the clock mechanism.Around Centre of Clock face " DEY TIME REGISTERS LTD"/ "HOWARD BROS./ made in USA/ 75 Queen Victoria St./ LONDON E.C."/ On Brass plate at base are Patent registrations moorabbin, clocks, wages, punch clock -

Numurkah & District Historical Society

Numurkah & District Historical SocietyWall Clock

... Round-faced wooden clock with Roman numerals. Glass front... can be taken off to reveal the clock's mechanism. Also ...Possibly belonged in the original ANZ bank (cnr of Melville & Quinn St)Round-faced wooden clock with Roman numerals. Glass front can open. Back of clock is rectangular wooden box with a curved base. This section can be taken off to reveal the clock's mechanism. Also on the rectangular box are various smaller openings. The opening on the curved based can be used to hang the pendulum which is currently inside the wooden box.Indecipherable pencil writing on the back. Two possible dates: 5/1/07 and 10/5/1920 The word "Numurkah" is distinguishable. On clock face: Jas Murray & Co 107 Bourke St East Melbourneclock, wall clock, anz bank, time -

Federation University Historical Collection

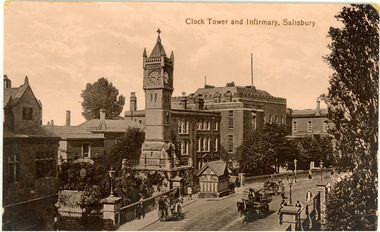

Federation University Historical CollectionPostcard - photographic, Clock Tower and Infirmary, Salisbury

... installed the illuminated clock mechanism with four faces... installed the illuminated clock mechanism with four faces ...The Salisbury Clock Tower was built in memory of Arabella Roberts who died on 23 January 1892. The firm Smith of Derby installed the illuminated clock mechanism with four faces and was still responsible for maintenance when, in December 1970, it replaced the original gravity mechanism with a more modern movement. The original clock mechanism was sold to a customer in Providence, USA. In 1997, the new mechanism was completely refurbished and updated to include automatic adjustment for British Summer Time. At the same time the tower itself was restored, the main contractors for this work being R. Moulding and Co of South Newton. Smith of Derby continues to be responsible for maintaining the clock, and so this firm has now been providing a service to the City for over 100 years. Sepia photographic postcard depicting a bridge and road lined with buildings and a clock tower in Salisbury, Wiltshire, England.salisbury, clock tower, chatham-holmes family collection, carriage, bridge -

Seaworks Maritime Museum

Seaworks Maritime MuseumGODAVARI clock

... clock mechanism in the top left corner. Item is housed in blue... part of the display as well. Copwud clock mechanism in the top ...A clock with a coloured photograph of a frigate GODAVARI and the statue of liberty in the background. A small quartz clock in the upper right corner. Gold writing in the bottom edge stating ‘Presented by The Commanding Officer & Officers.’ There is also a stamp ship crest for the ship GODAVARI next to the writing. There is a wooden stand insert on the secured by two screws. There are two metal holders on the upper part of the display as well. Copwud clock mechanism in the top left corner. Item is housed in blue velvet box with twin clasps.‘Presented by The Commanding Officer V Officers’ The DOGAVARI crest. Lower right corner, verso: PMA0146 On wooden stand holder: PMA0146/1 -

Tennis Australia

Tennis AustraliaClock, Horology, Circa 1900

... Brass vertical clock with pendulum and mechanisms hanging... Park Melbourne melbourne Tennis Brass vertical clock ...Brass vertical clock with pendulum and mechanisms hanging below face. Materials: Brass/Metal compositetennis -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

