Showing 51 items matching "dairy processors"

-

Cheese World Museum

Cheese World MuseumBook, Spectrum Print Solutions, Pioneering Dairy Families, May 2013

... dairy processors... with Victoria's oldest dairy processing manufacturer. The company ...Book developed from the Heritage Week 2011 display featuring some pioneering farming families connected with Warrnambool Cheese and Butter Factory Ltd. The book was printed and launched at the 125th Anniversary celebrations of the factory in May 2013. Families featured are Anderson, Burke, Burleigh, Chislett, Kelly, Logan, Mahony, McConnell, Rea, Taylor, Uebergang.Records the contribution of early dairy farming families connected with Victoria's oldest dairy processing manufacturer. The company was established in May 1888 and commenced commercial processing in November 1888. The company remained as an independent processor until early 2014.White cloth bound book with chrome screw binding, green and cream Warrnambool Cheese and Butter Factory Company logo and title in green print; 12 laminated pages, full colour. Book printer details on sticker on inside back cover.Spectrum Print Solutions/for all your printing needs/Shop2,377 Raglan Pde, Warrnambool/Ph 03 5561 5233 www.spectrum-oz.comdairying, dairy processors, milk, butter, cheese, families, anderson, burke, burleigh, kelly, logan, mahony, mcconnell, rea, taylor, uebergang, warrnambool cheese and butter factory company, wcb, anniversary celebrations -

Cheese World Museum

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

... dairy processors... and Butter Factory Company Ltd Kraft Foods Ltd dairy industry dairy ...Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Cheese World Museum

Cheese World MuseumCentrifuge, manual, c1890

... dairy processors... industry dairy processors Babcock test OFFICIAL BABCOCK TESTER Four ...The Uebergang family came from Silesia to Australia in 1848 and were early settlers in the Allansford area. The sons and other descendants also purchased farms in the area. The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992 after which the property was sold. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. The collection of items from their property was put into store for a number of years before being given into the care of the Cheese World Museum. The family often re-used, recycled and repaired items and examples can be seen in the museum. This Babcock tester is part of the collection of items given into the care of the Cheese World Museum. The Babcock tester was used to determine the butter fat content in milk. Prior to the use of the Babcock test farmers were paid on volume and milk was sometimes watered down to increase the supply to the factory. Once the Babcock test was introduced it provided a consistent means of paying farmers for milk supplied to the factory. The Babcock tester is significant as a scientific means of testing fat content of milk and the subsequent consistent payment mechanism to farmers. This test also provided a means for farmers to identify poor performing cows and upgrade the quality of their herd and subsequent milk supply to the factory.Four tipping metal testing tubes which revolve on a brass base. A winding handle has a wooden grip. The base and arms holding the metal tubes is painted red.OFFICIAL BABCOCK TESTERallansford, dairy farming, dairy industry, dairy processors, babcock test -

Cheese World Museum

Cheese World MuseumBook, laboratory notes

... dairy processors... into the dairy processing industry at this period. allansford dairy ...Kraft Walker commenced cheese processing at Allansford in 1935 under a lease arrangement with Warrnambool Cheese and Butter Factory. This arrangement remained in place until Kraft officially ceased bulk cheese production at Allansford in February 1993. Kraft was responsible for farm collection of milk which was then shared between the two companies -Kraft for bulk cheese manufacture and Warrnambool Cheese and Butter Factory for whole milk, milk powder and butter manufacture. Laboratory technicians tested milk and cheese during the receival and manufacturing processes to ensure a high quality product. Derek Shaw, whose notebook this is, was the first person in charge of the Kraft Allansford laboratory. He kept notes of testing undertaken and recorded results of anything considered unusual. This notebook is one in a series of 33. Les O'Callaghan commenced work in the laboratory as Derek Shaw's assistant and technician in charge following Derek's retirement. He too kept notebooks of test results.Kraft laboratory technician/bio-chemist Les O'Callaghan was responsible for the introduction of a number of quality control measures which are still in use in the dairy industry today. Les was mentored by Derek Shaw. This note book provides an insight into the dairy processing industry at this period.Black exercise book with lined pages; white sticker on front cover showing dates usedLH/ 17/11/1938 / 2/5/1939allansford, dairy industry, dairy processors, cheese making, kraft foods ltd, warrnambool cheese and butter factory company -

