Showing 11 items matching "combs and cutters"

-

National Wool Museum

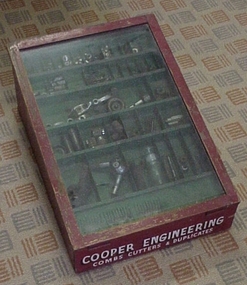

National Wool MuseumDisplay Case

Cooper shearing parts display case and contents purchased by donor at auction of the WH Lyons Collection at Echuca in 1994.Cooper shearing parts display case and contents.Cooper Engineering Combs Cutters and Duplicatesshearing machinery, cooper engineering company pty ltd, shannahan, mr peter, echuca, victoria -

National Wool Museum

National Wool MuseumDisplay Board

Shearing combs and cutters, mounted on white paper on cream painted masonite board. Information about manufacture and use of "Combs and Cutters" List of combs and description List of combs including descriptionshearing -

Clunes Museum

Clunes MuseumEquipment - SHEARING HAND PIECES

.1 Hand piece complete with one comb cutter and leather covered hand piece grip. (thin top comb missing from bracket). Also has rubber guard tied on with leather thong. .2 One shearing hand piece without comb cutter metal. shearing, sheep, mechanical -

National Wool Museum

National Wool MuseumShearing Handpiece

Lister shearing handpiece with comb and cutter. (Note on comb/cutter - "Although the handpiece appears to have been presented complete with comb and cutter I think the tools are modern (Tom Crocker 3/11/93)".) Early version of the Lister S Hardened, No. 31. Hand piece contains genuine parts.LISTER / S/ HARDENED/31537shearing, sheep stations management, animal health, sheep stations - management -

National Wool Museum

National Wool MuseumShearing cutter

19 shearing cutters inscribed "HEINIGER XP4S", 2 shearing combs inscribed "LISTER XLII' and 1 shearing comb marked "SUNBEAM Gem""HEINIGER XP4S" "LISTER XLII' SUNBEAM Gemshearing, cutter, sunbeam -

Dunkeld Museum Inc.

Dunkeld Museum Inc.Shearers Oil Can, Untitled, Shearer's Oil can, 1920's

Small copper oil can used in the shearing industry to oil combs and cutters.This item is made of copper as opposed to regular ones which were manufactured from tin plate.Copper cone shaped oil can. Soldered metal base. Brass screw top with pourer attachedNoneshearing, oil can, combs and cutters -

National Wool Museum

National Wool MuseumShearing cutter

Shearing machine cutter inscribed "Sunbeam ARROW".Sunbeam ARROW Although the L/H/pce appears to have been presented complete/with combs and cutter/ I feel the tools are modern/ TC.3/11/93shearing animal health sheep stations - management, shearing, animal health, sheep stations - management -

National Wool Museum

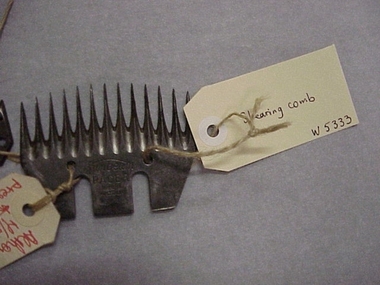

National Wool MuseumShearing comb

Shearing machine comb inscribed "Sunbeam PACER".Sunbeam PACER/ MADE IN AUSTRALIA Although the L/H/pce appears to have been presented complete/with combs and cutter/ I feel the tools are modern/ TC.3/11/93shearing animal health sheep stations - management, shearing, animal health, sheep stations - management -

Mont De Lancey

Mont De LanceyFunctional object - Horse Clippers, A. Martin & Co, Unknown

Used in the 20h century.A pair of vintage hand horse clippers with two steel blades, a lower blade or comb and a moving blade or cutter that work together to cut the hair. It attached with screws to two steel handles with wooden grips attached by brass fitments.Imprinted on the metal joining the blades - 'A. Martin & Co. Manufacturers'horse accessories, horses, horse clippers -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