... Ceramic clock; the mechanism is plated steel and set... Great Ocean Road Shipwreck Coast clock roy wines ceramic ceramic ...It is possible that this may have been a wedding present or gift to Roy Wines and or his family as his name is scratched on the bottom. Roy was married in 1924 in Warrnambool. Roy Arthur Wines was Born in 1897 in Mailors Flat Victoria Australia and Died in 1980 in Ballarat. Roy lived for a number of years in Warrnambool during his married life.A massed produced item that at the time was cheap to buy with no makers mark or date stamp thousands would have been produced using a mould to make the ceramic case in two half's by pouring liquid clay into the mould and then joining the half's together when cured. This item could have been produced in Holland at any number of pottery factories at this time for export in vast quantities.Ceramic clock; the mechanism is plated steel and set in a ceramic case with glass over the face. The ceramic base colour is white with royal blue ceramic colour to the front and sides only. The blue ceramic has been painted over with lime green house paint on the front and sides. An inscription of a handwritten name is on the case and a hard-to-read model or batch number is on the cast base. Handwritten "Roy Wines" Cast number "6072"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, clock, roy wines, ceramic, ceramic clock, horology, time keeper, travel clock, bedside clock, timepiece -

Federation University Historical Collection

Federation University Historical CollectionObject, Synchronome Co. Ltd, Synchronome Frequency Checking Master Clock No. 2191, c1930

... contained electric clock. The main mechanism is of the gravity arm... electric clock mechanism on door (Frequency time clock): >200/250 V... Seconds" Synchronous electric clock mechanism on door (Frequency ...Information from Norman F. Dalton: Ballarat had a reticulated DC supply in the early part of last century and in 1905 had sufficient generating capacity to enable the trams to be changed from horse drawn to DC electricity. The use of electricity increased with the main power station located on Wendouree Parade, near Webster Street, under the ownership of The Electric Supply Company of Victoria. AC generating plant was installed in 1925 and conversion to AC proceeded. In 1934 the company was taken over by the State Electricity Commission Victoria (SECV) and more AC generation was installed and the changeover of customers was accelerated. This is around the time that the Synchronome Frequency Checking Mast Clock was installed at the Wendouree Parade Power Station. The SECV Annual Report of 1921 states: ::Section 11 of the act directed the COmmission to enquire into the question of securing the adoption of such standards of plant and equipment of a system, frequency and pressure for the generation and distribution of electricity as will admit of the efficient interconnection of undertakings throughout the State. In 1934 when the SECV took over the Ballarat operations the question of linking with the State grid had been a planned operation for some years but due to financial considerations had hindered it and in fact would continue to do so for a further 10 years. So while the need for close frequency control for interconnection was hardly an issue, the need to keep electric clocks correct was important, particularly as this item was a frequent sales point to cover the inconvenience and sometimes expense of converting from DC to AC. The clock is a very accurate pendulum clock with provision for varying effective length during operation for precise time regulation. There are two normal time dials and one is controlled by the pendulum and the other is operated by the system frequency. When