Cheese World Museum

Cheese World MuseumDVD, Dairy farming

... dairy processors... cheese factory cows dairy industry dairy processors Dairy Farming ...This tells the story of the dairy industry in south west Victoria through interviews with local farmers and workers at the Heywood cheese factory. Garry Kerr has produced a series of local history stories, initially for the Heywood [history group] and more recent items privatelyFull colour DVD cover with photographs of house cows with a rotary diary, Heywood cheese factory and cows walking along in a paddock.Dairy Farming A Hundred Years of Change/Produced by Garry Kerrallansford, kerr, garry, heywood cheese factory, cows, dairy industry, dairy processors -

The Beechworth Burke Museum

The Beechworth Burke MuseumAudio - Oral History, Jennifer Williams, Mr Alfred Spencer, 17th February 2000

Alfred 'Alf' Spencer grew up on a dairy farm run by his mother, west south west of Beechworth 'down Robertson Road', and was very well connected to the wider Beechworth area. In this oral history, he recalls his time driving the milk cart around Beechworth as well as the time he spent buying lollies and seeing the pictures. He talks extensively about working as a butcher at his brother's store, including how the butchers interacted with the rest of the town and the staff, as well as his time constructing roads and the pipe network of Beechworth. He discusses the dynamics of other workplaces around Beechworth, describing issues with how the local tannery treated its workers as well as how post-war migrants integrated across the town. He briefly discusses racial tensions between Chinese migrants and other miners on the goldfields. He also discusses the experience of health care in a rural area during his childhood. This oral history recording was part of a project conducted by Jennifer Williams in the year 2000 to capture the everyday life and struggles in Beechworth during the twentieth century. This project involved recording seventy oral histories on cassette tapes of local Beechworth residents which were then published in a book titled: Listen to what they say: voices of twentieth century Beechworth. These cassette tapes were digitised in July 2021 with funds made available by the Friends of the Burke.Alfred Spencer's oral history of his life around Beechworth during the 20th century is historically and socially significant to the cultural history of the region and Victoria. There is a lot of detail about workplaces, their staff, and how the resources of the town interacted. He explores themes that are important to Victorian history, such as migration. This oral history account is socially and historically significant as it is a part of a broader collection of interviews conducted by Jennifer Williams which were published in the book 'Listen to what they say: voices of twentieth-century Beechworth.' While the township of Beechworth is known for its history as a gold rush town, these accounts provide a unique insight into the day-to-day life of the town's residents during the 20th century, many of which will have now been lost if they had not been preserved.This is a digital copy of a recording that was originally captured on a cassette tape. The cassette tape is black with a horizontal white strip and is currently stored in a clear flat plastic rectangular container. It holds up to 40 minutes of recordings on each side.Mr Alfred Spencer /listen to what they say, beechworth, oral history, burke museum, spencer, alfred spencer, migration, post-war migration, goldfields, health care, farm, farming, dairy farm, black springs, butchers, meat processing, butcher, road, road network, labour relations -

Orbost & District Historical Society

Orbost & District Historical Societybutter pat

This butter pat is typical of the period when food processing was done at home. It would have been before the time of mass food processing factories.A hand-made wooden butter pat.butter-pat hand-made dairy butter -

Orbost & District Historical Society

Orbost & District Historical Societycream separator, 1920s - 1950s

This item would have been very common on farms throughout the Orbost area. Prior to bulk milk, cream was the major commodity which was sold to the butter factory. This is a small separator, typical of home use. This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesHand operated rusted metal cream separator with metal and wood handle.Front - A.O Handle-75.T.PR.MIN Back- (RHS) A.O. (LHS) Co-op in outline of Australia.cream-separator domestic-food-preparation dairy-farming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Milk Churn, Malleys Ltd, 1870-1932

Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. An early item made by an Australian manufacturer of dairy equipment in Australia specifically for the local market. The item gives an insight into early Australian manufacturing processes and is a significant part of Australian early social history.Milk Churn or Milk Can, Medium sized galvanised container to hold milk Malleysflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk container, malleys ltd, dairy equipment -

Warrnambool and District Historical Society Inc.

