Showing 13 items matching "enterprise manufacturing company"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Enterprise Manufacturing Company, circa 1911

... enterprise manufacturing company...This particular food mincer was manufactured by Enterprise...Enterprise Manufacturing Company... was manufactured by Enterprise Manufacturing Company. Located ...This particular food mincer was manufactured by Enterprise Manufacturing Company. Located in Philadelphia, this company specialized in making hardware products. The company was especially known for its cherry pitters, apple peelers, and coffee mills. The company was founded in 1864 and was located on the corner of Dauphin, 3rd, and American Streets. Enterprise Manufacturing Co. remained in business until 1956 when it was bought by Silex Co.A mass produced early domestic item made for home food preparation this item's first patent design was approved in 1897. Manufactured by a well known company in the USA the "Enterprise Manufacturing Company” up until 1956. They specialised in making kitchen appliances of various types for domestic use and for export. Food mincers of the subject items design are still being produced today under the brand name of "Universal" made by Universal Trading Inc USA.Food mincer, metal, clamp on bench style, with rotating wooden handle. Inscriptions stamped on metal.Marked "Enterprise tinned Meat Chopper" "No. 10" "Enterprise MF'G Co. PHILA. USA" "PAT. JAN.30.83" flagstaff hill, warrnambool, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mincer, food mincer, meat mincer, food preparation, kitchen utensil, domestic object, enterprise manufacturing company, kitchen appliance -

Orbost & District Historical Society

Orbost & District Historical Societymeat grinder, Late 19th century

... Enterprise Manufacturing Company... Enterprise Manufacturing Company ...This is one of many models of the Enterprise Tinned Meat Chopper No5This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesSmall black metal meat grinder with screw down grip for use on bench tops and tables. Still in working order. Carved wooden handle.Enterprise MFG.Co. PH'A, U.S.A. on clamp. Pat.Jan.30.83.June.5.88 on other side. Enterprise-Tinned-Meat-Chopper on barrel.grinder domestic food-preparation enterprise-mfc -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

... Enterprise Manufacturing Company... Manufacturing Company ...This item is an example of a food processing appliance used in the late 19th century long before electricity came to Orbost.A cast iron raisin stoner. It has a clamp for attachment to a bench and has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

... Enterprise Manufacturing Company... Enterprise Manufacturing Company ...This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesA cast iron raisin stoner with a clamp. It has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Federation University Historical Collection

Federation University Historical CollectionMagazine, The Courier, Leading Industries in Western Victoria: A Special Courier Publication, 19/03/1999

The Greenhill Enterprise Centre is on the Ballarat Technology Park, Mount Helen.Soft covered booklet featuring a number of Ballarat Industriesindustry, ballarat, techcast, coonara, c.e. bartlett, haymes paint, skilled equipment manufacturing, drake, ballarat group training, wiltronics research, greenhill enterprise centre, university of ballarat, powercor, workcover, maxitrands, macain foods, ballarat meat company, hakabaku, mars confectionary, sunicrust bakeries, hancock victorian plantations, john valves, valcor australia, f.j.& a.m. benney, learmonth road smash repairs, david miller, greenwaste, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers,Shaving cream, J.B.Williams Co, mid 20thC