the clock was in use it was installed by the MEter and Tests Laboratory and the time was checked daily by radio time signals. The two dials were repeated in the operators control panel in the Power Station. A maximum deviation between the two dials was set in the operating instructions (eg 5 seconds) and the operator would correct this when necessary by remote manual alteration of the turbine governor set point. The clock was used to drive and regulate a system of "slave" clocks which were used to display the time in various locations around the power station. A slave clock is a simple clock which is driven by a small electric motor, its accuracy is regulated by the master clock every 30 seconds to ensure that it and all the other slave clocks in the station are on exactly the right time; slave clocks were placed in various locations, from common rooms to workshops. A master clock could potentially run thousands of slave clocks at one plant. The clock also contains a rectifier. A rectifier is a device that is used to convert AC power to more stable DC current.Two clocks in a timber case. Both are electric, one is powered by the main pendulum mechanism, the other is a self contained electric clock. The main mechanism is of the gravity arm and roller type, which sends an impulse to the slave clocks every 30 seconds. The This Synchronome Frequency Checking Master Clock was used at the Ballarat Power Station. Below the main section of the case is a smaller cabinet containing a rectifier to provide consistent DC power for the clock. The rectifier was made by the Victorian company Hilco, which was located in Burwood. There is a high chance this is not the original rectifier from this clock as there appears to be brackets to hold a larger device in the space the rectifier occupies.Front below main clock face on front of case: "Patented Sychronome Brisbane" Lower left-hand clock face: "Frequency time" Lower right-hand clock face: "Standard Seconds" Synchronous electric clock mechanism on door (Frequency time clock): >200/250 V. 50~ >"Synchronomains" Made in England >Direction indicator for clock starting switch >"To start move lever in direction of arrow and release" >"Patent applied for" Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for main clock face: >"English Made" >"Patented" >Serial number "8751" >0 above right-hand pillar on front-plate Inside case, back panel, top enamel plate: >Seconds Battery + Pos. > Battery Common or - Neg. >1/2 min dials Inside case, back panel, bottom enamel plate: external seconds dial Inside case, right hand side, electrical knobs: two switches, both "A.C. mains" Pendulum rod, below suspension spring: Serial number (?) 0000005 Rectifier in bottom cabinet: >"Hilco Rectifier" >"A.C. Volts 230/240" >"Model 1060/S" >"A.C. Amperes" >"Serial No. 1060/S >"Phases 1" >"D.C. Volts 6" >"C.P.S. 50" >"D.C. Amperes 1" >"Made in Australia by Hilco Transformers McIntyre St., Burwood, Victoria." Bakelite electrical plug: makers mark Lower cabinet, RH side panel, pressed tin plate: "AC" (upside down) Brass speed adjustment, outer right RH side: "S" and "F" Ivory and wood pendulum beat ruler: >Ruler, with 0 in centre and numbers 1-5 in ascending order from centre on left and right. > "Synchronome Patent." Steel plate, back panel, inside case, right hand side: >N R A" (descending) >"2191" serial number/part number Face of main clock: "Synchronome Electric" synchronome frequency checking master clock, electricity, state electricity commission, wendouree parade power station, secv, clock, time, pendulum, electric supply company of victoria, norman f. dalton, ballarat power station, rectifier, slave clock -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter Ammeter Recorder, Circa 1950