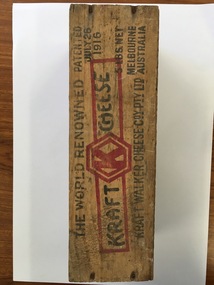

Warrnambool and District Historical Society Inc.Container - Kraft cheese box used for storing bulbs, Mid 20th century

This is a box for packaging Kraft Cheese in Victoria. A Melbourne man, Fred Walker, negotiated with the American company the Kraft processing of cheese and established the Kraft Walker Cheese Company in 1934 and leased the Warrnambool Cheese and Butter Factory premises in Allansford in 1935. Until 1993 this factory produced Cheddar Cheese, Swiss Cheese, Cracker Barrel and Tasty Cheddar Cheese and other varieties and won many Australian awards. A microbiological laboratory was established and from 1939 Ls O’Callaghan, a noted Warrnambool historian, worked in this laboratory, establishing the basis of the dairy industry guidelines for effective and scientific processing of milk. He worked there for 45 years. The Warrnambool Cheese and Butter Factory is still today a major industry in the Warrnambool area. This box is of key importance as an item that held Kraft Walker Cheese Company cheese. This company and its factory in Allansford was a key business in the dairying industry in the Warrnambool area for nearly 60 years. The box may have been used locally in the Allansford factory. This is a wooden oblong box with no lid. It has been nailed together with 12 nail heads visible and three nails protruding from the top edges. It has been used to package five pounds of Kraft Cheese. There is handwritten material in pencil on three sides (some crossed out) and the Kraft Cheese information with the ‘K’ logo is stamped on the bottom. ‘The World Renowned Kraft Cheese (K), Patented July 26 1916, 5 lbs net, Kraft Walker Cheese Co. Pty. Ltd., Melbourne, Australia’kraft walker cheese company (allansford), fred walker, warrnambool cheese and butter factory, warrnambool, history -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyButter Stamp Block, Circa 1950

At the time when this shortbread / butter stamp block was used, rural dairies and larger properties who manufactured their own butter used butter stamps blocks for identifying the source of the butter or for decoration.. The patterns stamped into the warmed butter provided for a range of decorative visual enhancement to the "plain" and "boring" straight leveled normal butter surface. Although the wooden surfaces could be hard to keep clean commercial usage would have been limited and eventually replaced by a non porous and hygienically cleaner material. Greater hygiene controls where introduced. from the late 1940s on. These controls were the result of high infectious illnesses due to contaminated milk and dairy handling methods.This shortbread / butter stamp was used by a Kiewa Valley dairy and it presents what the domestic butter beautification processes were available during the mid to latter 1900s was. Their was a pride by rural properties in their produce and its by-products.This shortbread / butter stamp is made from wood, round and fashioned from a flat bed to a dome top. The top has a round moulded hole with screw indentations for fastening a pressure pole. The pattern on the face of the stamp is of an eleven petalled flower pattern around a small circular flower head. Both the head and petals have indentations which are will produce raised points in the pressed butter. Enclosing the flower pattern is a pattern which when pressed against the butter would produce small ridges radiating outward.On the dome stamped in black ink "T. & W. Davies"butter stamp, domestic butter blocks, domestic food preparations., shortbread, stamp, dairy, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyChurn Butter - Wooden

This type of butter churn was used around the early to mid 20 century by household and small farms of the Kiewa Valley who kept cows for Milk. The buy product of the milk was cream and butter. Once the cows had been milked, often by hand, women would place the milk in shallow dish, and next morning the cream would be separated from the milk. Or a cream separator machine would be used. The cream would then be churned by the paddles in the butter churner until it formed in butter clumps. Butter Pats would be used to take the butter out and press into triangle butter blocksThis butter churner is significant due to its historical value which explains how butter was made by hand before this process became mechanistically made. Many houses or small farms in the Kiewa Valley had these butter churns to make their own butter for their household or to sell. This has very good interpretation significance as it adds to the history of dairy industry in the Kiewa Valley. Wooden box with a metal handle for turning the blades /paddles /slats inside the box.These blades churn the cream when the handle is turned. There is also a wooden handle and a wooden lid.butter, dairy, milk, manual, domestic, item, food, preparation, dairying, technology -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Tobacco selling, Tobacco sale floor, 1950 to 199

