Showing 32 items matching "double twist"

-

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDouble twist

... Double twist...double twist, 1/2"... of Australia. double twist, 1/2" Double twist ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.double twist, 1/2" -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBit, W M Ridgway

... double twist...Bit, double twist with lead screw, size 11 Maker W M... twist double twist bit W M Ridgway Bit, double twist with lead ...Bit, double twist with lead screw, size 11 Maker W M Ridgway Sheffield 222mm x 13mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bit, double twist, double twist bit, w m ridgway -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Scotch eye beam auger, with double twist and Lead screw. ... Scotch eye beam auger, with double twist and Lead screw. Tool ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Scotch eye beam auger, with double twist and Lead screw. ..., with double twist and Lead screw. Tool Scotch Eye Beam Auger W M ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ridgway & sons, wood boring tool, carpenters tools, coopers tools, marine tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Scotch eye beam auger, with double twist and Lead screw. ... Sheffield Scotch eye beam auger, with double twist and Lead screw ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw, bit �" length..., Double Twist with Lead Screw, bit �" length 585mm Auger ...Ring Auger, Double Twist with Lead Screw, bit �" length 585mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw, with round shaft... Ring Auger, Double Twist with Lead Screw, with round shaft ...Ring Auger, Double Twist with Lead Screw, with round shaft 590.5mmL flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring auger, Double Twist with Lead Screw. 1 inch auger. ... stamped Mathieson Ring auger, Double Twist with Lead Screw. 1 inch ...Ring auger, Double Twist with Lead Screw. 1 inch auger. stamped Mathiesonflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist - Lead Screw. 1 inch. 63.5cmL..., Double Twist - Lead Screw. 1 inch. 63.5cmL Auger ...Ring Auger, Double Twist - Lead Screw. 1 inch. 63.5cmLflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Thomas R Ellin, First half of the 20th century

... Ring Auger, Double Twist with Lead Screw, bit 1... Imprinted 'footprint' trademark Ring Auger, Double Twist with Lead ...Footprint Tools is a hand tool manufacturer based in Sheffield, England. In 2014 most of their hand tools were still made in Sheffield at the Footprint factory. Footprint Tools can trace its manufacturing history as far back as the 1760s when Alfrid Ridge & Sons was established as a manufacturer of woodworking tools. Ridge was bought by the current owning family in 1932. The Footprint brand originates from 1875 when Thomas R Ellin, a member of a cutlery manufacturing family, started a tool manufacturing business under the brand "Footprint". This subsequently became known as Thomas R Ellin (Footprint Works). This company was bought by the current owning family in 1948 and began to manufacture a range of tools under the Footprint, Domino, Climax, John Bull, and Clinker brands. During World War 2 the divisions of the business were engaged in manufacturing hand tools for British and Commonwealth forces. After the war Footprint continued to grow, manufacture, and expand its range of hand tools for the professional tradesman. In 2008 Footprint moved to a larger factory and invested in new forging equipment, but this process was interrupted by a global recession, and Footprint was unable to generate enough business to cover the cost of the upgrades. In early 2009 the company was forced to liquidate and lay off its staff to pay creditors. The Jewitt family retained the brand and intellectual property, and later that year revived the company under the name Footprint Sheffield and began producing a smaller range of products at first. With the same family of owner-managers, now run by the fourth generation, in 2015 Footprint continues to manufacture most of their products in Sheffield, England, and exports worldwide.This item gives us a look into the history of the beginnings of an early company that made tools in Sheffield England and is still producing tools today.Ring Auger, Double Twist with Lead Screw, bit 1" with round shaft Imprinted 'footprint' trademarkflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Auger Bit, Double Twist with screw 35mm1500mm long Round..., Double Twist with screw 35mm1500mm long Round shaft tapered ...Auger Bit, Double Twist with screw 35mm1500mm long Round shaft tapered at end.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw, �" bit, 580mm..., Double Twist with Lead Screw, �" bit, 580mm long, with shaped ...Ring Auger, Double Twist with Lead Screw, �" bit, 580mm long, with shaped wooden handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Mathieson, First half of the 20th Century

... Ring Auger, Double Twist with Lead Screw, 1 1/8 inch bit... ring auger ship building Stamped Mathieson Ring Auger, Double ...In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medal The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Ring Auger, Double Twist with Lead Screw, 1 1/8 inch bit with round shaft Stamped Mathiesonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, auger, ring auger, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Robert Sorby, First half of the 20th Century