... is recording the correct voltage and that the clock mechanism... voltage and that the clock mechanism is advancing correctly. Meter ...This testing voltmeter recorder was last certified by SEC Vic laboratories on the 17/4/77. It was used extensively as mobile recorder placed for periods of one month at locations experiencing unacceptable fluctuations of power. These locations would cover the North East regions of Victoria. They cover voltage drops at domestic and business properties especially those that were experiencing regular fluctuations(daily) at approximately the same time of the day. As the electrical network is required to operate within a set level of voltage, fluctuations outside of this has to be investigated and necessary remedial action taken. This is especially so for rural properties where power "drainage" can occur through animal/bird and tree interference. It can also be the result of defective wiring and overloading at peek operational times (milking machines).This mobile voltage recorder is very significant to the Kiewa Valley because it highlights the difficulties that can occur in maintaining a power supply that experiences fluctuating power demands by the rural industries that it supplies. The requirement of a mobile testing apparatus to cover the various sections in the Kiewa Valley and other rural areas in the northeast region is one of necessity as electricity once connected to a rural property is a labour saving supply as generators on rural properties require a higher degree of maintenance an ultimately at a higher cost. The testing of the SEC Vic supplied electricity to rural properties,those who had previously run on generators, had to be quick and unassuming with certainty of correct supply levels.The mechanism of this voltage recorder has been installed(by the manufacturer) into its own protective wooden box. This box has a front (swing open) lockable section which permits direct access to the installed measuring equipment (for servicing and data collection). The top section of the box has two screw on terminals for access to the machine being tested. This tester has its own inbuilt ink supply facilities and a mechanical clockwork device that unwinds a roll of paper onto a second roll at a rate of 10 mm per hour. The recording chart is marked with time slots against voltage. There is a recording arm which has an ink pen at the end. Both arm and pen carry the ink supply from the ink reservoir, located on the left side of the cabinet door in specially constructed bottle holder( three small bottle capacity). To record a suspect power problem to a home or business establishment the voltmeter is connected to a power supply outlet being tested and wind the recording clockwork mechanism (gives a four week running time). Before leaving the recorder in situ the electrician checks to see if the chart is recording the correct voltage and that the clock mechanism is advancing correctly.On the front of the access "door" at the top a metal label "RECORDING AMMETER" below this "MURDAY SYSTEM" below this "ALTERNATING CURRENT" and below this the manufacturer's registered number "No. 139156" Below this is a metal tag with State Electricity Commission of Victoria Electrical Engineer's Section equipment number "338" Below these tags and above the viewing window is the manufacturer's dtails "EVERSHED & VIGNOLES Led LONDON"sec vic kiewa hydro scheme, alternate energy supplies, alpine feasibility studies temperature, rainfall, power outages -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... to New Jersey to make seven-foot cases for clocks mechanisms... cases for clocks mechanisms. In 1816 he went to work for Eli ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... to New Jersey to make seven-foot cases for clocks mechanisms... cases for clocks mechanisms. In 1816 he went to work for Eli ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Dioptric Apparatus, mid 19th century