Shaving cream is a cream applied to the face, or wherever else hair grows, to facilitate shaving. The use of cream achieves three effects: lubricates the cutting process; swells keratin; and de-sensitizes skin. Shaving creams commonly consist of an emulsion of oils, soaps or surfactants, and water. James Baker Williams was born in 1818 in Lebanon, Connecticut USA and, in 1834, began employment with F. and H.C. Woodbridge, a general store located in Manchester. Williams was offered half-interest in the store in 1838, after which its name was changed to Keeny and Williams. Two years later, Williams sold his interest in the store, but retained his share in the drug department. He began experimenting with various soaps to determine which were best for shaving, and eventually developed Williams' Genuine Yankee Soap, the first manufactured soap for use in shaving mugs. In 1847, Williams moved his enterprise to a rented gristmill on William Street in Glastonbury, Connecticut, and his brother, William S. Williams, joined the firm around 1848, when the firm's name was changed to the James B. Williams and Company. William's shaving soaps were sold throughout the United States and Canada and James Williams supervised many aspects of the company until shortly before his death in 1907 at the age of eighty-eight. The Williams family continued to manage the company until it was sold in 1957. By the early 1900s, the company was known throughout the world. In addition to its line of shaving creams, the firm produced talcum powder, toilet soaps, and other toilet preparations. The original 1847 factory is still standing in Glastonbury and, in 1979, was converted into a condominium complex. I In 1983 it was placed on the National Register of Historic Places. 1927 - 1990 Salmond and Spraggon (Australia) Limited , Sydney , New South Wales, was registered as a company on 10 June 1927 following the liquidation of Salmond and Spraggon (Australia) Limited known as the Old Company. The company distributed household cleaning and mineral, metal and chemical wholesaling, pharmaceutical wholesaling throughout Australia on behalf of manufacturers. In 1990 the company was taken over by Alberto Culver, a manufacturer of hair and skin products. A clear glass jar with a screw lid containing 'Williams Shaving Cream' Front Label : J.B WILLIAMS / LUXURY / SHAVING CREAM Back Label : The contents of this jar are guaranteed to be / The J.B.WILLIAMS Luxury Shaving Cream Jar has been changed to meet the Wartime conditions but / the cream is of the same high quality / made in Australia for / J.B. WILLIAMS COMPANY / Glastonbury, Conn. U.S.A. / Vendors / SALMOND & SPRAGGON (AUST.) PTY.LTD. / All Statesshaving equipment, razors, safety razors, cutthroat razors, soap, world war 11 1939-1945, moorabbin, bentleigh, cheltenham, early settlers, shaving cream, williams j.b. company ltd, connecticut usa, glastonbury connecticut usa, salmond & spraggon pty ltd, sydney, new south wales, toiletries, shaving soap, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

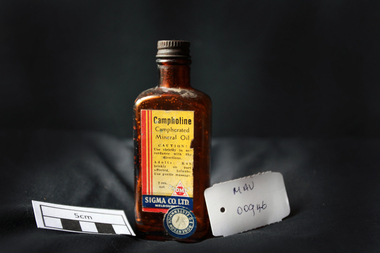

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, brown bottle 'Campholine', c1950

Sigma was founded by two Melbourne pharmacists in 1912, it has grown to become one of the key players in Australia’s pharmacy industry .Edwin Thomas Church (1864 – 1947) and Ernest Holloway Leete a prominent chemist and a member of the College of Pharmacy who had established his own pharmacy in 1897. The entrepreneurial Leete had been part of a move in 1904 among a group of commercially-minded chemists to put up proprietary preparations. 1913 - 1927 Initially, the fortunes of the Sigma enterprise relied on E. H. Leete ‘working from home’, and even as late as 1915 company address was in Claremont Avenue Malvern. Following the establishment of the business in 1912, the Sigma Company Limited was located at Flinders Lane, Melbourne. Sigma – Tromax, 1928 E.H. Leete after sixteen years, said he would not stand again as a director of the company because interests were also turning elsewhere. He was assisting another company as its agent in the motor trade. 1938 to1953 was characterised by steady growth for Sigma, accelerated by manufacturing opportunities during World War Two. Between 1975 and 1996 the company was transformed as it entered a period of both consolidation and rapid growth. The appointment, in 1996, of new Managing Director, George Savvides, marked a break from the past. Today Sigma is a leading full line wholesale and distribution business to pharmacy. Sigma is also the owner of some of Australia’s best known pharmacy brands in Amcal, Guardian and Amcal MaxA triangular shaped, brown glass, bottle with a metal screw top containing ‘Campholine’Front label : Campholine / Camphorated / Mineral Oil / CAUTION ! / Use strictly in accordance / with the directions / Adults : Rub briskly on parts affected . Infants ; Use gentle massage . / 20z. / TROMAX / SIGMA CO. Ltd. / MELBOURNE / Label Sticker : ROBERTSON OF ELSTERNWICK 1/ 8 pharmacy, medicines, campholine, glassware, bottles, moorabbin, bentleigh, cheltenham, melbourne, tromax-sigma co ltd, leete ernest, church edwin, sigma company pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rowing Oar