This promotional photograph by the Tobacco Growers Association was in response to a 1935 meeting of tobacco growers from Victoria, South Australia and Queensland which produced four major resolutions for the industry covering the remainder of the 1900s. These four resolutions were: (1) Adequate tariff protection (2) Control of pests and diseases (3) Orderly marketing (4) The formation of an advisory council of growers. History has produced the following results. (1) adequate tariff protection was never achieved,(2) control of disease through benzol vapour (CSIRO) breakthrough, was later identified as carcinogenic, (3) orderly marketing was achieved through (4) the establishment of the Tobacco Growers Association(19840. In October 2006, by way of Government buy back of tobacco leases from growers, resulted in the end of Tobacco farming in Australia (after 136 years of planting the first crop). It was also significant that the major tobacco companies such as Philip Morris and The British American Tobacco Australasia advised the industry that it would source its tobacco requirements overseas by 2009.This particular photograph shows prospective buyers (from the major processing firms of Philip Morris and British American Tobacco Australasia) inspecting the dried tobacco leaves at the Melbourne sales, before 2009, when they moved to overseas growers.The remnants of the Tobacco Industry can still be viewed throughout the Kiewa Valley and adjacent regions on the former tobacco farms, which still have the former tobacco drying sheds but now converted into hay sheds. The death of the tobacco industry(2006) resulted in the expansion of the dairy , sheep, beef cattle, venison and lama wool producers in the Kiewa Valley and surrounding regions. The problems from the large quantities of carcinogenic infused soil of farmlands in the region, still remains a problem now and for future generations. The tighter restrictions of where the final product can be smoked and the higher tax levied (no tariff protection) was the main contributor to this one time lucrative industry's demise.Coloured photograph pasted onto a thick wood chip backing. Two galvanised eyelets at the top of the frame, 50mm from each end, with a twine cord stretch from each, for hanging purposes. See also KVHS 0054A to KVHS 0054EA sign, which has been removed from the picture at some previous point in time is "Tobacco sale floor"tobacco, farming, rural industry, licences, ollie mould, blue mould, benzol vapour, photograph -

Warrnambool and District Historical Society Inc.

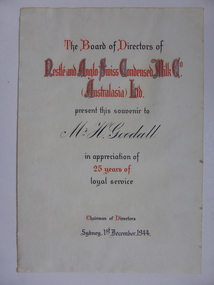

Warrnambool and District Historical Society Inc.Document, Certificate Mr H Goodall, 1944

This certificate was awarded in appreciation of 25 years service to the Nestle Company which operated a dairy factory at Dennington in Warrnambool. The company came to Warrnambool in 1907 and purchased 17 acres at Dennington and a new dairy plant was established by 1911. At its peak it employed 600 people and processed 55000 gallons daily in the milk condensery which is a process whereby much of the water content is drawn from the milk and sugar is added making a product which has a long shelf life and because it is processed at low temperature the milk maintains much of its vitamin content.A certificate which links a local person to a long and well known industry in Warrnambool and the Western district.Cream soft card certificate with red and black text.Mr H Goodall. Nestle and Anglo Swiss Condensed Milk Co Australasia Ltd. dated 1st December 1944. The signature of the Chairman of directors is unreadable.warrnambool, nestle dennington, h goodall -