... cycle similar to an old grandfather clock mechanism. Once... clock mechanism. Once the weight lifted to its apex ...Before the introduction of electricity, lighthouses had a clockwork mechanism that caused the lens to rotate with a light source inside that was either powered by Kerosene or Colza oil. The mechanism consisted of a large weight attached by a cable through the centre of the lighthouse to the top where the cable wrapped around a barrel, drum or wheels that controlled the speed of the lights rotation by a clockwork mechanism. The keeper would crank the clockwork mechanism, which would lift the weight ready for the next cycle similar to an old grandfather clock mechanism. Once the weight lifted to its apex at the bottom of the first landing, the keeper would let it fall, which would pull on the cable, which would, in turn, operate a series of gears activating the rotation of the Fresnel optical lens, which would then rotate to create the lighthouse’s unique light speed of rotation characteristic. Creating a specific characteristic required a way to regulate the speed of the rotation, and was important as sailors could identify a particular light by its speed and time between flashes. The weight had to fall at a certain rate to create the proper rotation speed of the lens and a regulator within the mechanism accomplished this. History: From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world. James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by Fresnel lenses to increase the available light output these cages, are known as optics and they revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution the light flashes. The noted English physicist and engineer, John Hopkins invented this system while employed at Chance Brothers. Chance Brothers and Company was a glass works and originally based in Spon Lane, Smethwick, West Midlands England. The company became a leading glass manufacturer and a pioneer of British glass making technology. The Chance family originated in Bromsgrove as farmers and craftsmen before setting up a business in Smethwick near Birmingham in 1824. They took advantage of the skilled workers, canals and many other industrial advances taking place in the West Midlands at the time. Robert Lucas Chance (1782–1865), known as 'Lucas', bought the British Crown Glass Company's works in Spon Lane in 1824. The company specialised in making crown window glass, the company ran into difficulty and its survival was guaranteed in 1832 by investment from Chance's brother, William (1788 – 1856). William owned an iron factoring business in Great Charles Street, Birmingham. After a previous partnership that Lucas had dissolved in 1836, Lucas and William Chance became partners in the business which was renamed, Chance Brothers and Company. Chance Brothers invented many innovative processes and became known as the greatest glass manufacturer in Britain. In 1848 under the supervision of Georges Bontemps, a French glass maker from Choosy-le-Roi, a new plant was set up to manufacture crown and flint glass for lighthouse optics, telescopes and cameras. Bontemps agreed to share his processes that up to then had been secret with the Chance Brothers and stayed in England to collaborate with them for six years. In 1900 a baronetcy was created for James Timmins Chance (1814–1902), a grandson of William Chance, who had started the family business in 1771 with his brother Robert. Roberts grandson, James became head of Chance Brothers until his retirement in 1889 when the company became a public company and its name changed to Chance Brothers & Co. Ltd. Additional information: Lighthouses are equipped with unique light characteristic or flashing pattern that sailors can use to identify specific lighthouses during the night. Lighthouses can achieve distinctive light characteristics in a few different ways. A lighthouse can flash, which is when brief periods of light interrupt longer moments of darkness. The light can occult, which is when brief periods of darkness interrupt longer moments of light. The light can be fixed, which is when the light never goes dark. A lighthouse can use a combination of flashing, oscillating, or being fixed in a variety of combinations and intervals to create individual light characteristics. It is a common misconception that a lighthouse's light source changes the intensity to create a light characteristic. The light source remains constant and the rotating Fresnel lens creates the various changes in appearance. Some Fresnel lenses have "bulls-eye" panels create beams of light that, when rotated between the light and the observer, make the light appear to flash. Conversely, some lenses have metal panels that, when rotated between the light and the observer, make the light appear to go dark. This Dioptric clockwork apparatus used to turn a lighthouse optical lens is very significant as it is integral to a lighthouses operation, we can also look at the social aspect of lighthouses as being traditionally rich with symbolism and conceptual meanings. Lighthouses illustrate social concepts such as danger, risk, adversity, challenge and vigilance but they also offers guidance, salvation and safety. The glowing lamp reminds sailors that security and home are well within reach, they also symbolize the way forward and help in navigating our way through rough waters not just on the oceans of the world but in our personal lives be it financial, personal, business or spiritual in nature. Nothing else speaks of safety and security in the face of adversity and challenge quite the way a lighthouse does. Revolving dioptric clockwork apparatus used to turn a Fresnel optical lighthouse lens. A cylindrical cast metal pillar and cabinet painted green with 3 glass doors enclosing the top section. Inside the pillar/cabinet is a large clockwork mechanism used to turn and regulate a lighthouse light by means of weights and a chain attached to same. One door has the name "Adams Mare" in metallic dots similar to "Braille" to the inside edge of door frame.shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff hill, maritime-museum, shipwreck-coast, warrnambool, flagstaff-hill-maritime-village, revolving dioptric mechanism, dioptric mechanism for lighthouse, lighthouse clockwork timing mechanism, acetylene lighthouse light mechanism, 19th century lighthouse mechanism, kerosene light, fresnel lenses, colza oil, chance brothers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, c. 1860s

