Showing 7 items matching "drop method"

-

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Mask, Yankauer, c. 1904

... drop method... anaesthesia mask around 1904. The drop method involved placing... anaesthesia mask around 1904. The drop method involved placing ...Sidney Yankauer, M.D. (1872-1932), an ear, nose and throat specialist and pioneer in bronchoscopy, practiced at the Mount Sinai Hospital in New York. Dr. Yankauer, a prolific inventor of medical equipment, might best be known for the tube he designed for suctioning the mouth and throat. Yankauer introduced the wire-mesh anaesthesia mask around 1904. The drop method involved placing the mask over the patient’s nose and mouth, and then placing gauze over the mesh of the mask. Next, liquid anaesthetic, such as ether or chloroform, was applied in drops or lightly poured onto the gauze so that the patient breathed in evaporated anesthetic as well as air. The gutter around the base of the mask was designed to catch any residue of the harmful anaesthetic. (The Wood Library Museum, 2016; Museum of Healthcare Kingston, 2016)A metal tear-shaped mask with gauze wire dome, gutter around the base and detachable spring piece with open circular handle to secure cloth over gauze. Found inside medical carry box #899Stamped underneath neck of circular handle: HATRICKdr [e.s.] holloway, hatrick, yankauer, drop method, mask, gauze -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

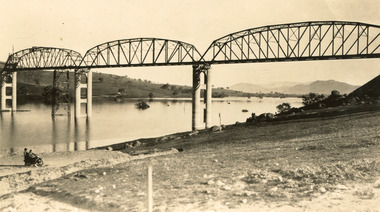

Taken between 1928 and 1930, depicted is the Bethanga Bridge under construction. The Bridge was completed in 1930 and was built to assist residents of the Bethanga district to travel to Albury. Other bridges would become submerged by the backed-up water of the Murray and Mitta Rivers so the Bethanga bridge was built two miles above the Mitta Weir. The Bethanga Bridge was built north of the future Hume Dam which would be completed in 1936. At 2430 feet long, Bethanga Bridge was the longest road bridge in Australia at the time of its completion. The Bridge is 20 feet wide and made up of nine 270 feet long spans. Materials used include ten tons of paint for the steel works; 1600 tons of steel; 900 tons of timber for the decking; and reinforced concrete for the piers. The tender for the construction was awarded to C. Ruwolt Pty. Ltd., engineers who were located on Victoria Street, West Richmond. The contract was awarded for £71,890. It was predicted between 250 and 300 men would find employment on the project. The news was well received by trade unions at the time as there had been a drop in available engineering work.This photograph is historically significant as it depicts the progress of the Bethanga Bridge construction, which was important infrastructure for the area. It is also a good example of methods used in the area to assist in travel over the river prior to the construction of the Hume Dam.Black and white rectangular photo printed on matte photographic paper.Reverse: 1997 3186 / 84-19-3 / This is the bridge. / It is not yet open to traffic / yet. will not be completed / until May next / It is a wonderful bridge the / pillars are 100 feet high. / KODAK PRINT Envelope Obverse: Peterson PHOTO / Hume Weir Envelope Reverse: BMM 84-20-1,2+3. bethanga bridge, lake hume, hume dam, hume weir, murray river, bridge, bethanga, albury -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 2, June 1976 - August 1977

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period from June 1976 to August 1977.Book with deep red and white cover back and front, spiral bound. staffing advertisements, graeme beanland new principal, technical colleges under strain, meeting on farm apprenticeships, drop in apprenticeship intake, business studies course, new college concept for ballarat, big year ahead for school of mines, 1977 courses, ballarat school for bricklayers, deputation moves to retain girls' high school, t a f e in the ballarat region, barry stoddart top marks in plumbing exam, time for entries for external studies, studying without classes, adult education courses, counselling goes public, farming courses, nursing bursaries for smb students, remedial teachertraining for woolgrowers, parents concerned says principal, smb principal questions education values, smb honors council president, founders' prize for glen glasson, new course to help building industry, new teaching method gives hope for poor readers, mr thompsonwill open bricklaying school, first need is for tradesmen, workshop tackles reading problem, cabinet gets hot reception, the official history of the school of mines, satellite learning for aust?, apprenticeship week exhibition, fijian education officer visits schools in ballarat -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Container - World War 1939-45 Ration pack, c1940