Orbost & District Historical Society

Orbost & District Historical Societymetal butter churn, first half 20th century

... before the time of mass food processing factories. dairy butter ...Used domestically, though any extra butter could have been sold to neighbours. Many families kept a cow or two for milk etc. Cream needed to be at least 2 days old - the thicker the better. The handle was turned until the cream turned to butter,the whey was poured off and the butter washed in cold water until the water ran clear. Generally salt and bicarbonate of soda were added. Two pats were used to form butter into 1lb lots. This butter was most typically meant for consumption by the family, but in some instances it may be taken away for consignment by commercial receivers of dairy produce. This item is typical of the period when food processing was done at home. It would have been before the time of mass food processing factories.A metal butter churn with cast iron hand crank on side. The bowl container has a steel lid. It sits on a tripod stand.dairy butter-churn farming -

Cheese World Museum

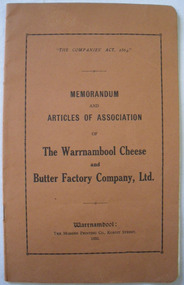

Cheese World MuseumBooklet, The Modern Printing Company, Memorandum and Articles of Association of the Warrnambool Cheese and Butter Factory Company Ltd, 1932

The Warrnambool Cheese and Butter Factory Company Limited was established in 1888 at Allansford and remained as an independent dairy manufacturer until 2014 when it was taken over by Canadian company Saputo. The factory was burnt in 1929 and all records lost. This booklet is a reprint of the original.Warrnambool Cheese and Butter Company Ltd was the earliest dairy manufacturer registered in Victoria. Registered in May 1888, it commenced processing in November 1888. The Articles record the early rules of the company and some of those early people involved in the company.Brown soft cover 12 page booklet 'Memorandum & Articles of Association of Warrnambool Cheese & Butter Factory Company Ltd', with black border around the black text.The Companies Act 1864/ Memorandum/ and/ Articles of Association/ of/ The Warrnambool Cheese/ and/ Butter Factory Company Ltd/ Warrnambool: / The Modern Printing Company, Koroit St/ 1932allansford, warrnambool cheese and butter factory company, companies, commerce, articles of association, companies act 1864, dairy industry -

Cheese World Museum

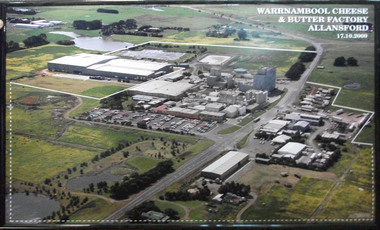

Cheese World MuseumPhotograph, Warrnambool Cheese and Butter Factory Co Ltd site 2000 -aerial view, 2000

Warrnambool Cheese and Butter Factory Company was formed by a group of Warrnambool business men. The company was registered in May 1888 and commenced commercial production in November 1888. The company retained its independence for more than 125 years until acquired by Canadian firm Saputo. It has operated from the same site since its inception and also has an office in Japan. Milk processing is undertaken by Sungold. Milk powder for export is also produced on-site. Cheese World is a retail arm of the company operates on a connected site selling company products, local food products, wine and cheese tasting. Cheese World Museum operates under the Cheese World umbrella.Aerial colour photograph of Warrnambool Cheese and Butter Factory in wooden frame. Shows buildings and surrounds. Lines indicate factory boundaries, dotted lines indicate property extension. Date is recorded on the image.17.10.2000allansford, warrnambool cheese and butter factory company, saputo, dairyiing, dairy manufacturing, diary manufacturers, cheese, butter -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

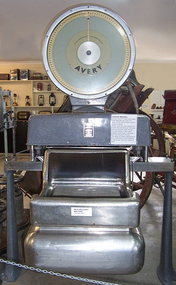

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food -

Myrtleford and District Historical Society

Myrtleford and District Historical SocietyButter Churn

The churn was used by Elise Weston (nee Trahair) at Barwidgee Creek and Myrtleford in the immediate post-war period. Prior to this time it was in the possession of the Trahair family on their family farm where a small dairy herd met family requirements.The churn represents an aspect of self sufficient living in rural areas outside township boundaries. It assisted households to meet family needs using simple processing technology and more so when surplus butter could be sold on in local markets.An upright clear-glass butter churn with screw-on metal cap, handle and gears. The churn mechanism is fully enclosed. "Daisy" brand with "3Qt" inscribed in the glass.glass butter churn