... This 1864 hall clock originates from the Warrnambool Post...” embossed on the back of the fusee mechanism behind the clock. ... on the back of the fusee mechanism behind the clock. This 1864 hall ...The clock was either made or sold by T. Gaunt & Co. of Melbourne, a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888. Thomas Gaunt History: Thomas Gaunt established Melbourne's leading watchmaking, optical and jewellery business during the second half of the 19th century. Gaunt arrived in Melbourne in 1852, and by 1858 had established his own business at 14 Little Bourke Street. Around 1869 he moved to new premises in Bourke Street on the corner of Royal Arcade, Gaunt's shop quickly became a Melbourne institution. Gaunt proudly advertised that he was 'The only watch manufacturer in the Australian colonies'. While many watches and clocks may have had Gaunt's name on the dial, few would have been made locally. Gaunt did make some watches for exhibitions, and perhaps a few expensive watches for wealthy individuals. Gaunt's received a telegraph signal from Melbourne Observatory each day to correct his main clock and used this signal to rate and repair ship's chronometers and good quality watches. His main horological manufacturing was directed at turret clocks for town halls, churches and post offices. These tended to be specific commissions requiring individualised design and construction. He made the clock for the Melbourne Post Office lobby, to a design by Government Astronomer Robert Ellery, and won an award at the 1880-81 Melbourne International Exhibition for his turret clock for the Emerald Hill Town Hall. He became well known for his installation of a chronograph at Flemington Racecourse in 1876, which showed the time for the race, accurate to a quarter of a second. The firm also installed the clockwork and figures for Gog and Magog in the Royal Arcade. Thomas Gaunt also developed a department that focused on scientific instrumentation, making thermometers and barometers (from imported glass tubes), telescopes, surveying instruments and microscopes. Another department specialised in electroplating for trophies, awards and silverware, and the firm manufactured large amounts of ecclesiastical gold ware and silverware, for the church including St Patrick's Cathedral. There are no records that disclose the number of employees in the firm, but it was large enough for Gaunt to hold an annual picnic for the watchmakers and apprentices at Mordialloc from 1876; two years previously they had successfully lobbied Gaunt to win the eight hour day. Gaunt's workforce was reportedly very stable, with many workers remaining in the business for 15 to 30 years. Gaunt's wife Jane died on September 1894, aged 64. They had one son and six daughters, but only three daughters survived to adulthood. Two became nuns at the Abbotsford Convent and one daughter, Cecelia Mary Gaunt (died 28 July 1941), married William Stanislaus Spillane on 22 September 1886 and had a large family. Gaunt died at his home in Coburg, Victoria, leaving an estate valued at ₤41,453. The business continued as T. Gaunt & Co. after his death. Post Office and Clock History: Warrnambool’s Post Office has been in existence since 1857, when it was originally situated on the corner of Timor and Gilles Street. In March 1864 the Warrnambool Borough Council purchased this clock from Henry Walsh Jnr. for the sum of £25, “to be put up in front of the Post Office”. Henry Walsh Jnr was the eldest son of Melbourne’s Henry Walsh, maker and retailer of clocks, watches, thermometers and jewellery. In 1854 Henry Walsh Jnr. began business in Warrnambool as a watchmaker and jeweller later becoming a Councillor with now a local street named after him. The Post Office was extensively remodelled in 1875-76. Early photographs of this building show that the clock was installed on the northern outside wall, Timor Street, under the arches and between the 2 centre windows, where it could be seen by passers-by. Although spring loaded clocks date back to the 15th century, and fob and pocket watches evolving from these date to the 17th century, personal pocket watches were only affordable to the very fortunate. Public clocks such as this Post Office clock provided opportunity for all to know the time, and for those in possession of a personal watch to check and set their own timepieces to the correct time. During post office reservations during the 1970s the clock was removed and was eventually donated to the Flagstaff Collection. The Clock’s maker Thomas Gaunt, is historically significant and was an established and well renowned scientific instrument and clock maker in Melbourne during the 1860s. He was at that time the only watchmaker in the Australian colonies. In the 1870’s and 1880’s he won many awards for his clocks and was responsible for sending time signals to other clocks in the city and rural areas, enabling many businesses and organisations to accurate set their clocks each day. Warrnambool Borough Council purchased this clock from Henry Walsh Jnr. for the sum of £25 and the clock used to stand in front of the Warrnambool post office to allow ordinary citizens to set their time pieces as they walked by. The item is not only important because it was made by a significant early colonial clock maker and retailed by a locally known clock maker and jeweler but also that it was installed in the Warrnambool Post Office a significantly historical building in it's own right. Built in 1857 and regarded as one of the oldest postal facilities in Australia, with a listing on the National Heritage Database, (ID 15656). This 1864 hall clock originates from the Warrnambool Post Office. The clock glass is hinged to the top of the clock face and has a catch at the bottom. The metal rim of the glass is painted black. The clock face is metal, painted white, with black Roman numerals and markings for minutes and five minutes. The tip of the small hour hand is shaped like a leaf. "T. GAUNT / MELBOURNE" is printed in black on the clock face. The winding key hole is just below the centre of the clock face. The key winds a fusee chain mechanism, attached to the brass mainspring barrel that powers the pendulum with an 8-day movement. The speed of the clock can be adjusted by changing the position of the weight on the pendulum, lengthening or shortening the swing; raising the pendulum shortens its swing and speeds up the clock. The metal fusee mechanism has an inscription on it. The rectangular wooden casing is with a convex curve at the bottom that has a hinged door with a swivel latch. The original stained surface has been painted over with a matte black. There are two other doors that also allow access to the clock’s workings. The case fits over the pendulum and workings at the rear and attaches to the clock by inserting four wooden pegs into holes in the sides of the case then into the back of the clock. A flat metal plate has been secured by five screws onto the top of the case and a hole has been cut into it for the purpose of hanging up the clock. There is a nail inside the case, possibly used for a place to the key."T. GAUNT MELBOURNE" is printed on the clock face. “6 1 3” embossed on the back of the fusee mechanism behind the clock. warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, shipwrecked artefact, clock, warrnambool post office, fusee, henry walsh jnr, thomas gaunt, t gaunt & co, post office clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock

... . It was spring powered by winding the key mechanism with the clock's key... Warrnambool great-ocean-road This wall clock originated from the Bank ...This wall clock originated from the Bank of Australasia. The label on the base matches other items from the same donor. It was spring powered by winding the key mechanism with the clock's key through the hole in the clock face. The hinged door on the base of the clock's case allows access to the clock's working mechanism. James Murray (son of James Murray 1780-1847) was a maker of clocks and chronometers. He worked at No. 1, Royal Exchange, London and from 1861 at 107 Great Bourke Street, Melbourne. In 1854 William Kerr ordered a clock from James Murray and erected it on the Albert Street frontage of the National Model & Training School in Spring Street Melbourne. It was Melbourne's first turret clock and remained there for 80 years before it was transferred to the Public Library in Melbourne in 1934 (now Museum Victoria). The Bank of Australasia was incorporated by Royal Charter of England in March 1834. It had its Australian beginning on 14th December 1835, opening in Sydney. The Acting Superintendent of the bank at that time was David Charters McArthur. He was Superintendent from 1867-to 1876. The Melbourne branch opened on 28th August 1838 in a two-roomed brick cottage on the north side of Little Collins Street, where two huge mastiff dogs were used at night to guard the bank. The government also provided an armed military sentinel. Due to the bank's rapid growth, a new building for the Melbourne branch was opened in 1840 at 75 Collins Street West. By 1879 the bank had been upgraded to a magnificent two-storey building on the corners of Collins and Queens Streets, with the entry on Collins Street. In 1951 the Bank of Australasia amalgamated with the Union Bank to form the Australia and New Zealand Bank, now known as the ANZ. Then in 1970, the ANZ merged with both the ES&A and the London Bank of Australia to form the ANZ Banking Group Limited. The ANZ Banking Group Ltd kindly donated a variety of historic items from the Bank of Australasia. BANK of AUSTRALASIA, WARRNAMBOOL – In 1854 Warrnambool had two banks, the Union Bank and the Bank of Australasia. Later, completely different bank businesses opened; in 1867 the National Bank of Australasia, then in 1875 the Colonial Bank of Australasia. The original Warrnambool branch of the Bank of Australasia was established in July 1854, and operated from a leased cottage on Merri Street, close to Liebig Street. The bank next bought a stone building previously erected by drapers Cramond & Dickson on the corner of Timor and Gibson Streets. Samuel Hannaford was a teller and then Manager at the Warrnambool branch from 1855 to 1856 and the Warrnambool Council chose that bank for its dealings during 1856-57. In 1859 Roberts & Co. was awarded the contract to build the new Bank of Australasia branch for the sum of £3,000. The land was on a sand hill on the northeast corner of Timor and Kepler Streets and had been bought in 1855 from investor James Cust. The new building opened on May 21, 1860. The bank continued to operate there until 1951 when it merged with the Union Bank to form the ANZ Bank, which continued operating from its Liebig Street building. Warrnambool City Council purchased the former Bank of Australasia building in 1971 and renovated it, then on 3rd December 1973 it was officially opened as the Art Gallery by Cr. Harold Stephenson and Gallery Director John Welsh. The Gallery transferred to the purpose-built building in Liebig Street in 1986 and the old bank building is now the Gallery club. Staff at the Bank of Australasia in Warrnambool included the following men but others were also involved: Samuel Hannaford, Teller then Manager from 1855-1856; W H Palmer, Manager from January 1857 until November 1869 when the Teller Basil Spence was promoted to Manager; H B Chomley, Manager from April 1873 and still there in 1886; A Butt, Manager in 1895-1904; J R McCleary Accountant and Acting Manager for 12 months, until 1900; A Kirk, Manager 1904; J Moore, staff until his transfer to Bendigo in December 1908; J S Bath was Manager until 1915; C C Cox, Manager until April 1923; Richard C Stanley, Manager 1923 to April 1928. The clock has significance through its association with the Bank of Australasia. The early Australian bank was established in 1834 by Royal Charter and opened in Sydney, Australia, in Sydney in 1835. The bank had many Australian offices in November 1877, particularly on the east and south coasts. Victoria had 45 percent of all Offices. The clock is significant for its connection with the quality clockmaker James Murray, originally from Royal Exchange London with a branch that opened in Melbourne in 1861. James Murray is renown for making the first turret clock to be installed in Melbourne. The clock is locally significant for its association with the Warrnambool Bank of Australasia, which was established in 1854. It was Warrnambool Council’s first bank. The bank continued to operate until the organisation's merger in 1951 when it became the ANZ Bank Group today. The Bank was an integral part of the growth of local commerce and the community.Wall clock with a round face behind glass in a wooden case. The painted brass face has Roman numerals, two decorative hands, divisions for minutes and a keyhole. The curved base of the case has a hinged access door with a keyhole and adhesive label. The back of the clock's case has metal mounting brackets. Inscriptions on the rectangular white label. Made by James Murray, Melbourne.Face: "JAMES MURRAY / - GT. BOURKE ST. / MELBOURNE / & / ROYAL EXCHANGE / LONEON" Label: "A M / 40"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bank of australasia, boa, union bank, australia & new zealand bank, anz bank, james murray, clock, wall clock, great bourke street melbourne, royal exchange london, william kerr, turret clock, old model school, national model & training school, access door, winding key -

