Showing 4 items matching "dental engine"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... dental engine... to most communities the electrically powered dental engines began... treadle powered dental engine (or dentist drill) was in common use ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... dental engine... to most communities the electrically powered dental engines began... treadle powered dental engine (or dentist drill) was in common use ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Warrnambool and District Historical Society Inc.

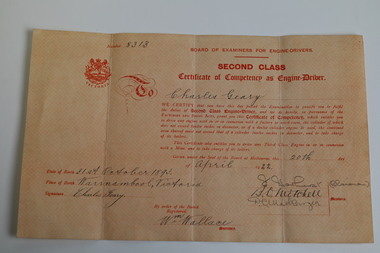

Warrnambool and District Historical Society Inc.Document - Charles Geary Collection, 1915-1922

... the Australian Imperial Expeditionary Force A.A.M.C. Dental Reserve, his ...This collection of six documents (1915-1922) belonged to Charles Geary who was born in Warrnambool, the son of Thomas and Martha Ellen Geary in 1893. The collection documents his joining the Australian Imperial Expeditionary Force A.A.M.C. Dental Reserve, his subsequent discharge and post military employment in the Town of Warrnambool as a Hackney Carriage Driver and later as a second class engine driver.. This collection gives examples of references and certificates of leave required to join the A.I.F. in 1916. The discharge certificate is a good example of what was given to military personnel after their services were no longer required. The llicense and certificate of competency show some of Charles' post war endeavours. Charles is listed on the Warrnambool Fire Brigade World War 1 Honour Roll as an active member. (.1) Typewritten refence on Robinson's Motor Pty. Ltd. green and navy printed letterhead with a purple ink stamp and black written signature and embossed company seal. (.2) Reference, handwritten in black ink on blue 8mm lined white paper with a 38mm printed margin. (.3) Black print on a cream certificate completed in black ink. (.4) Cotton woven paper certificate completed in blue, black and red ink with black ink thumb prints. (.5) Black printed Certificate number 1069 on cream paper completed in black ink. (.6) Peach coloured certificate with red printing on heavy weight paper completed in black ink and numbered 8313charles geary, australian army medical corps dental reserve, a.a.m.c., robinson's motor proprietary limited, geo powell, country fire brigades board of victoria, hackney carriage driver's license, second class engine driver, dental mechanic