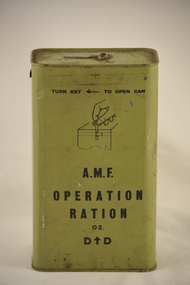

AMF Operational Ration This ration pack was developed by Sir Stanton Hicks. It contained three meals, each waterproofed (a vital consideration for the tropics), which offered a balanced selection of meat, vegetables, fruit and vitamin supplements. Before the development of this ration pack, Australian soldiers were supplied with quantities of preserved food that were difficult for a man to carry and divide, and which often did not provide a nourishing diet. Sir Cedric Stanton Hicks (1892-1976), university professor and army catering officer, was born on 2 June 1892 at Mosgiel, New Zealand. University of Otago (B.Sc., N.Z., 1914; M.Sc. Hons, 1915; M.B., Ch.B., 1923) 1916-18 Hicks served as a non-commissioned officer in the New Zealand Expeditionary Force and he assisted Professor J. K. H. Inglis in the synthesis and production of Chloramine-T for use against meningitis among the troops. Hicks was appointed government analyst in 1918. On a Fellowship 1923, he travelled to England and studied at Trinity College, Cambridge (Ph.D., 1926) and caried out research in Switzerland, Germany and the United States of America. 1927 he was appointed to the new chair of physiology and pharmacology at Adelaide University, which he was to hold until 1957. During the Depression he studied the dietary patterns of five hundred families receiving relief. 1940 Hicks was appointed temporary captain, Australian Military Forces, and performed part-time duty as catering supervisor. Moved to Melbourne as chief inspector of catering, he began a campaign for applying scientific principles to the feeding of troops. 1943 the Australian Army Catering Corps was formed. Hicks altered the basis of the allowance for military rations from a monetary to a nutrient entitlement, improved the pay and promotion opportunities of cooks, established schools of cooking and catering, devised new methods for preparing food, supported the service's adoption of the Wiles steam-cooker, and designed jungle-patrol, emergency and air-drop rations. His 'Who Called the Cook a Bastard?' (Sydney, 1972) gave an account of his experiences in military catering.Men from most families in the City of Moorabbin area served in the Australian Military Forces during World War 2.A tin container , khaki colour, used for the storage of a food ration item for a soldier serving in the Australian Military Forces World War 11.TURN KEY ← TO OPEN CAN / diagram of key / A.M.F. / OPERATION/ RATION/ 02 / D↑Dworld war 11, australian military forces, sir cedric stanton hicks, army catering corps, soldier rations, food supplys, australian diggers, food preservation -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - MERCURY BUCKET

Cast iron mercury bucket, used to hold mercury, potentially in the process of recovering minute pieces of gold mixed in soil and sediments. See research page for description of one process of using mercury to extract gold.gold mines, mining equipment, mercury bucket, miners used mercury in a number of ways to amalgamate gold, with each mill or battery operator having their preferred method depending on the nature of the ore. by the late 1850s the most common way of crushing goldbearing quartz ores or consolidated alluvial cements was in a stamp battery. the battery featured heavy iron stamp heads held in a frame, with each head often weighing up to 500 pounds (226 kg) or more (see msv 1880, page 45) (birrell 2005). stamp heads were lifted and dropped by a rotating overhead cam shaft driven by a steam engine or water wheel. ore was fed into a large cast-iron battery box, mixed with a steady stream of water, and pulverised by the stamp heads. in some batteries, mercury was placed in the base of the boxes to amalgamate with freed gold. the violent agitation of the mercury in the mortar box, however, could cause the mercury to break into myriad tiny globules that were carried away by the water with the tailings, thus losing a certain amount of gold in the process (thompson 1867; ritchie & hooker 1997). the water and sand slurry was splashed by the falling stamps from the box through fine mesh screens and onto inclined wooden tables below the mortar box (figure 2). the tables were covered with copper sheets or plates coated with mercury, which caught and amalgamated with a portion of the gold. the grey putty-like amalgam was periodically scraped off the sheets and retorted in a furnace to collect the gold and recover the mercury for reuse. mercury was inevitably lost from the plates, while poor maintenance resulted in further losses of gold and mercury in the tailings. mercury use and loss from gold mining in 19th century victoria. peter davies1, susan lawrence, and jodi turnbull, department of archaeology and history, la trobe university. -

National Wool Museum

National Wool MuseumPrint, Chris McClelland, Shearing the Rams – Tuppal Station, 210