The Beechworth Burke Museum

The Beechworth Burke MuseumFunctional object - Watch, Unknown

Wristwatches became popular after World War 1, where they were used to ensure soldiers could undertake operation at the same time over a last distance. In the 1920s the automatic watch was invented by John Harwood and the mass production of wristwatches began, allowing all members of society the ability to keep track of time.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.Small silver watch, with black and white number face, with the exception of a red ink 12. The watch has a small gold hand mechanism turner on the right side and a small silver spike sitting on the bottom of the watch.Clock is currently set on five past one. watch, horology, early 20th century -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

... in Prague. This type of clock mechanism was replaced as watchmakers ...In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Bendigo Military Museum

Bendigo Military MuseumDomestic object - CLOCK, MANTLE PIECE, Gilbert Clock Co. U.S.A, possible 1918 - 1921

This clock was originally in the front Office of the Soldiers Memorial Institute Bendigo on the mantlepiece of the fireplace. Original donor or date of being placed is unknown. It was last used in 2005 by Jack Barnes OAM who wound it every day he was in the Office, he was Secretary for 43 years of the BRSL. After the renovations to the SMI in 2016 - 18 it was placed on the mantlepiece of the fireplace in what is now called "The Building and RSL History Room"Mantle Piece Clock, timber frame, hinged glass cover over the face is missing, numbers are 1 - 12 on clock face, rear door to the mechanism, a pendulum weight is taped to the inside, no wind up key.On Clock face, "Gilbert". Around clock face, "Made in Winsted Conn United States of America"brsl, smirsl, mantle -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Clock, Mantle Clock, Early 20th century

This is a mantel clock used probably in the dining room or lounge room of a house. It would have been a common item in a household in the 20th century and was often an heirloom passed down from grandparents. This type of clock is an attractive item and is still regarded as highly desirable today.This clock has no known local significance but is retained as an attractive and historical item and serves as an example of a high quality household object of the past. This is a black wooden clock with a rectangular base with ornamental metal corner pieces and two ornamental gilt metal patterns. The clock has an overhanging rectangular top with two gilt handles on the side. Also on the sides of the lock are two green inset faux columns with two metal ornaments in between. The brass mechanism at the back of the clock has four wheels. The clock face has a glass front, black numbers and metal hands. There is a strip of brass around the outside of the face. There are two key holes on the face. 'Sessions'warrnambool, mantel clock -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales, Imperial, Spring, 'Salter Household Scale’ 28lb, c1920

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged.Salter Brand No. 46 Household Spring Balance Kitchen Scales made of green painted metal with a white large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing. HOUSEHOLD SCALE / NO. 46 / SALTER / TO WEIGH 28 LB / ( rope & arrow TM) BRITISH MADE Base rope & anchor S (trade mark) weights, measures, shops, scales. balances, grocery stores, early settlers, moorabbin, bentleigh, cheltenham, salter housewares pty ltd, west bromwich, england, salter george, salter richard, bilston england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales,Spring Balnce Imperial ‘Household’ Salter, 20thC