Showing 20 items matching "firebox"

-

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumIron, c.1900

Charcoal iron with 'improvised' wooden handle and firebox.7 1/2 on firebox. -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, Estimated late 19th century

Large 4 wheeled single cylinder (horizontal) steam engine designed to be towed. Fire box painted black, boiler and steam cylinder green, wheels red. Boiler is not sound so engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Brass water drain tap on firebox. Also other brass fittings on firebox. Cast brass disc with red background fixed high on firebox :- "Marshal Sons & Co. / Made expressly / to the order / Shut, No. 45781, Open / of / Robison Bros / South Melbourne." "10017" raised in relief on firebox door. machinery; engines; steam power source -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, 1877

Restored by Maldon Flywheelers Association. Originally owned and used by Zemster Brothers of "Brook Mount" Shellbourne.Known as "Aunty Jack"Large 4 wheeled 9 HP single cylinder (horizontal) steam engine, designed to be towed. Front wheels smaller than rear. Folding smoke stack with spark arrestor. Fire box and smoke stack painted black, boiler and steam cylinder green, wheels grey. In working order but engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Timber front turntable and back brake pad assembly. Brass water drain tap on firebox. Also other brass fittings on firebox.On brass ring near top of firebox:- "Serial No. 5672, Marshal Sons & Co. / Limited / Engineers / Gainsborough England". Metal plate on front turntable:- "Restoration of the Front Undercarriage / and retubing of the boiler by / Castlemaine Technical School / 1979". Cast in relief on wheel hubs:- "Marshal Sons & Co. Gainsborough".machinery - engines - steam -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, ca 1880

This little steam boiler has been beautifully built. It could have been used to drive an engine in a small workshop, a boat or launch, or even farming equipment. It is an example of the steam technology and mechanisation of the 19th century. William Cook introduced steam heating in England in the 18th century. Steam combined with pressure was used for powering transport, such as steam engines for trains, and manufacturing, such as steam engines driving manufacturing machines. Steam boilers are still used today as an energy-efficient means of power.This steam boiler would have been suitable to drive a small engine, possibly that of a small boat. Coal was added to the firebox for fuel to heat water in the boiler. It is an example of the power used to drive machinery and equipment in the mid-to-late 19th century. Steam boilers like this one have played a part in the evolution of steam power. Steam engine boiler; vertical cylindrical coal-fired boiler with a black firebox at its base and a dome top. The cylinder's sides and top have brass fittings, inlet and outlet taps. A round opening near the base is covered by an adjustable metal plate that controls the boiler's temperature. The front door of the firebox has two hinges at the base and when the side clips are opened. A shiny brass collar tops the tall chimney. Oak wood planks around the sides of the boiler, and held in place by brass bands with nut and screw fixtures. The boiler stands on a metal and wood frame with a looped handle at the back. An inscription has been noted. Circa 1880. "1948 D/430" flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, boiler, steam engine, steam boiler, coal fired boiler, vertical boiler, boat boiler, power source, steam driven, engine boiler, steam machine, firebox, steam engine boiler -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: PRODUCTS OF LOCOMOTIVE FIREBOX COMPANY - BROCHURE

Product of locomotive firebox company - glossy printed brochure Circ 1931. Title 'Syphon Safety from boiler explosions caused by low water' advert for the Thermatic Syphon.document, memo, railway, (x ref 1325.39) locomotive firebox company / thermatic syphon -

Dunkeld Museum Inc.

Dunkeld Museum Inc.Bee Smoker

Many farming families in the district kept bees as a source of honey for home consumption. This item was made for use on the family farm. Most of the equipment used in the local industry was homemade.During the early to mid 20th century bee keeping was a significant rural industry in Dunkeld and surrounding districts. It is believed that there were nearly twenty apiarists operating in the area. Honey in large quantities was railed to Melbourne for sale.Homemade bee smoker consisting of a copper cylindrical firebox and rectangular bellows constructed of wood and leather. Components are assembled with rivets, scrap wire, sheet metal, nuts and bolts and nails. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: PRODUCTS OF LOCOMOTIVE FIREBOX COMPANY - BROCHURE

Products of locomotive firebox company - brochure Circ 1931. Including Nicholson Thermic Syphons Cyclone front ends, Christy Pneumatic Lubricators and Syphon Sanders. Glossy brochure 2 pages.document, memo, railway, locomotive firebox company / nicholson thermic syphons cyclone front ends , christy pneumatic lubricators and syphon sanders ( x ref 1325.40 ) -