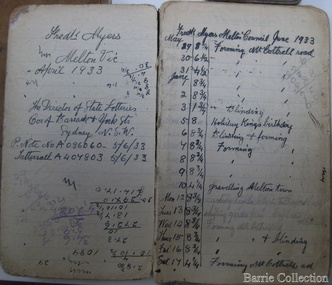

Melton City Libraries

Melton City LibrariesBook, Frederick Myers work notebooks/diaries, 1923-1933

FREDERICK THOMAS MYERS Born 20th February 1877 at Melton Married Martha Mary Watson 30th April 1908 at the Manse 101 Gore Street Fitzroy according to the rites of the church (Cong) – Congregational. Died Bacchus Marsh and District War Memorial Hospital 30th April 1963 Frederick lived in Melton all his life. Work Notebooks/ diary 1901 – 1905 No 1 1901 Shearing Tally Rockbank, 1901, 1902. Lists 3 Combs 6.0, 12 Cutters 5.0, Tab 1.6 Jongebloed account – Tobacco, matches sardines. Shearing shed 1904 Tuppal 20 Aug. Daily Tally of sheep shorn Total 1730 E C Shopping list - 6 pages of household items, Leader, Age and Weekly Times Tomato Sauce- recipe written in ink Toolern Road Hours worked 35 ½ Reverse order from back cover – Harwood 29th Aug 1902 Shearing Tally 1083 November 1902 - List of dates Mon- Sat. Nov 3rd - Fri Dec 5th E Chalmer. Tally of hours worked. Jan 1903 Thur 1st - 31st Toohey Keilor Road, Feb – March 14th Payment L75:4:9 J Walker April 1903 – 23rd 18 Cutters 7:6 5 Combs 10:0 2 Tab 3:0 Ticket 15:0 Total 1:15:6 Tucker 3:12:6 Other pages are calculations related to hours worked and amounts The notebook contains 26 pages with some blank and other torn out. It measures 2 ½ x 4 inches with a hard black cover. FREDERICK MYERS Workbook/ Diary No 2 Opening 5 pages – Gottfried Jongebloed account - paid 2/11/04 List of grocery and household items. E Chalmer -Pr Boots, 8:9 Tab 1:8 Leader 3’ Reverse order Eynesbury 7th Oct 1904 Shearing Tally 1635 Tucker payment L1:18:6 Tuppal 20th Aug 1904 Tally 1636 [ 4 weeks and 4 days] Feb 1905 Melton 1st – 13, Toolern Rd 14th , April Braybrook Rd. Melton town, G Hobbs Boundary Rd, Melton May G Hobbs 2 pages of food expenses and amount paid Simpson & Co – Butcher account and amount paid Mon 5th –July 22nd Toohey days and hour worked 34 yards Tuppal 20th Aug additional list 1735 Eynesbury 3rd Oct additional list 2093 Diagram 3 drawings in ink –a type of tool Nov 21 1904 List Dunmore Stn Orford Vic Barwidgee Stn Caramut Vic Wharparanna Stn via Tocumural N.S.W. Puckawidgee vis Aug Deniliquin N.S.W. Bundure Stn via Aug Jerilderie Trawalla Ballarat Oct Woorywooryte Oct Vic Yancannia Bourke July Pretty Tower Stn Beaufort November Size of Notebook 2 ¼ x 5 inches. WORK NOTEBOOK 1909, 1910 Wandook 17th Aug 1909. 21 days of shearing 1248 Total. Payment L14 ?? Boomanoomana 23 Sept 1909. 17 days shearing 1124 Total. L13.12.9 Eynesbury 20th Oct 1909. 17 days shearing 1587 Total L17. 13.0 Cobran Aug 13 1910 Studs Rams Total 3397 List of expenses includes 12 cutters, 3 combs, Union ticket, matches, tobacco stamps. Miller, J Egan. Eynesbury Oct 1910 Total 1467 Lal Lal Nov 21 Total 1172 For Backache Tincture of Gentian Compound one ounce Syrup of Rhubarb one ounce Liquid Barkola Compound one ounce Syrup of Ginger five ounce Dose a teaspoonful after each meal and one at bedtime John Collins, Woodside Via Yarram Yarram Mr Fisken Lal Lal Via Yendon Woodlawn Deniliquin 15th October Oct 12th 1911 Eucla Jarrett Barfold 21,000 7? Shearers Clark Moir Estate 10th Aug 1910-1911 Income amounts Shearing income. Mc Donald – thrasher Keating Toohey Cobran 1911 Studs and Rams 1793 Cobran 14th Aug per man 1500 Golf Hill 26th Sept per man 1900 Cobran 14th Aug Cut out 23rd Sept 2368 payment L21..19..4 [after expenses] Spring Plains Oct 2nd 1022 Total Barfold 2636 Total Chaffcutting J.B. Loft Feb 17th - 31 ½ hours John Minns Toohey Started Deep Creek Whelahan Ballarat Rd May 25th Mr J Walker Koohnamu Stn via Junta S.A. N Aitken Bringlibit via Kyneton Income list 1911 to 1912 and amounts earned Cobran L29..0..9 , Spring Plains Barfold L42..6..3, John Minns L4..8..0, J.B. Loft L3..0..6, D Whelahan L22.. 6..0, E Toohey L15.. 1..0, = total L123..2..6 John Minns 12..0, JB Loft 4.. D Whelahan L10..2..0, Barrie L11..5. Total Amount L145..5..6. Cobran 1912 15th Aug 1922 total Rams double. Expenses include 12 + 6 Cutters, 2+2+2 Combs, Political fund, Ticket, Mess Account, Hut Keeper, Hospital, Cook Total L11..8..3. Station Rd - L11..2..9. Golf Hill Sept 26 Cut out 31 Oct Total 2332 Lal Lal Nov 6th 19th 1912 6 days Total 1066 Contracts – Cameron, Barrie, McKay, Toohey, Stn Rd ? Cobran 1913 – Aug 14- 1913 Total 1621 Cobran 1621 Kyneton Park 515 Golf Hill 2144 Lal Lal 1066 Total 5,346 1913 – 1914 Income 5, 350 sheep Local contracts E. Barrie, Greig, Weir, S Barrie, Jongebloed, Burton, E Toohey, Total L133..3..0. Trench & Moran L19..8..0. End of front section of Notebook Work notebooks belonging to Frederick Myers local identities