... Scotch Eye Auger, Double Twist with Lead Screw, square... trade mark Scotch Eye Auger, Double Twist with Lead Screw ...A scotch eye auger is perfect for quickly making holes in dry or wet wood for making chairs, stools, and any number of woodworking projects. The scotch eye serves as a peg gauge and whatever peg you make to go into the hole should fit into the augers eye. Robert Sorby & Sons: The forbearer's of Robert Sorby had been cutlers in the Sheffield region of England, dating from the mid 17th century. Robert Sorby and Sons were registered in Sheffield in 1828 as a manufacturer of edge tools, saws, scythes and hay knives. In addition to manufacturing tools, they also diversified into the manufacture of crucible steel for tool manufacture. From circa 1860-1967, the Sorby factory in Sheffield was known as the “Kangaroo Works”. The Kangaroo Brand of tools was made by Robert Sorby & Sons. During the 19th century, they had a large trade in Australasia. By the early 20th century, they were manufacturing carving tools, planes and plane irons, circular saws, wood saws, butchers saws and cleavers, garden tools, pruning knives, coopers’ knives, bricklayers tools and joiners tools. In 1923 Robert Sorby & Sons was bought by Sheffield company Hattersley and Davidson. They are today one of the few remaining British tool manufacturers.The company has a long tradition of making edged tools for various uses and exporting them to Australia, however the subject item was probably made from the early 20th century up until 1967 when the company stopped exporting to Australia.Scotch Eye Auger, Double Twist with Lead Screw, square shaft, socket set at right angleRob Sorbey Sheffield stamped on shaft with Kangaroo trade markflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger, carpenders tools, hole drilling, rob sorby & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist - Lead Screw, round shaft tapering..., Double Twist - Lead Screw, round shaft tapering to square 74.5L ...Ring Auger, Double Twist - Lead Screw, round shaft tapering to square 74.5L. 4cm diamflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw. Square shaft..., Double Twist with Lead Screw. Square shaft with chamfered edges ...Ring Auger, Double Twist with Lead Screw. Square shaft with chamfered edges, Bit 2" 630mm L .flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Mathieson, First half of the 20th Century

... Scotch Eye Auger, Double Twist with Lead Screw, bit 7/16..., Double Twist with Lead Screw, bit 7/16 inch with round shaft ...In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medal The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Scotch Eye Auger, Double Twist with Lead Screw, bit 7/16 inch with round shaft 695mmL Stamped Mathiesonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, auger, ring auger, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBit

... Augur screw bit double twist. ?" screw size. Maker... screw bit double twist. ?" screw size. Maker Mathieson. Has ...Augur screw bit double twist. ?" screw size. Maker Mathieson. Has broken shaft. Length 530mm flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw, 645mm long.1 inch..., Double Twist with Lead Screw, 645mm long.1 inch bit. Rustic ...Ring Auger, Double Twist with Lead Screw, 645mm long.1 inch bit. Rustic handle attached.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Mathieson, First half of the 20th Century

... Scotch Eye Auger, Double Twist with Lead Screw 2 inch bit..., Double Twist with Lead Screw 2 inch bit with round shaft leading ...In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medal The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Scotch Eye Auger, Double Twist with Lead Screw 2 inch bit with round shaft leading to handle socketStamped A Mathiesonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, auger, ring auger, ship building -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncWrench

... wrench, double jaw twist handle... of Australia. wrench, double jaw twist handle Wrench ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.wrench, double jaw twist handle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Ring Auger, Double Twist with Lead Screw, square shaft... mark Ridgway Sheffield and DO stamped. Ring Auger, Double Twist ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Ring Auger, Double Twist with Lead Screw, square shaft (which has had a welded repair), socket set at right angle. Broad arrow mark Ridgway Sheffield and DO stamped. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAuger

... Ring Auger, Double Twist with Lead Screw and Curved Cutting... auger Ring Auger, Double Twist with Lead Screw and Curved ...Ring Auger, Double Twist with Lead Screw and Curved Cutting Lips, 1 1/2 inch with wooden handle 666mmL made by A Mathieson Glasgow. Marked H on shaftflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ring auger, auger -

Stawell Historical Society Inc

Stawell Historical Society IncTool - Realia, 3 Large wooden boxes, with carpenter, Shipwright tools beloning to G Pert of Stawell