Friends of Kurth Kiln

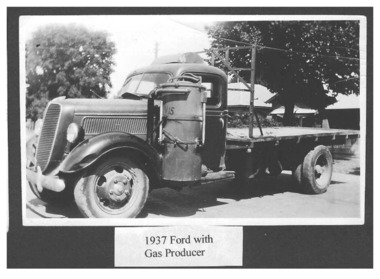

Friends of Kurth KilnPederic Gas Producer,1939

The Unit was picked up from a paddock on a farm in Bagshot, near Bendigo. It was donated to the Friends of Kurth Kiln Heritage Collection by the Family of Cyril H Peatling on 23 December 2006.Gas Producer Units are of significance to Kurth Kiln because they demonstrate the enduse of the charcoal that was created at Kurth Kiln. Considerable documentation has been made available to us on its history, including a picture of the truck is was mounted on. A Gas Producer Unit that converted charcoal into a gas suitable for the combustion engine. Used on motor vehicles during WWII petrol rationing restrictions. It consists of a hopper to hold the charcoal and a firebox to generate the gasNameplate missinggas producer, bagshot, wilma -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive K-185 at the coal hopper, Echuca Railway Station, c.Aug. 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencygeorge coop collection, echuca railway station, k-185, k-class steam locomotive (vr newport workshops), railway workshop -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive K-158 filling up with water at the coal hopper, Echuca Railway Station, November 1963, 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencycoal hopper, echuca railway station, george coop collection, k-158, k-class steam locomotive (vr newport workshops) -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive J-500 at the coal hopper, Echuca Railway Station, November 1963, 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencyechuca railway station, george coop collection, j-500, j-class steam locomotive (vulcan foundry) -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive R-727 at the coal hopper, Echuca Railway Station, November 1963, 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencycoal hopper, echuca, echuca railway station, george coop collection, r-727, r-class steam locomotive -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive R-727 being filled with water at the coal hopper, Echuca Railway Station, November 1963, 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencycoal hopper, echuca, echuca railway station, george coop collection, r-727, r-class steam locomotive -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, VR Commissioner's Special train, steam locomotive D3-639 at Echuca Railway Station, 1962

VR Commissioner's Special train, steam locomotive D3-639 filling up with water at the coal hopper, Echuca Railway Station, 1962. The tender has been all polished up. THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so.Digital TIFF file Scan of black and white print enlargement on textured paper (14.5 x 21 cm)coal hopper, d3-639, d3-class steam locomotive, echuca railway station, george coop collection, vr commissioner's special train -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Steam locomotive K-158 at the coal hopper, Echuca Railway Station, November 1963, 1963

THE ECHUCA COALING STAGE. Locomotives would stop alongside to receive coal dropped into their tenders from small overhead rail mounted tipping trays. Water could be obtained from either the elevated tank at one end or the connected standpipe at the opposite end. Locomotive firebox contents could be dumped into pits between the rails from locomotives once they were carefully positioned above them. Such locomotives then could move onto the Engine Shed area for overnight parking. Firebox fires would be re-lit when the locomotive was next needed in a day or so. Image dated as November 1963 based on same image in Port of Echuca collection (possibly frame 32 of film) (print 19.5 x 24.5cm) On reverse in pencil: " K Class at Echuca" Echuca K Class. 1940-1968". In blue pen:" Photo by: George L. Coop Nov 1963" https://victoriancollections.net.au/items/59de9cc421ea6b12dc3f7597Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencycoal hopper, echuca railway station, george coop collection, k-158, k-class steam locomotive (vr newport workshops) -

Bendigo Historical Society Inc.

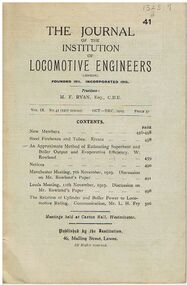

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: THE JOURNAL OF THE INSTITUTION OF LOCOMOTIVE ENGINEERS (LONDON )

The journal of the institution of locomotive engineers (London) with grey cover and black text. The journal president is M. F. Ryan Esq CBE. Publisher: the institution, 46 Malling St , Lewes Sussex , England. The contents include: new members, steel fireboxes and tubes, superheat estimation, Manchester meeting, Leeds meeting, relation of cylinder and boiler power to locomotive rating, writing on page 2 'J Badham 16 Abbott St Bendigo', item date 1919.M F Ryancottage, miners, j badham/the journal of the institution of locomotive engineers(london ) m f ryan -

Mont De Lancey

Mont De LanceyDomestic object - Kitchen Stove, C. Andrews, c1900's

The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously, cooking was mostly carried out in the outdoors on open fires, and later in fireplaces indoors. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. A vintage cast iron kitchen stove set in the back wall of the Mont De Lancey Slab Kitchen. It has two steel decorative hinged doors with a handle to open and close. There is one pull out metal shelf in each compartment. Between the two doors is a round door which opens to reveal the wood box with a slatted base. This allows the ash and small coals from the fire to fall though to a pull-out tray below to be emptied outside when cooled. There is another lift-out kid to clean the ash and coals underneath.On the chimney plate 'Andrews, Patent Non Pariel' On the front of the stove below the round wood box 'C Andrews Geelong'cooking equipment, cooking stoves, fuel cooking stoves, domestic ovens -

Port of Echuca

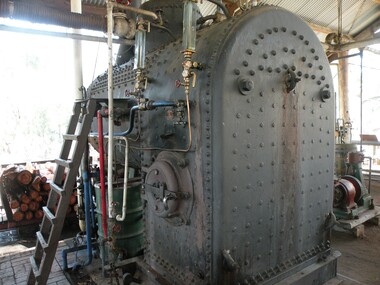

Port of EchucaFunctional object - Locomotive Type Fire Tube Boiler, 1927

This Johnson Bros. (USA) Locomotive Type Boiler was from a steam shovel (that moved on rails) that excavated rock and soil during the construction of Stevens Weir near Deniliquin NSW in 1934. It has a working pressure of 100psi. This is an example of a fire tube boiler where the fire from the fire box heats the water surrounding the fire tubes running through the boiler, smoke escapes out the smoke stack and the steam is captured in the dome and sent through pipes toward other engines in the Port of Echuca Steam Display. Two glass gauges are fitted on the side of the firebox. Two safety valves are fitted at the top of the boiler to maintain the correct and safe pressure. It still functions today for visitors most days of the week.A good example of the technology and industrial history of the Riverina region of southern NSW and northern Victoria. It is an integral part of the Port of Echuca Steam Display running secondary engines off the steam produced within this boiler. Large cast iron, fire tube boiler with 124 fire tubes, fire box, steam dome and exhaust chimney. boiler, johnson bros, steam display, kevin hutchinson steam shed -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future.