The family-owned timber manufacturing business Pelco was started by Cecil Victor Woodfield in 1937. The joinery company Pelco began by making wooden ladders and was registered as the Palmerston Extension Ladder Company. C V Woodfield, who lived from 1884 -1959, arrived in Palmerston North from Canterbury NZ in the aftermath of the Great Depression to work in construction. The company got its first step up when Woodfield was asked by a commercial painter to make a ladder, and the founder set up shop in a garage on Ruahine St. According to the company website, Pelco made its name in New Zealand with its Oregon Extension Ladders, and up until its closure, manufactured non-conductive Lamilite Ladders for the electrical supply and service industry worldwide. The company was incorporated as a joinery business in 1946 and continued making high-end cabinetry for seven decades. Under director Geoff Woodfield, in the 1950s, the company embarked on the production of Fleetcraft plywood boats. Another water-related enterprise followed, with the manufacture of oars and paddles. Its branded Gull Superior Oars and Paddles business began exporting in 1972 to Australia and subsequently to the United States, UK and Japan. The company ceased trading in April 2018 and was placed into receivership.This pair of lightweight oars represents the maritime tradition of handmade oar making, which has evolved over the centuries. Their shape is still similar to early oars and continues to serve the same purpose, to steer and propel a boat. Pair of blonde varnished Tasman Fir oars with a flattened paddle at one end. Made by Gull of New Zealand, sold by James Edwards & Sons of Melbourne. Inscriptions on printed labels on the oars."GULL Superior Oars and Paddles, Pelco, Palmerston North NZ" "JAS. EDWARDS & SONS, Boat Builders, Oar and Skull Makers, & Importers, PRINCES BRIDGE MELBOURNE"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oar, oars, gull oars and paddles, new zealand oars and paddles, jas edwards and sons melbourne, rowing equipment, new zealand oak, paddle, james edwards and sons melbourne, james edwards, tasman fir, gull superior oars, marine equipment, marine technology, ship fitting, boat fitting, rowing oar, boat oar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rowing Oars

The family-owned timber manufacturing business Pelco was started by Cecil Victor Woodfield in 1937. The joinery company Pelco began by making wooden ladders and was registered as the Palmerston Extension Ladder Company. C V Woodfield, who lived from 1884 -1959, arrived in Palmerston North from Canterbury NZ in the aftermath of the Great Depression to work in construction. The company got its first step up when Woodfield was asked by a commercial painter to make a ladder, and the founder set up shop in a garage on Ruahine St. According to the company website, Pelco made its name in New Zealand with its Oregon Extension Ladders, and up until its closure, manufactured non-conductive Lamilite Ladders for the electrical supply and service industry worldwide. The company was incorporated as a joinery business in 1946, and continued making high-end cabinetry for seven decades. Under director Geoff Woodfield, in the 1950s, the company embarked on the production of Fleetcraft plywood boats. Another water-related enterprise followed, with the manufacture of oars and paddles Its branded Gull Superior Oars and Paddles business began exporting in 1972 to Australia and subsequently to the United States, UK and Japan. The company ceased trading in April 2018 and was placed into receivership.This pair of lightweight oars represents the maritime tradition of handmade oar making, which has evolved over the centuries. Their shape is still similar to early oars and continues to serve the same purpose, to steer and propel a boat. The oars are associated with a significant family business situated in Palmerston New Zealand that along with making ladders also graduated into making wooden boats and oars.Pair of blonde varnished Tasman Fir oars with a flattened paddle at one end. Made by Gull of New Zealand, sold by James Edwards & Sons of Melbourne. Inscriptions on printed labels on the oars.(1) "GULL Superior Oars and Paddles, Pelco, Palmerston North NZ" (2) "JAS. EDWARDS & SONS, Boat Builders, Oar and Skull Makers, & Importers, PRINCES BRIDGE MELBOURNE"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oar, oars, gull oars and paddles, new zealand oars and paddles, jas edwards and sons melbourne, rowing equipment, new zealand oak, paddle, james edwards and sons melbourne, james edwards, tasman fir, gull superior oars, marine equipment, marine technology, ship fitting, boat fitting, rowing oar, boat oar -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Letter - Abbott Collection: letter from Mr. Willthorne (?), April 14th 1877