... and ga=shaft. 1 Bit - Bit Double twist Matherison 1 Bit - Bit... and ga=shaft. 1 Bit - Bit Double twist Matherison 1 Bit - Bit ...41 items of Woodworking equipment and tools once belongng to G. Pert, 25 Seaby Street, Stawell, Victoria, Australia. Toolbox - Timber box with hinged lid and removable tray. Contents include woodworking tools. L 83.5 x D 41 x 211 cm. Toolbox - Timber Box black, hinged lid, lock. l 88 x H 32 x w 35 cm. Toolbox - tiber box, black metal handle, lock mechanism and tools. L 82 x H 30 x w 29 cm. 1 Plane Smoothing plane, coffin type, 1 Plane, Rabbet moulding plane, 1 Plane - Jack-type Farquarson, blade and wedge. 1 Auger - Ring auger. 1 Auger - Ring Auger, Mathieson. 1 Auger - Ring Auger. 1 Auger - Ring Auger, Matieson. 1 Auger - Ring Auger, Mathieson. 1 Ring Auger, Mathieson. 1 auger - Ring Auger. 1 Auger - Ring auger. 4 Auger - Ring Auger Mathieson. 1 Auger - Nose bit Auger JB & co. 1 Auger - Nose Bit auger. 2 Auger - Nose Bit Auger Mathieson 1 Auger - Nos bit Auger Sheffield. 1 Auger - nos bit auger Mathersion, L Vernes & co. 1 Auger Nosebit auger Matheison. 1 Auger Nose bit Auger Mathieson & Son. 3 Auger - nose bit Auger 1 uger head and ga=shaft. 1 Bit - Bit Double twist Matherison 1 Bit - Bit Double Twist, Barnsly (Broken end) BIt double twist symbol (3 Clovers) Mallet - Caulking Mallet wooden Head, iron Ferrules. Tool - Imporovised tool wooden handle metal ferrules. 1 Screwdriver - wooden handle Sheffield, Thos Well & sons. 1 Gauge - Bevel gauge wooden adjustable. 1 Nippers - wire nippers, pivoted, spring loaded, symbol (footprint) 1 Drill - drill hand operated, wooden handles an some red paint. 1 Maul - Shipwright maul, metal head, replaced handle. dotted embosssed inscription of name h 9.5 x L 63 x w 17 cm2 Black & 1 Brown boxes wiyh G Pert 25 Seaby St Stawell Victoria Australia painted on the lids. -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionUniform - VSR OR scarlet doublet, c 1898-1912

... are decorated with three rows of doubled, twisted white wool braid; each... with three rows of doubled, twisted white wool braid; each row ...Scarlet wool doublet with yellow stand collar and cuffs and Inverness skirts. Lower edge of collar, left front of doublet, cuffs and Inverness skirts all edged with white piping. Cuffs and skirts are decorated with three rows of doubled, twisted white wool braid; each row completed with a large whitemetal coloured metal "King Edward VII Australian Commonwealth" button of the period 1901-1911. Shoulder straps are scarlet wool with MISSING whitemetal 'VSR' title, a MISSING whitemetal 'letter' title, a small ERVII Australian Commonwealth button on left shoulder, and a small silver coloured metal Victorian Military Forces button on the right shoulder. Seven large buttons at front of tunic (one missing), and two at back waist. Two large brass belt hooks at side waist of doublet. Lower front skirt flaps have welt pockets lined with linen. Body of tunic lined with a white wool mixture, lightly padded around the underarms. Lower skirt flaps lined with a medium weight cream wool twill and upper smaller flaps lined with a finer cream wool twill. Sleeves lined with cream cotton twill and printed in black ink on the centre back lining is '5/8 38'. Collar lined with red wool and neck fastened with a single brass hook and eye over a black patent leather tab.Printed in black ink on the centre back lining is '5/8 38' -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1870s-1910s

This clear, green tinged, Half Whirley (or Whirly) salad oil bottle has been handmade by a glassblower from 1870s-1910s. A bottle with such elaborate decoration would have been sought after as there was no need to decant the sauce into another jug or bottle to make it acceptable for table service. It is possible that this bottle was recovered from the Loch Ard, wrecked in 1878. A diver found the bottle on a shipwreck in the coastal waters of Victoria about 100 years from when it was made. The diver who found this bottle has recovered objects from several different shipwrecks between the late 1950s and early 1970s. A sizeable proportion of those objects was from the wreck of the famous clipper ship Loch Ard. This salad oil bottle may very well have been amongst that ship’s cargo. It is part of the John Chance Collection. A paper titled ‘Glass Bottles from the Loch Ard Shipwreck (1878): A Preliminary Study’ by Iain Stuart, (published in Australian Historical Archaeology, 9, 1991) included a study of twelve salad oil bottles from the wreck of the Loch Ard. The bottles were of this same Half Whirley design (half meaning that it was Whirley on the upper half but not on the lower half of the body), as well as the same colour and size. A diagram of one of these twelve bottles matches the bottle in our collection. The paper mentions that eleven of the twelve bottles have a number on their base, just as this one has. It is estimated that foreign and salad oil bottles totalled four percent of all of the bottles carried as cargo on the ship. The Half Whirley bottle has side seams from below the lip to the base, indicating that the bottle was made in a two-piece mould that included the heel, body, shoulder and neck. The fancy ‘whirly’ twist pattern and panelled sides would have been cut into the mould’s inner surface. The uneven thickness of the ridge around the base comes from adding a separately moulded and embossed base after the bottle was removed from the mould. The applied finish (mouth and lip) was also added to the bottle. The elongated bubbles in the glass are evidence of the glass being mouth blown into the mould, thus forming the shape and pattern from the inside shape of the mould. The bottle probably had a glass stopper with a round top and wedge-shaped shank with a ground surface, allowing the bottle to be re-sealed. The ring between upper and lower lip allows the closure to be sealed and anchored. The embossed numbers are either “133” or “833” and may represent a particular bottle pattern, manufacturer or filler. Although the bottle is not currently linked to a particular shipwreck, it is recognised as being historically significant as an example of bottles imported for use in Colonial Victoria in the mid-to-late 19th century. This whirley salad oil bottle is matches the whirley salad oil bottles recovered from the Loch Ard in the 1990s, adding depth of interpretation to the array of salvaged Loch Ard artefacts in Flagstaff Hill’s collection. The salad oil bottle is an example of the type of food condiment containers that were used in Victoria’s early days. The bottle is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks, including the Loch Ard, have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Bottle; glass Half Whirley salad oil bottle, green-tinged, with some opalescence. Handmade, elaborately decorated bottle with round neck and base, and five-sided body. Applied double lip; straight upper, flared lower. The lower neck and shoulder have twisted spiral whirley patterns in the glass. The body tapers slightly inwards towards the base. It has five plain panels, one wider than the others. Side seams run from below the lip to the heel. The heel of the bottle is uneven in width, height and density where it joins the body of the bottle. The base is not level. Embossed characters on base. Glass has elongated bubbles towards the base and orange-brown sediment inside, on one side. Embossed "133" or “833” (the first character may be an “8”) flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, handmade, mouth blown, blown bottle, 19th century bottle, collectable, bottle, green glass, tinged green, two piece mould, food bottle, oil bottle, salad oil bottle, whirley, whirly, half whirley, condiment bottle -