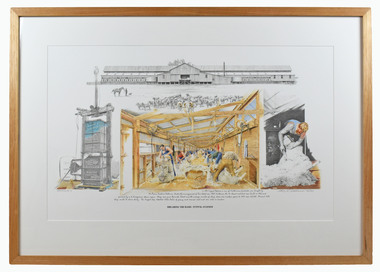

Chris was invited to be artist in resident for the historic re-enactment of “Shearing the Rams” at the North Tuppal Station woolshed held on the 4th and 5th June 2010. The celebration attracted record crowds to witness the shearing of the station rams by 72 blade shearers. Over a single weekend in 2010, thousands of people queued for hours to see a piece of Australian history recreated at North Tuppal Station near Tocumwal, NSW. In 1900, Francis Faulkner invested a staggering £4000 to extend his shearing shed on Tuppal Station, making it the biggest in the country. Over the next decade more than three million sheep trod its pine boards and were shorn in its 72 stands. After years of drought and the Great Depression, the property fell into disrepair and the station was split up. When North Tuppal Station was sold to the Atkinson family in 1928, just five of the 72 stands were in operation. In 2010, Sport Shear Australia approached the Atkinson family about holding an event in the historic shearing shed to raise money for a team of Australian shearers to go to the world shearing title in Wales. An army of volunteers restored the T-shaped shed and yards and organised a weekend of events. Over two days, 6,000 sheep were shorn and all 72 stands of the restored North Tuppal shed were brought back to life. A total of 117 shearers shared the boards with 90 wool handlers who skirted 19 fleeces every minute. For a period on each day of this historic weekend, the machines were then silenced, and 72 shearers picked up their old blade shears to recreate past shearing methods. “When they fired up and got the blades out there was deathly silence on the board - you could hear a pin drop because normal shearing you have all the machines and it is quite noisy. Here you could just hear the click, like in the song Click Go the Shears Boys. People had tears in their eyes. It was quite an emotional thing to see that and very proud to be here.” George Falkiner, grandson of Francis FalkinerColoured framed print of shearing scene in the Tuppal station, Ferrrier’s wool press on the left-hand side and station on the top. Print in framed in a light-coloured wooden frame with white coloured matte.Under artwork - In 1891 Tuppal Station, a sum of 176,000 acres threshold, was bought by Mr Fiane Sadlies Falkines, Under the management of his eldest son F.B.S. Falkines, the 72 stand woolshed was build in 1900 and powered by a 16 horsepower steam engine. Sheep were pure Boonoke blood and the average numbers of sheep shorn over nineteen years to 1909 was 152,780. Around 7200 sheep could be shorn daily. The largest clip totalled 3326 baled of greasy and scoured wool and was sold in London. Bottom right corner - Chris McClelland 181/720 Shearing The Rams – Tuppal Station -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black and White - demolishing cable tram track Smith St and Queens Parade 1954/55

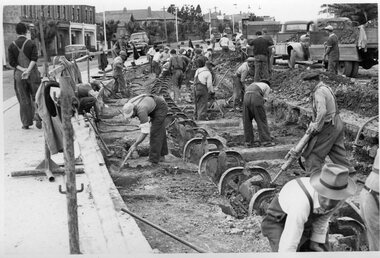

The photograph shows the demolition or removal of the cable tram track at the intersection of Smith St Gertrude St. Fitzroy. The workmen are excavating the former cable tram track The inbound cable tram track remains in position. The 1955 Annual Report notes that work commenced following the completion of the Queen's visit in March 1954 and that all work was done by day-labour. The track was opened to service in late June 1955. The second image is from a Melbourne and Metropolitan Board of Works plan (part) No. 1217 - Collingwood for the intersection, obtained for reference from the State Library of Victoria Collection of MMBW Plans. It shows the layout of the cables and the large sheave pit that the cable itself passed around. The trams were required to drop the cable from the grip prior to the entry to the curve and then coast around. Photographer is possibly Keith Kings.Yields information about the extent of work need to convert the former Northcote Cable tram route to Electric trams, the people and the methods used to undertake the work.Photograph - Black and White of the demolition of the cable tram track at the corner of Queens Parade - Smith St Clifton Hill.trams, tramways, cable trams, workmen, mmtb, demolition, track work, conversion, smith street, queens parade, clifton hill