Four pages handwritten from Willathorne Co. dated 14th April, 1877 detailing a list of items relating to the stock of the Abbott Company sent to Sandhurst as samples on credit because Mr. Willathorne (?) was unable to get up there. The sender address is stated as Lonsdale Street East.business letter, commercial, abbott family, shoe manufacturing, commercial enterprise. -

Wodonga & District Historical Society Inc

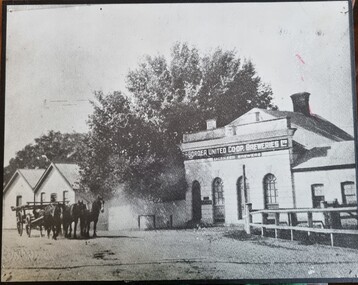

Wodonga & District Historical Society IncPhotograph - Border United Co-op Breweries

The Border United Co-operative Breweries Limited was formed in 1911 by the amalgamation of The Albury Brewing and Malting Company Limited and The Anglo-Australian Brewery Company Proprietary Limited which operated breweries in Beechworth, Tallangatta and Yarrawonga. The Anglo-Australian Brewery was owned by the Billson family. By August the new plant was operating near the Union Bridge on the border of Victoria and NSW as shown in this photo. However the enterprise failed in August 1914 when not enough co-operative shares could be sold and also due to declining water quality. In December 1914 its spirit merchant’s license was transferred to the newly established Murray River Proprietary Company. In 1922, the brewery and 32 acres of land was sold to Mr E E Waite. Waite sold the buildings for removal.This image represents buildings related to early industries in the Albury-Wodonga region.Black and white image of brewery buildings. The image has been mounted on board.On building wall: "The BORDER INITED CO-OP BREWERIES LTD/LICENSED BREWERS"breweries northeast victoria, murray breweries, manufacturing history albury wodonga -

Bendigo Historical Society Inc.

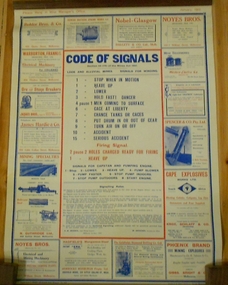

Bendigo Historical Society Inc.Document - MARKS COLLECTION: CODE OF SIGNALS FOR MINES CHART

Poster, printed on coated fabric, wooden hanger on top. Yellow background, printed in red and blue. 'Code of Signals, Section 45 (19) of the Mines Act 1961. lode and alluvial mines, signals for winding' Signals: 1 stop when in motion, 1 heave up, 2 lower, 3 hold fast danger, 4 pause men coming to surface, 6 cage at liberty, 7 change tanks or cages, 8 put drum in or out of gear, 9 turn air on or off, 10 accident, 15 serious accident. Also lists firing signals. Advertisements for suppliers to mining companies around border of poster. E.g. Jaques Bros., Engineers, Coppin Street, Richmond, Melbourne. Ore and Stone Breakers manufactured in various sizes (has illustration of machine). James Hardie & Co., 581 Little Collins Street, Melbourne. Necessaries for success in mining enterprises are: Dick's original balata belting to drive your machinery with; Genuine Dodge wood split pulleys on the shafting, and fibro ciment(sic) sheets to protect you from fire. These sheets are also acid-proof.bendigo, mining, code of signals