National Wool Museum

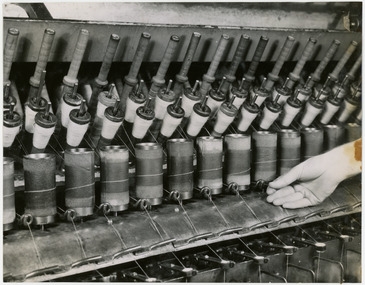

National Wool MuseumPhotograph - Twisting or Doubling, 1960s

... . Twisting or Doubling...., / MELBOURNE AUSTRALIA / W18 / W18. Twisting or Doubling. Black ...One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing detail of machinery with spools of wool. A hand is shown on the right handling a thread of wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W18 / W18. Twisting or Doubling.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Corkscrew

The design of the corkscrew may have been derived from the gun worm, which was a device from at least the early 1630s, used by men to remove unspent charges from a musket's barrel in a similar fashion. The corkscrew is possibly an English invention, due to the tradition of beer and cider, and the 'Treatise on Cider' by John Worlidge in 1676 describes "binning of tightly corked cider bottles on their sides", although the earliest reference to a corkscrew is, "steel worm used for the drawing of Corks out of Bottles" from 1681. In 1795, the first corkscrew patent was granted to the Reverend Samuel Henshall, in England. The clergyman affixed a simple disc, now known as the Henshall Button, between the worm and the shank. The disc prevents the worm from going too deep into the cork, forces the cork to turn with the turning of the crosspiece, and thus breaks the adhesion between the cork and the neck of the bottle. The disc is designed and manufactured slightly concave on the underside, which compresses the top of the cork and helps keep it from breaking apart. The winged corkscrew, sometimes called a cork extractor, butterfly corkscrew, owl corkscrew, Indian corkscrew, or angel corkscrew, has two levers, one on either side of the worm. As the worm is twisted into the cork, the levers are raised. Pushing down the levers draws the cork from the bottle in one smooth motion. The most common design has a rack and pinion connecting the levers to the body. The head of the central shaft is frequently modified to form a bottle opener, or foil cutter, increasing the utility of the device. Corkscrews of this design are particularly popular in household use. In 1880, William Burton Baker was issued British Patent No. 2950 for his double lever corkscrew, with both levers sliding onto the upper end of the shank. The first American patent was in 1930 granted to the Italian Domenico Rosati who emigrated to Chicago, Illinois, to work as bartender before prohibition. Rosati's design had an exposed rack and pinion mechanism. Such design was adapted by other brands as the wine-market grew in popularity. The winged owl version, with two side-plates covering the rack and pinion mechanism, was first designed and manufactured in 1932 by the Spanish industrial designer David Olañeta for his brand BOJ and was later adopted by others, such as the 1936 US Patent No. 98,968 by Richard Smythe marked HOOTCH-OWL https://en.wikipedia.org/wiki/CorkscrewThis object is significant as an example of an item in common use in the 19th and early 20th centuries, and that was developed further in the 1930s.Winged corkscrew with a T-shaped wooden handle, metal spring and worm-wheel screw section.None.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, corkscrew, beverages, kitchen equipment, bottle opener